Axial-flow blower fan impeller

A fan impeller and axial flow technology, applied to mechanical equipment, non-variable pumps, machines/engines, etc., can solve problems such as broken blades or impeller damage, fatigue cracks of fan blades, and outage of generator sets, etc., to achieve extended Operating life, reduction of probability of fatigue cracks or fractures, effect of increasing natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

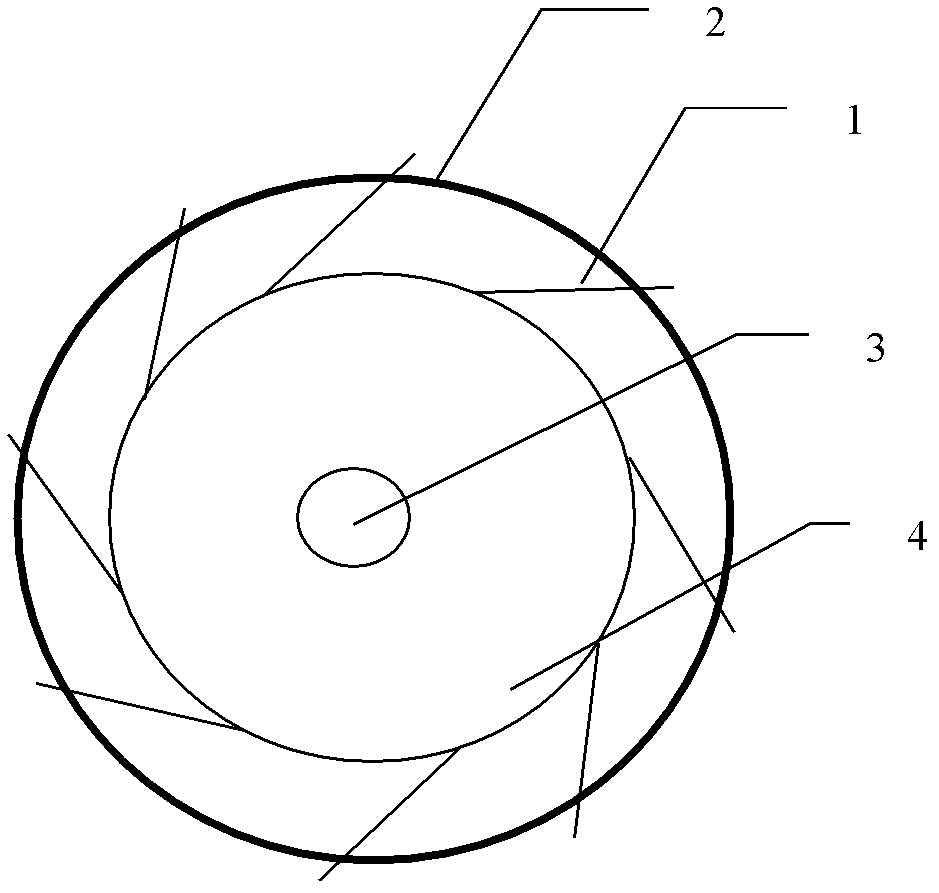

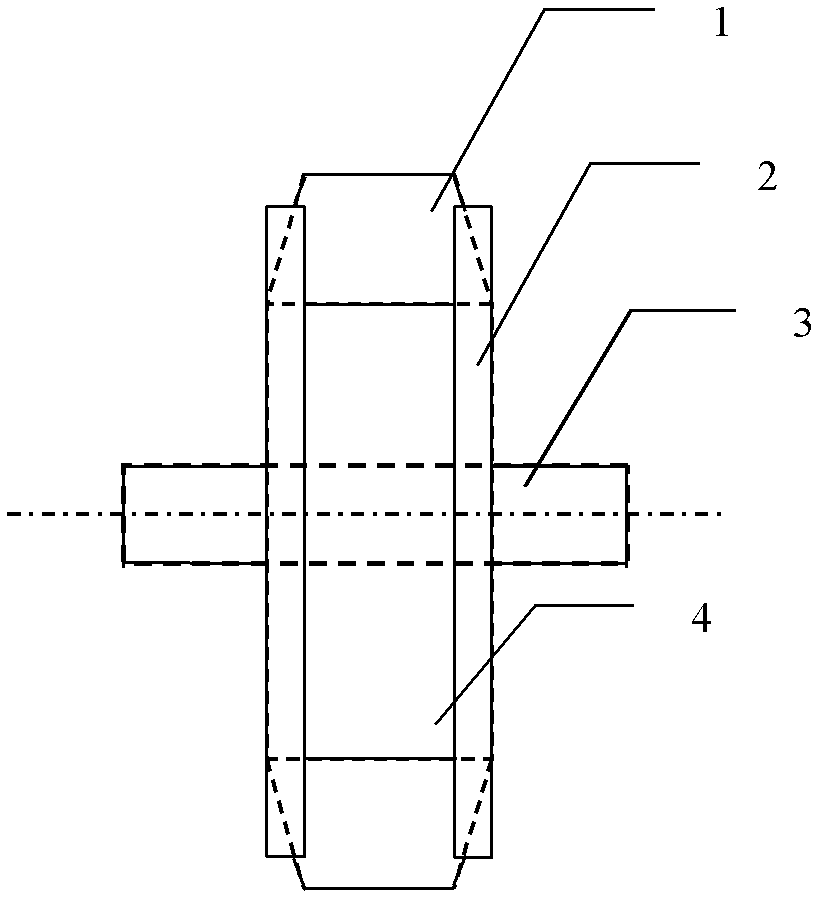

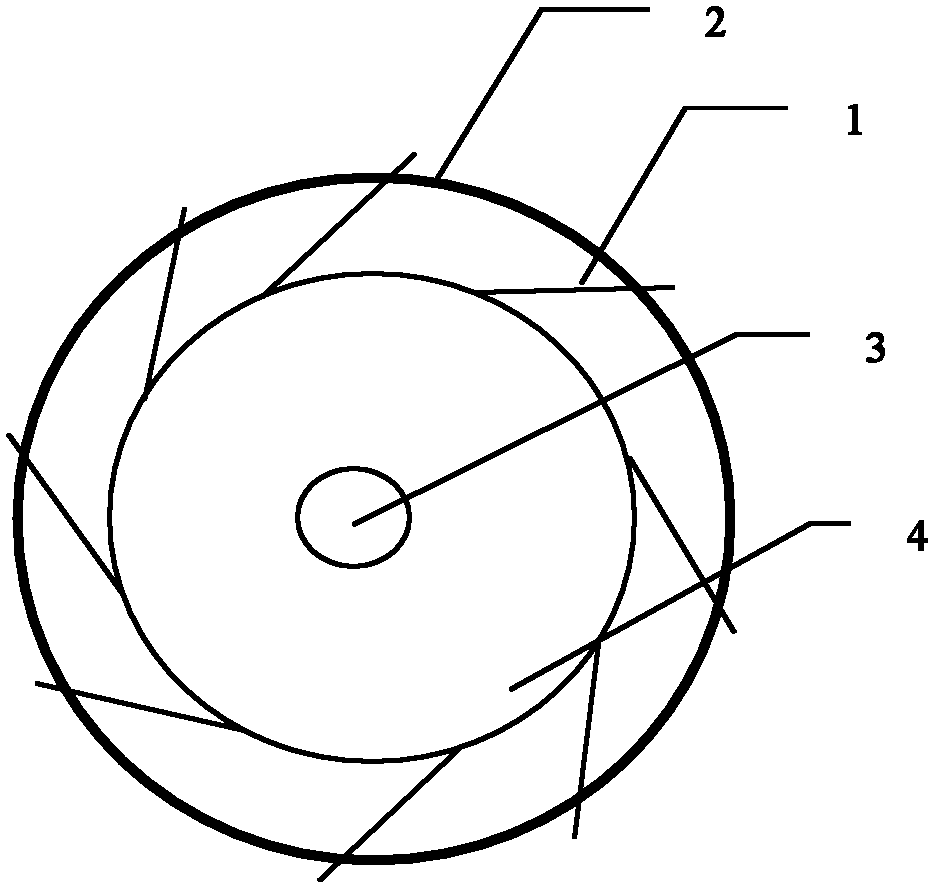

[0016] An axial-flow fan impeller, including a transmission shaft 3, an impeller hub 4 and several blades 1, the transmission shaft 3 is connected to the impeller hub 4, the blades 1 are arranged around the impeller hub 4, and a reinforcing ring 2, such as figure 1 , figure 2 As shown, among them, there are several grooves on the reinforcement ring 2, and several blades 1 are connected with the reinforcement ring 2 by embedding the grooves, and the blade 1 is improved from a cantilever structure to an integrally connected ring structure (this method is preferred);

[0017] Another implementation method is: the blade 1 is provided with a groove, and the reinforcing ring 2 is connected to several blades 1 by being embedded in the groove, so that the blade 1 is improved from a cantilever structure to an integrally connected ring structure.

[0018] There is another impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com