Copper-free friction material and brake pad

A technology of friction materials and brake pads, which is applied in the field of copper-free friction materials and brake pads, can solve the problems of unstable friction coefficient, heavy metal pollution, cost teaching, etc., and achieve improved dual state effect, thermal crack resistance and wear resistance good, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Copper-free automobile brake pad friction material of the present invention, by weight (1 weight part is 1g), comprises raw material:

[0024] 35 parts of steel fiber, 10 parts of modified phenolic resin, 8 parts of nitrile rubber, 12 parts of styrene-butadiene rubber, 12 parts of graphite, 3 parts of molybdenum disulfide, 5 parts of cryolite, 8 parts of barium sulfate, 2 parts of aramid, weight 3 parts of high-quality calcium carbonate, 3 parts of heavy magnesium oxide, 3 parts of white corundum, and 3 parts of silicon carbide.

[0025] Mix the components uniformly according to the above ratio to obtain a mixture, put the mixture in a mold and press it, set the pressure to 10Mpa, and the pressing time to 150s, then heat the pressed blank, set the heating temperature to 180 °C, cured for 20 hours to prepare automobile brake pads.

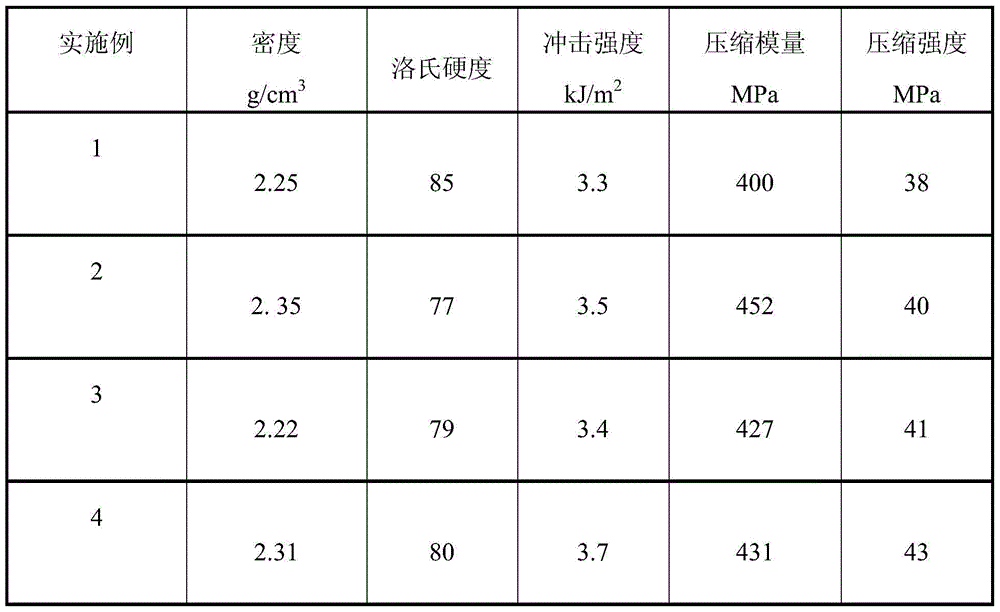

[0026] The performance of the automobile brake pads prepared above is shown in Table 1.

Embodiment 2

[0028] Copper-free automobile brake pad friction material of the present invention, by weight (1 weight part is 1g), comprises raw material:

[0029] 40 parts of steel fiber, 7 parts of modified phenolic resin, 6 parts of nitrile rubber, 12 parts of styrene-butadiene rubber, 15 parts of graphite, 3 parts of molybdenum disulfide, 5 parts of cryolite, 7 parts of barium sulfate, 5 parts of aramid, weight 5 parts of high-quality calcium carbonate, 5 parts of heavy magnesium oxide, 2 parts of white corundum, and 3 parts of silicon carbide.

[0030] Mix the components evenly according to the above proportions to obtain a mixture, put the mixture in a mold and press it, set the pressure at 15Mpa, press time for 100s, and then heat the pressed blank, set the heating temperature at 160°C , cured for 21 hours, and made of automobile brake pads.

[0031] The performance of the automobile brake pads prepared above is shown in Table 1.

Embodiment 3

[0033] Copper-free automobile brake pad friction material of the present invention, by weight (1 weight part is 1g), comprises raw material:

[0034] 30 parts of steel fiber, 12 parts of modified phenolic resin, 10 parts of nitrile rubber, 15 parts of styrene-butadiene rubber, 12 parts of graphite, 3 parts of molybdenum disulfide, 8 parts of cryolite, 5 parts of barium sulfate, 5 parts of aramid, weight 3 parts of high-quality calcium carbonate, 1 part of heavy magnesium oxide, 3 parts of white corundum, and 4 parts of silicon carbide.

[0035] Mix the components uniformly according to the above ratio to obtain a mixture, put the mixture in a mold and press it, set the pressure at 13Mpa, and the pressing time for 125s, then heat the pressed blank, set the heating temperature at 150°C, After curing for 23 hours, an automobile brake pad is obtained. The performance of the automobile brake pads prepared above is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com