Patents

Literature

72results about How to "Reduce fatigue cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

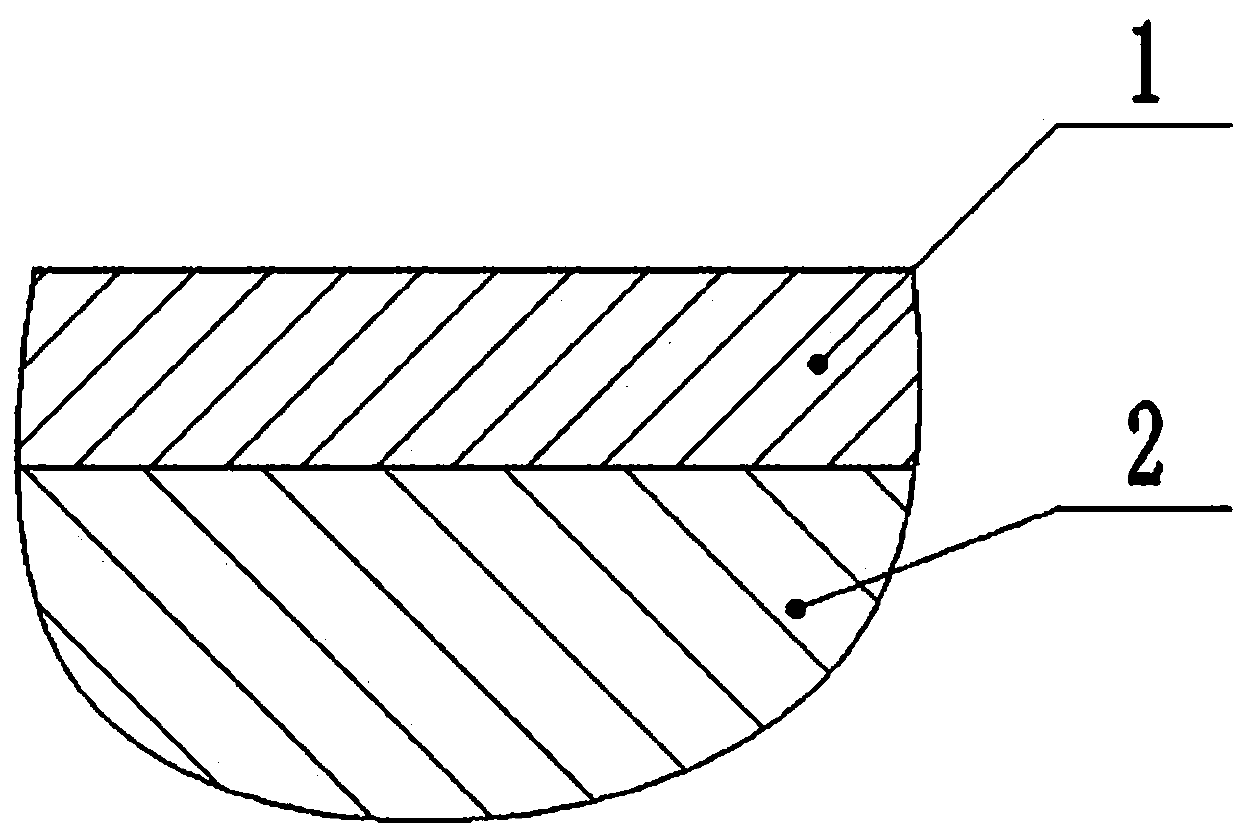

Cold spraying type epoxy thin bridge deck paving material and preparation method thereof

The invention relates to a cold spraying type epoxy thin bridge deck paving material and a preparation method thereof. The cold spraying type epoxy thin deck paving material is characterized by comprising a binder and a single grading fine aggregate, wherein 1-2kg / m<2> of the binder is smeared on a bridge deck so as to form a binder layer; 5-8kg / m<2> of the single grading fine aggregate is sprayed on the binder layer so as to form a single grading fine aggregate layer; the binder is formed by mixing a component A with a component B, and the weight ratio of the component A to the component B is (1-1.4):1; the component A comprises the following raw materials in parts by weight: 75-85 parts of epoxy resin, 15-25 parts of modified epoxy resin and 5-10 parts of diluent; and the component B comprises the following raw materials in parts by weight: 20-30 parts of cycloaliphatic amide curing agent, 10-20 parts of modified amine curing agent and 40-60 parts of cured accelerator. The cold spraying type epoxy thin bridge deck paving material has the characteristics of good skid-resisting and wear-resisting properties, high adhesion strength with the bridge deck, good waterproof and seepage-proofing properties and good low temperature flexibility.

Owner:武汉兴正源路桥复合材料有限公司 +1

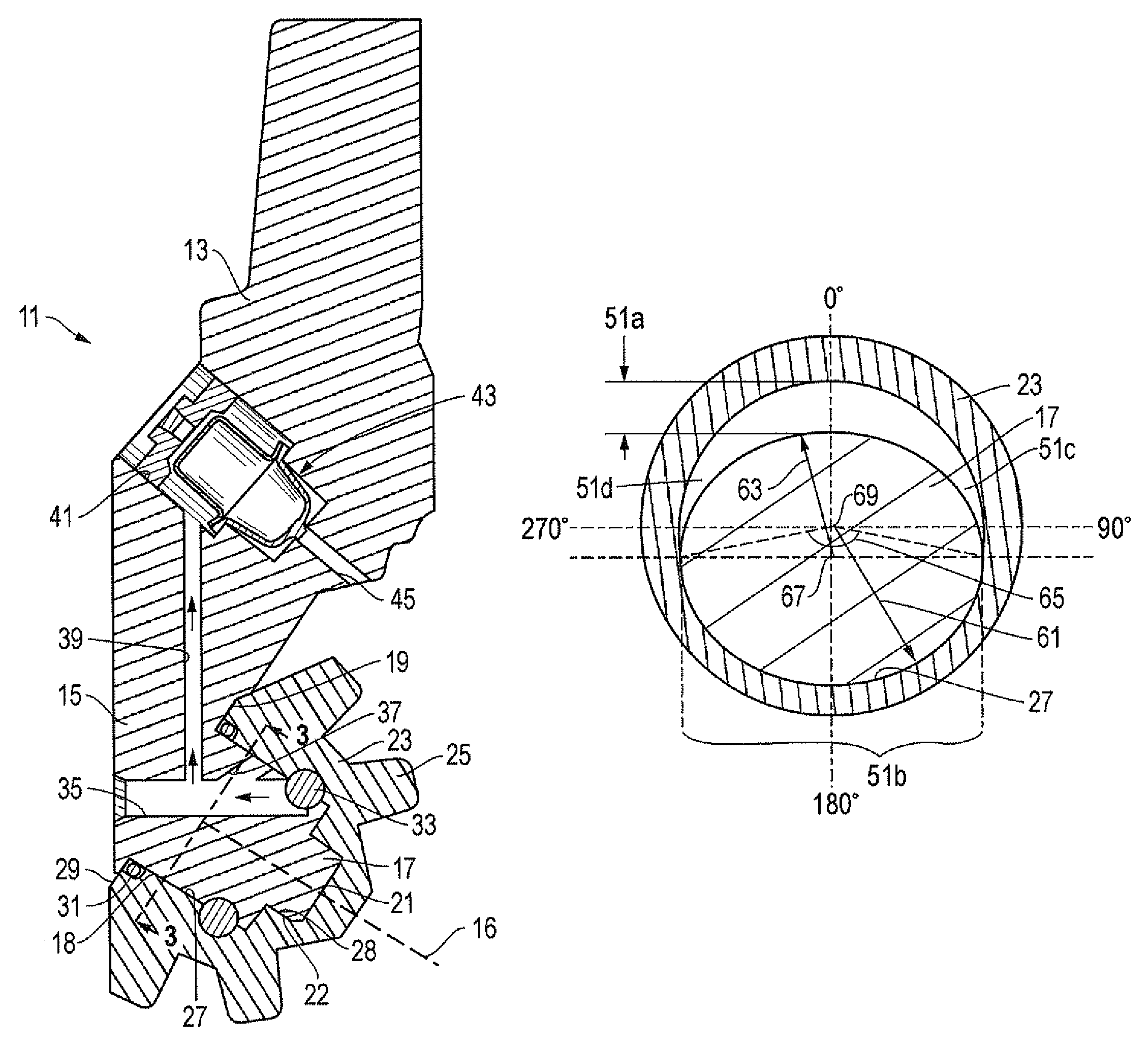

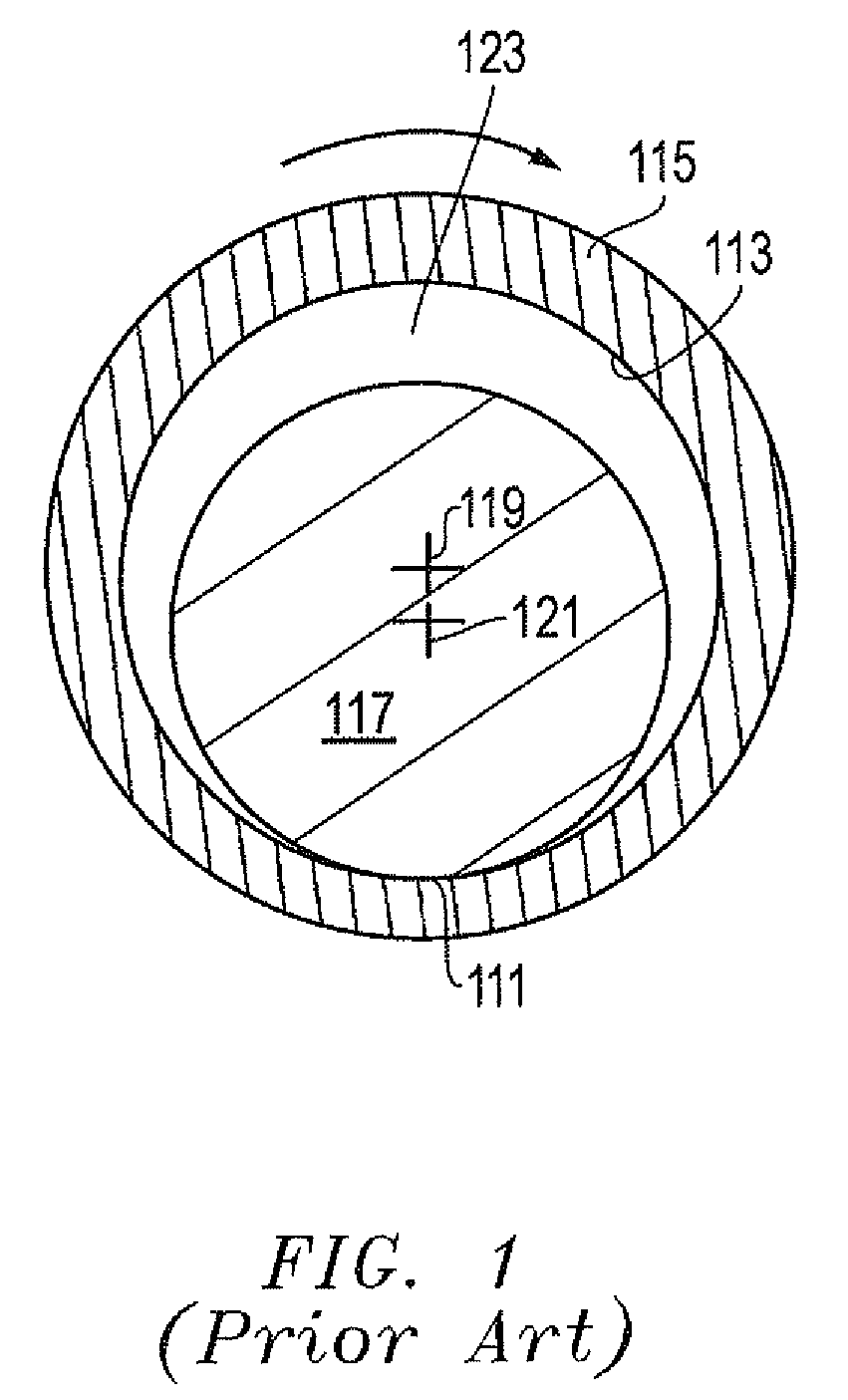

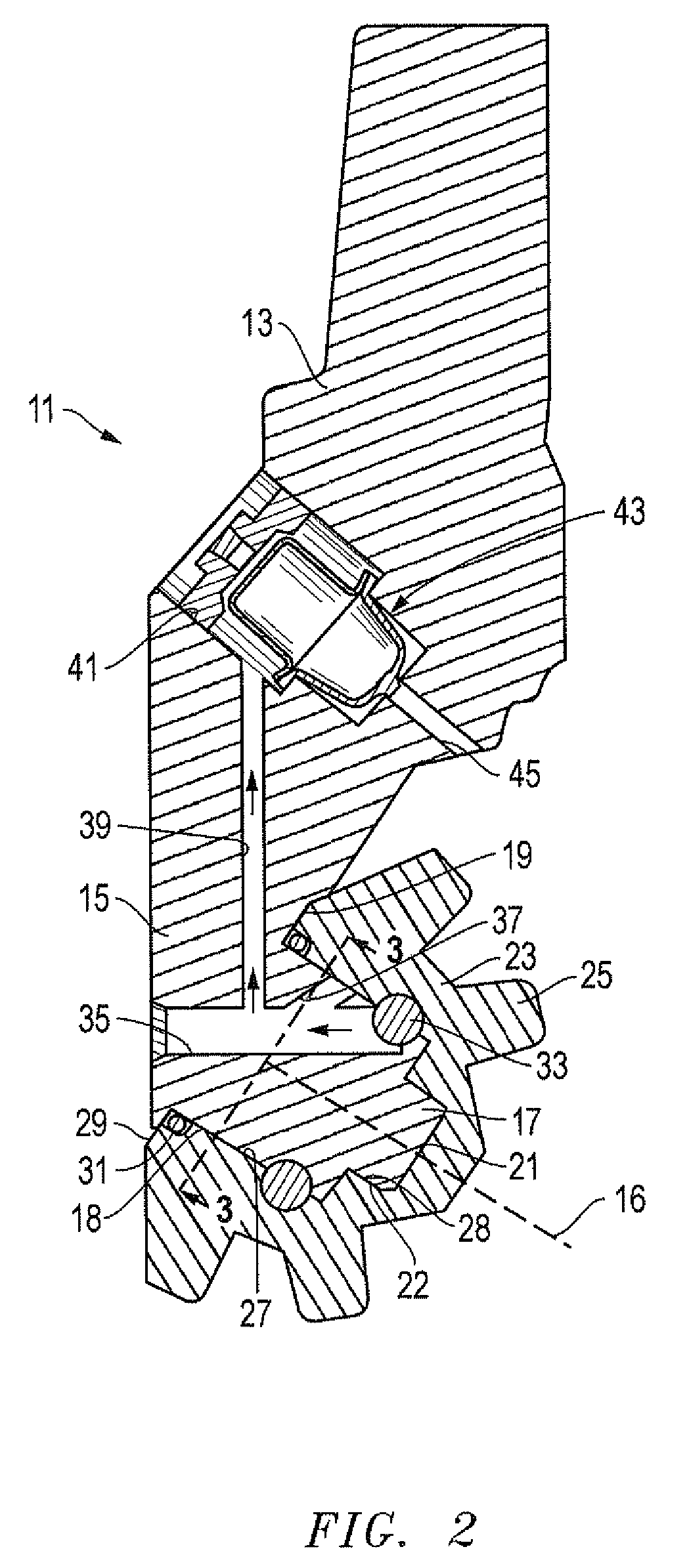

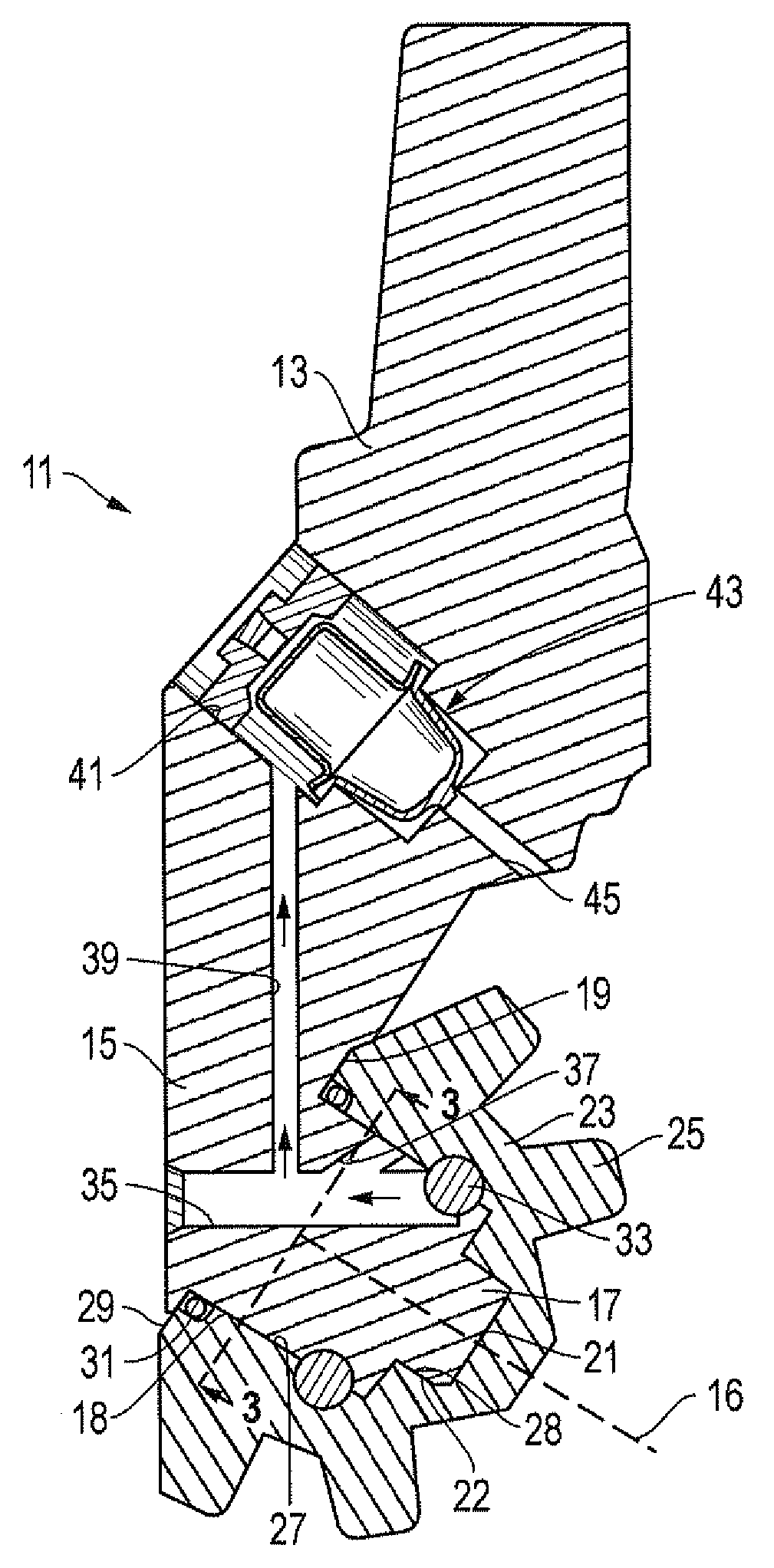

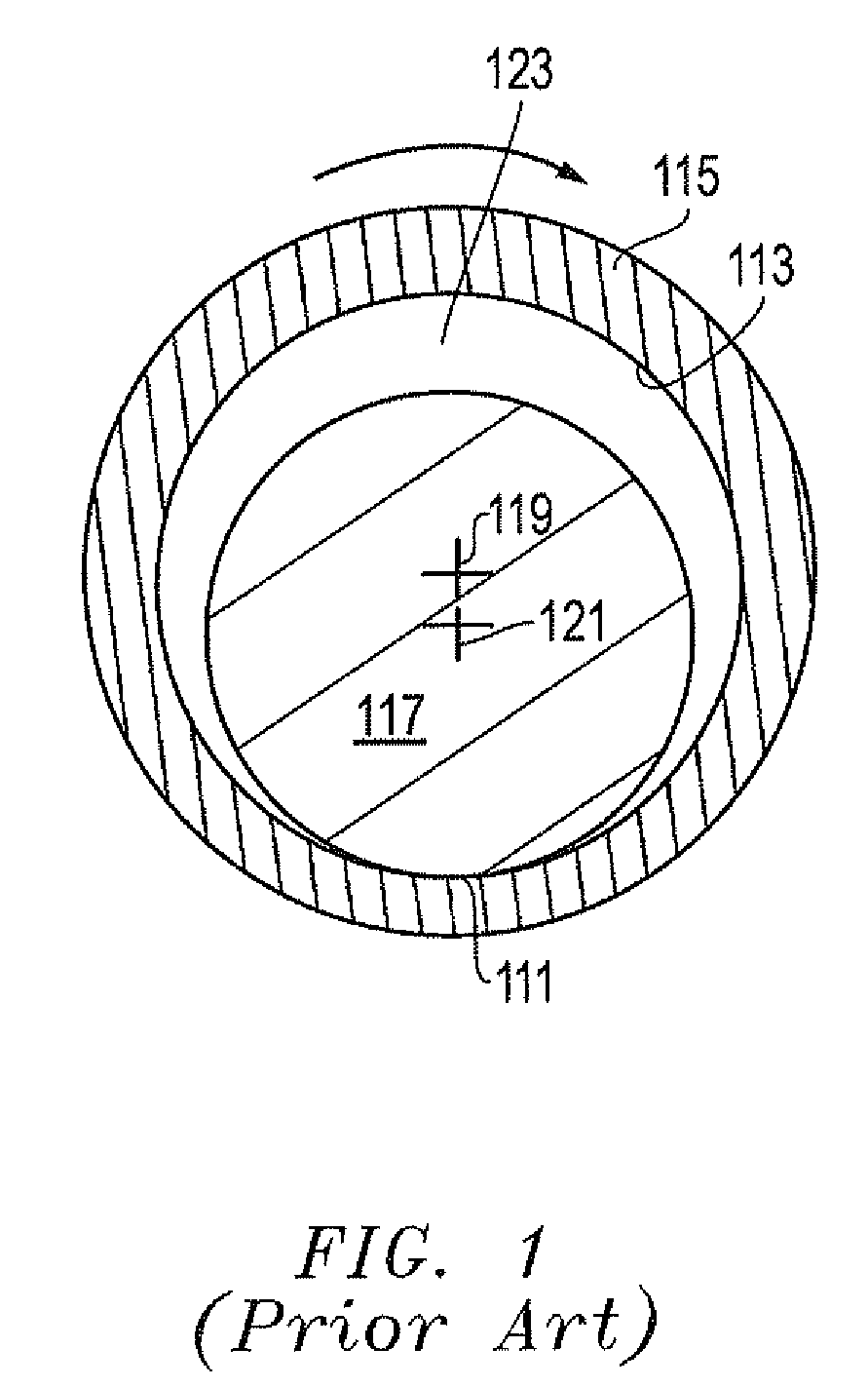

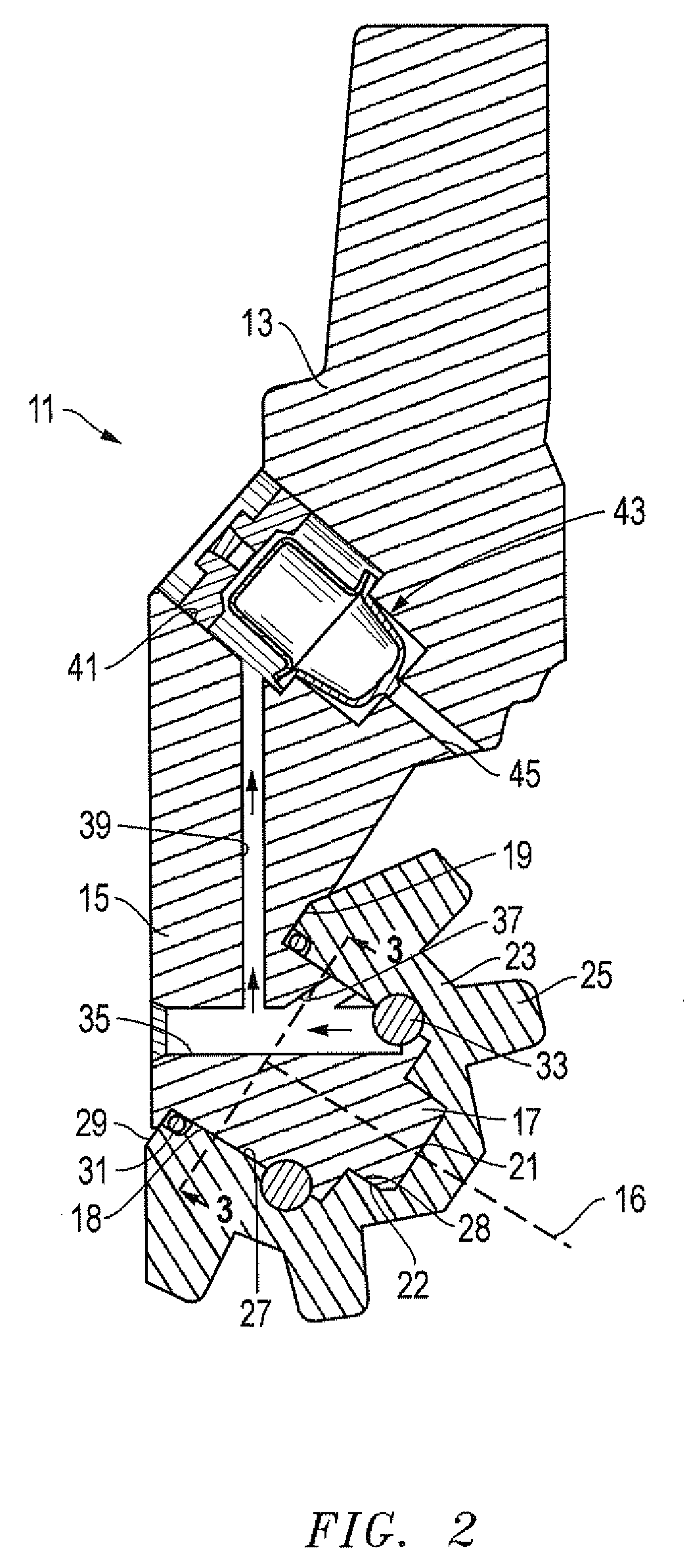

Conformal bearing for rock drill bit

ActiveUS7861805B2Increase apparent contact surface areaMaximize supportDrill bitsBearing componentsStructural engineeringBearing surface

Owner:US SYNTHETIC CORP +1

Conformal bearing for rock drill bit

ActiveUS20090283332A1Maximizes load supportIncrease apparent contact surface areaDrill bitsBearing componentsStructural engineeringBearing surface

A rock drilling bit having PDC radial bearings has journal and cone bearing surfaces with increased contact area to increase load support. The radius of curvature of the bearing pin journal and cone bearing surfaces are matched or conformed on the bearing pressure side. The conformal journal surfaces may be formed on the main journal bearing, the pilot pin radial bearing, or both surfaces. In addition, diamond inlays may be located on the bearing surfaces of the cone, the bearing pin, or both components.

Owner:US SYNTHETIC CORP +1

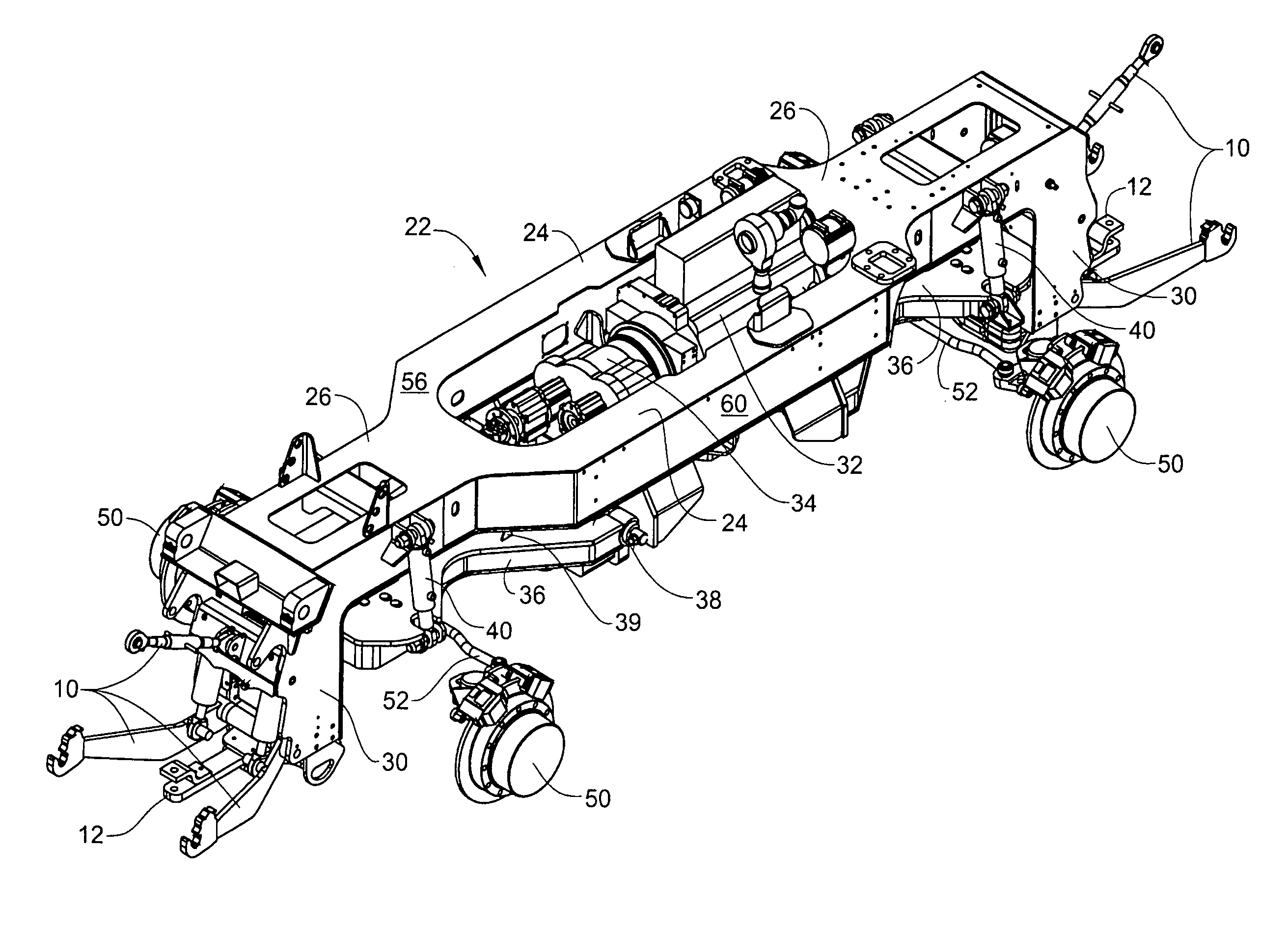

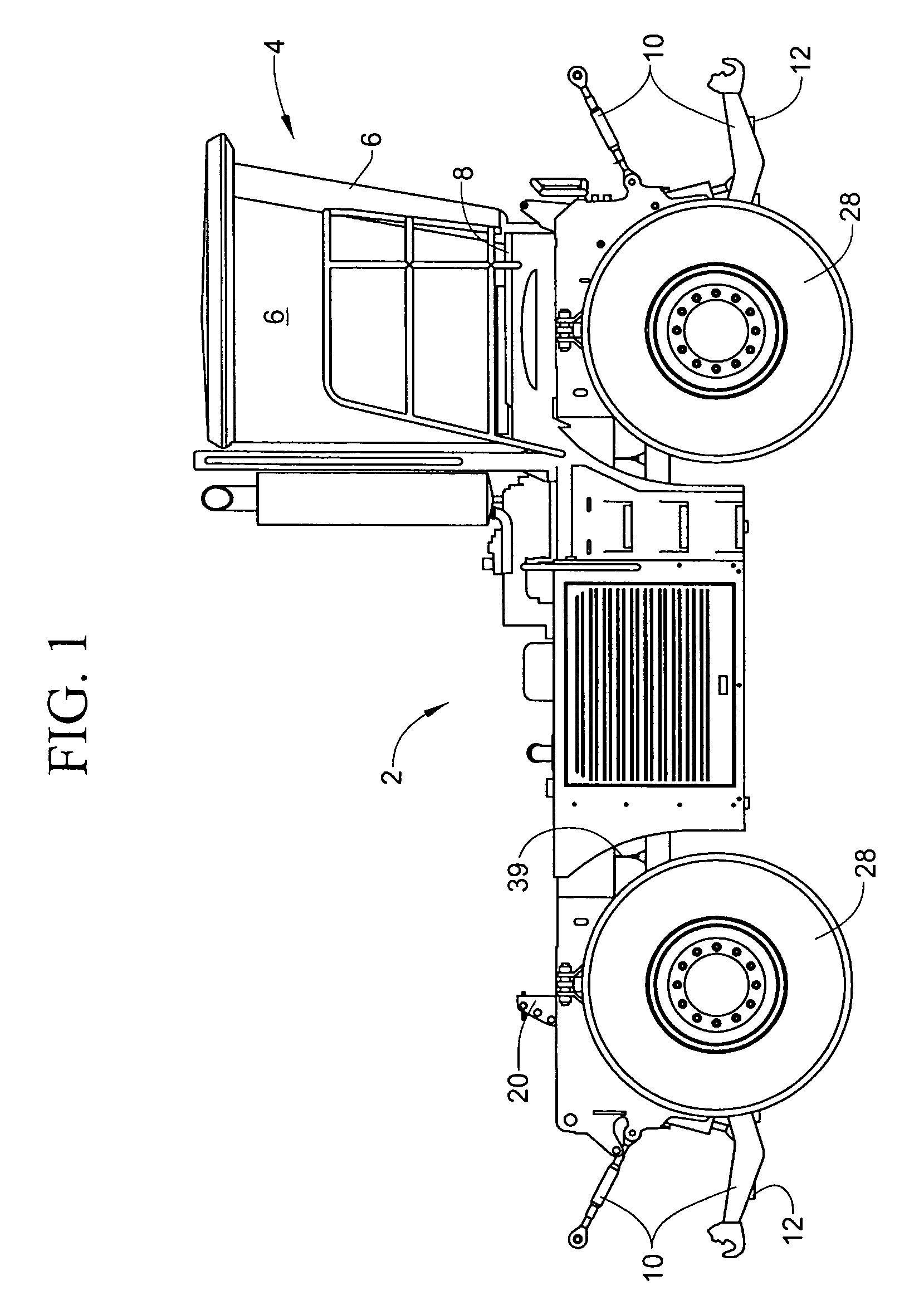

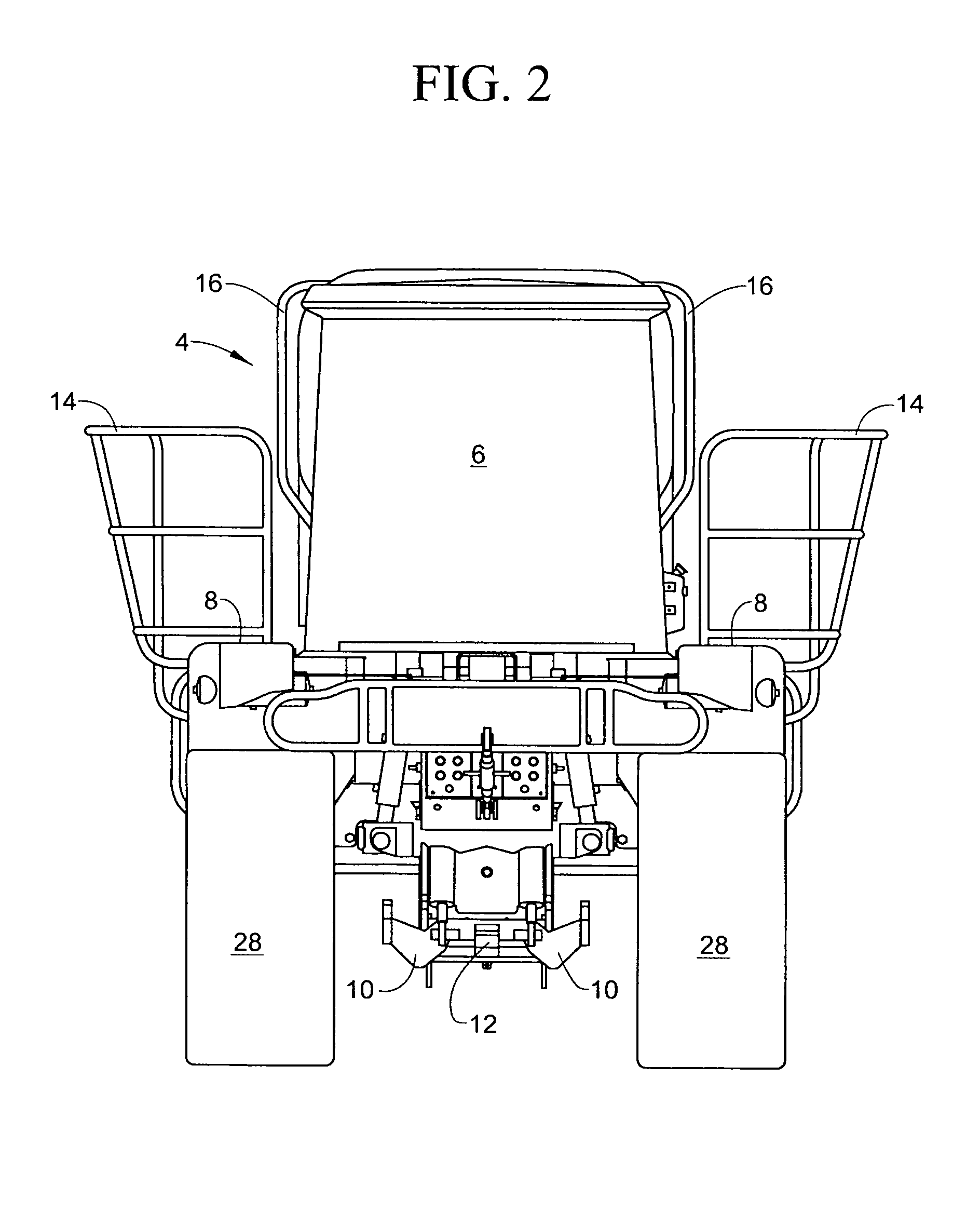

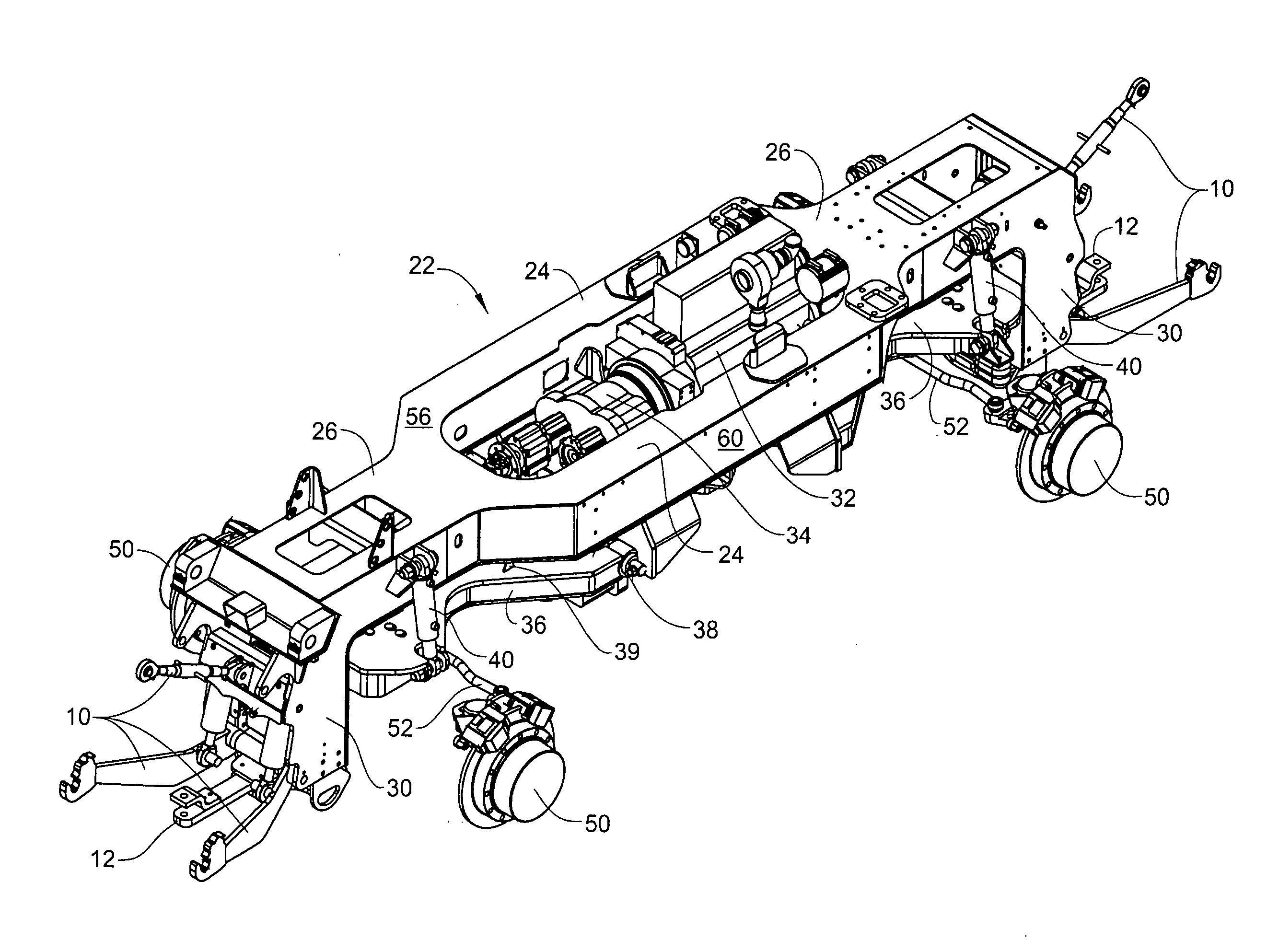

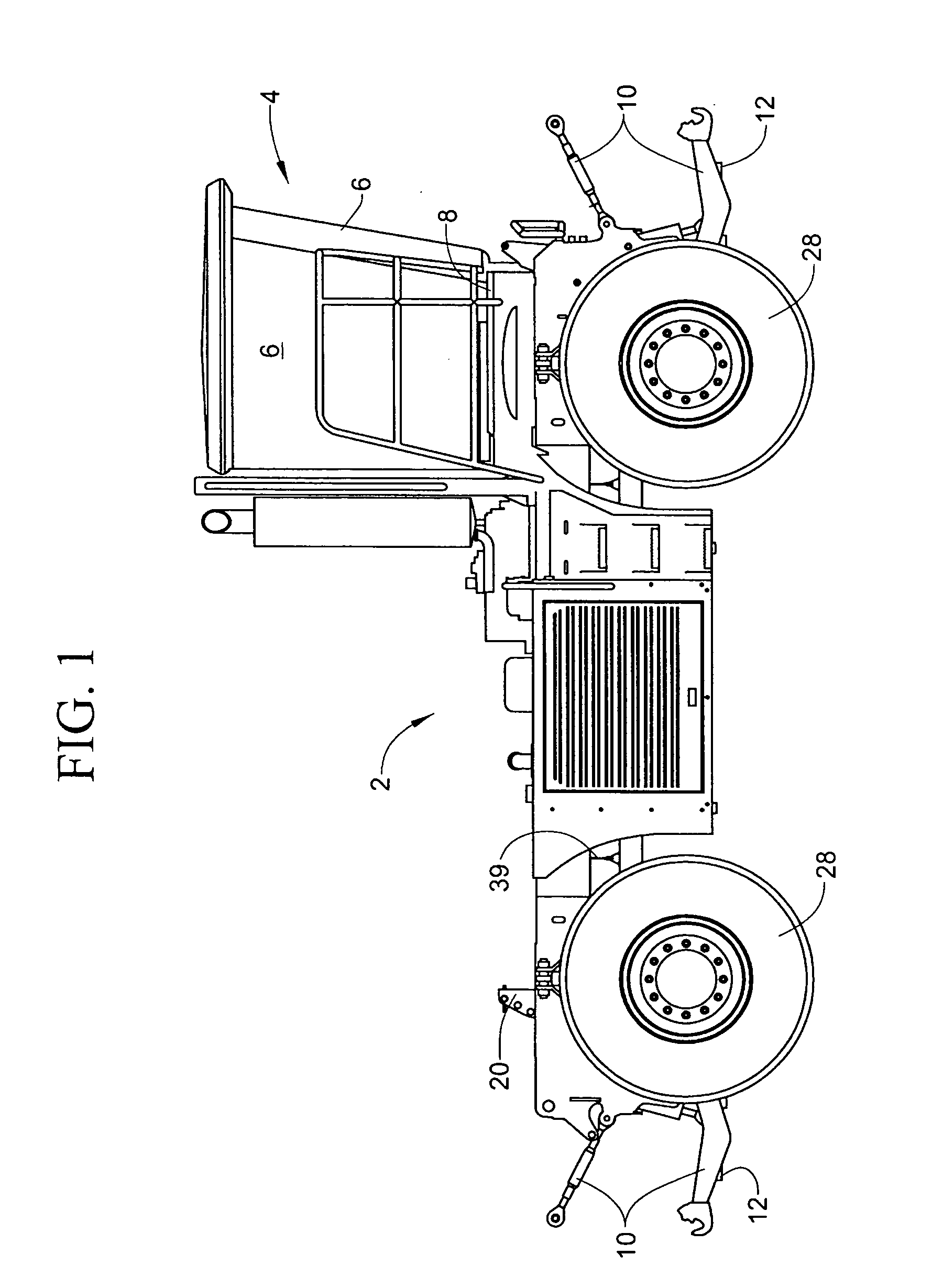

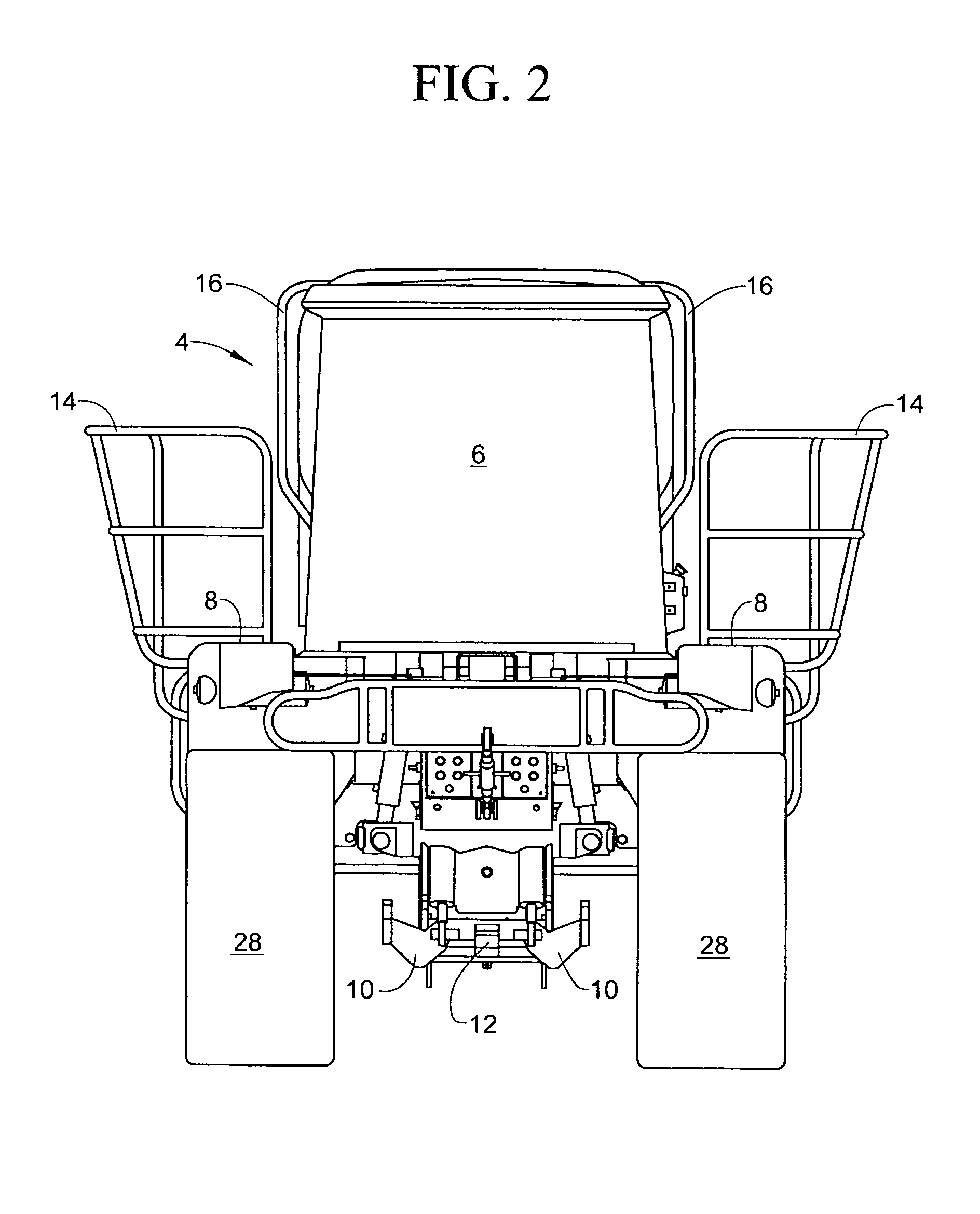

Multipurpose utility vehicle

ActiveUS8534412B2Excellent visibility and utilityImprove visibilityVehicle body-frame connectionsUnderstructuresVisibilityVehicle frame

A multiuse vehicle comprises a frame having longitudinal portions forming a central opening for supporting an engine and end portions extending forward and rearward from said longitudinal portions, each of the end portions having a downwardly extending leg portion with one or more hitches. A suspension system includes the use of pivoting arms that carry trunnion-mounted differentials. An operator's cab is mounted on a forward portion of the frame to provide the operator with increased visibility. The frame behind the operator's cab is configured to receive any of a variety of devices such as a dump bed, a sprayer tank, a salt spreader, or a flat bed.

Owner:HUHN MICHAEL CARL +1

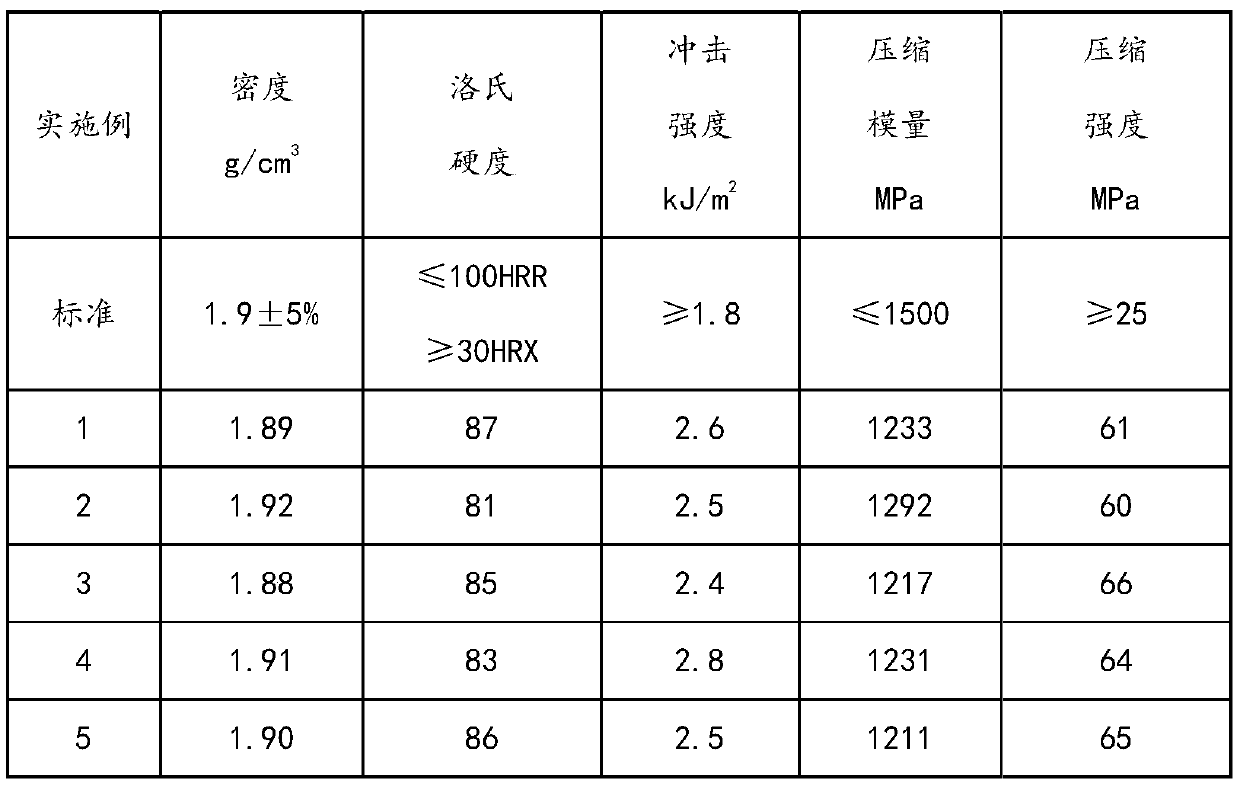

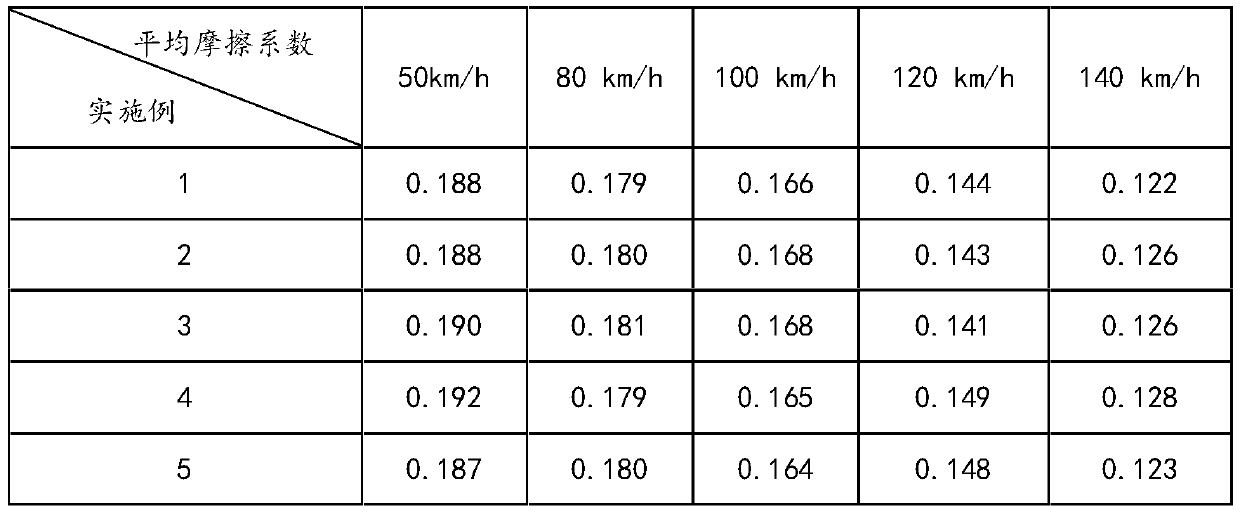

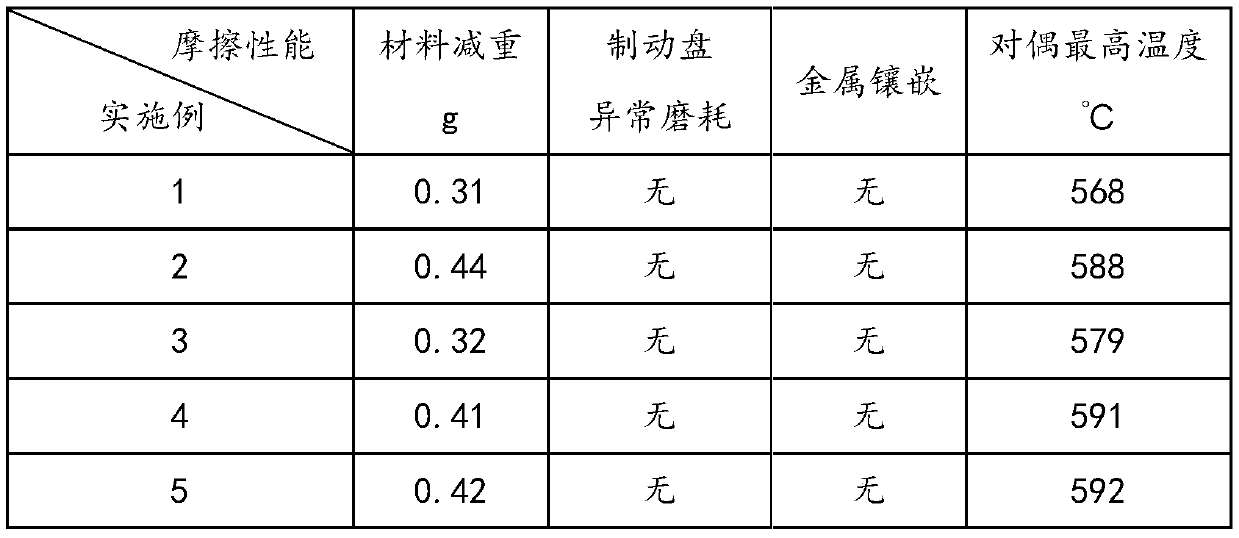

Copper-free friction material and brake pad

ActiveCN105670564AImprove stabilityReduce wearOther chemical processesFriction liningButadiene-styrene rubberMagnesium

The invention discloses a copper-free friction material and a brake pad. The copper-free friction material comprises the following raw materials by weight: 30-40 parts of steel fiber, 5-15 parts of modified phenolic resin, 5-10 parts of nitrile butadiene rubber, 10-15 parts of styrene butadiene rubber, 10-15 parts of graphite, 3-4 parts of molybdenum disulfide, 5-10 parts of cryolite, 5-8 parts of barium sulfate, 1-5 parts of aramid fiber, 1-5 parts of heavy calcium carbonate, 1-5 parts of heavy magnesium oxide, 1-3 parts of aramid fiber, and 3-4 parts of silicon carbide. The brake pad made of the copper-free friction material provided by the invention has good hot cracking resistance and wear resistance, and low wear rate, thereby prolonging the service life. And reasonable control of the friction material composition proportion can ensure no abnormal wear to a brake disc.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Heat-treatment cooling process for train wheel

ActiveCN110055394AImprove mechanical propertiesEasy to useFurnace typesHeat treatment furnacesThree stageHardness

The invention discloses a heat-treatment cooling process for a train wheel, and belongs to the technical field of heat-treatment cooling for train wheels. The heat-treatment cooling process for the train wheel comprises the steps that first, the whole wheel is heated to be completely austenitized; second, the wheel is transferred onto a quenching table and is made to rotate, a gas-mist two-phase flow with the pressure being increased step by step is sprayed onto a wheel tread; and third, the whole wheel is placed into a tempering furnace for heat preservation and is finally taken out to be air-cooled, wherein the gas-mist two-phase flow with the pressure being increased step by step is sprayed onto the wheel tread sequentially through three stages, the rotation speeds V1, V2 and V3 of thewheel, the water pressures P1, P2 and P3 and the quenching times T1, T2 and T3 in the three stages are controlled, and the numbers of started nozzles which are distributed at equal intervals in the circumferential direction of the wheels in the three stages are respectively M, 2M and 3M. By adoption of the heat-treatment cooling process for the train wheel, the capacity to cool the interior of a rim can be improved, the cooling speed is kept balanced and consistent from the wheel tread to the deep interior of the rim, the structure of the whole cross section of the rim is optimized, and accordingly, the radial hardness gradient of the rim is greatly reduced, and the mechanical property and usability of the wheel are greatly improved.

Owner:MAANSHAN IRON & STEEL CO LTD

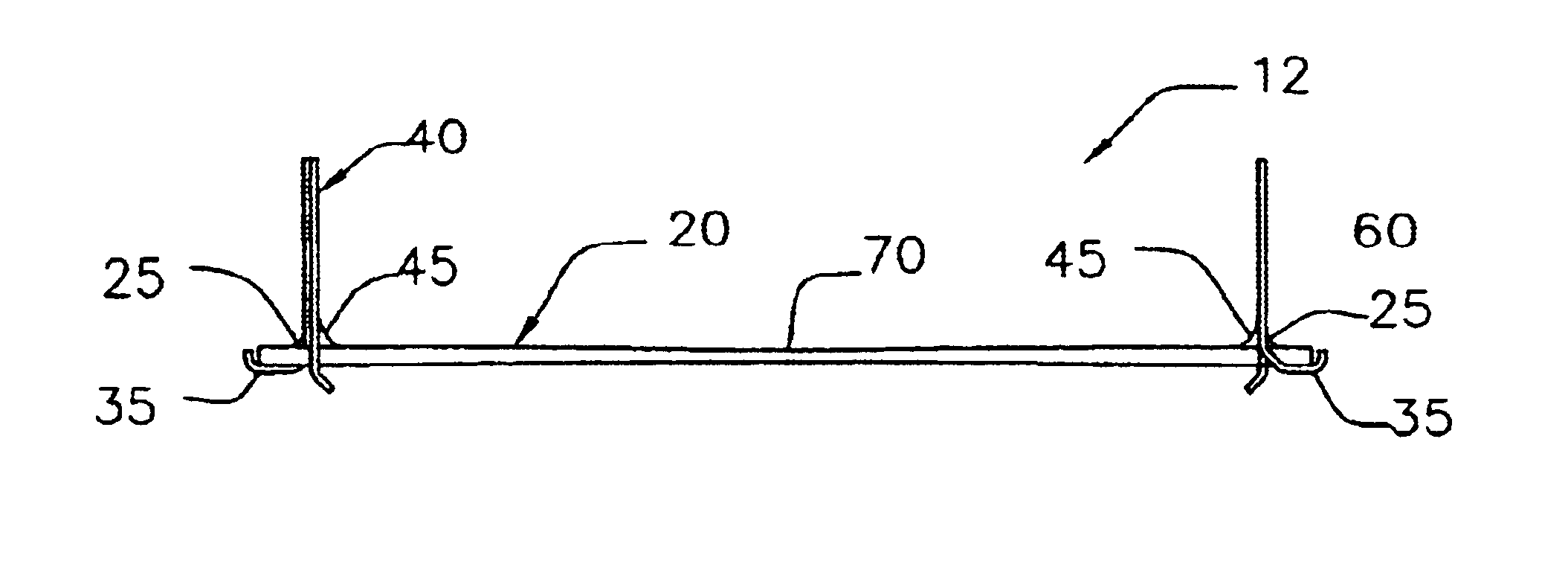

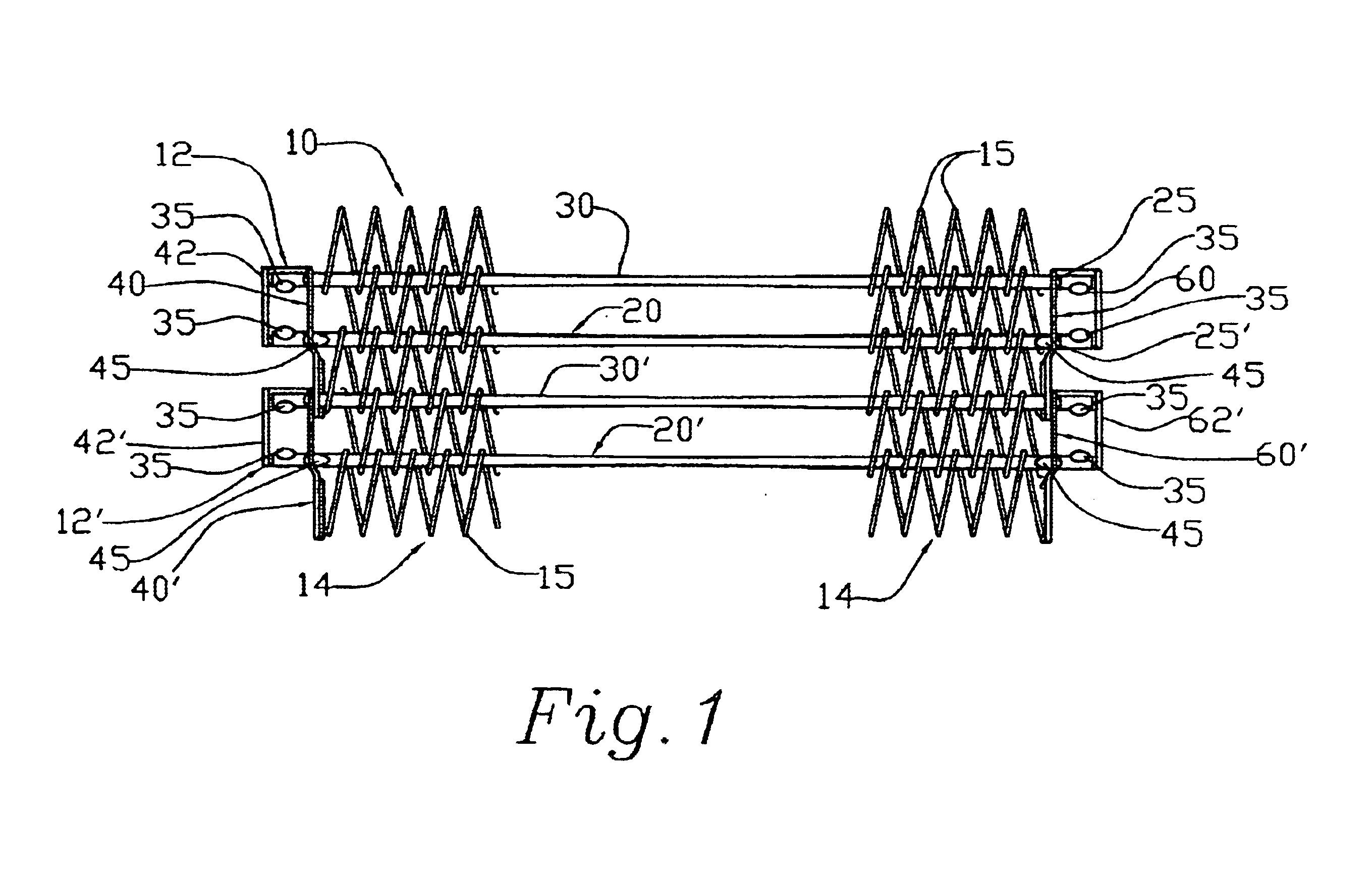

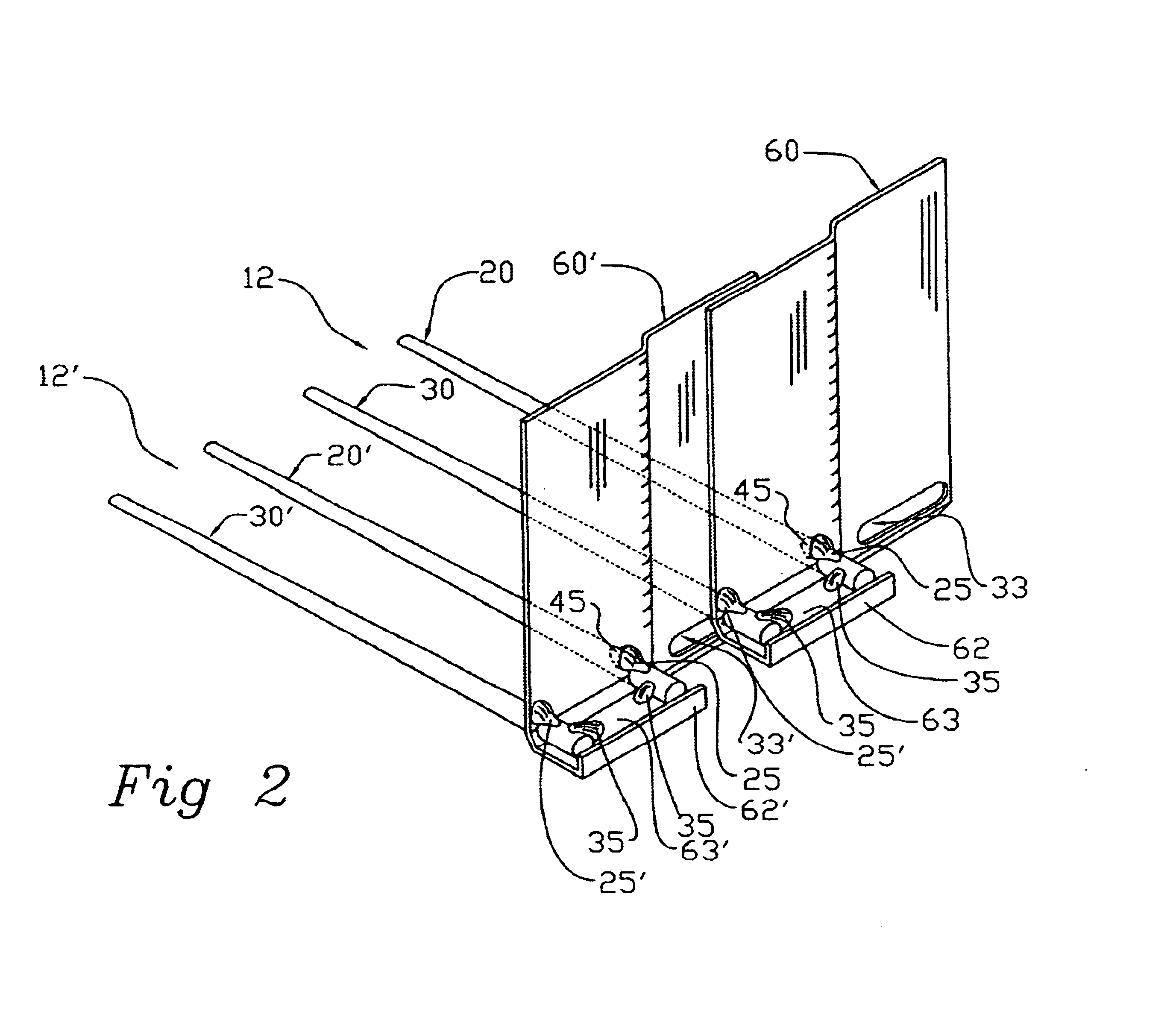

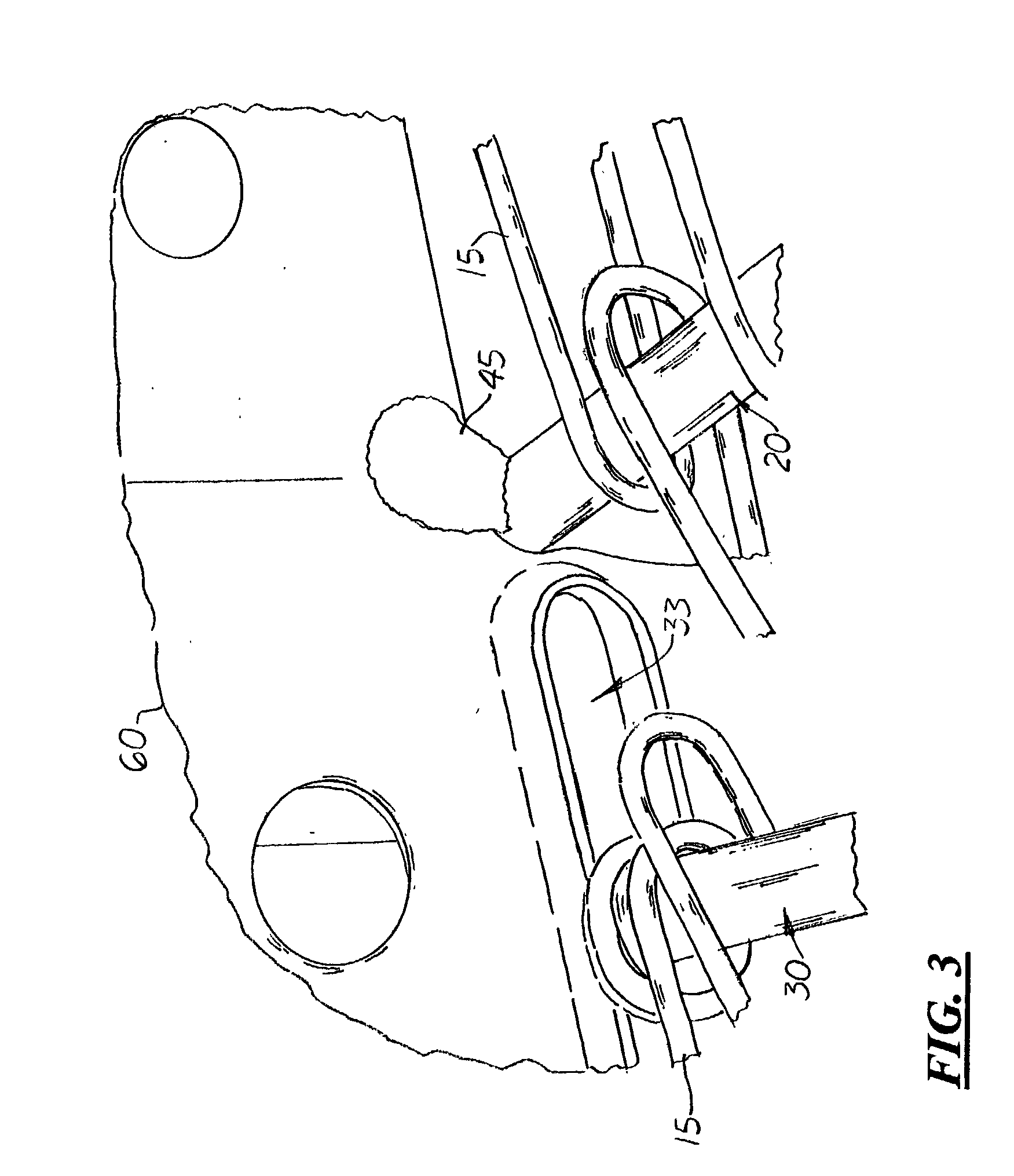

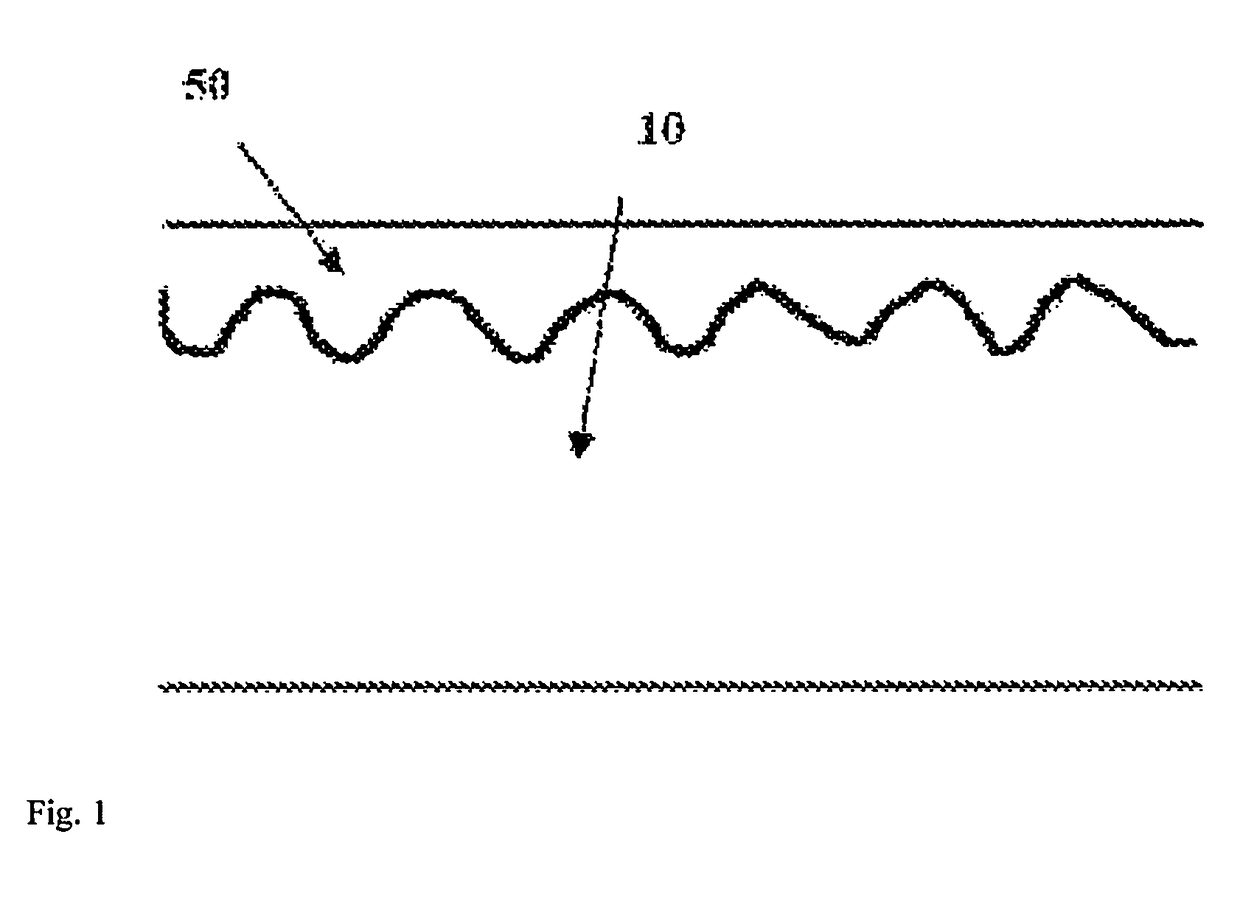

Self-stacking conveyor belt and method

An improved endless conveyor belt made of a plurality of interconnected links, each including two rods with two side plates perpendicularly aligned and attached to their opposite ends. The improvement comprising the addition of an internal buttress-type welded joint located between the inside surface of each side plate and one or both transverse rods with at least one bendable section. During use, the transverse rod is allowed to bend so that the side plates may deflect when force is exerted on them. By adding the welded joint and by adding the bendable section to the transverse rod, the number of cracks or breaks in the conveyor belt is substantially reduced.

Owner:GEA REFRIGERATION NORTH AMERICA

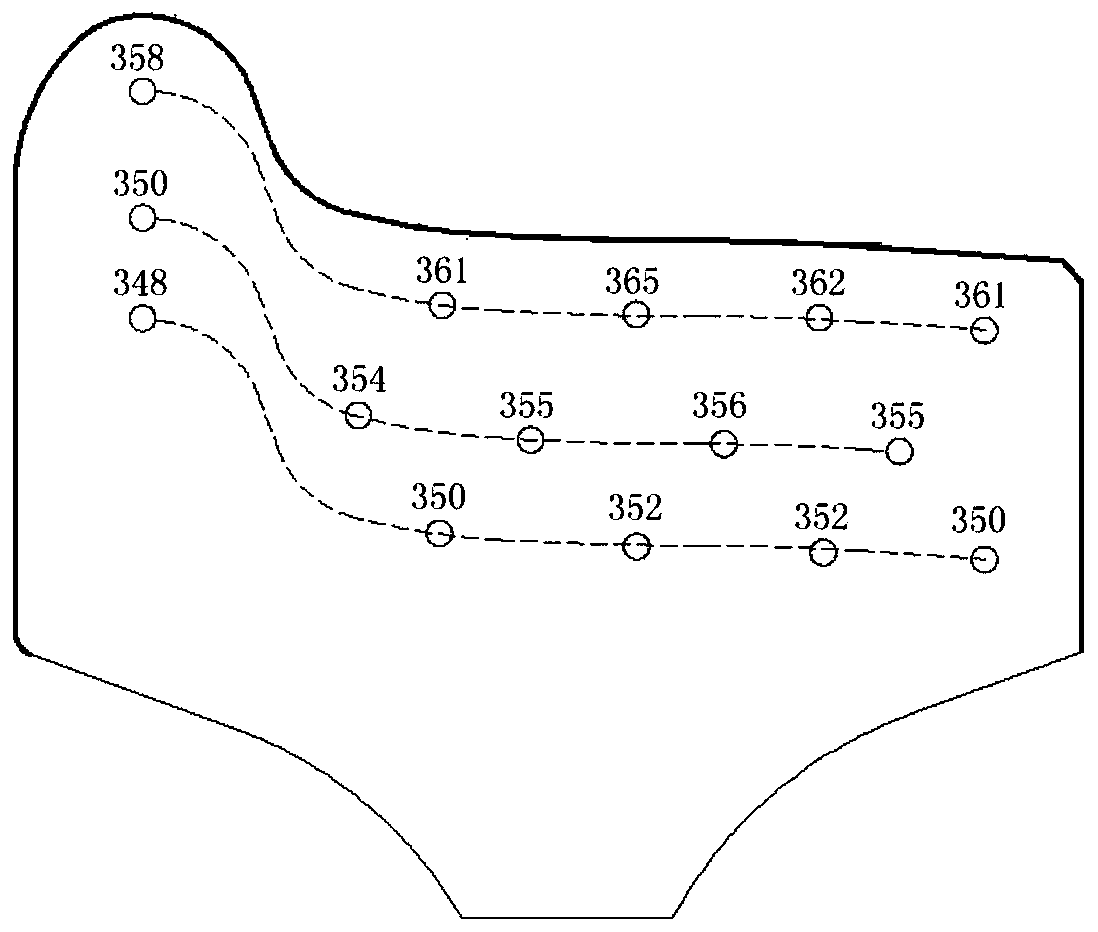

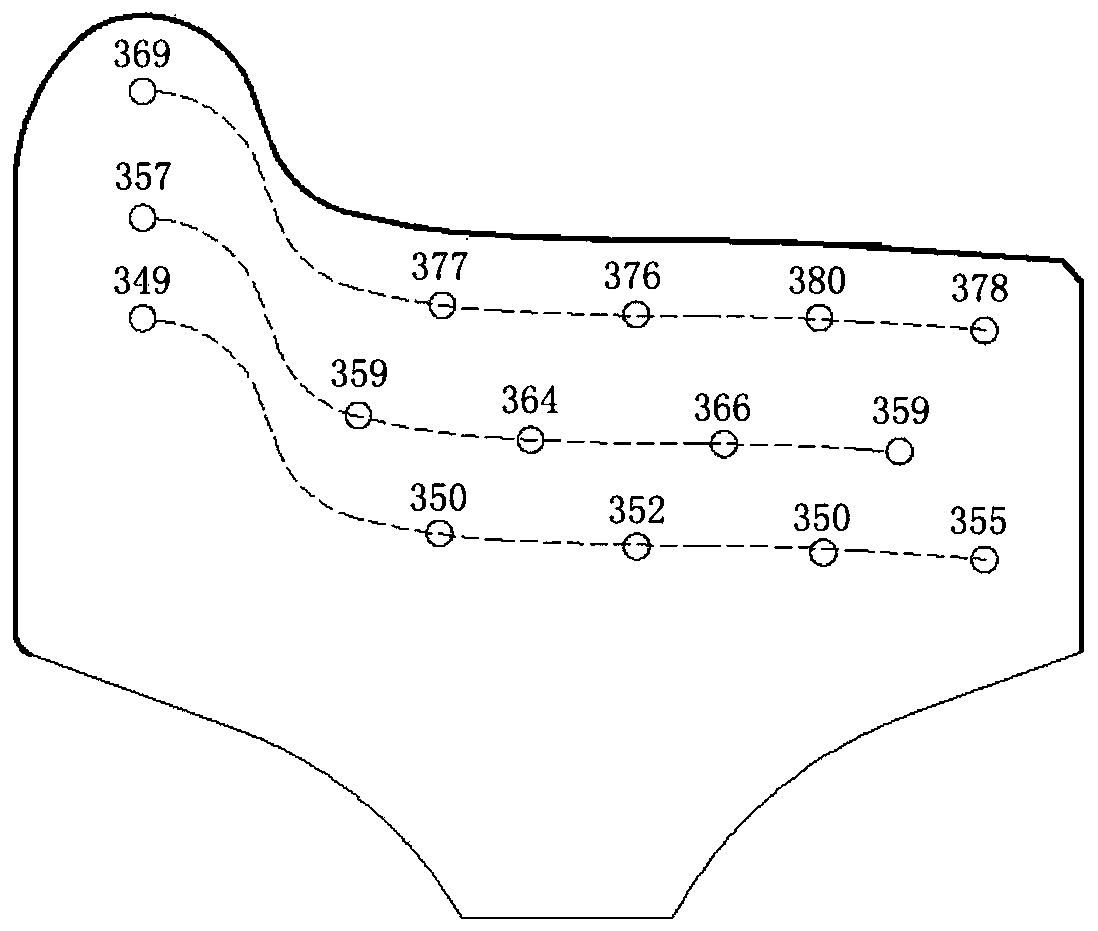

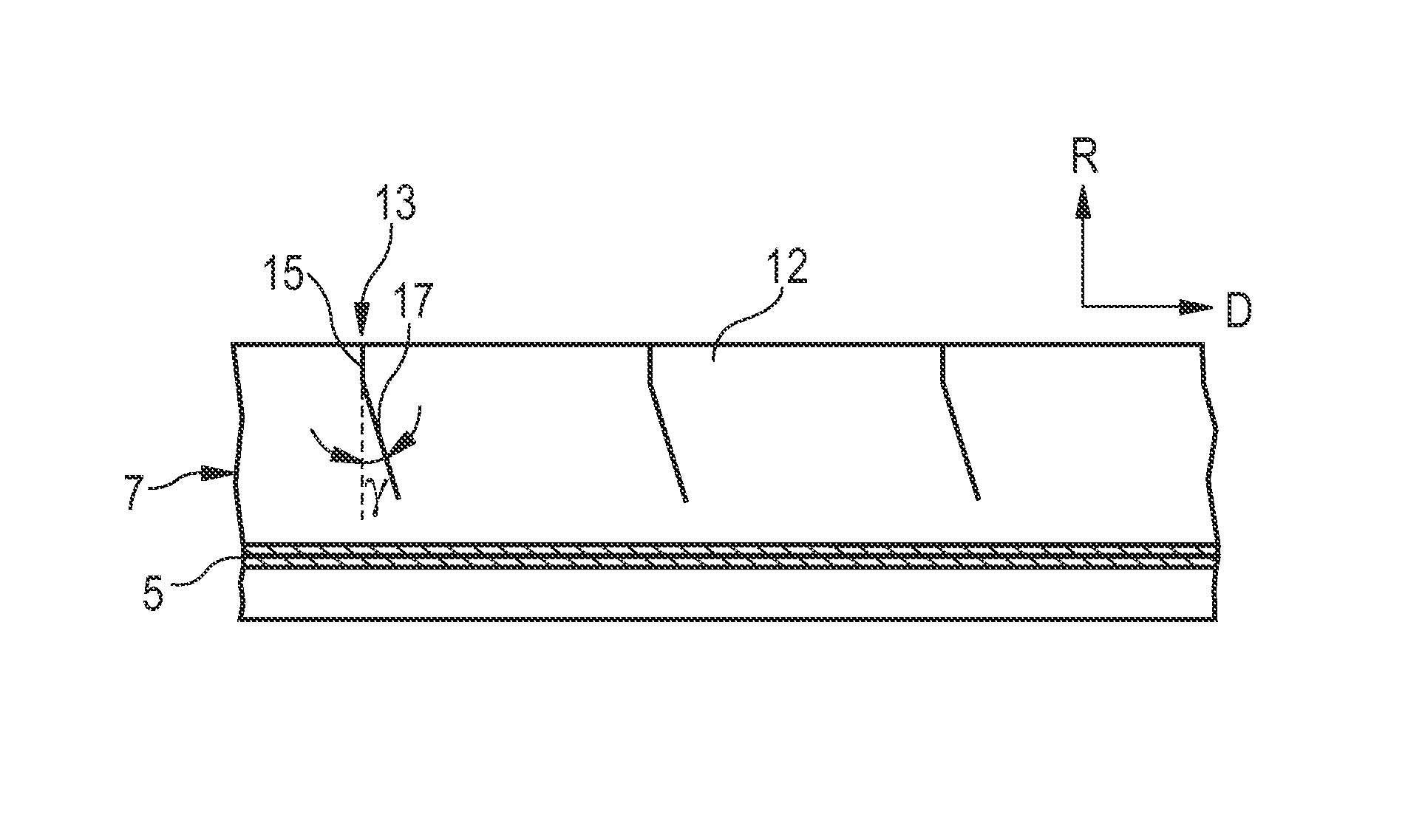

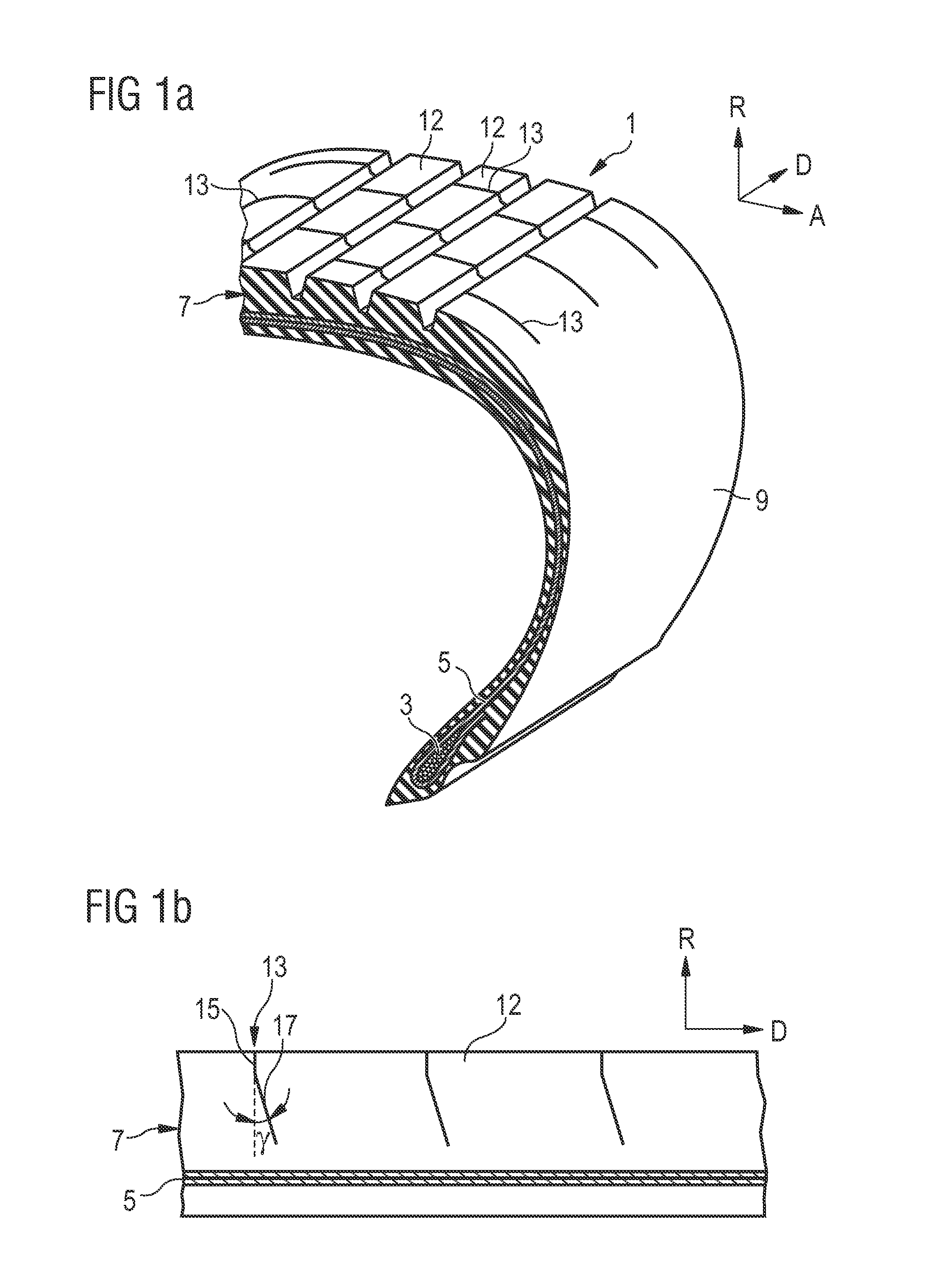

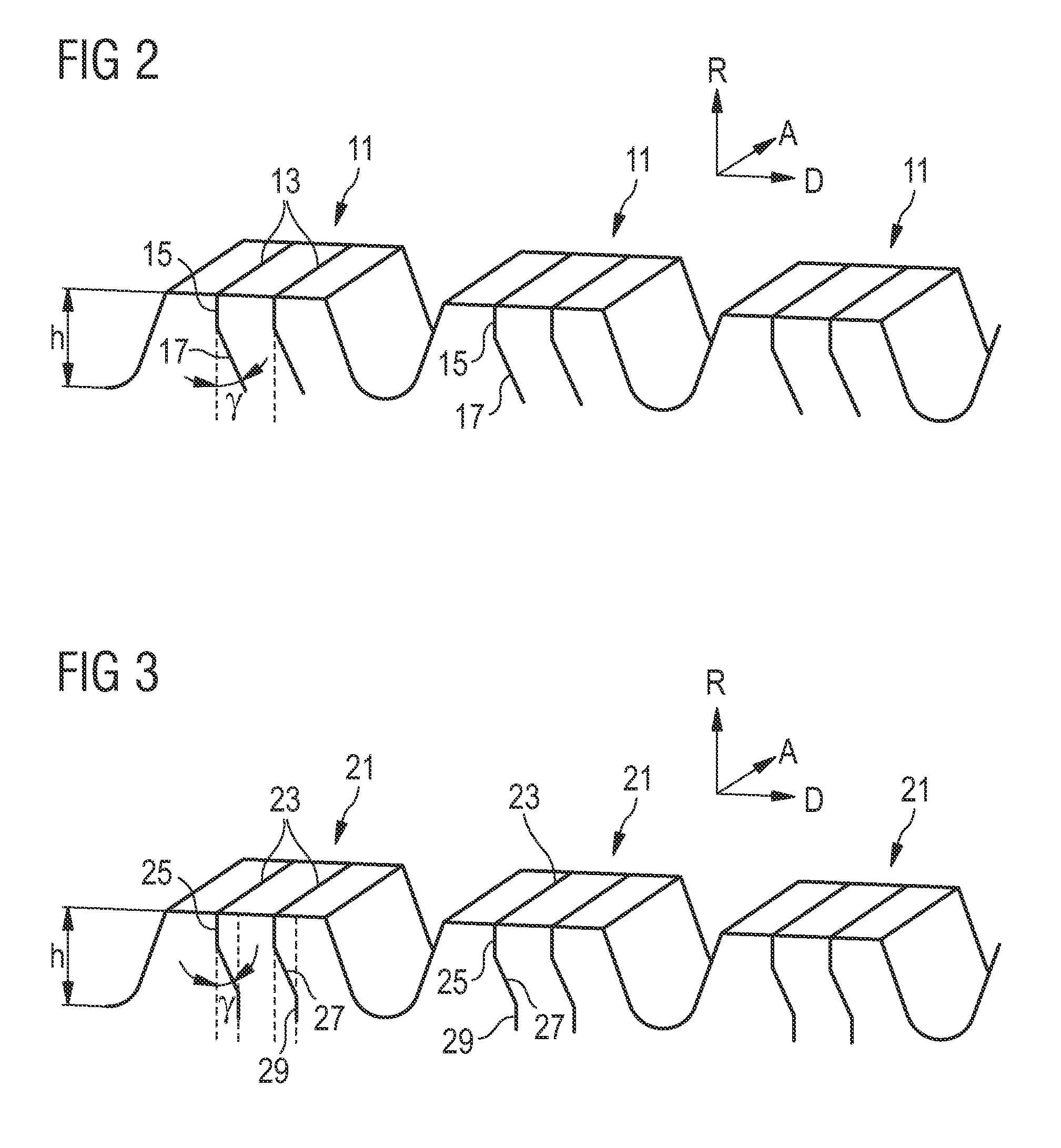

Pneumatic tire

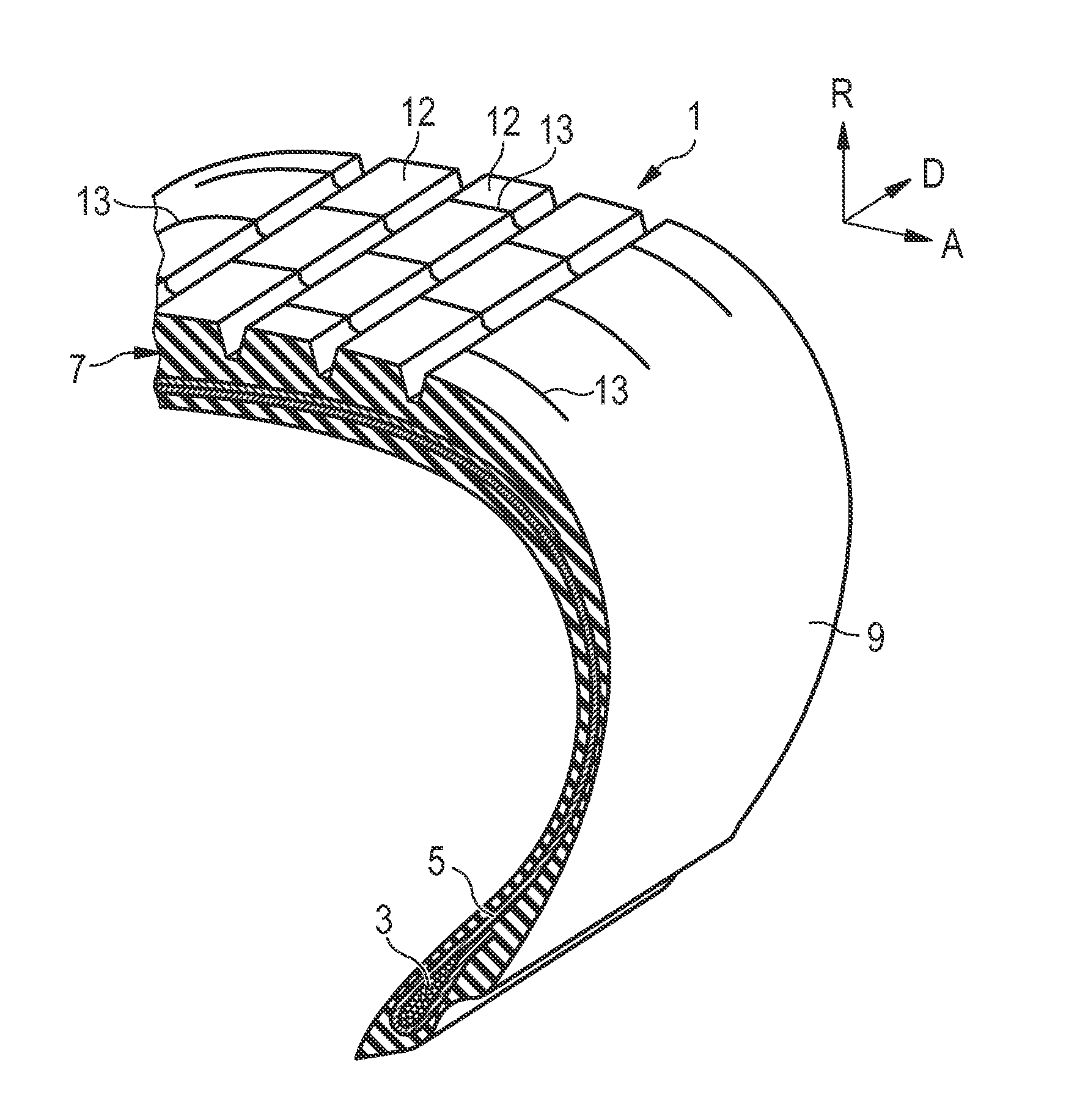

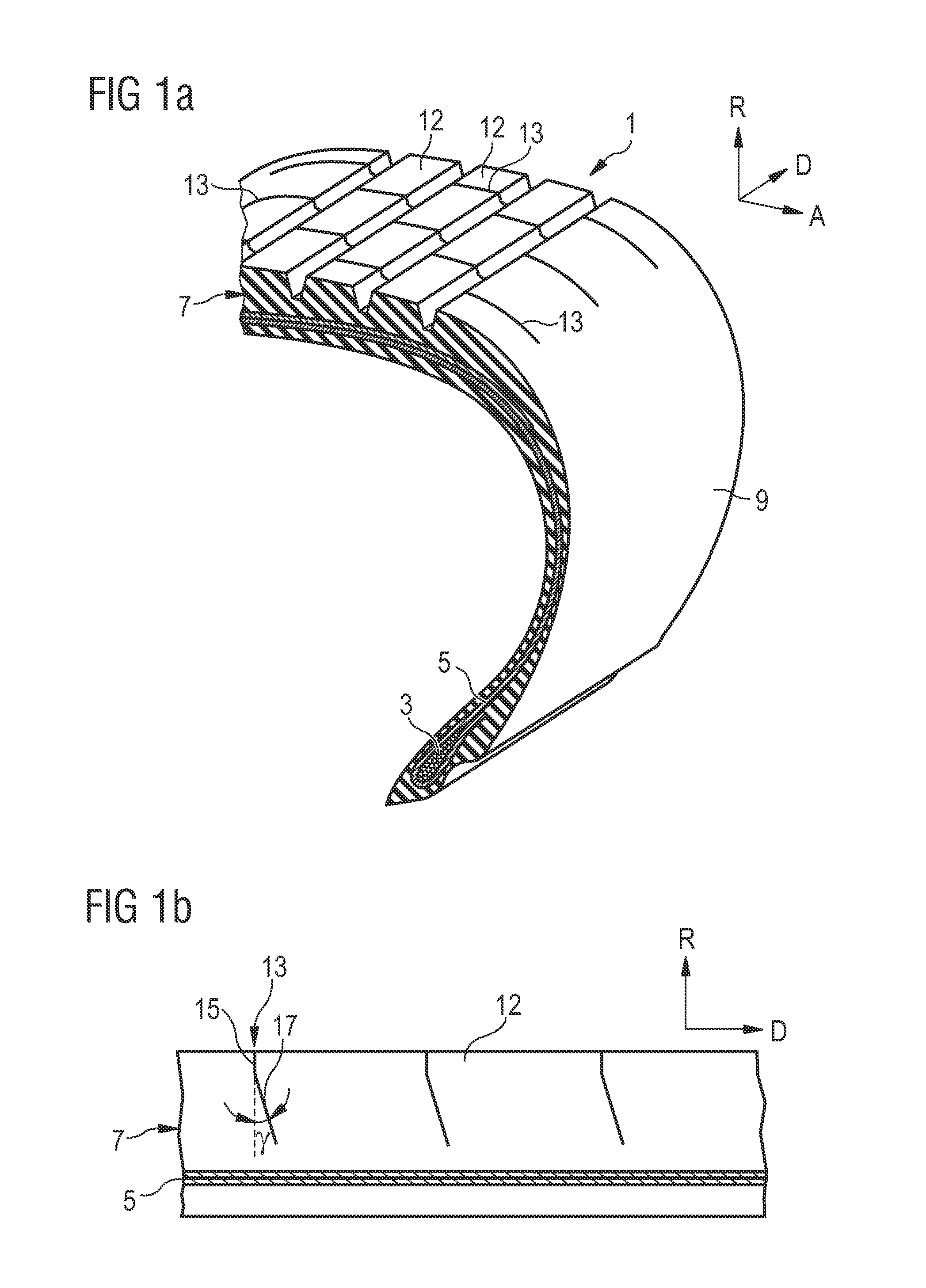

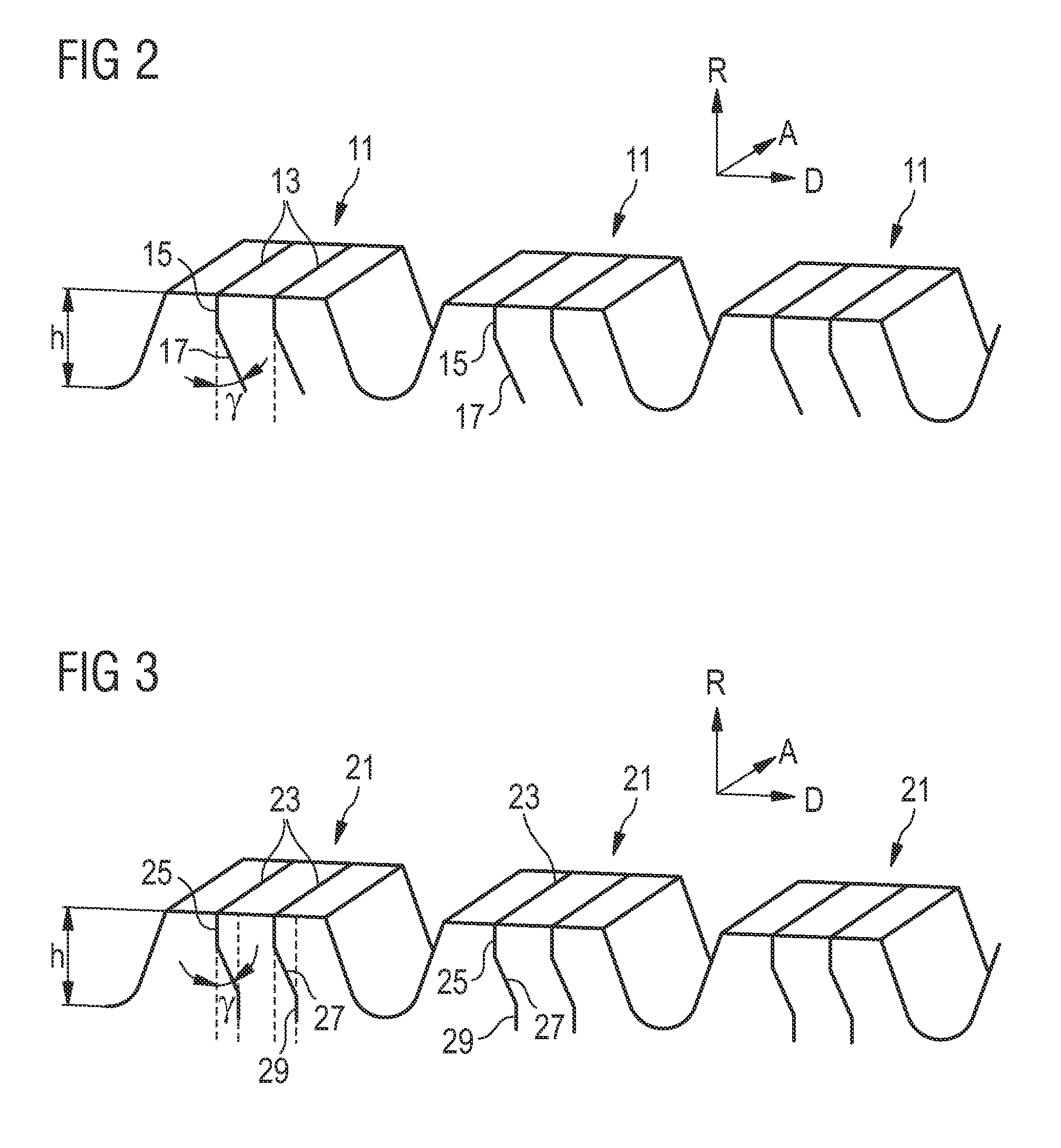

ActiveUS20120160383A1Increased durabilityImprove performanceTyre tread bands/patternsNon-skid devicesMechanical engineeringTread

The present invention is directed to a pneumatic tire 1, comprising at least one pair of parallel annular beads 3; at least one carcass ply wrapped 5 around said beads 3; a tread 7; and first and second sidewalls 9 disposed between said tread 7 and one of said at least one pair of beads 3. In accordance with an embodiment of the invention, the tread comprises tread blocks 11 and / or tread ribs 12, wherein the tread blocks 11 and / or tread ribs 12 comprise sipes 13 extending essentially in an axial direction A of the tire 1, the sipes 13 consisting of an upper portion 15 essentially aligned with the radial direction R of the tire and a lower portion 17 inclined in the direction of rotation D of the tire 1.

Owner:THE GOODYEAR TIRE & RUBBER CO

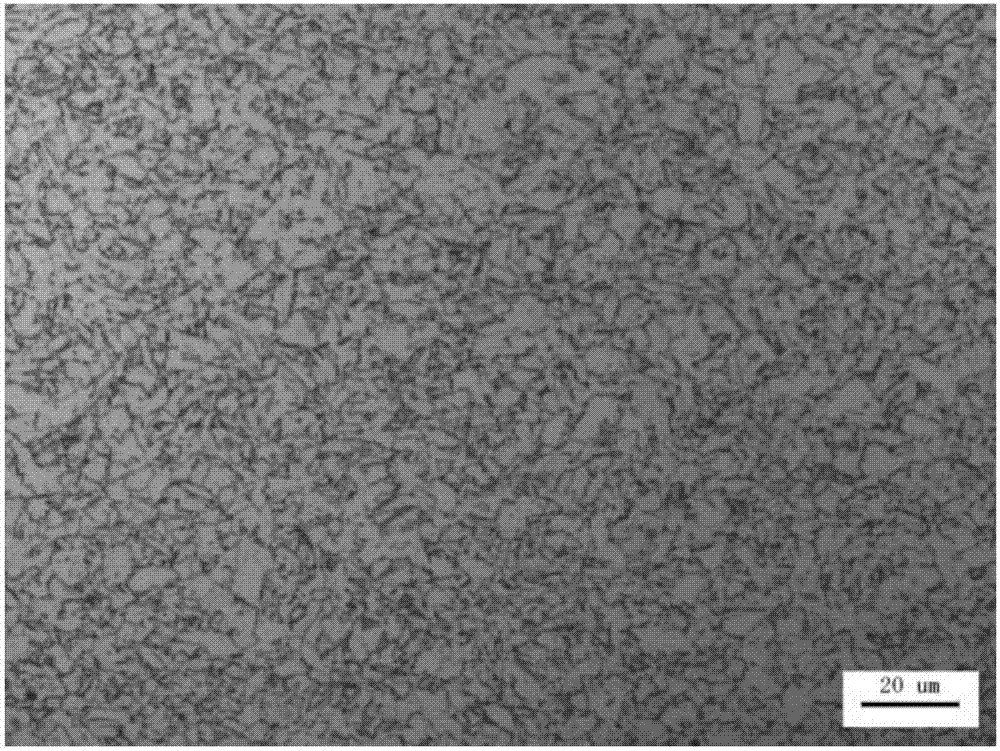

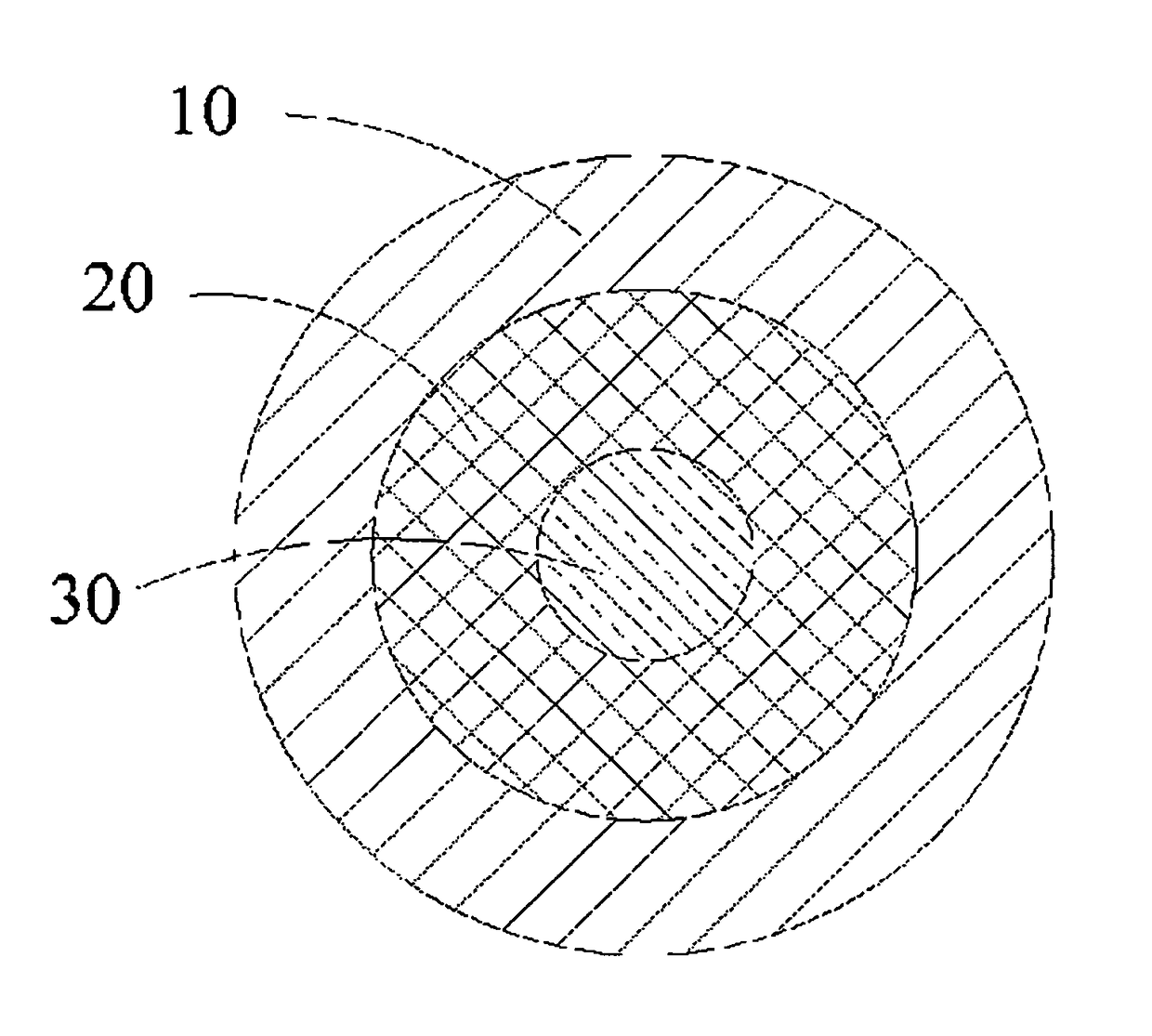

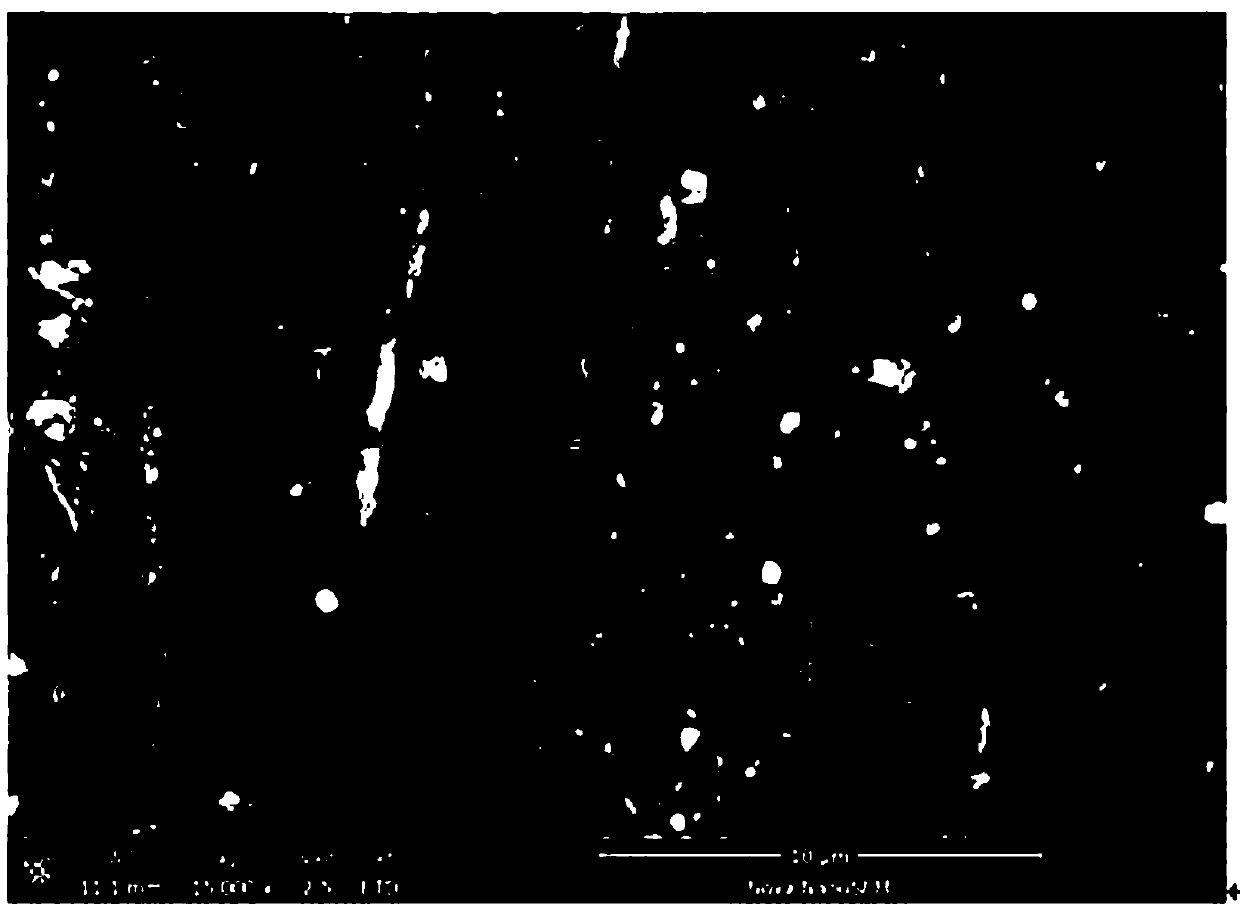

Sliding bearing based on structure energizing material and preparation method thereof

InactiveCN110592465ASelf-lubricatingReduce noiseFurnace typesSliding contact bearingsStructure of the EarthMicrometer

The invention discloses a sliding bearing based on a structure energizing material. The sliding bearing is prepared from the structure energizing material. The matrix structure of the sliding bearingis austenite and graphite spheres. The diameter of graphite spheres is less than or equal to 25 micrometers, the spheroidization rate is 100%, and the density of graphite spheres is 300-600 / mm<2>. According to the preparation method, the components of molten iron are timely regulated and controlled to be within a small range of eutectic components by observing the color of a profile which is justpulled out by one step, so that the spheroidization rate is remarkably increased, and the situation that large blocks of primary graphite appear to cause mechanical property damage is avoided; and thesliding bearing with self-lubricating property is prepared through rough machining and grinding machining. The self-lubricating sliding bearing has self-lubricating property, no oil filling hole or no oil guide groove needs to be machined, sound absorption and shock absorption are realized, the service life is long, and a copper or steel sliding bearing can be replaced.

Owner:XIAN UNIV OF TECH

Heat treatment process of carbide alloy for cold heading dies

The invention discloses a heat treatment process of a carbide alloy for cold heading dies, which comprises the following steps: (1) putting the sintered carbide alloy for cold heading dies into a heating chamber of a double-chamber vacuum furnace, and vacuumizing the heating chamber until the pressure of the heating chamber is (2*10-1)-(4*10-1) Pa; (2) heating the heating chamber in two stages, in the first phase, heating the heating chamber to 900 DEG C at a speed of 5-8 DEG C / min, and then carrying out heat preservation for 30-45 minutes, and in the second stage, heating the heating chamber to 1100-1300 DEG C at a speed of 8-10 DEG C / min. and then carrying out heat preservation 30-40 minutes; (3) filling high-purity nitrogen gas as shielding gas in the furnace, under the condition that the vacuum degree is 0.5-0.8 bar, completely soaking a heated product into a cold-chamber oil-quenching bath for 4-6 minutes, then ascending and separating the obtained product, and cooling the obtained product to below 60 DEG C; and (4) putting the obtained product into a vacuum tempering furnace to carry out tempering treatment for 5-6 hours at a tempering temperature of 450-600 DEG C, carrying out furnace cooling on the obtained product until the obtained product is at room temperature, and taking out the obtained product. According to the invention, the content of a face-centred cubic structure alpha-Co in the alloy is increased, the toughness and the strength are improved, the comprehensive mechanical properties are good, phenomena such as fatigue cracking, breakage and early wear in the process of application are reduced, and the purposes of prolonging the service life, reducing the application cost and increasing the application efficiency are achieved.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Self-stacking conveyor belt and method

An improved endless conveyor belt made of a plurality of interconnected links, each including two rods with two side plates perpendicularly aligned and attached to their opposite ends. The improvement comprising the addition of an internal buttress-type welded joint located between the inside surface of each side plate and one or both transverse rods with at least one bendable section. During use, the transverse rod is allowed to bend so that the side plates may deflect when force is exerted on them. By adding the welded joint and by adding the bendable section to the transverse rod, the number of cracks or breaks in the conveyor belt is substantially reduced.

Owner:GEA REFRIGERATION NORTH AMERICA

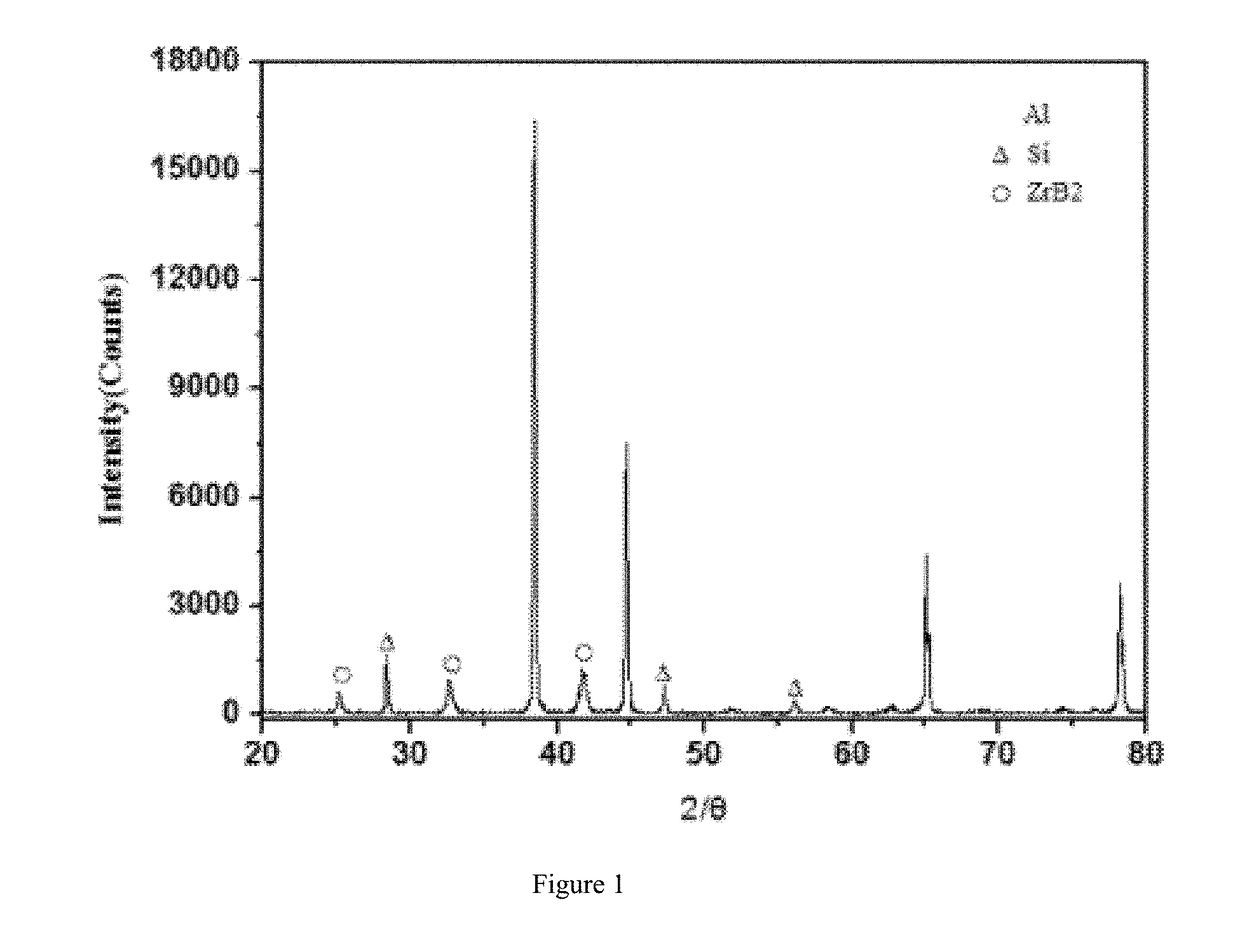

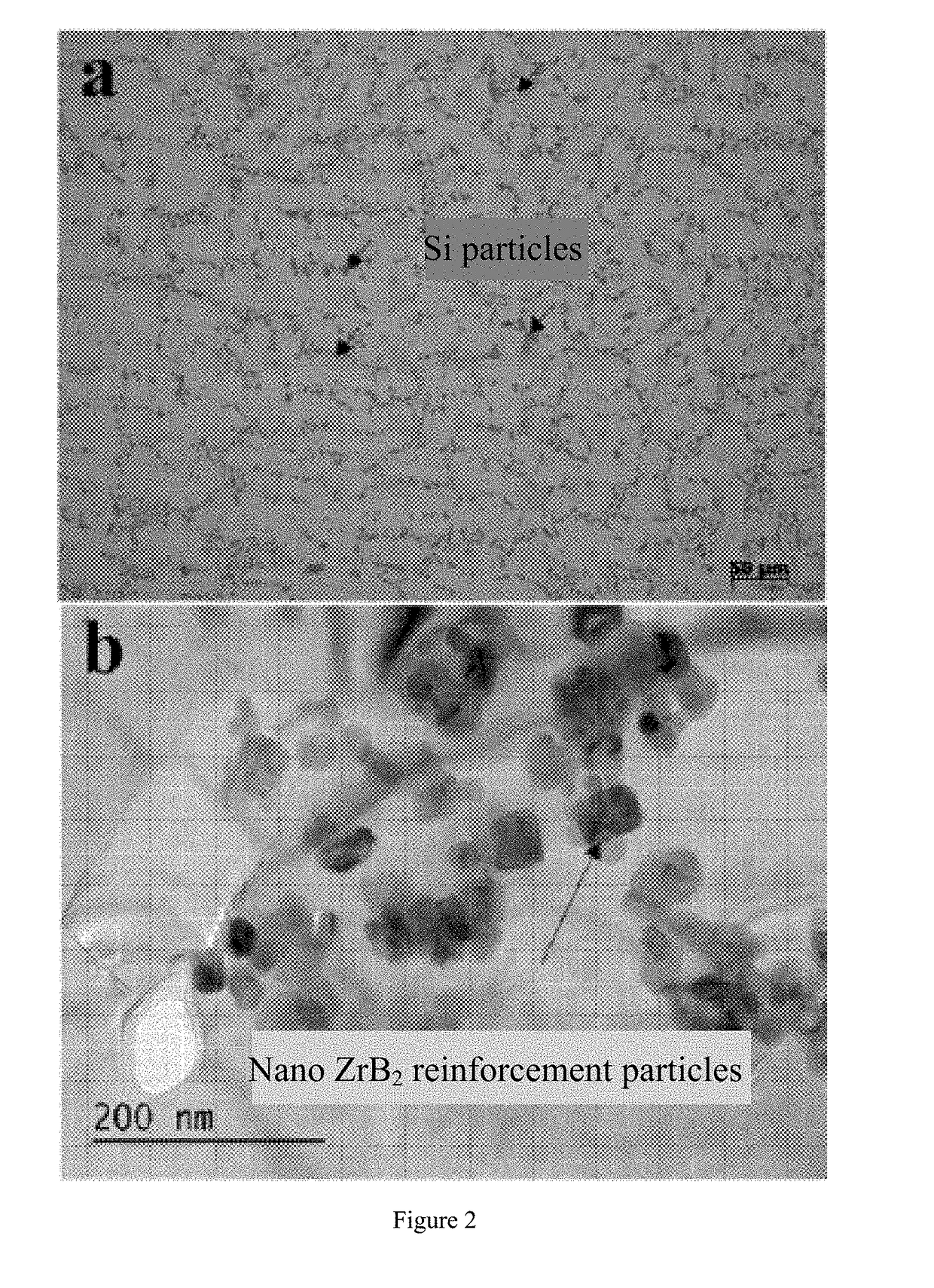

Anti-fatigue in-situ aluminum-based composite material for heavy-load hubs and preparation method therefor

ActiveUS20190010580A1High strengthHigh modulusMaterial nanotechnologyHubsRare-earth elementAdditive ingredient

Provided are an anti-fatigue in-situ aluminium-based nanocomposite material for heavy-load automobile hubs and a preparation method therefor. By means of the fine adjustment of components and a forming process, in situ nano-compositing, micro-alloying and rapid compression moulding techniques are combined. That is, after the addition of elements Zr and B, an in-situ reaction occurs to form a nano ZrB2 ceramic reinforcement which is distributed in aluminium crystals and crystal boundaries and bonded to a metallurgical interface kept firm with the matrix. Moreover, with rare earth elements Er and Y and element Zr as addition ingredients and after the increase in the contents of Cr and Mn, a structure having fine aluminium crystal grains with a large number of micro-alloyed nano precipitated particles contained in the grains, fine and round eutectic silicon grains and a fine Mg2Si phase mainly dispersed inside the grains is obtained in the process of the rapid compression moulding and thermal treatment of the hubs; and thus, the tensile strength, the yield strength and the fatigue strength of an alloy are effectively improved.

Owner:JIANGSU UNIV +1

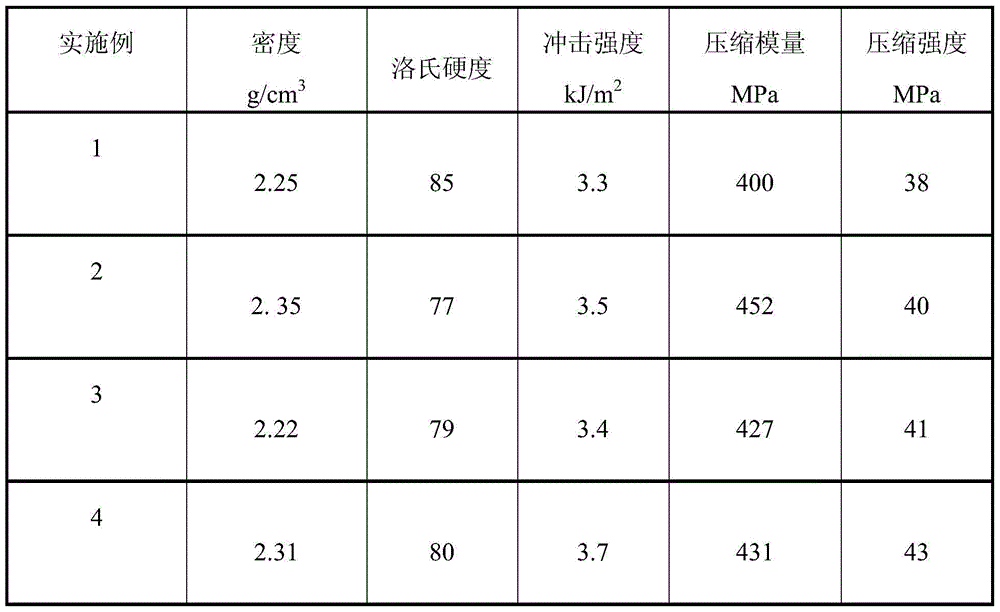

Friction material, composite brake shoe and preparation method

InactiveCN111043202AHigh hardnessReduce coefficient of frictionOther chemical processesFriction liningCalcium hydroxideBasalt fiber

The invention relates to a friction material, a composite brake shoe and a preparation method, and relates to the technical field of brake shoe preparation. The friction material comprises the following raw materials in parts by weight: 25-30 parts of steel fibers, 5-8 parts of boron-modified phenolic resin, 10-15 parts of phenolic resin, 3-5 parts of nitrile rubber, 10-15 parts of graphite, 5-10parts of glass fibers, 5-10 parts of basalt fibers, 2-5 parts of barite, 1-2 parts of aramid fibers, 15-20 parts of calcium hydroxide, 1-2 parts of silicon carbide and 2-5 parts of aluminum oxide. With the proportion of the metal content in the formula and the synergistic effect of the raw materials, the hardness of the friction material is increased, the friction coefficient is reduced, the elasticity modulus is increased and the heat resistance is enhanced. The brake shoe prepared from the friction material has the characteristics of good heat resistance, low and stable friction coefficientand good impact resistance effect and can prevent transfer, adhesion, damage and scratch of the base material during braking of the brake shoe and can overcome the defects of brake shoe chipping / cracking, metal inserts and the like generated during frequent braking of large-scale road maintenance machinery.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Pneumatic tire with tread having sipes

ActiveUS9174495B2Increased durabilityImprove performanceTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

The present invention is directed to a pneumatic tire 1, comprising at least one pair of parallel annular beads 3; at least one carcass ply wrapped 5 around said beads 3; a tread 7; and first and second sidewalls 9 disposed between said tread 7 and one of said at least one pair of beads 3. In accordance with an embodiment of the invention, the tread comprises tread blocks 11 and / or tread ribs 12, wherein the tread blocks 11 and / or tread ribs 12 comprise sipes 13 extending essentially in an axial direction A of the tire 1, the sipes 13 consisting of an upper portion 15 essentially aligned with the radial direction R of the tire and a lower portion 17 inclined in the direction of rotation D of the tire 1.

Owner:THE GOODYEAR TIRE & RUBBER CO

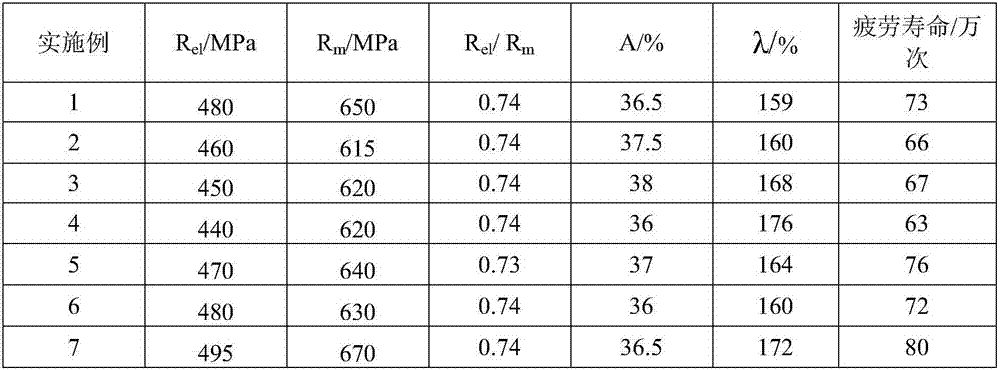

Steel used for high-strength automobile wheel with excellent flange elongation and production method thereof

The invention discloses a high-strength automobile wheel steel with excellent stretch flangeability and a production method thereof. The chemical composition in steel is by weight percentage: C 0.07%~0.1%, Si0.15%~0.25%, Mn 1.2%~1.4%, P<0.02%, S<0.008%, Als0.02%~0.04%, RE / S=1.8-2.2, wherein the rare earth RE is one or a combination of more than two elements in La, Ce and Nd, the content is 0.007%-0.018%, and the balance is Fe and unavoidable impurities. Heat the continuous casting slab to 1200-1300°C and keep it warm for 2-3 hours; the starting temperature of rough rolling is 1100-1250°C, the finishing rolling temperature is >1000°C; the finishing rolling starting temperature is 950-990°C, and the total reduction ratio is >70 %, the final rolling temperature is 780-840°C; the laminar flow cooling process is adopted, the cooling rate is 25-30°C / s, and the final cooling is 450-500°C for coiling.

Owner:ANGANG STEEL CO LTD

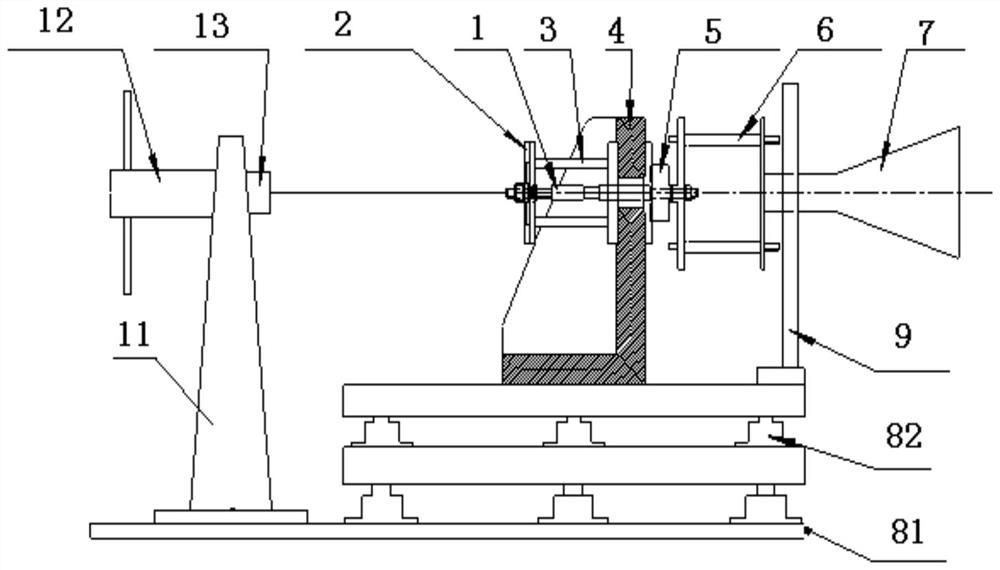

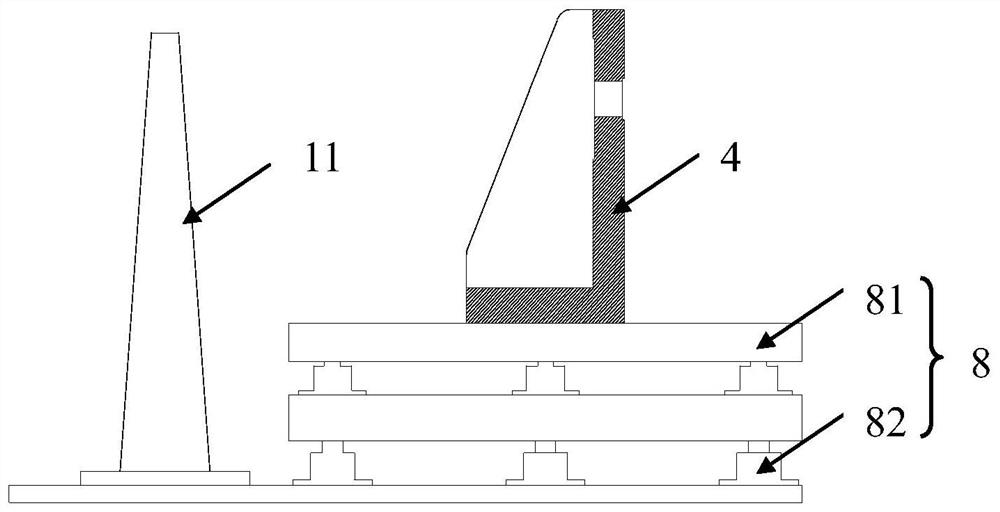

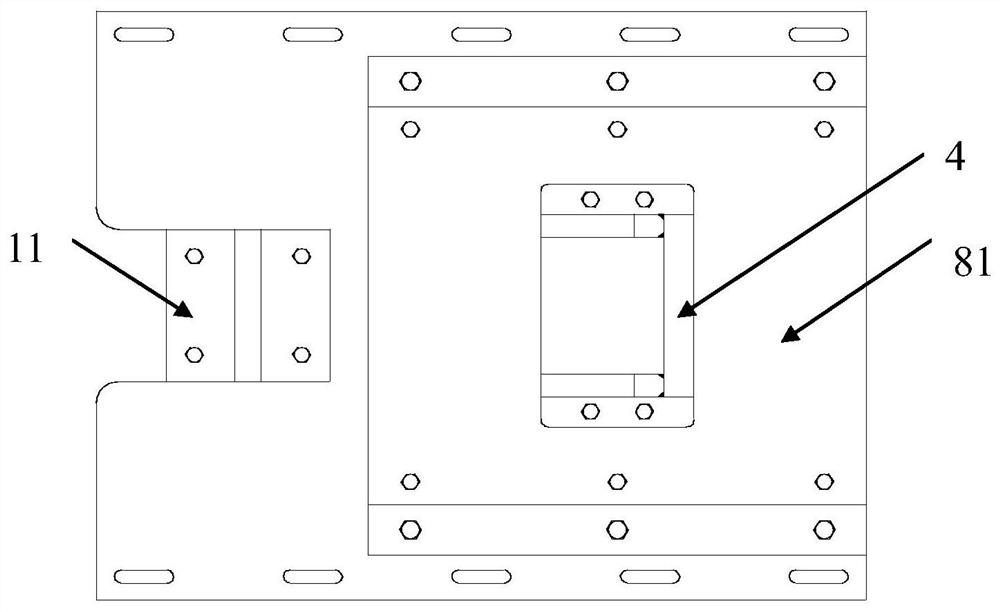

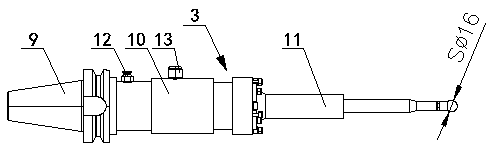

Integrated equipment and method for thrust measurement and in-situ calibration of attitude control engine

ActiveCN112378561ACompact structureImprove stability and reliabilityApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingPhysicsAttitude control

The invention relates to a spaceflight liquid engine test device, particularly to integrated equipment and method for thrust measurement and in-situ calibration of an attitude control engine, and aimsto solve the problems that a measuring force sensor of an existing attitude control engine bears large initial torque, fatigue cracks are prone to being generated, and influences of external factorssuch as heat radiation, vibration and the like on thrust measuring precision are large. According to the technical scheme, the integrated equipment comprises a thrust measurement device, a calibrationforce loading device, a data acquisition system and a data processing system, wherein the thrust measurement device comprises a center shaft, an elastic sheet, a connecting frame, a fixed frame, a measurement force sensor and an adapter frame, and the calibration force loading device is arranged on one side of the center shaft and comprises a calibration frame, a lead screw loading mechanism, a standard force sensor and a steel wire. The invention further provides an attitude control engine thrust measurement and in-situ calibration method.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Bioabsorbable medical device or medical device component and preparation method thereof

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

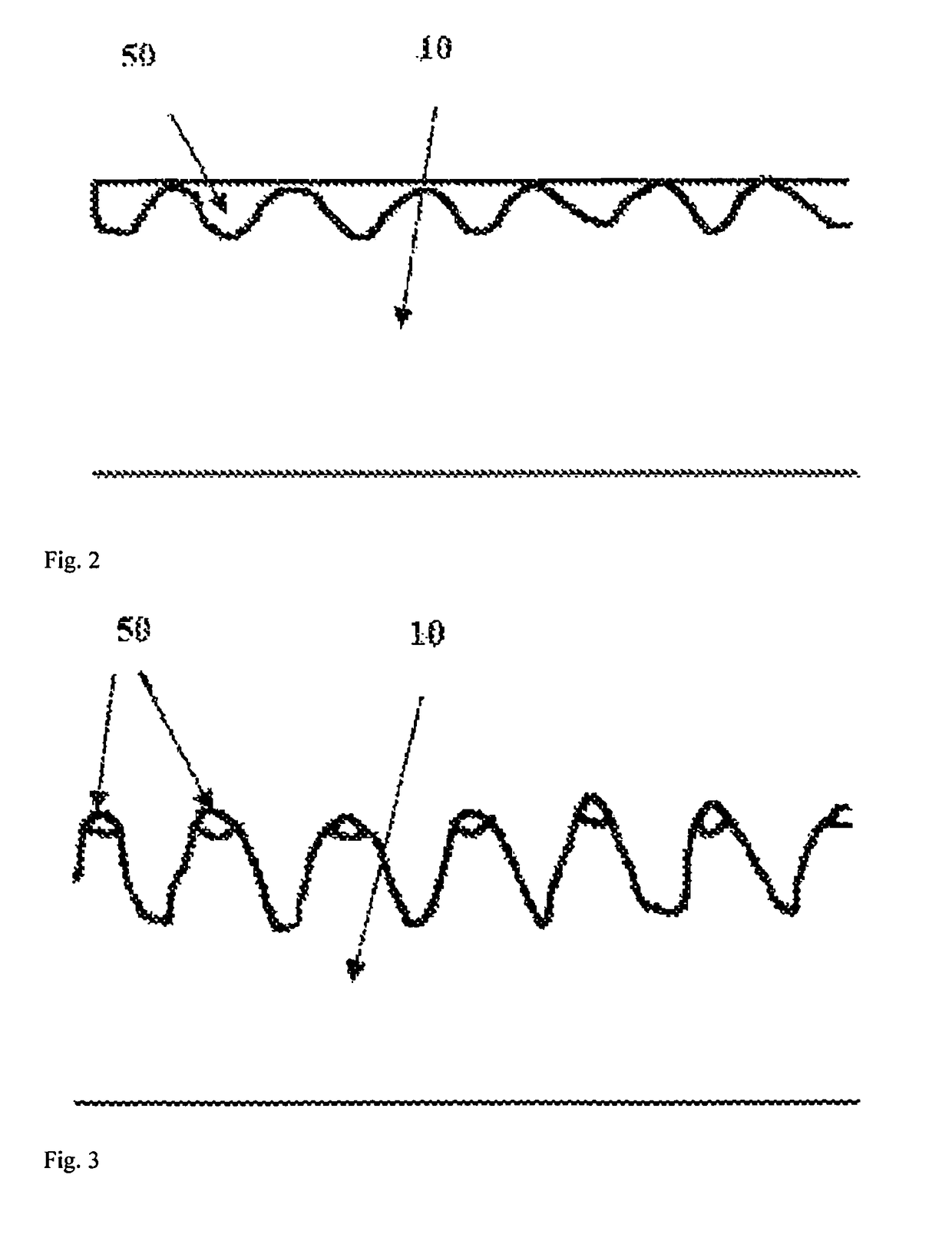

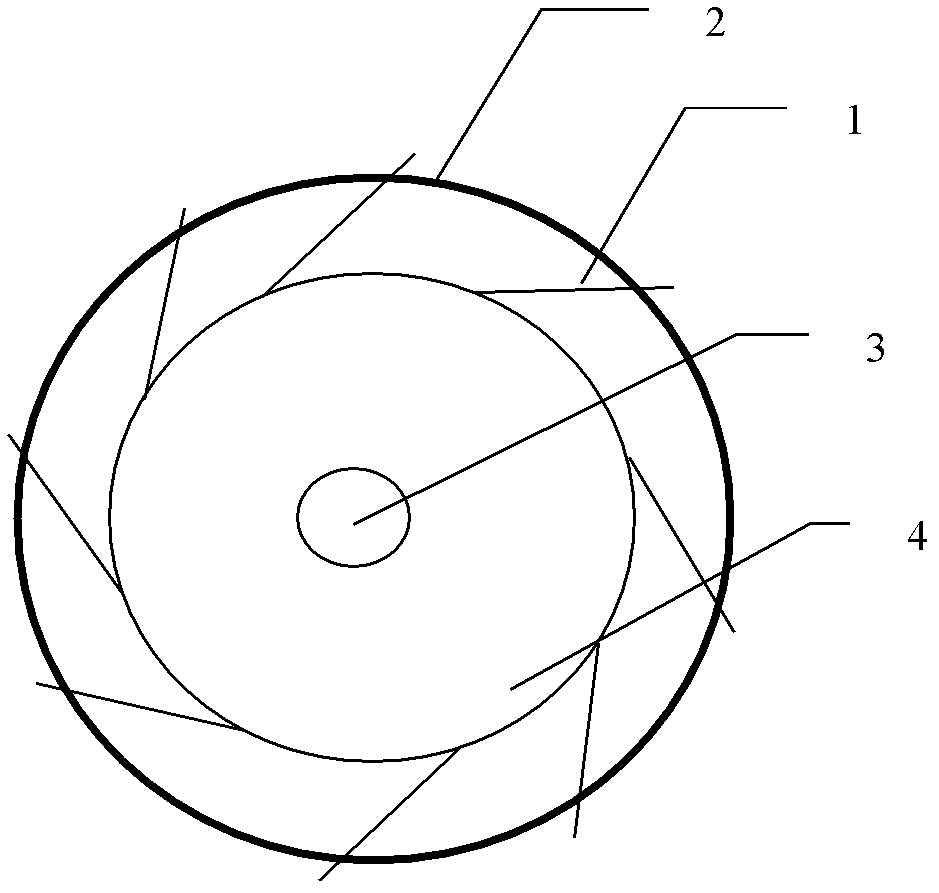

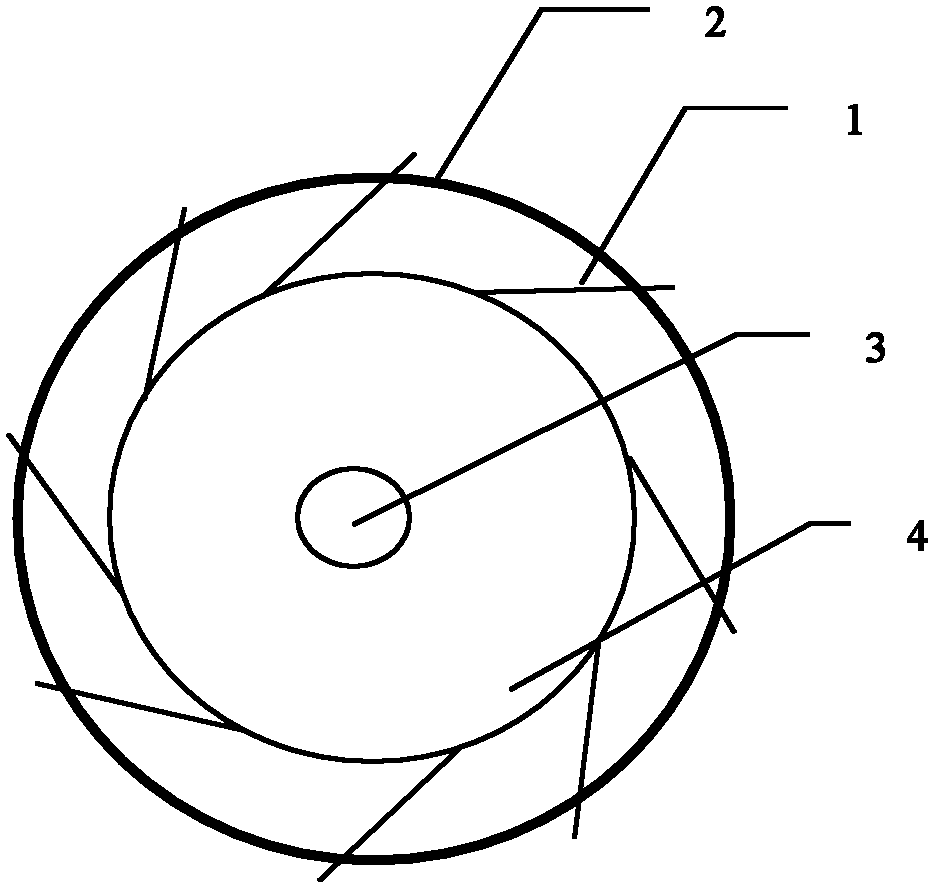

Axial-flow blower fan impeller

InactiveCN102322445AIncreased operating lifeRaise the natural frequencyPump componentsPumpsImpellerDrive shaft

The invention discloses an axial-flow blower fan impeller, which comprises a transmission shaft, an impeller hub and a plurality of blades, and further comprises a strengthening ring, wherein the transmission shaft is connected with the impeller hub; the blades are arranged on the periphery of the impeller hub; a plurality of grooves are arranged on the strengthening ring; the blades are connected with the strengthening ring by being embedded in the grooves; or the grooves are arranged on the blades, and the strengthening ring is connected with the blades by being embedded in the grooves. The invention discloses another embodiment as follows: the axial-flow blower fan impeller comprises a transmission shaft, an impeller hub and a plurality of blades, wherein the transmission shaft is connected with the impeller hub; the blades are arranged on the periphery of the impeller hub, adjacent blades are connected through a plurality of rib-stiffened plates, and the rib-stiffened plates are arranged in an annular way to constitute a strengthening ring. According to the axial-flow blower fan impeller disclosed by the invention, the structural strength of the blades and an impeller is increased, the fatigue strength of the blade resisting pulse airflow is increased, the rate of fatigue crack or breakage of the blades is reduced, and the operating life of a blower fan is prolonged.

Owner:SHANDONG ELECTRIC POWER RES INST +1

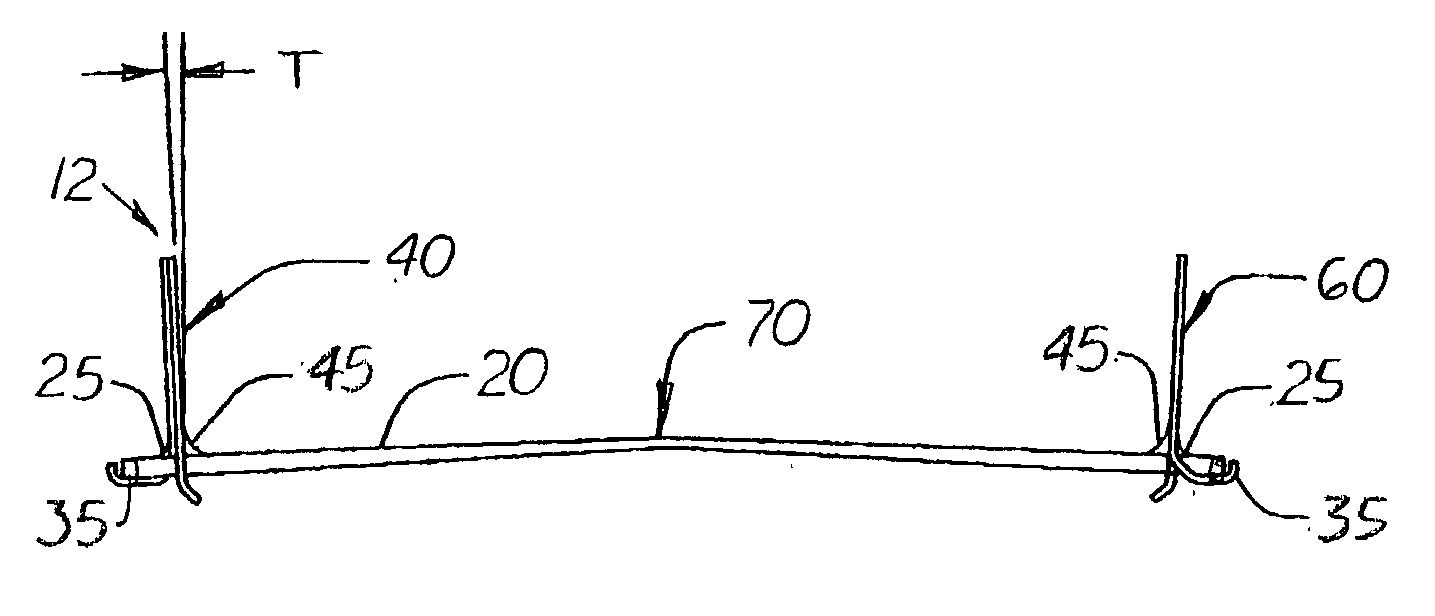

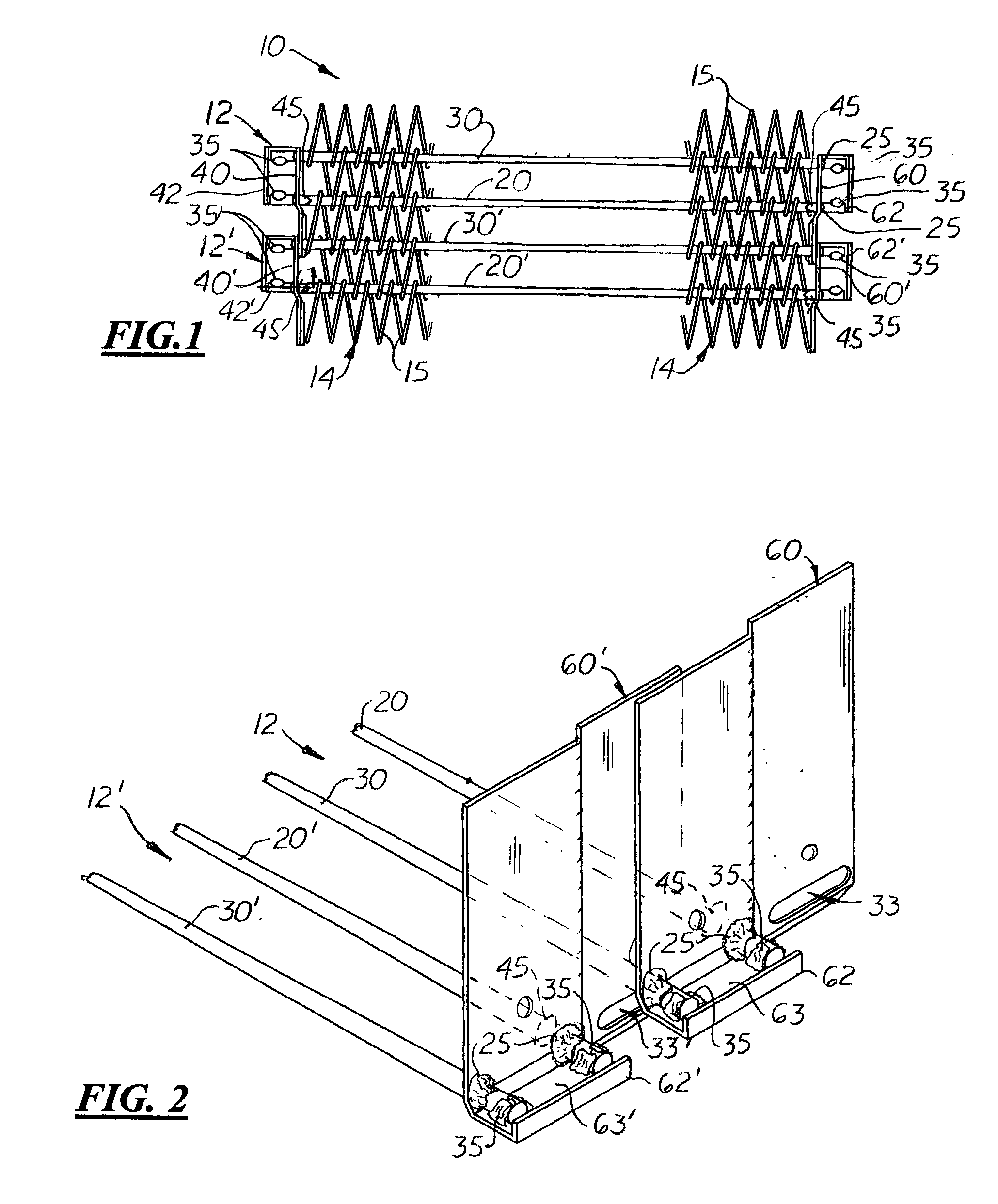

Multipurpose utility vehicle

ActiveUS20110175336A1Excellent visibility and utilityImprove visibilityVehicle body-frame connectionsUnderstructuresVisibilityVehicle frame

A multiuse vehicle comprises a frame having longitudinal portions forming a central opening for supporting an engine and end portions extending forward and rearward from said longitudinal portions, each of the end portions having a downwardly extending leg portion with one or more hitches. A suspension system includes the use of pivoting arms that carry trunnion-mounted differentials. An operator's cab is mounted on a forward portion of the frame to provide the operator with increased visibility. The frame behind the operator's cab is configured to receive any of a variety of devices such as a dump bed, a sprayer tank, a salt spreader, or a flat bed.

Owner:HUHN MICHAEL CARL +1

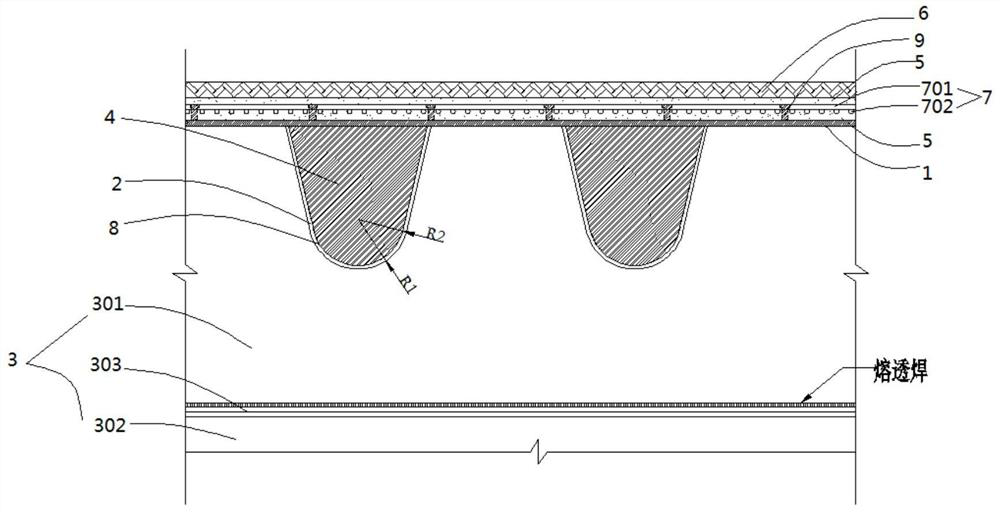

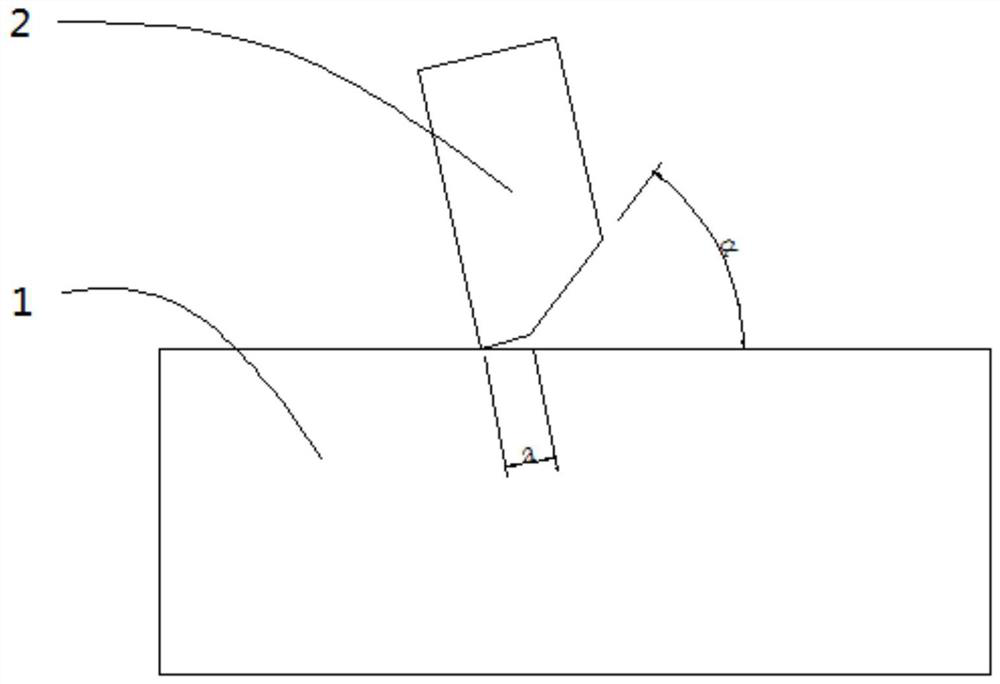

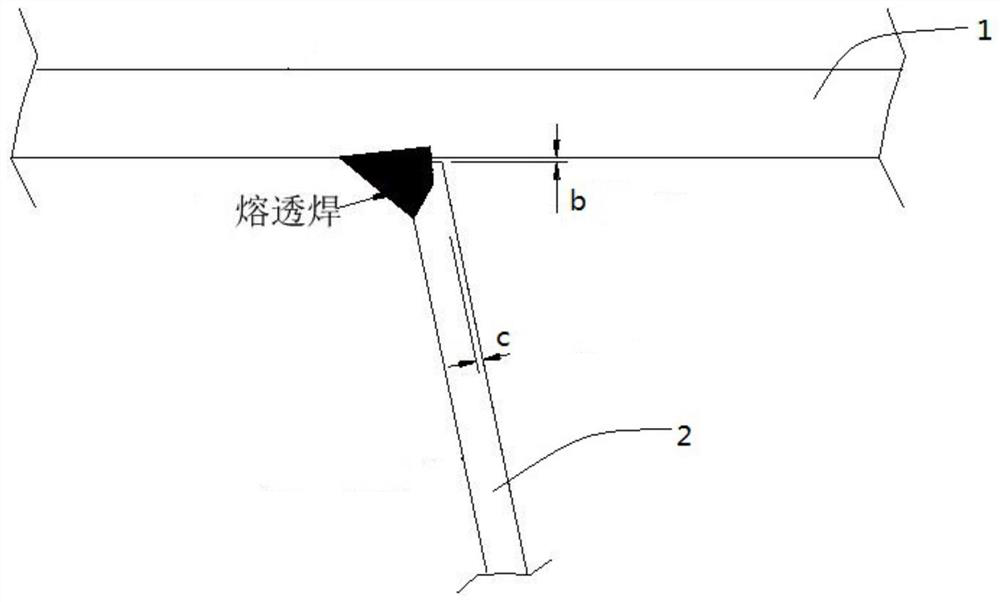

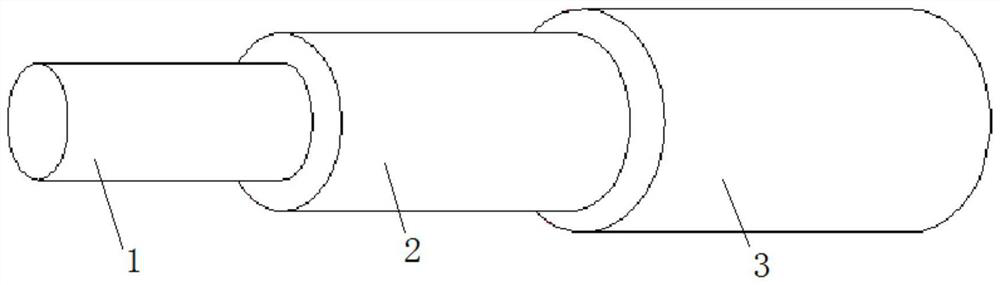

Novel orthotropic steel bridge deck without arc-shaped notch and manufacturing method of orthotropic steel bridge deck

PendingCN112267377AIncrease stiffnessImprove performanceBridge structural detailsBridge deckMesh reinforcement

The invention discloses a novel orthotropic steel bridge deck without an arc-shaped notch and a manufacturing method of the orthotropic steel bridge deck. The novel orthotropic steel bridge deck comprises a panel, U-shaped longitudinal ribs, a transverse partition plate and an inner partition plate, the panel is an upper flange shared by the U-shaped longitudinal ribs and the transverse partitionplate, a UHPC layer and an asphalt wearing layer are sequentially laid on the surface of the panel from bottom to top, reinforcing steel bars and a reinforcing steel bar net are arranged in the UHPC layer, the U-shaped longitudinal rib is welded with the bottom surface of the panel to form a groove-shaped longitudinal rib abdominal cavity, the transverse partition plate is perpendicular to the U-shaped longitudinal rib and is welded with the bottom surface of the panel, a notch for the U-shaped longitudinal rib to penetrate through is formed in the transverse partition plate, and the inner partition plate is welded in the longitudinal rib abdominal cavity and is positioned in the same plane with the transverse partition plate, the inner partition plate is matched with the inner contour ofthe cross section of the U-shaped longitudinal rib, the thickness of the inner partition plate is consistent with that of the transverse partition plate. According to the method, the stress response and deflection of the orthotropic steel bridge deck structure details can be reduced under the action of wheel loads, the fatigue resistance of the structure details is improved, the orthotropic steelbridge deck is prevented from cracking, and damage to steel bridge deck pavement can be avoided.

Owner:SHANTOU UNIV

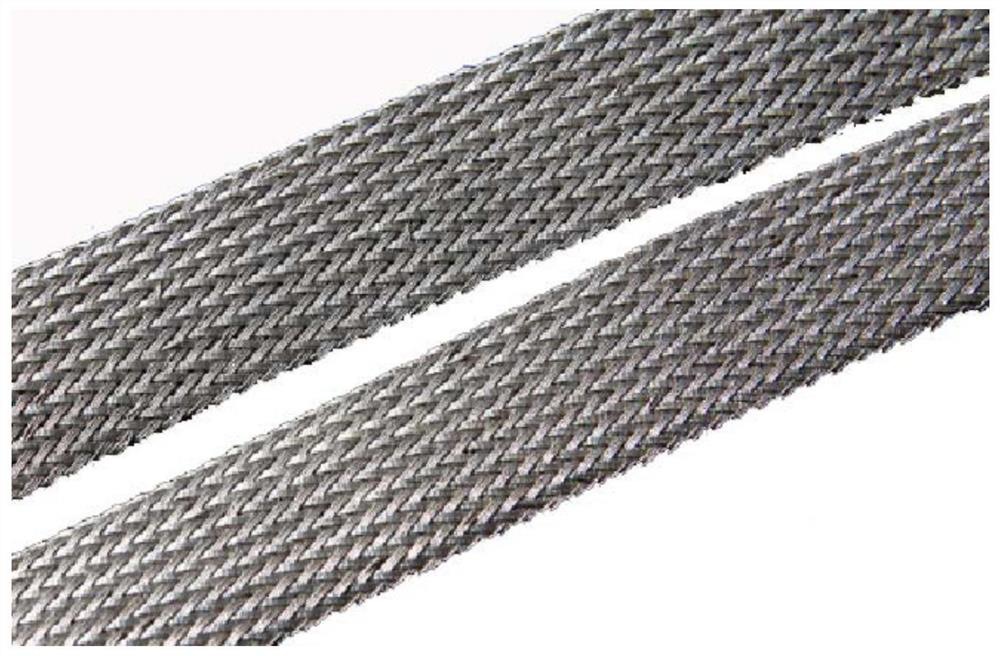

Light metal wave-proof sleeve and preparation method thereof

ActiveCN111988976AHigh tensile strengthOrganizational structureMagnetic/electric field screeningSuperimposed coating processMischmetalCopper plating

The invention discloses a light metal wave-proof sleeve and a preparation method thereof. The light metal wave-proof sleeve is formed by weaving nickel-plated copper-aluminum alloy wires, each nickel-plated copper-aluminum alloy wire sequentially comprises an aluminum alloy wire body, a copper-plated layer and a nickel-plated layer from inside to outside, the thickness of each copper-plated layeris 0.2-0.3 micrometer, and the thickness of each nickel-plated layer is 0.6-1.0 micrometer; the nickel-copper-plated aluminum alloy wire contains aluminum, copper, magnesium, silicon, zinc, manganese,lithium, titanium, vanadium, boron, nickel, chromium and rare earth metals in a weight ratio of (55-65): (8-12): (3-5): (2-4): (1-3): (1-3): (1-3): (1.5-2.5): (0.3-0.7): (0.4-0.8): (1.5-2.5): (1.2-1.6): (1.3-1.8). The light metal wave-proof sleeve has light weight and an excellent anti-electromagnetic shielding effect at the same time, and in addition, the preparation method has the advantages ofbeing easy and convenient to operate and easy to popularize.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

High-flame-retardant high-thermal-conductive PVC (polyvinyl chloride) compound cable material and preparation method thereof

InactiveCN109096656AImprove mechanical propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsPolyvinyl chlorideNano zinc oxide

The invention particularly relates to a high-flame-retardant high-thermal-conductive PVC (polyvinyl chloride) compound cable material and a preparation method thereof. The high-flame-retardant high-thermal-conductive PVC compound cable material is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride, 31-36 parts of polytetrafluoroethylene micro-powder, 44-49 parts of a perfluoroalkoxy copolymer, 15-25 parts of an ethylene-trifluorochlor oethylene copolymer, 30-35 parts of a composite compatibilizer, 20-30 parts of nano zinc oxide, 42-53 parts of thermal-conductive filler, 10-15 parts of para-aramid fiber and 10-15 parts of modified magnesium hydrate. According to the invention, polytetrafluoroethylene is dispersed in the perfluoroalkoxy copolymer and the ethylene-trifluorochlor oethylene copolymer in a form of micro-powder, and is then blended with polyvinyl chloride, and meanwhile, the thermal-conductive filler, a fire retardant and the aramidfiber are added at proper proportions, therefore, the prepared compound cable material is stable in chemical properties, excellent in physical mechanical properties, electrical insulation properties and flame retardance, high in thermal conductivity, high in tensile strength and strong in toughness, facilitates the production, and reduces production cost.

Owner:XINYA ELECTRONICS

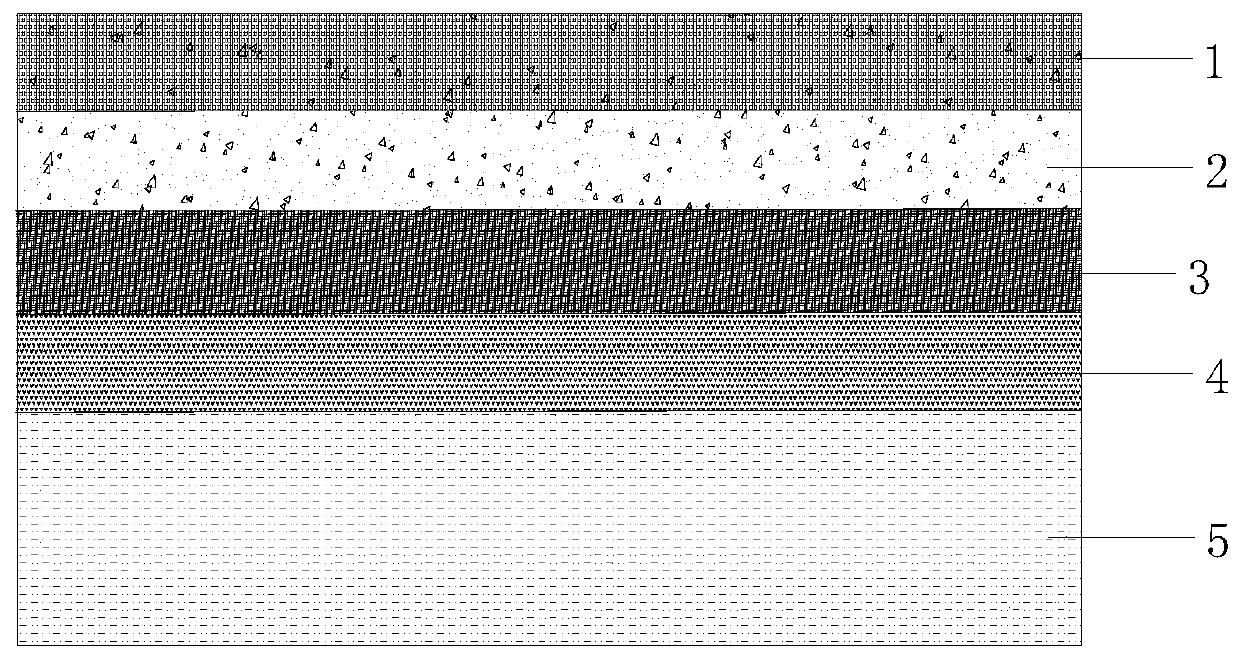

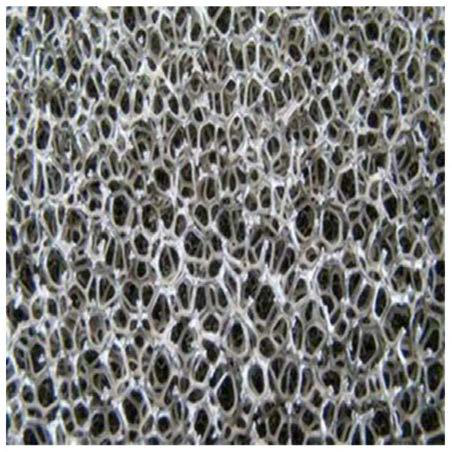

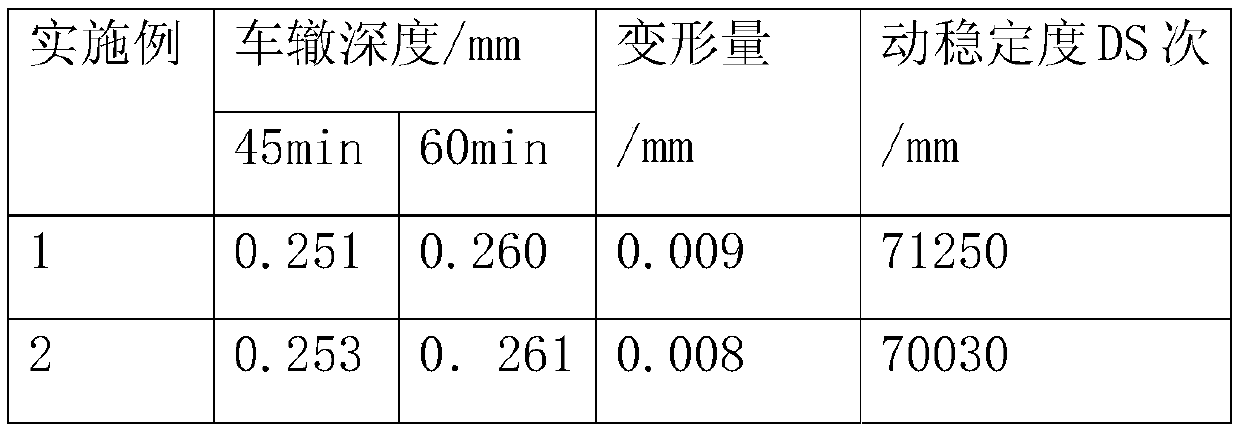

Steel slag semi-flexible composite pavement structure

ActiveCN110230240AReduce temperature stressAvoid temperature cracksIn situ pavingsPaving detailsCement boardTemperature stress

The invention discloses a steel slag semi-flexible composite pavement structure. The pavement structure sequentially comprises an asphalt concrete surface layer, a steel slag semi-flexible layer, a three-dimensional porous material layer, an old cement board layer subjected to fragmentation and a steel slag base layer from top to bottom, wherein the asphalt concrete surface layer is provided witha structure depth; glass beads loaded with nano titanium dioxide are embedded in the structure depth; three-dimensional communication structures are formed among pores of the three-dimensional porousmaterial, wherein the communication porosity is 50-99%, and the pore diameter is 0.1-20 mm; a specific composite structure layer is adopted, therefore, the shrinkage caused by cooling is relatively small, and relatively small temperature stress is generated to avoid temperature cracks; meanwhile, through interaction of different structural layers of all the layers, mutual tensile stress exists among all the layers, and fatigue cracking can be relieved by combining with use of specific functional materials; and the steel slag semi-flexible composite pavement has excellent high-temperature stability, low-temperature crack resistance, fatigue durability and water stability.

Owner:河北迁曹高速公路开发有限公司 +1

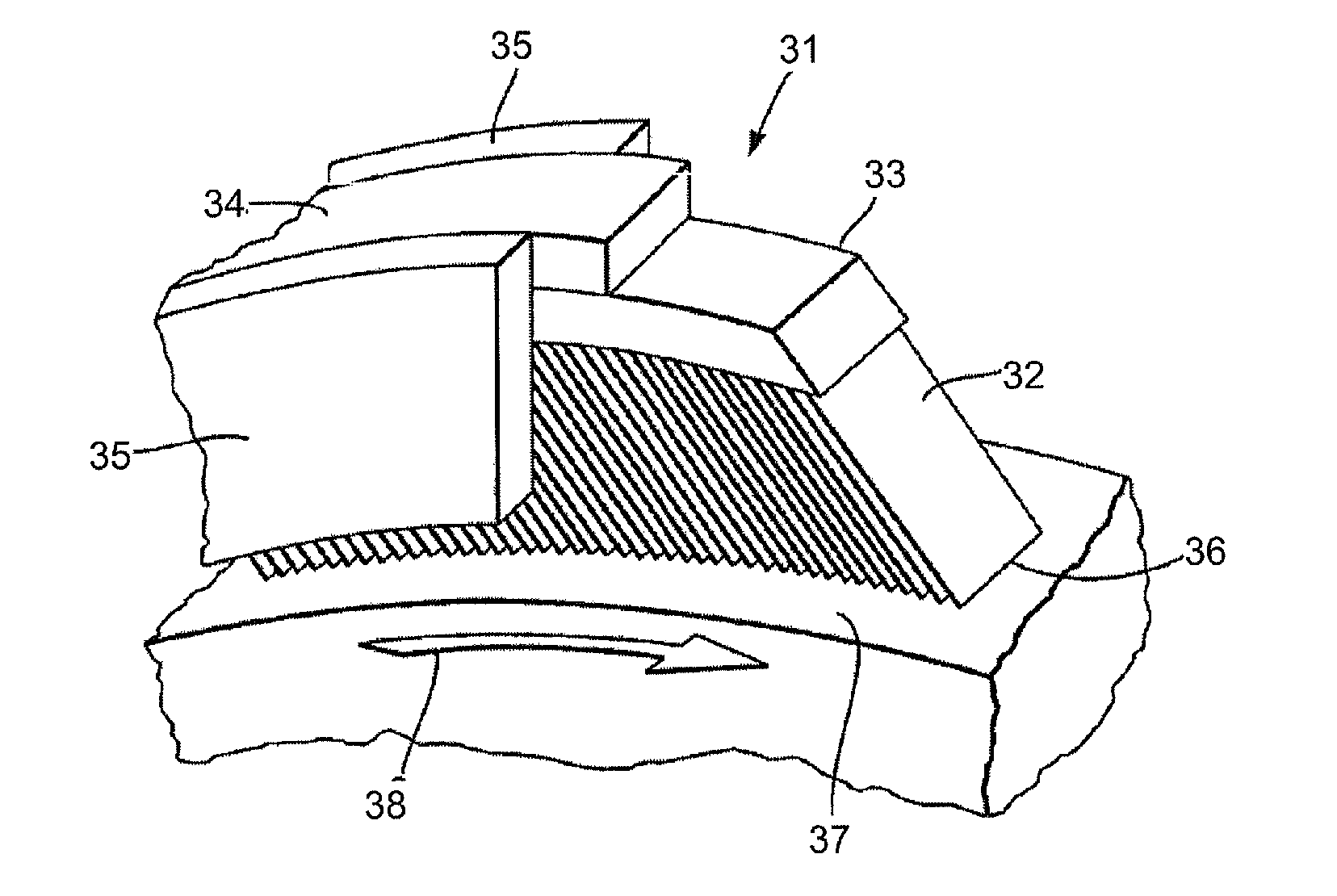

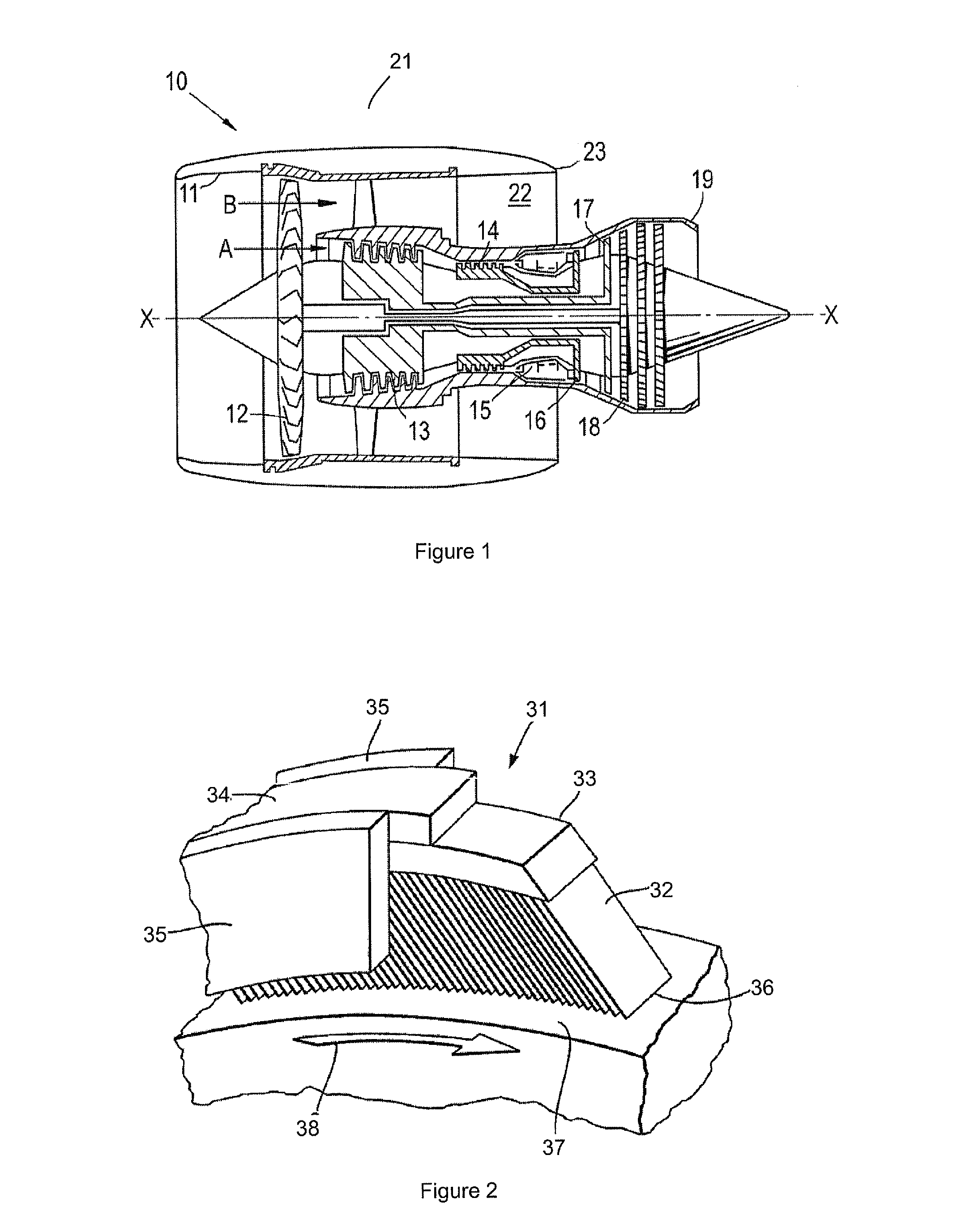

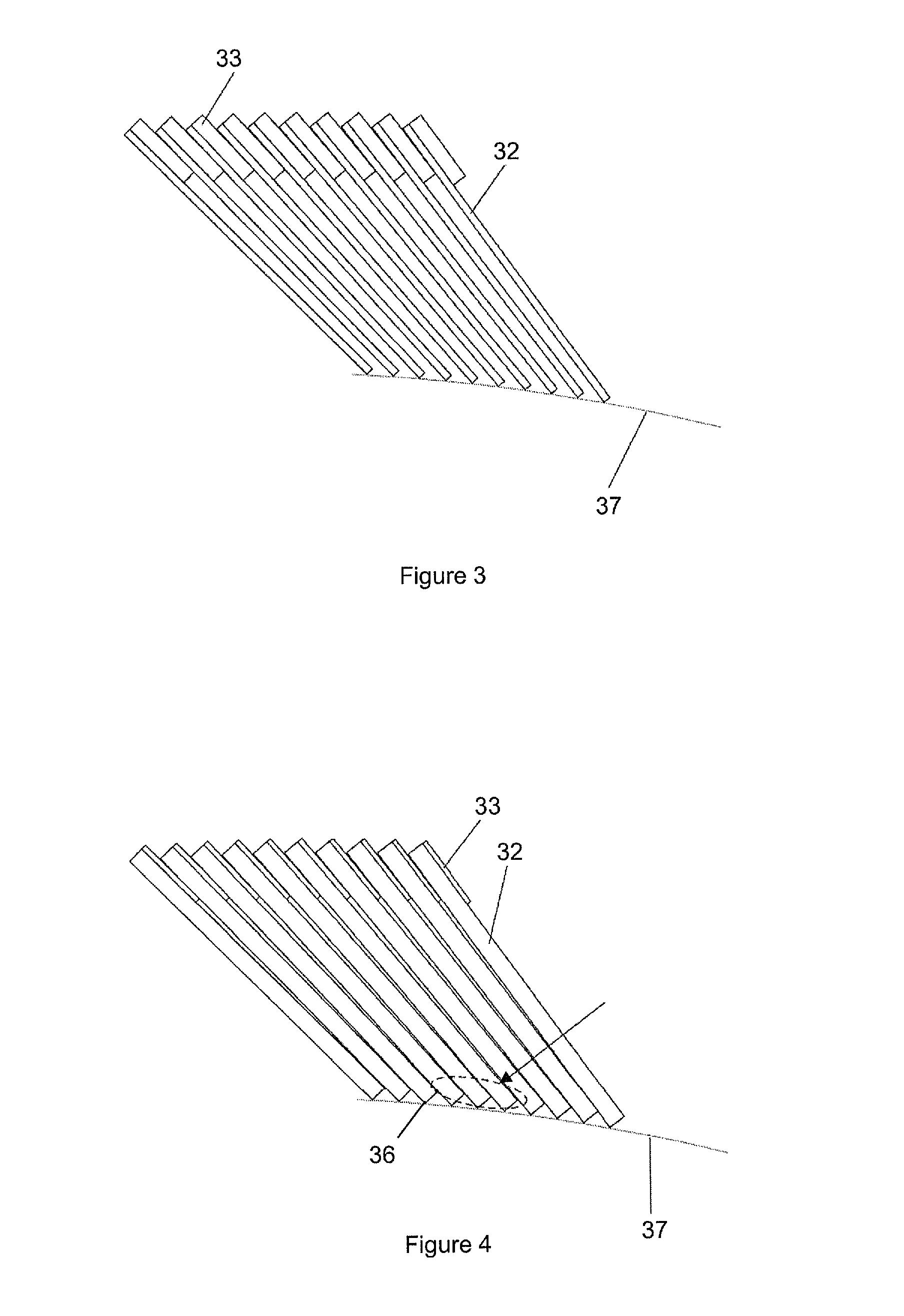

Leaf seal

ActiveUS20130119613A1Improve performanceReduce vibrationEngine sealsGas turbine plantsEngineeringLeakage flow

A leaf seal is provided for effecting a seal between two coaxial, relatively rotating components. The leaf seal has an annular pack of leaves which are stacked face-to-face within the pack, and which are mountable to one of the components at respective root portions of the leaves such that the leaves extend towards the other component and respective edges of the leaves are presented for wiping contact with the other component. The pack includes a plurality of spacers, each spacer separating the root portions of neighbouring leaves to form therebetween interleaf gaps which allow an axial leakage flow through the pack. The spacers are distributed around the pack such that the leaves are divided into blocks of two or more leaves sandwiched at their root portions between nearest-neighbour spacers.

Owner:ROLLS ROYCE PLC

Method for producing coating for AZ91D magnesium alloy vehicle active safety device component

InactiveCN105506531AGood anti-oxidation and corrosion performanceSimple structureMolten spray coatingActive safetyArc spray

The invention discloses a method for producing a coating for an AZ91D magnesium alloy vehicle active safety device component. The method is characterized by comprising the steps of conducting cleaning, degreasing, rust removal, washing and drying on the surface of the AZ91D magnesium alloy vehicle active safety device component, and immediately conducting protection with inert gas; adopting uniformly-mixed composite powder with the constituents being Ni-Cr-Ce-La-In, and forming a surface material layer on the surface of the AZ91D magnesium alloy vehicle active safety device component through a plasma arc spraying method, wherein the main constituents of the surface material layer are Ni-Cr-Ce-La-In, the diameters or the length dimensions of 75% or above of microcrystal units or particles of the surface material layer are within the range from 1 nm to 1500 nm, the different microcrystal units or particles are in close integration, the component surface material layer and a base material are integrated into a whole, and more than the distance, located within more than 30% of the contact surface area of the component surface material layer and the base material, between the component surface material layer and an atom order region of the base material is not more than 4 nm.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

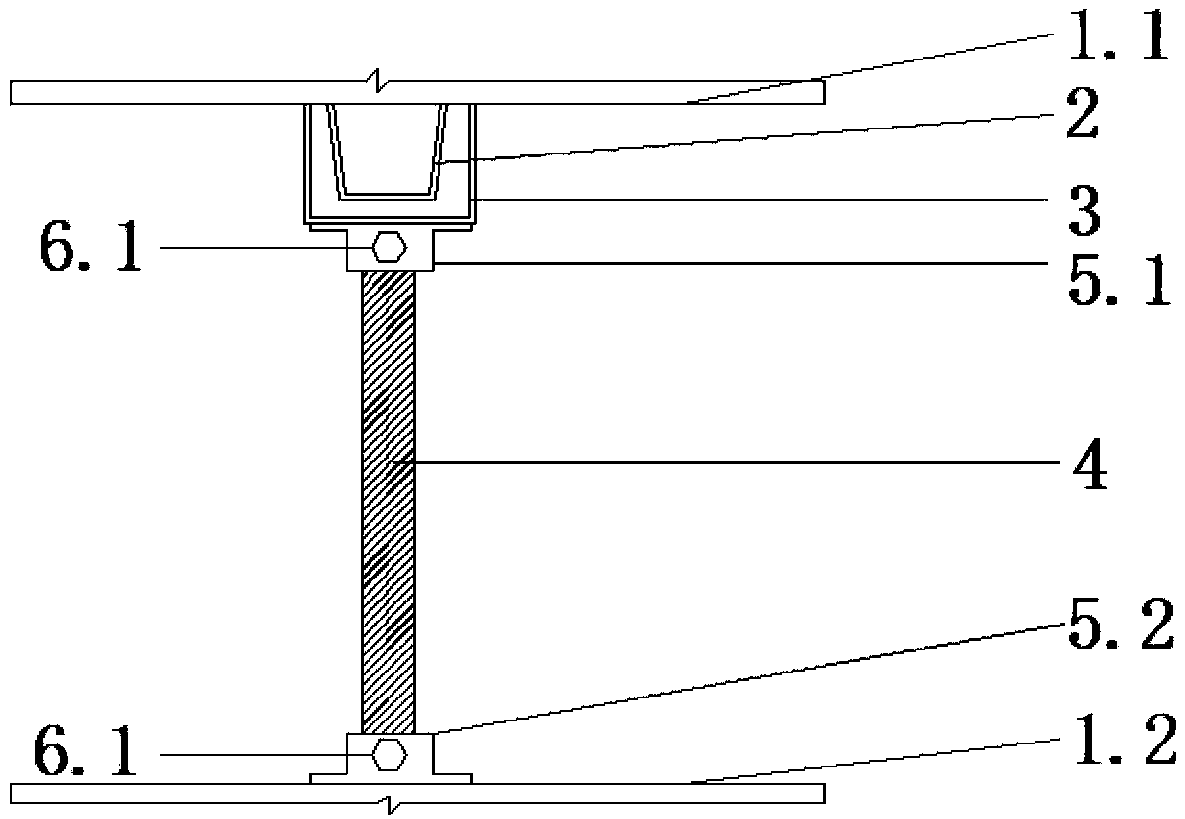

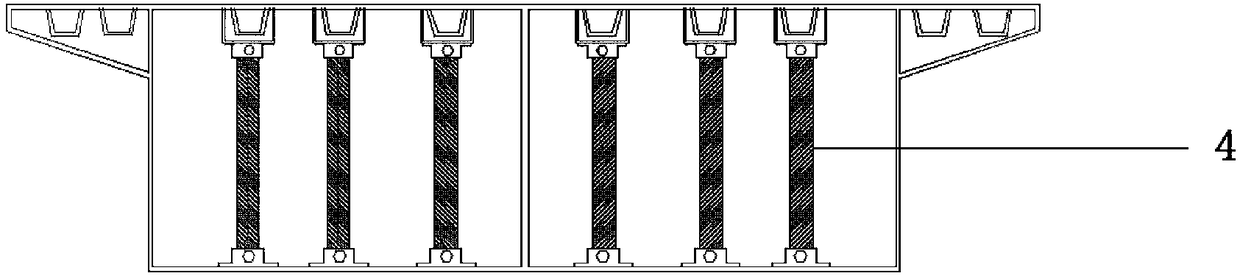

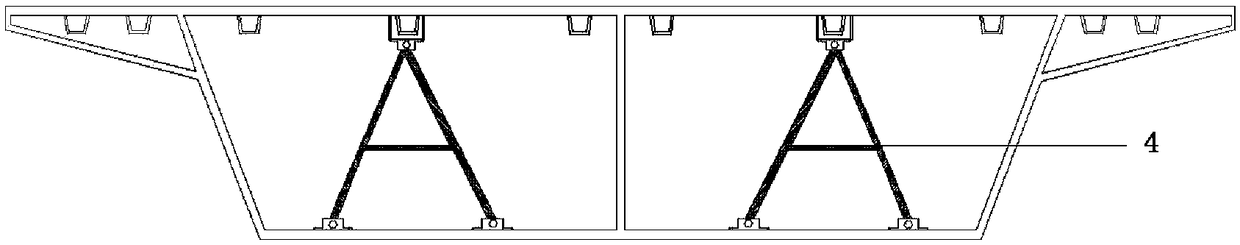

Replaceable component for improving fatigue property of steel box girder and construction method of replaceable component

ActiveCN108166373AAvoid fatigueAvoid and delay fatigueBridge materialsEngineeringStructural engineering

The invention discloses a replaceable component for improving the fatigue property of a steel box girder and a construction method of the replaceable component. The replaceable component comprises a longitudinal rib protecting section (3) fixedly connected with the lower surface of a steel box girder top plate (1.1). An upper groove fixing section (5.1) is connected to the lower surface of the longitudinal rib protecting section (3), and a lower groove fixing section (5.2) is fixedly connected to the upper surface of a steel box girder bottom plate (1.2). The upper groove fixing section (5.1)and the lower groove fixing section (5.2) are connected through a telescopic clamping component (4). During using, the local load borne by the steel box girder top plate (1.1) is transmitted to a steel box girder web, the steel box girder bottom plate (1.2) and the like through the replaceable component, thus fatigue cracks are prevented from generating or expanding, and the purpose of improving of the fatigue property is achieved; and under the effect of the vehicle load, after deformation or damage occurs to the telescopic clamping component (4), replacement can be quickly conducted, and practical application is facilitated accordingly.

Owner:SOUTHEAST UNIV

Anti-interference medical cable with high inflaming retarding

ActiveCN109119198AImprove fire resistanceImprove wear resistancePlastic/resin/waxes insulatorsAntifouling/underwater paintsInsulation layerPolyvinyl chloride

The present invention specially relates to an anti-interference medical cable with high inflaming retarding. The cable comprises a cable inner core, an aluminum foil shielding layer, a composite insulation layer, a high temperature resistance layer, a protection layer and a wearing layer which are arranged from the inside to outside in order in a vertical direction. Insect prevention coating filmsare sprayed on the composite insulation layer and the protection layer, the composite insulation layer and / or the protection layer is prepared by the following raw materials by the parts by weight: 100 parts of polyvinyl chloride, 31-36 parts of polytetrafluoroethylene micro powder, 44-49 parts of perfluoroalkoxy copolymer, 15-25 parts of ethylene-trifluorochloroethylene copolymer, 30-35 parts ofcomposite compatibilizer, 20-30 parts of nano-zinc oxide, 10-15 parts of para-aramid fibers and 10-15 parts of modified magnesium hydroxide. The medical cable is high in inflaming retarding, high anti-interference capacity, is more excellent in mechanical property and electrical insulation property, can prevent from biting by rats and ants, and is longer in life and safe and reliable in usage.

Owner:XINYA ELECTRONICS

Steel for wheels of rapid transit railway vehicles

Owner:CENT IRON & STEEL RES INST

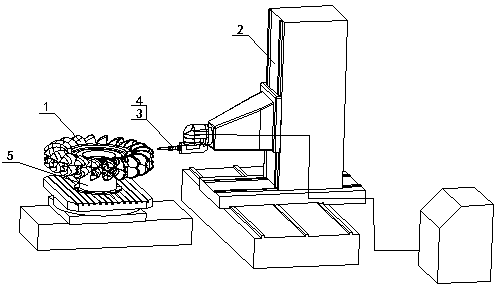

Surface recombination energy machining method for high-water-head impact type runner bucket

InactiveCN111168158AAchieving Fatigue-Resistant ManufacturingImprove fatigue resistanceNumerical controlCrazing

The invention discloses a surface recombination energy machining method for a high-water-head impact type runner bucket. The surface recombination energy machining method comprises the following stepsthat 1) clamping is conducted; 2) mounting is conducted; 3) the machining reference of a runner is determined; 4) a written machining program is executed by using a Hauck energy actuator A, and the surface of the runner bucket is machined; 5) a written machining program is executed by using a Hauck energy actuator B, and the root of the runner bucket is machined; and (6) after surface recombination energy machining of one bucket is completed through the step 4) and the step 5), indexing is conducted through a numerical control rotary workbench of a machining center, and machining of other water buckets one by one is achieved through the same steps. According to the surface recombination energy machining method for the high-water-head impact type runner bucket, anti-fatigue manufacturing of the root of the bucket is achieved, the anti-fatigue degree of the root of the bucket is improved, generation of fatigue cracks is reduced, mirror finishing of the inner side space molded surface ofthe bucket is achieved, a nano layer is directly machined on the inner side space molded surface of the bucket, residual tensile stress of the root of the bucket and a water cutting blade is eliminated, height-controllable pressure stress is preset, and the service life of the impact type runner is prolonged.

Owner:CHONGQING WATER TURBINE WORKS

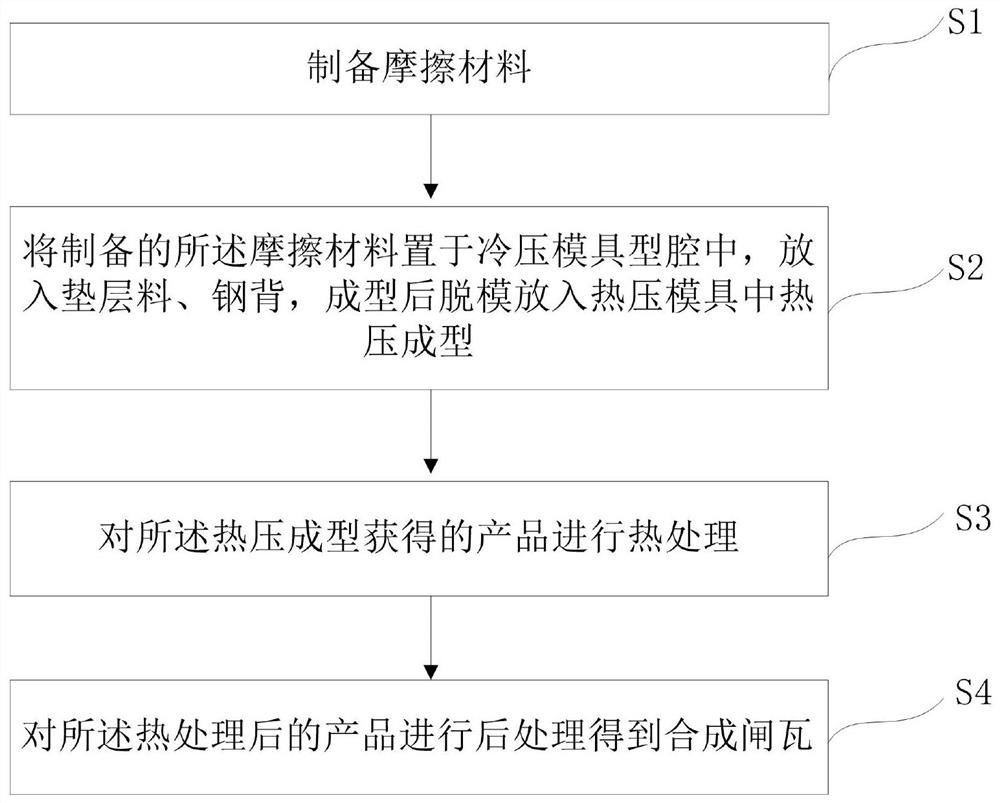

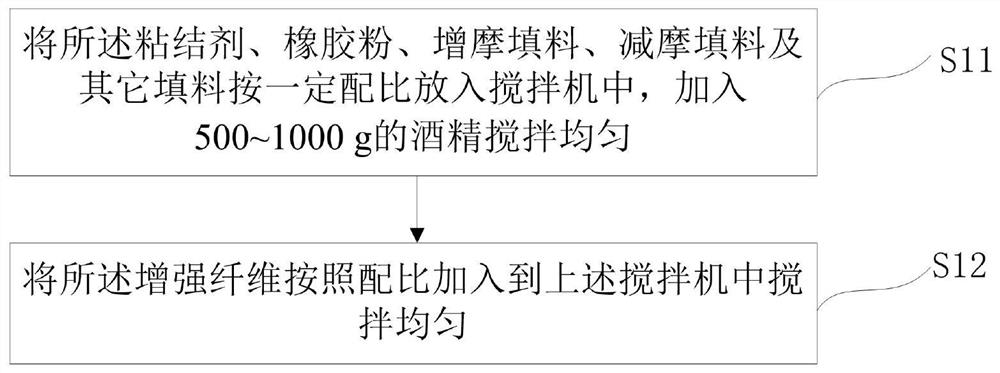

Friction material, composite brake shoe and preparation method

ActiveCN112852034AHigh hardnessReduce coefficient of frictionFriction liningOrganosolvMetallic sulfide

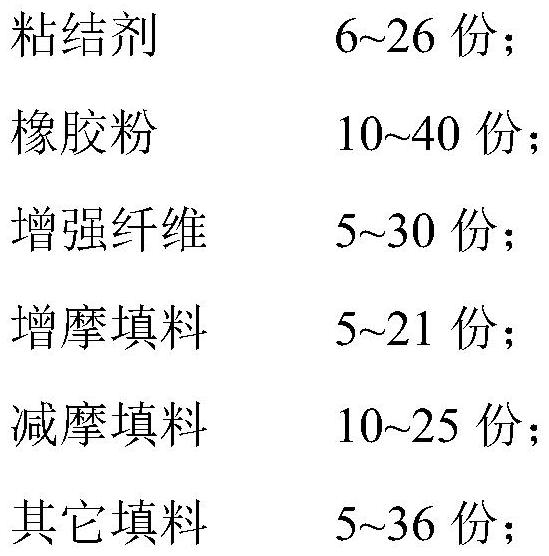

A disclosed friction material comprises the following raw material components in parts by volume: 6-26 parts of a binder, 10-40 parts of rubber powder, 5-30 parts of reinforced fibers, 5-21 parts of a friction increasing filler, 10-25 parts of an anti-friction filler and 5-36 parts of other fillers, wherein the reinforced fibers are a composition of aramid pulp, mineral fibers, potassium titanate whiskers and needle-like wollastonite, the antifriction filler is a composition of a carbon material, metal sulfide and polytetrafluoroethylene powder, and the other fillers comprise fluorite, flaky iron oxide, mica and calcium hydroxide. According to the friction material, coefficient decline and metal inlay under the humid working condition are remarkably improved, the brake service life of the composite brake shoe prepared from the friction material is prolonged, the mechanical strength of the composition brake shoe is improved, the invention further provides a preparation method of the composite brake shoe, toluene organic solvents are not used, the environmental protection property is effectively improved, and the working environment of workers is optimized.

Owner:SHANDONG GOLD PHOENIX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com