Replaceable component for improving fatigue property of steel box girder and construction method of replaceable component

A fatigue performance, steel box girder technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of time-consuming, labor-intensive, high economic costs, etc., and achieve the effects of reducing economic costs, fast and convenient replacement, and strong replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

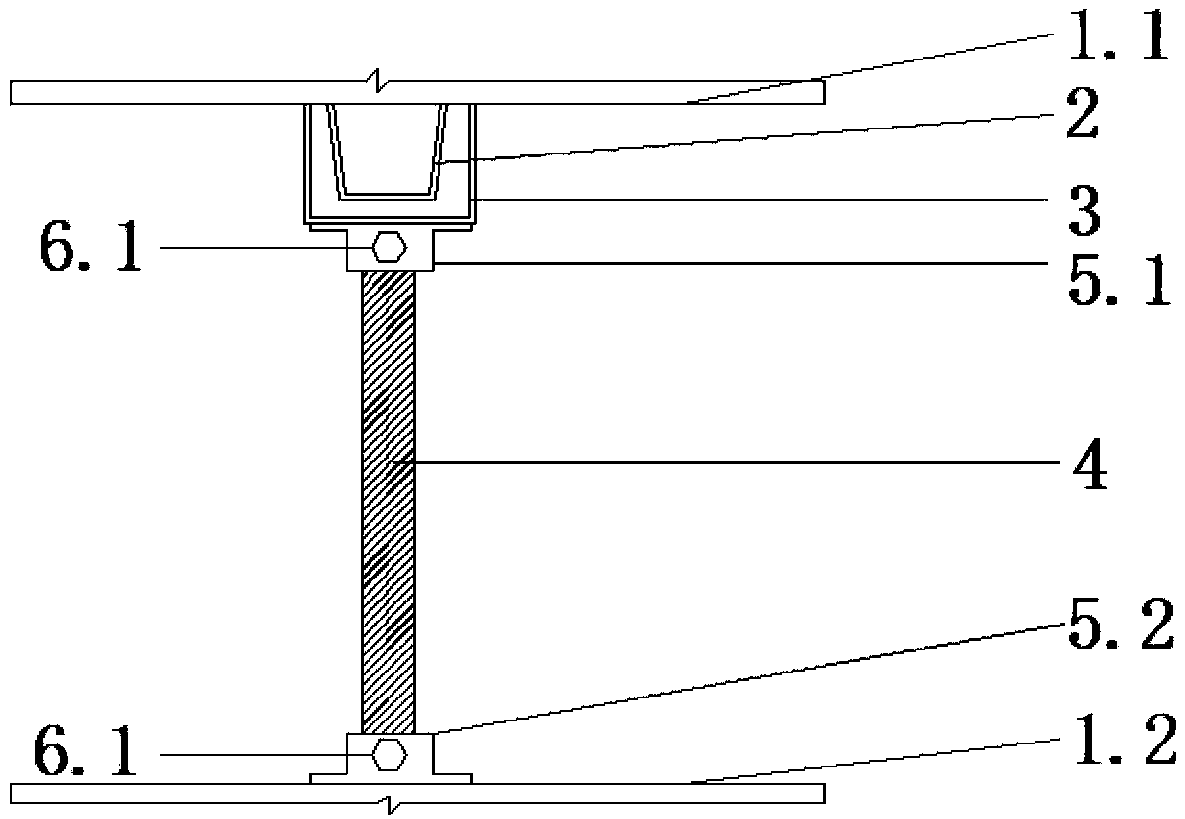

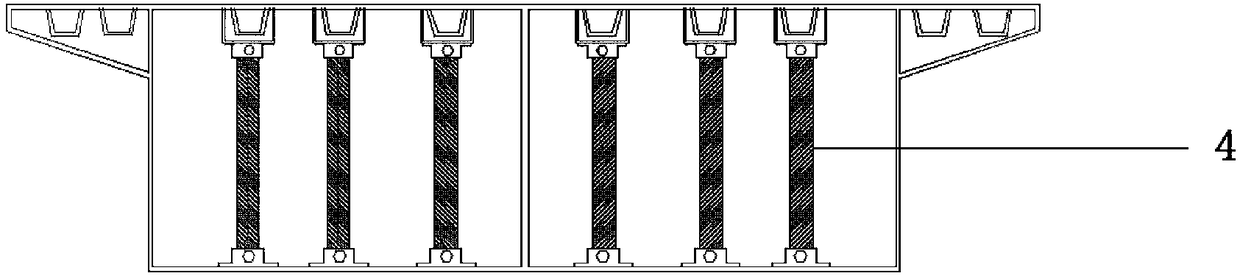

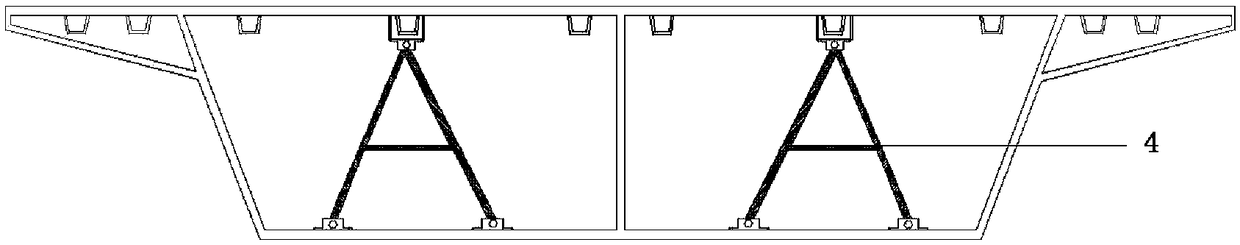

[0041] The invention uses replaceable clamping components to transfer the local load on the roof of the steel box girder bridge to the web or bottom plate with a lower stress level, reduces the stress amplitude of the roof that is prone to fatigue cracks, and improves the fatigue performance of the steel box girder It has good practical value and promotion and application prospect. Under the load of the vehicle, the telescopic clamping member 4 shares the load with the steel box girder roof 1.1 through its own strong compressive resistance. When the telescopic clamping member 4 is deformed or damaged, it can be replaced quickly and conveniently, avoiding and delaying the deformation of the steel box girder. Fatigue occurs on the top plate 1.1 of the box girder, which can obviously reduce the economic cost and is economical and applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com