Integrated equipment and method for thrust measurement and in-situ calibration of attitude control engine

An in-situ calibration and engine technology, applied in the direction of force/torque/power measuring instrument calibration/testing, force/torque/power measuring instrument, measuring device, etc. Components are prone to fatigue cracks and other problems, achieving the effects of high stability and reliability, isolation of vibration, and improvement of thrust measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical scheme of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Obviously, the described embodiments are not limitations of the present invention.

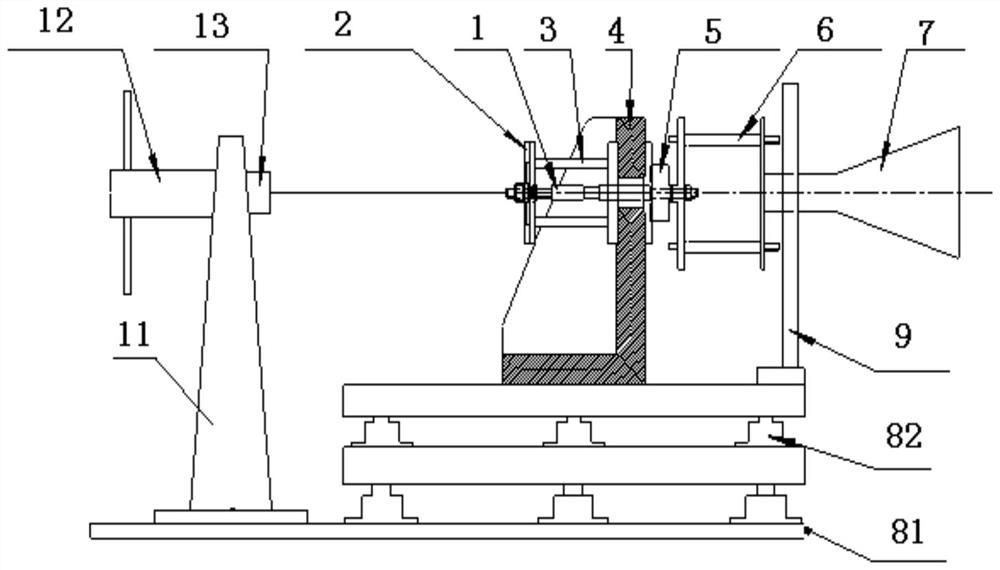

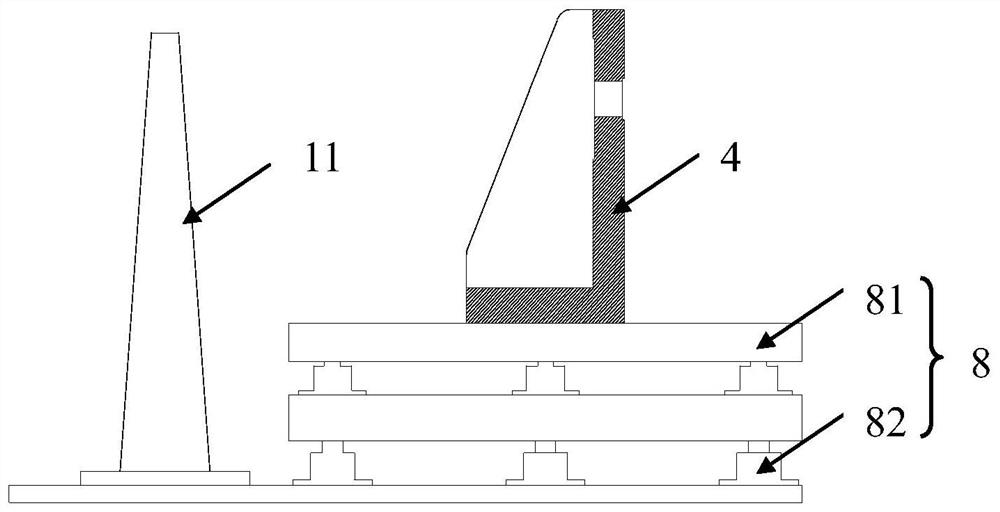

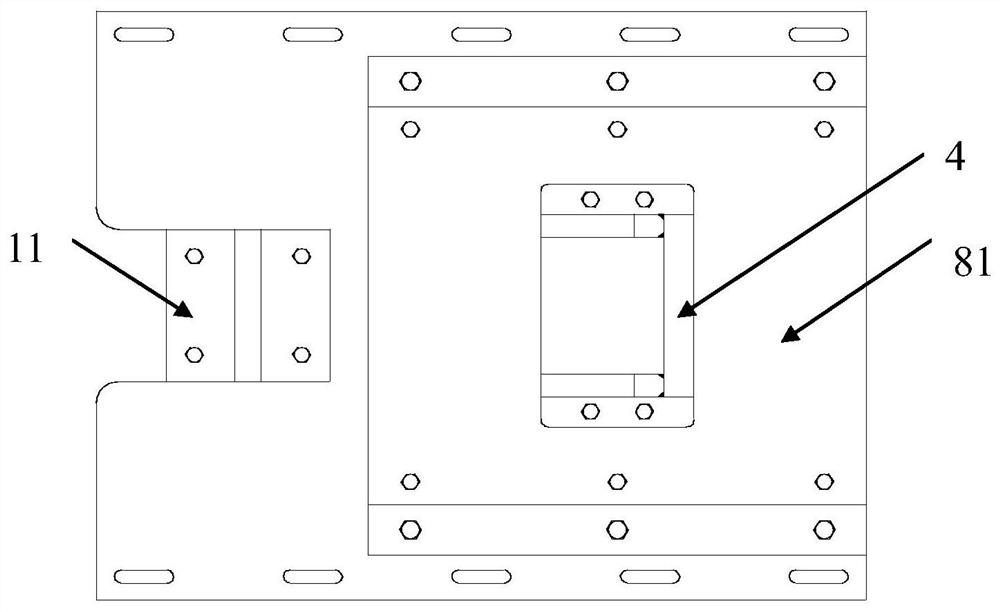

[0060] Such as figure 1 As shown, this embodiment provides a thrust measurement device for an attitude control engine, including an integrated device for thrust measurement and in-situ calibration of an attitude control engine, including a thrust measurement device, a calibration force loading device, a data acquisition system 16 and Data processing system 17, the thrust measuring device and the calibration force loading device are both arranged on the base plate;

[0061] The thrust measuring device comprises a central shaft 1, an elastic sheet 2, a connecting frame 3, a fixed frame 4, a measuring force sensor 5 and an adapter frame 6;

[0062] The central shaft 1 is installed on the fixed frame 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com