Conformal bearing for rock drill bit

a bearing and rock drill bit technology, applied in sliding contact bearings, mechanical equipment, cutting machines, etc., can solve the problems of bearing failure, drill bit heat generation, etc., and achieve the effect of increasing the apparent contact surface area, maximizing the load support, and maximizing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

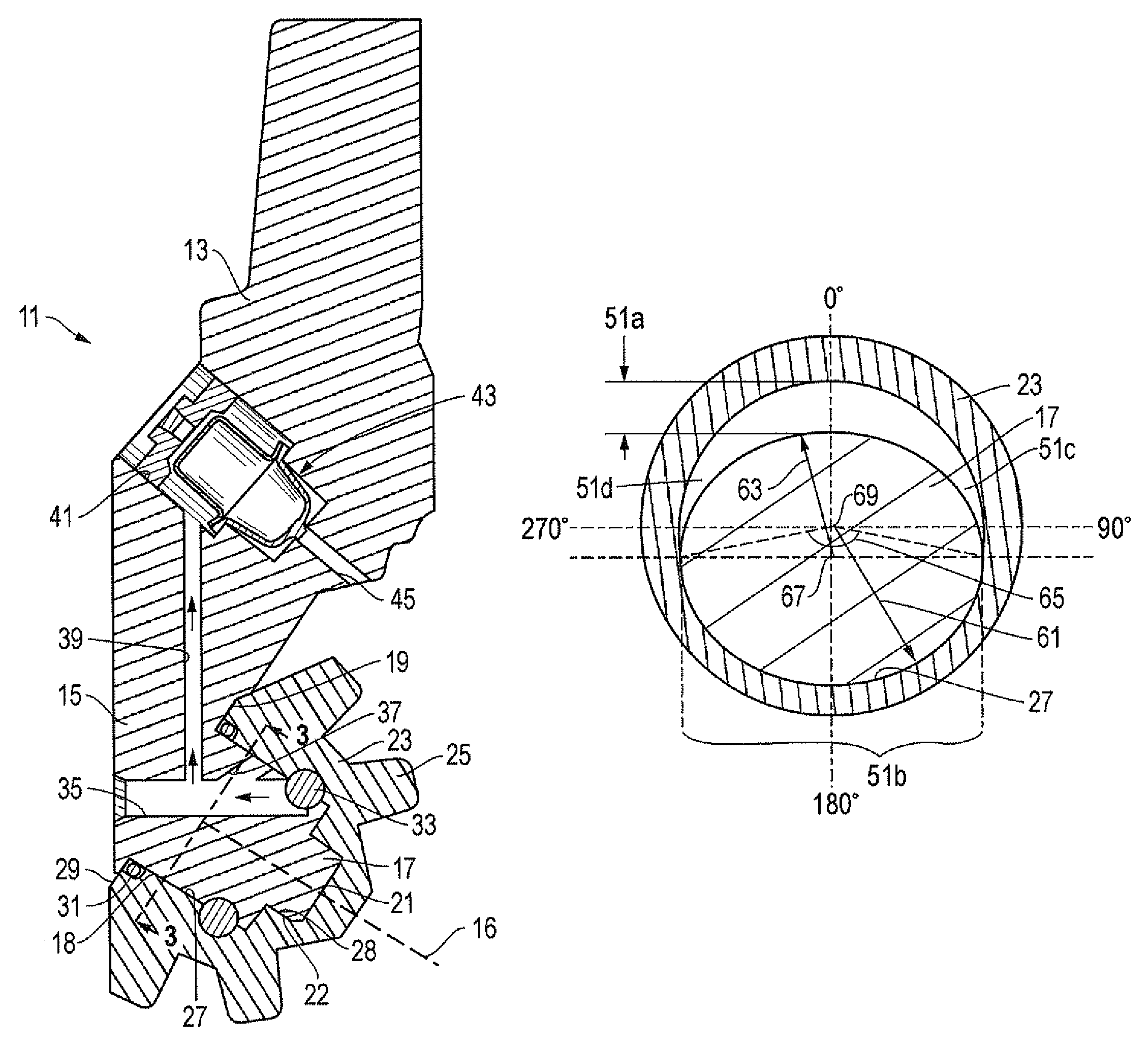

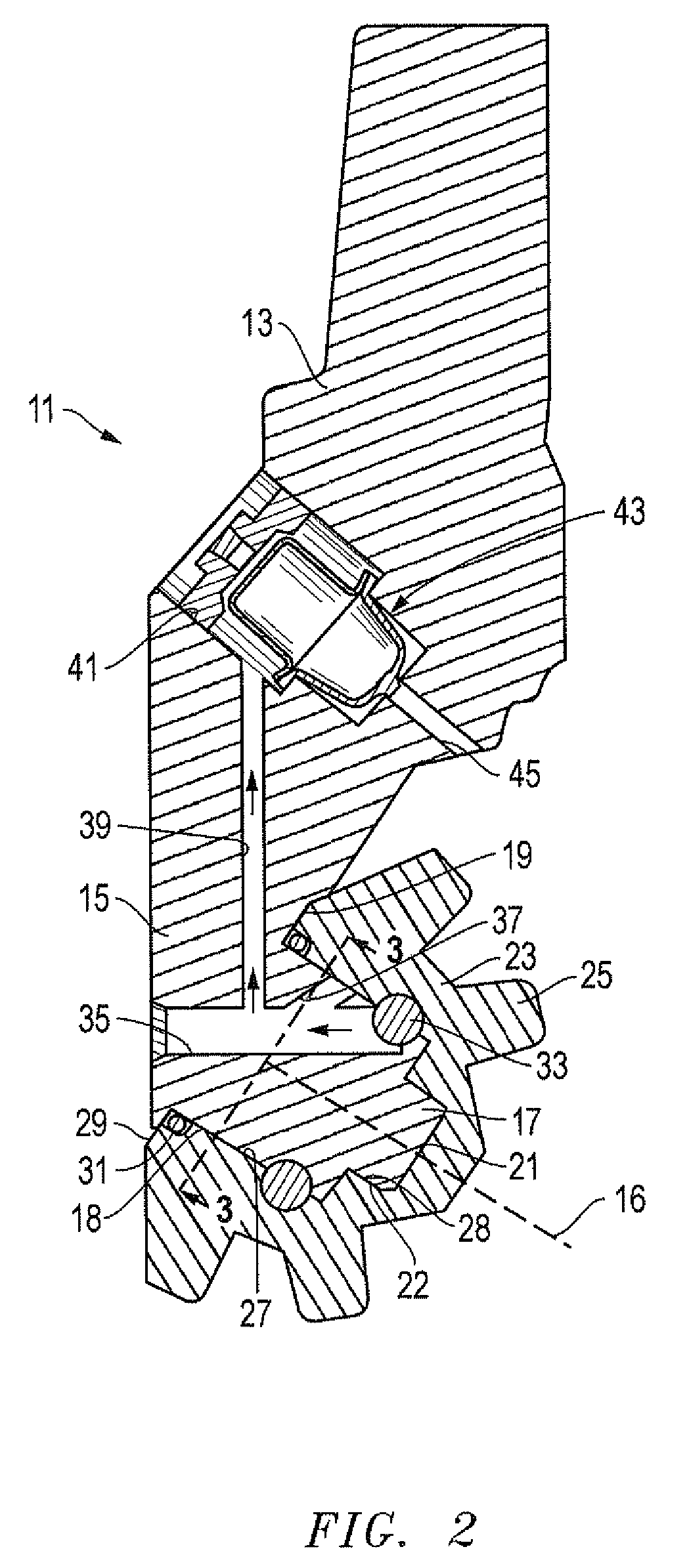

[0019]Referring to FIG. 2, a bit 11 has a body 13 at an upper end that is threaded (not shown) for attachment to the lower end of a drill string. Body 13 has at least one bit leg 15, typically three, which extend downward from it. Each bit leg 15 has a bearing pin 17 that extends downward and inward along an axis 16. Bearing pin 17 has an outer end, referred to as last machined surface 19, where it joins bit leg 15. Bearing pin 17 has a main journal surface 18 and a nose 21 having a smaller diameter than surface 18 that is formed on its inner end. Nose 21 also has a pilot pin radial bearing surface 22 that is parallel to surface 18 relative to axis 16.

[0020]A cone 23 rotatably mounts on bearing pin 17. Cone 23 has a plurality of protruding teeth 25 or compacts (not shown). Cone 23 has a cavity 27 that is slightly larger in diameter than the outer diameters of bearing pin 17. Cone 23 has a back face 29 that is located adjacent, but not touching, last machined surface 19. If the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com