Trigger actuated cable clamp

a technology of trigger and cable clamp, which is applied in the direction of couplings, rod connections, manufacturing tools, etc., can solve the problems of installationer with too short cable length, tendency for splicing to fail, and relatively susceptible to premature triggering or firing, so as to prevent the premature release of stored energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

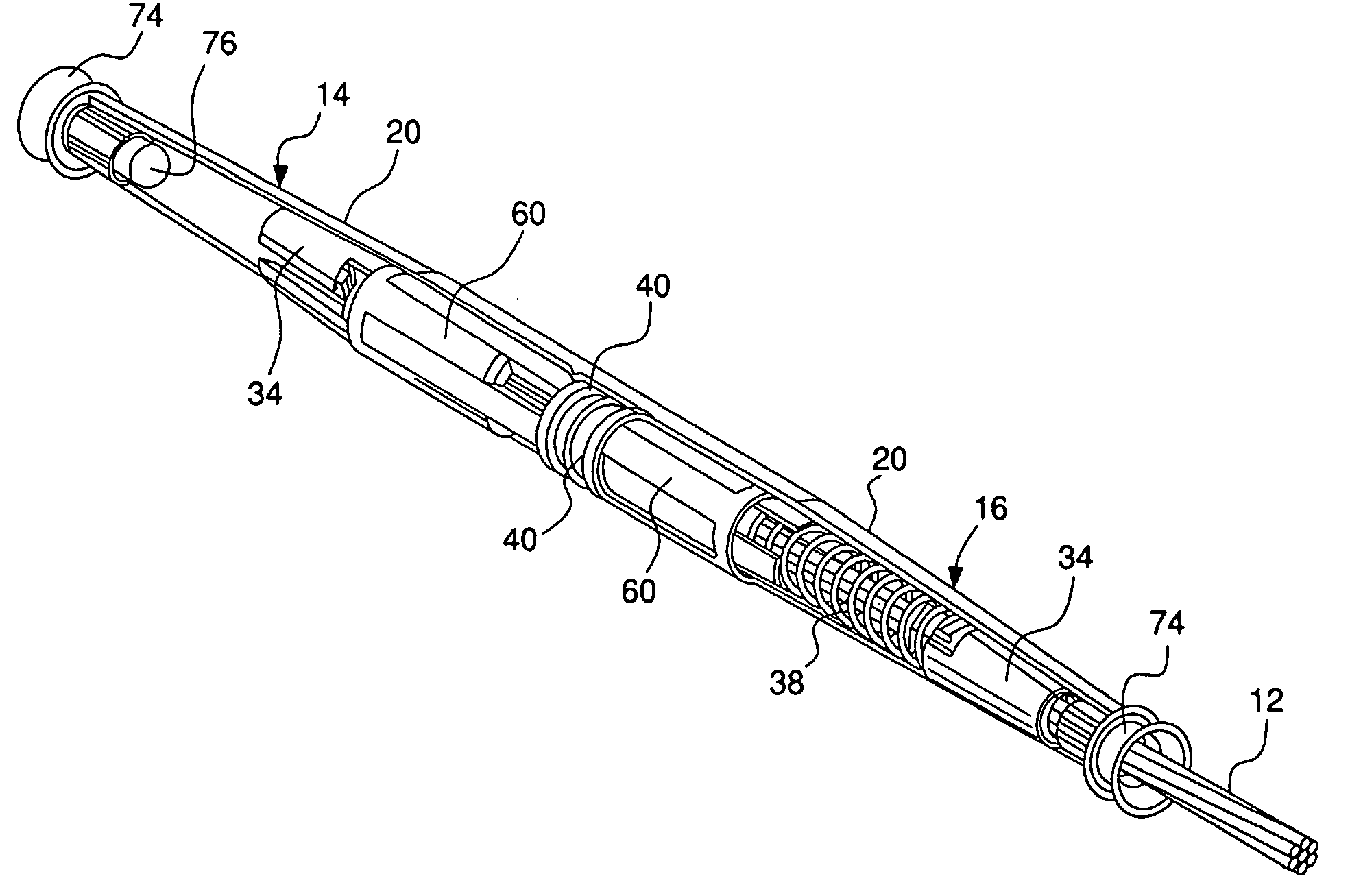

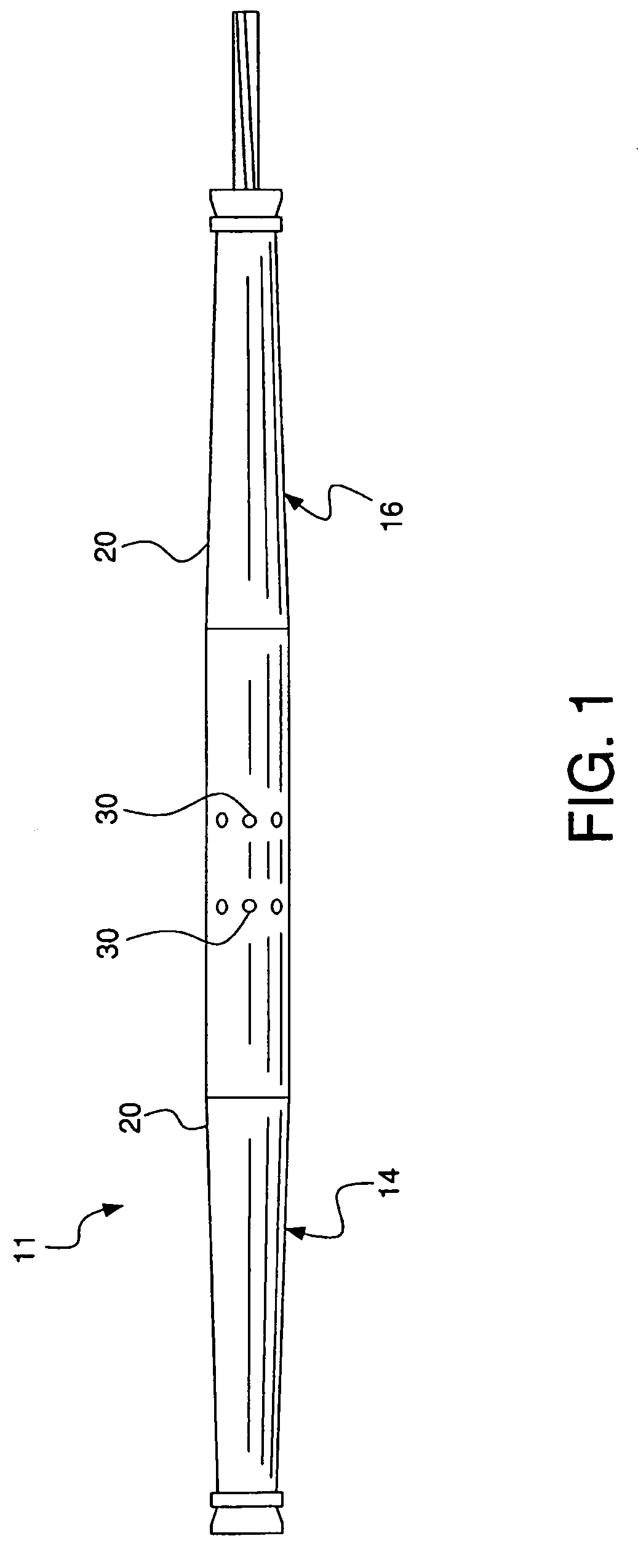

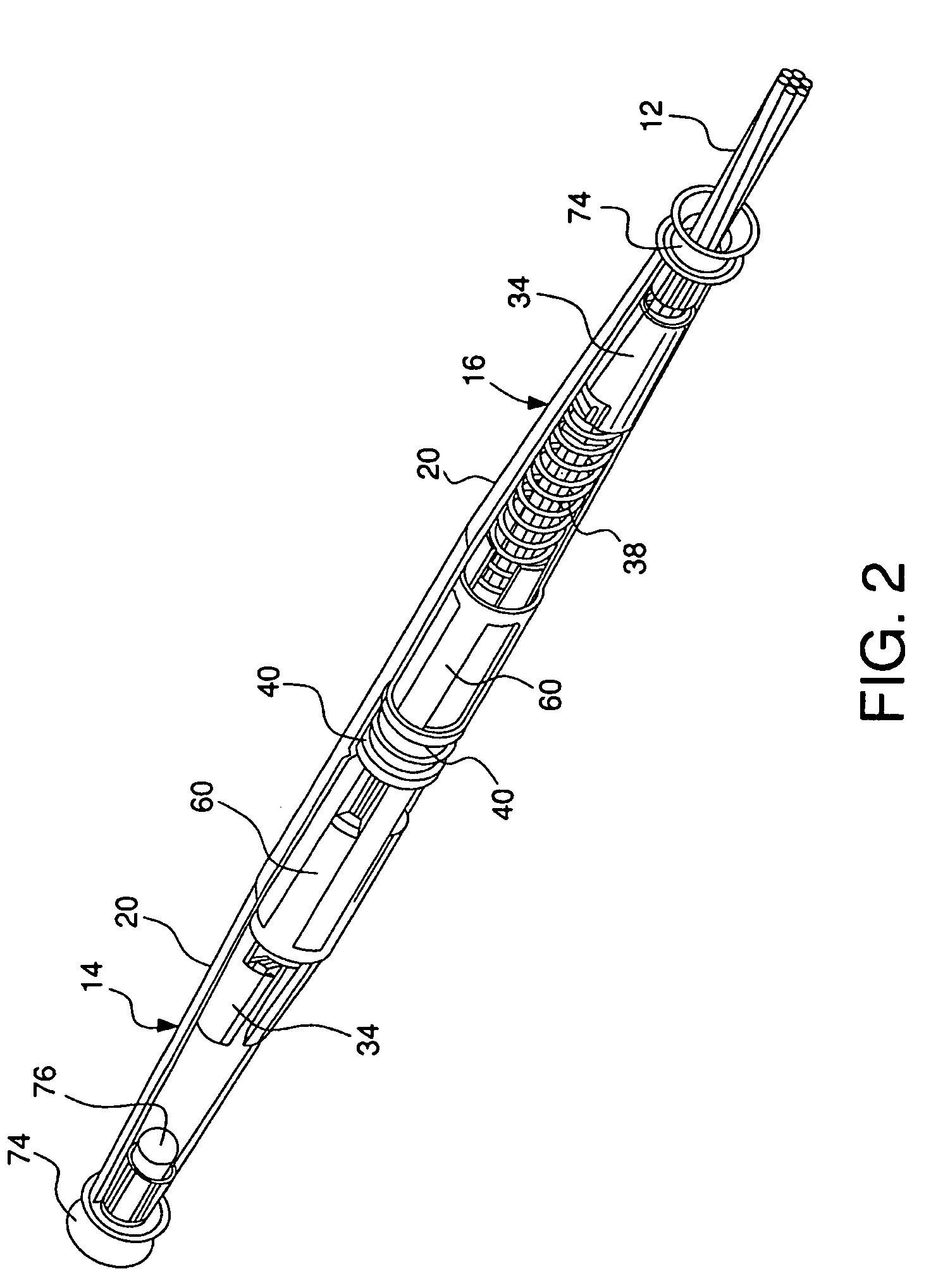

[0025]FIGS. 1–10 illustrate a splicing connector 11 for a cable 12 having first and second cable clamps 14 and 16, each cable clamp 14 and 16 being a mirror image of the other. In the exemplary embodiment, the cable clamps 14 and 16 are used to make an electrical and a mechanical connection (e.g. splicing); however, a single clamp assembly may be used to establish a mechanical connection. As best seen in FIG. 2, each clamp 14 and 16 includes a housing 20, a jaw assembly 34, a biasing member 38, a trigger 60, a retainer 40, a guide cup 76, and a funnel guide 74. In FIG. 2, the jaw assembly 34 of cable clamp 14 is in the locked position and the jaw assembly of cable clamp 16 is in the triggered position.

[0026]In FIGS. 3–5, each housing 20 is substantially conically shaped, tapers in an opposite direction, and has a receiving opening 22. Each housing 20 may be fabricated of a suitable material such as steel or aluminum. An interior cavity 24 (FIG. 3) extends between first and second en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com