Leaf seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

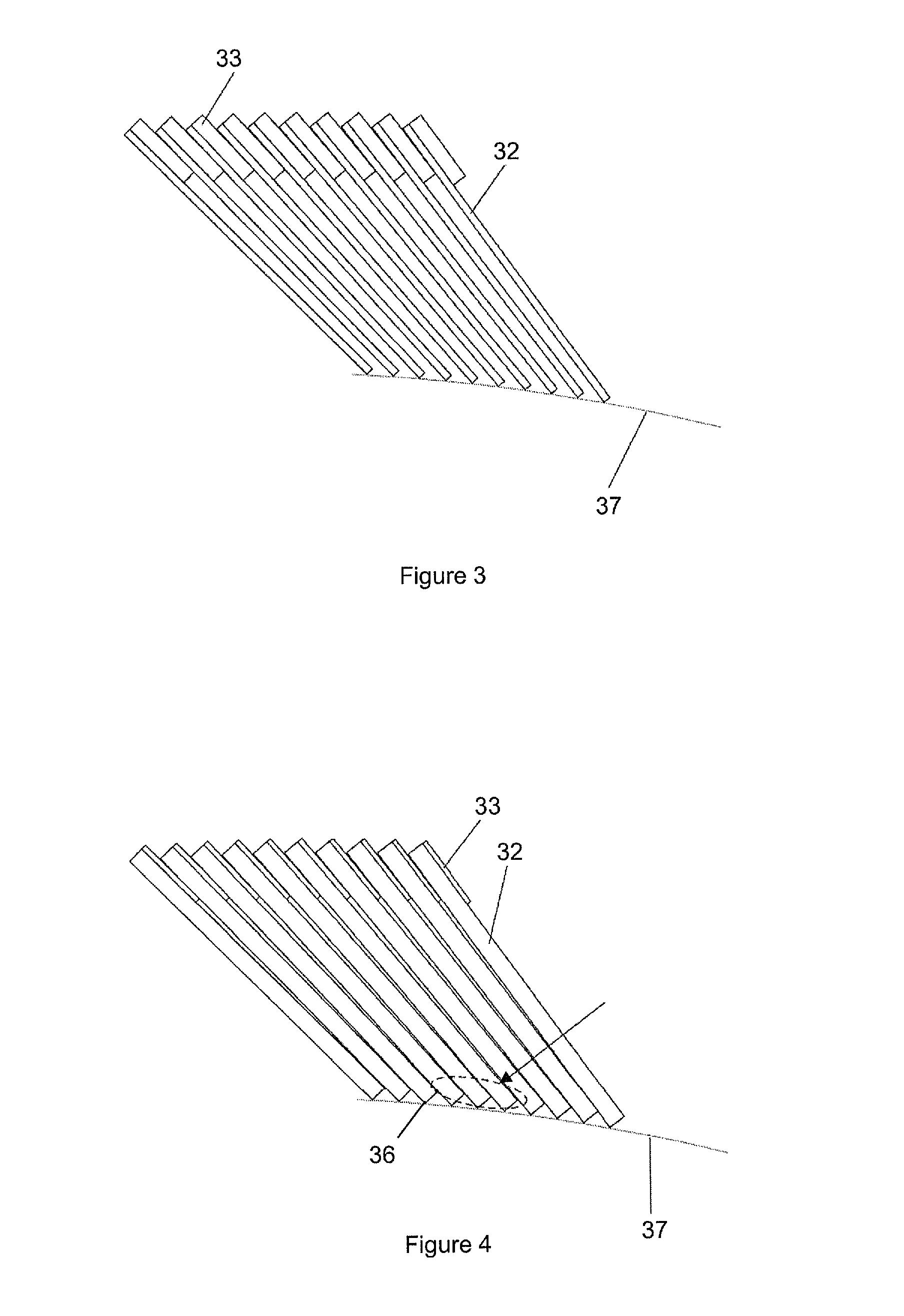

[0039]FIG. 5 shows schematically a view of part of an annular leaf pack for a seal according to the present invention. The leaves 42 of the pack are mounted at respective root portions 49 to a radially outer stationary housing (not shown) and extend towards leaf edges 46 that make wiping contact with the surface 47 of a radially inner rotor.

[0040]Spacers 43 are positioned around the pack after every second root portion. The spacers thus divide the pack into a plurality of leaf blocks, each containing two leaves 42 making face-to-face contact with each other over their entire length from their root portions 49 to their edges 46. The spacers also form interleaf gaps 50 between the end leaves of adjacent blocks, the gaps allowing an axial leakage flow through the pack.

[0041]FIG. 6 shows schematically the leaf pack of FIG. 5 before final assembly into a housing (not shown) comprising typically a backing ring and coverplates. In variants of the leaf pack, the spacers 43 can be positioned...

third embodiment

[0045]The concept of distributing the spacers around a leaf pack so that the leaves are divided into blocks of two or more leaves sandwiched at their root portions between nearest-neighbour spacers can be extended to seals having a plurality of leaf packs. For example, in relation to a seal according to the present invention and having three axially spaced annular packs, FIG. 10 shows schematically (a) a T-shaped lamella and an inverted-U-shaped lamella for forming the leaves of the packs, and (b) the lamellae in readiness for assembly. Each T-shaped lamella provides a leaf 42 and two spacer portions 51 which extending laterally from either side of the root portion of the leaf. Each inverted-U-shaped lamella provides two leaves 42′, 42″ and a spacer portion 51 which bridges the root portions of the leaves. The lamellae are assembled such that the leaves of the T-shaped lamellae form a central leaf pack and the spacer portions of the T-shaped lamellae form spacers between leaves of o...

fourth embodiment

[0047]In a similar fashion, FIG. 14 shows schematically (a) an M-shaped lamella, and (b) inverted-U-shaped, T-shaped and M-shaped lamellae in readiness for assembly according to a variant of FIG. 11. By increasing the number of T-shaped lamellae compared to inverted-U-shaped lamellae, as shown in FIG. 14, improved leakage characteristics and vibration resistance compared to the seal of FIG. 12 may be achieved while still maintaining a stiffer central leaf pack.

[0048]In relation to both the third and fourth embodiments, rather than increasing the number of T-shaped lamellae relative to the number of inverted-U-shaped lamellae, it is possible to increase the number of inverted-U-shaped lamellae relative to the number of T-shaped lamellae in order to stiffen the outer packs relative to the central pack.

[0049]While the invention has been described in conjunction with the exemplary embodiments described above, many equivalent modifications and variations will be apparent to those skilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com