Surface recombination energy machining method for high-water-head impact type runner bucket

A technology of surface compounding and processing method, which is applied in the field of surface compounding energy processing of high-head impact runner water buckets, and can solve the problems of reducing service life, affecting the operation safety of hydraulic turbine units, fatigue cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

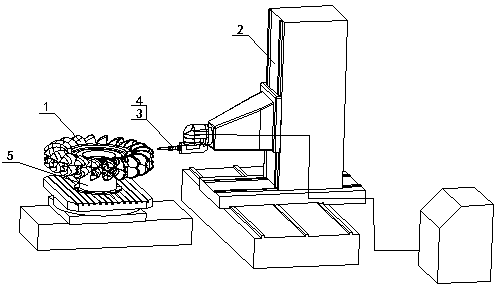

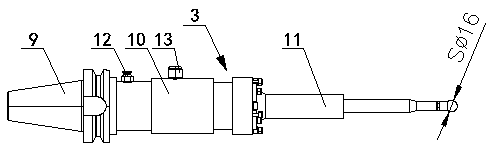

[0022] Embodiment 1: as figure 1 As shown, a high water head impact type runner bucket surface composite energy processing method is characterized in that the method includes the following laying steps: 1), clamping; clamping the runner 1 to be processed to the seven-axis five Linkage CNC machining center 2; 2) Installation; install the Hawker actuator on the seven-axis five-linkage CNC machining center 2, and connect it to the Hawker equipment system at the same time; 3) Determine the machining benchmark of the runner 1; 4) Use Hawker actuator A3 executes the written processing program to process the water bucket surface of runner 1; 5) Use Hawker actuator B4 to execute the written processing program to process the root of runner 1 bucket; 6 ) After completing the surface compound energy processing of a water bucket through step 4) and step 5), use the CNC rotary table indexing of the seven-axis five-linkage CNC machining center to realize the processing of other water bucket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com