Speaker mounting system

a technology for mounting systems and speakers, applied in the field of speaker mounting systems, can solve the problems of excessive unused space in the box of speakers, affecting the cost of shipping and warehousing as well as the cost of the product itself, and not an optimal situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

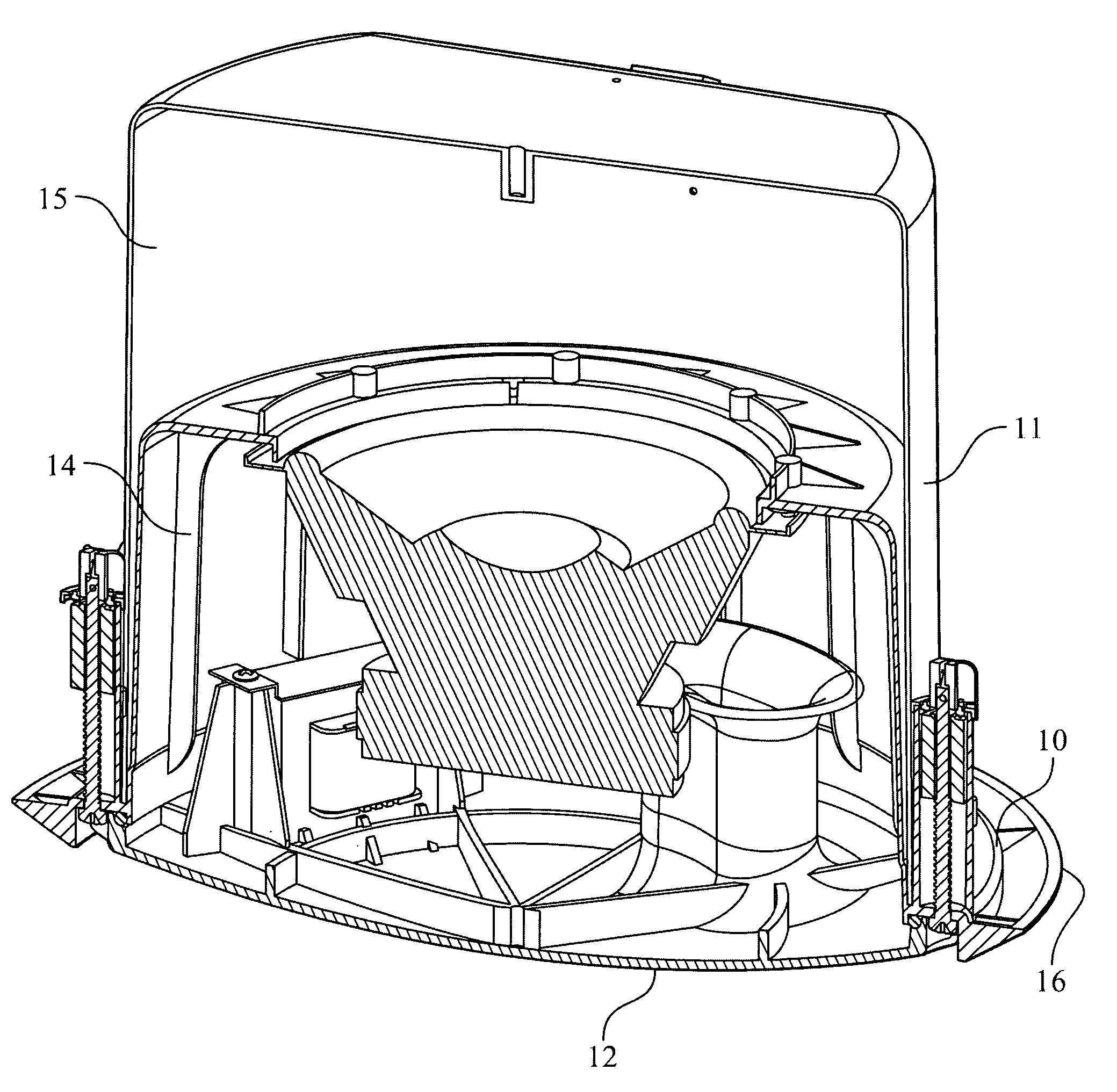

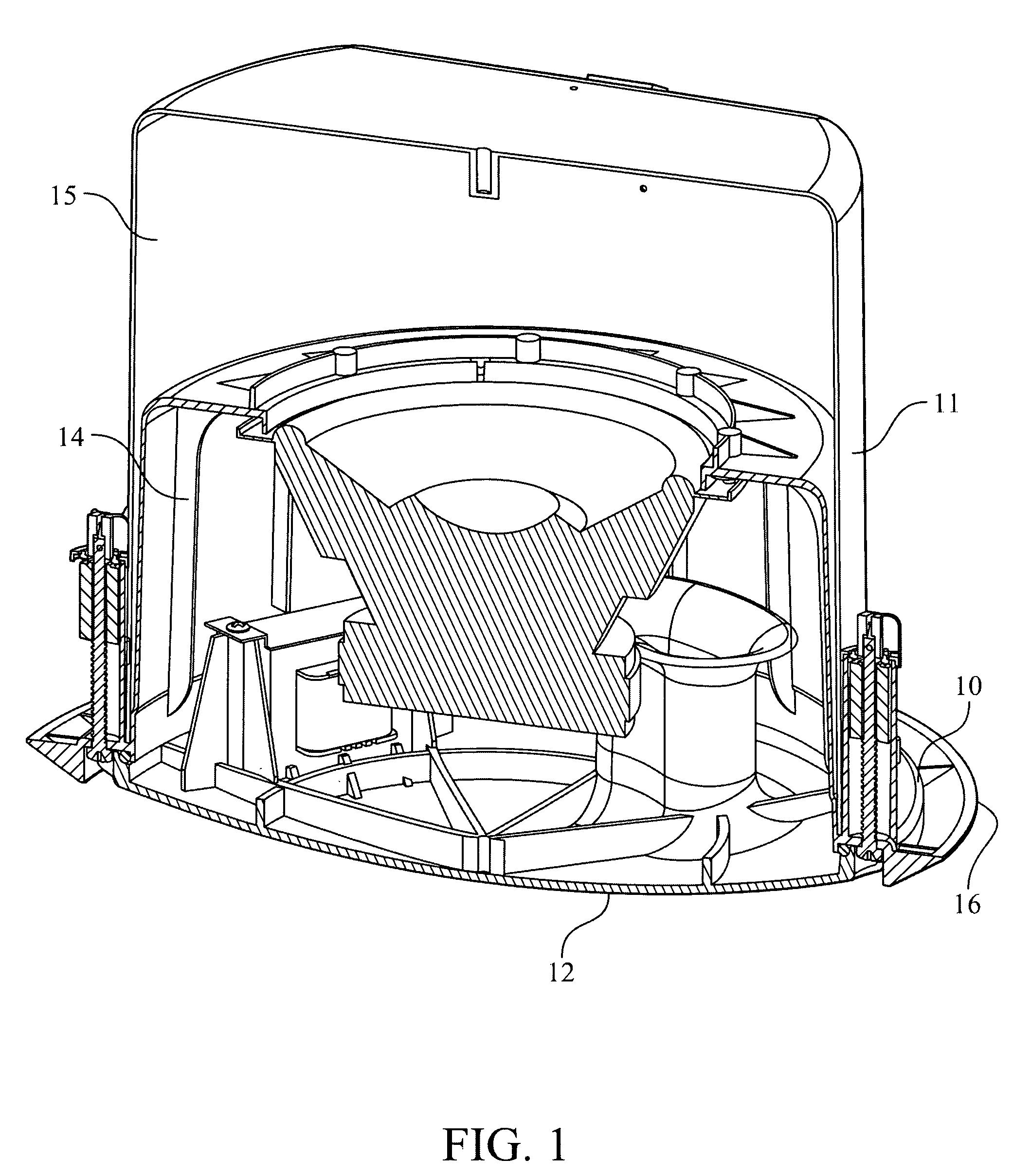

[0031]The embodiment shown in the drawings concerns a bandpass style subwoofer, but the invention is equally useful for many other speaker types and sizes. The subwoofer assembly as shown in FIG. 1 has a unique design where one molded cylindrical part 10 forms the mounting flange 16 and one half of a chamber 14. A cylindrical metal back-can 11 encloses this part and forms a second chamber 15. A ported cover 12 completes the first chamber. Back-can 11 has an angled terminal entry with flush cover to fit tight spaces.

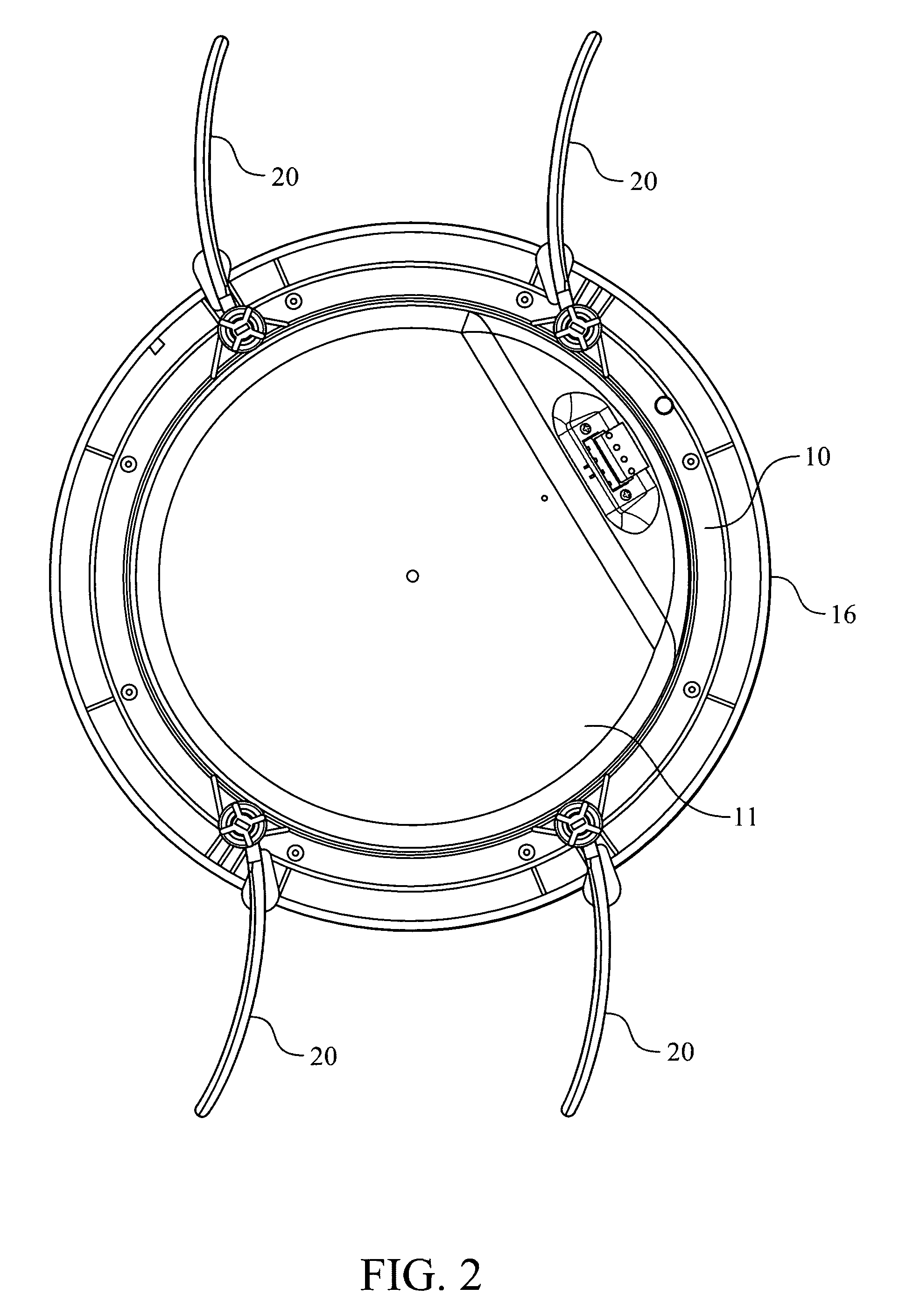

[0032]To eliminate the need for a separate tile bridge, four long clamp dogs 20 as shown in FIGS. 2 and 3, are connected to mounting flange 16 of the speaker. These are curved to fit tightly to the cylindrical metal back can 11 so the product assembly can be installed through the smallest possible mounting hole 51 in a ceiling tile 50, as shown in FIG. 7. Two of these clamp dogs 20 are placed close together, forming two pairs. This keeps their length to a minimum by getti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com