Method for producing coating for AZ91D magnesium alloy vehicle active safety device component

A technology of active safety and manufacturing method, applied in the direction of metal material coating process, coating, melting spray plating, etc., can solve the problem of no nano-Cr-Ce-La-In composite anti-corrosion coating, etc., to achieve strong economic applicability , good anti-oxidation corrosion performance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

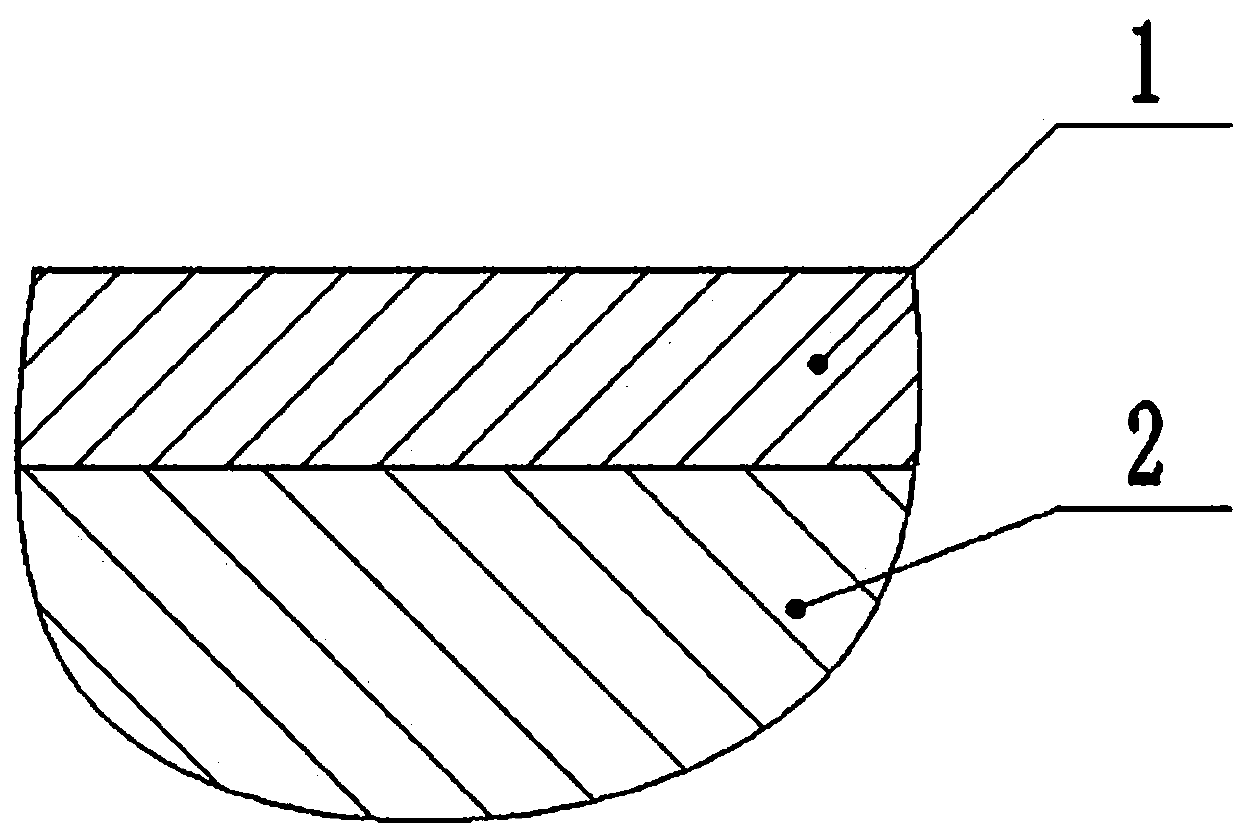

[0015] figure 1 It is a schematic diagram of the coating structure formed by the method for manufacturing the coating of AZ91D magnesium alloy automotive active safety device parts in Example 1 of the present invention.

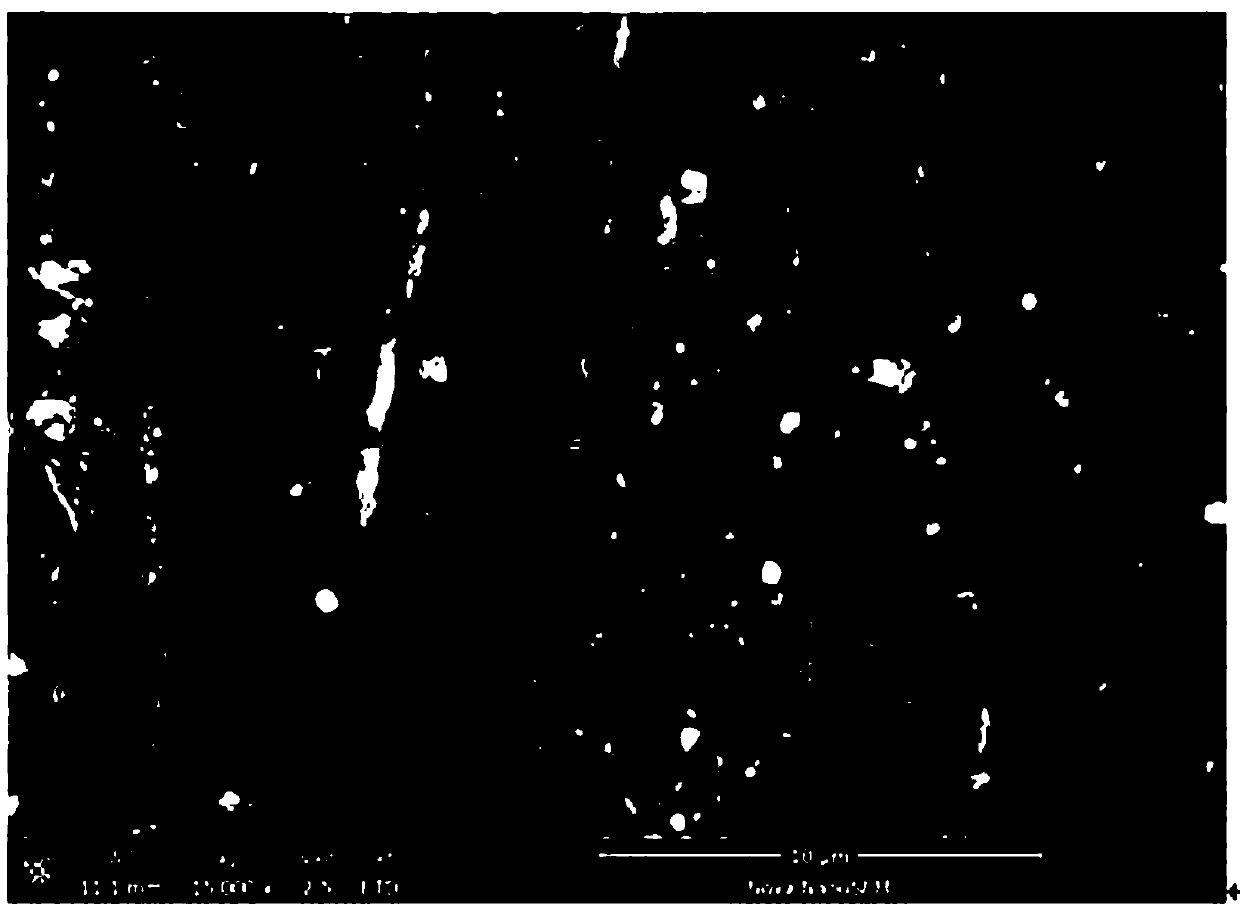

[0016] figure 2 It is a 15000 times scanning electron microscope image of the coating formed by the coating manufacturing method of an AZ91D magnesium alloy automotive active safety device part in Example 1 of the present invention.

[0017] In the accompanying drawings, 1 is a surface material layer, and 2 is a matrix material.

[0018] A kind of AZ91D magnesium alloy automobile active safety device part coating manufacturing method of the present invention is to use AZ91D magnesium alloy material to be made into blank by casting, mechanical processing method to make AZ91D magnesium alloy automobile active safety device parts, in AZ91D magnesium alloy automobile active safety device The surface of the parts is ground, cleaned, degreased, derusted, cleaned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com