Friction material, composite brake shoe and preparation method

A technology of friction materials and synthetic brake shoes, applied in friction linings, mechanical equipment, etc., can solve problems such as unstable friction performance, easy breakage of friction bodies, metal inlays, etc., achieve good impact resistance, low molding temperature, and improved The effect of metal inlays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

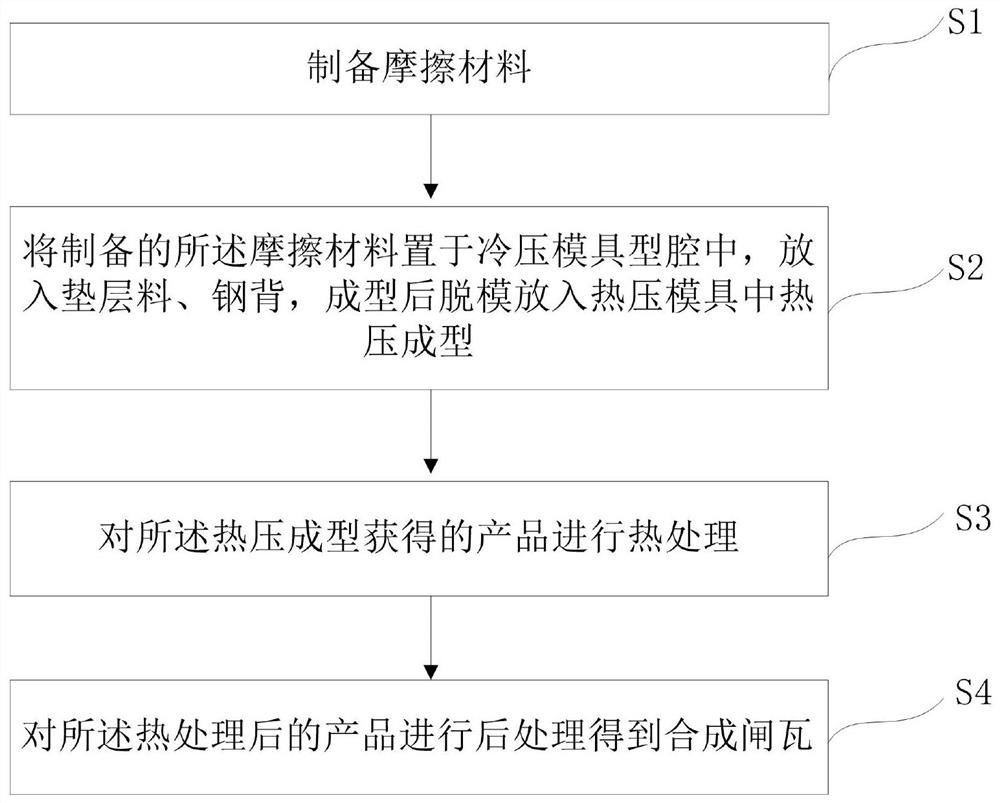

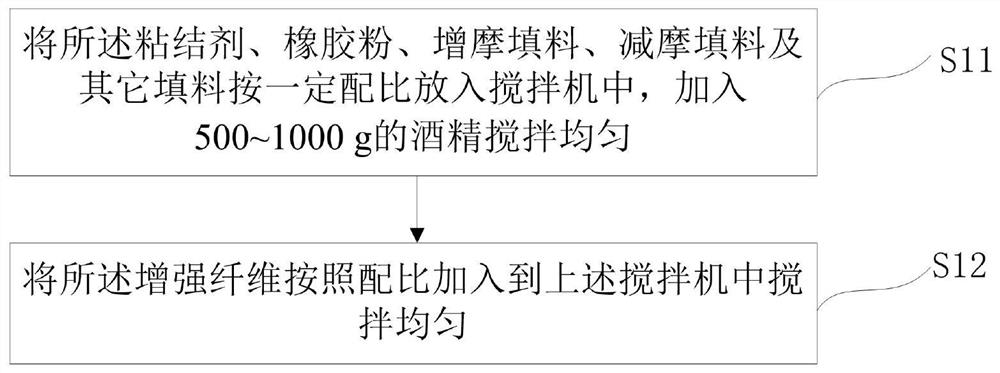

Method used

Image

Examples

Embodiment 1

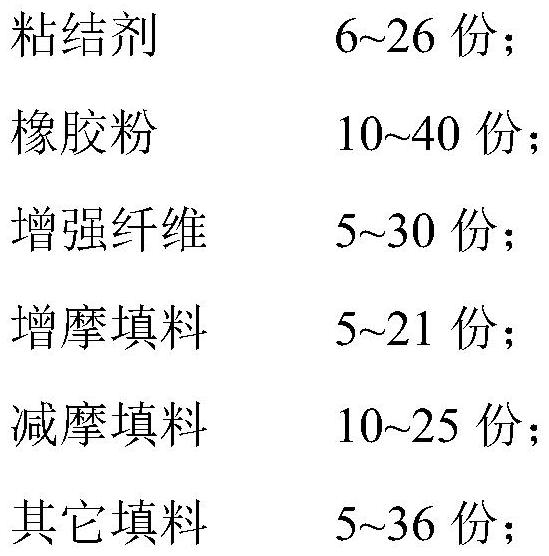

[0061] The friction material includes the following raw material components and parts by volume: 6 parts of binder, 40 parts of rubber powder, 15 parts of reinforcing fiber, 8 parts of friction increasing filler, 25 parts of friction reducing filler, and 6 parts of other fillers.

[0062] The binder is nylon modified phenolic resin; the rubber powder includes 15 parts of powdered nitrile rubber, 15 parts of powdered styrene-butadiene rubber and 10 parts of ethylene-propylene powdered rubber; the reinforcing fiber includes 3 parts of aramid pulp, 5 parts of mineral fiber, 3 parts of potassium titanate whiskers and 4 parts of acicular wollastonite; friction-increasing fillers include 3 parts of γ-alumina, 2 parts of heavy magnesia and 3 parts of zircon powder; friction-reducing fillers include 8.5 parts of coke, 5.5 parts Synthetic graphite, 5 parts of natural spherical graphite, 3.5 parts of carbon black, 1 part of antimony sulfide, 1 part of ferrous sulfide and 0.5 parts of pol...

Embodiment 2

[0072] The friction material includes the following raw material components and parts by volume: 26 parts of binder, 10 parts of rubber powder, 5 parts of reinforcing fiber, 21 parts of friction increasing filler, 20 parts of friction reducing filler, and 18 parts of other fillers;

[0073] Among them, the binder is nylon modified phenolic resin; the rubber includes 1 part of powdered nitrile rubber, 2 parts of powdered styrene-butadiene rubber and 7 parts of ethylene-propylene powdered rubber; the reinforcing fiber includes 2 parts of aramid pulp, 1 part of mineral fiber, 1 part of potassium titanate whisker and 1 part of acicular wollastonite; friction-increasing fillers include 3 parts of γ-alumina, 15 parts of heavy magnesia and 3 parts of zircon powder; anti-friction fillers include 8 parts of coke, 3 parts Synthetic graphite, 2 parts of natural spherical graphite, 1 part of carbon black, 3 parts of antimony sulfide, 2 parts of ferrous sulfide and 1 part of polytetrafluoro...

Embodiment 3

[0076] The friction material includes the following raw material components and parts by volume: 13 parts of binder, 30 parts of rubber powder, 15 parts of reinforcing fiber, 10 parts of friction increasing filler, 15 parts of friction reducing filler, and 17 parts of other filler;

[0077] Among them, the binder is nylon modified phenolic resin; the rubber powder includes 6 parts of powdered nitrile rubber, 14 parts of powdered styrene-butadiene rubber and 10 parts of ethylene-propylene powdered rubber; the reinforcing fiber includes 3 parts of aramid pulp and 3 parts of mineral fiber , 4 parts of potassium titanate whiskers and 5 parts of acicular wollastonite; friction-increasing fillers include 2 parts of γ-alumina, 4 parts of heavy magnesia and 4 parts of zircon powder; anti-friction fillers include 4 parts of coke, 2.5 1 part of synthetic graphite, 2 parts of natural spherical graphite, 1.5 parts of carbon black, 2 parts of antimony sulfide, 2 parts of ferrous sulfide and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com