Cable assembly for use with opto-electronic equipment enclosures

a technology of opto-electronic equipment and enclosures, applied in the direction of optics, fibre mechanical structures, instruments, etc., can solve the problems of no mechanism, no additional protection provided for fibers, no mechanism,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

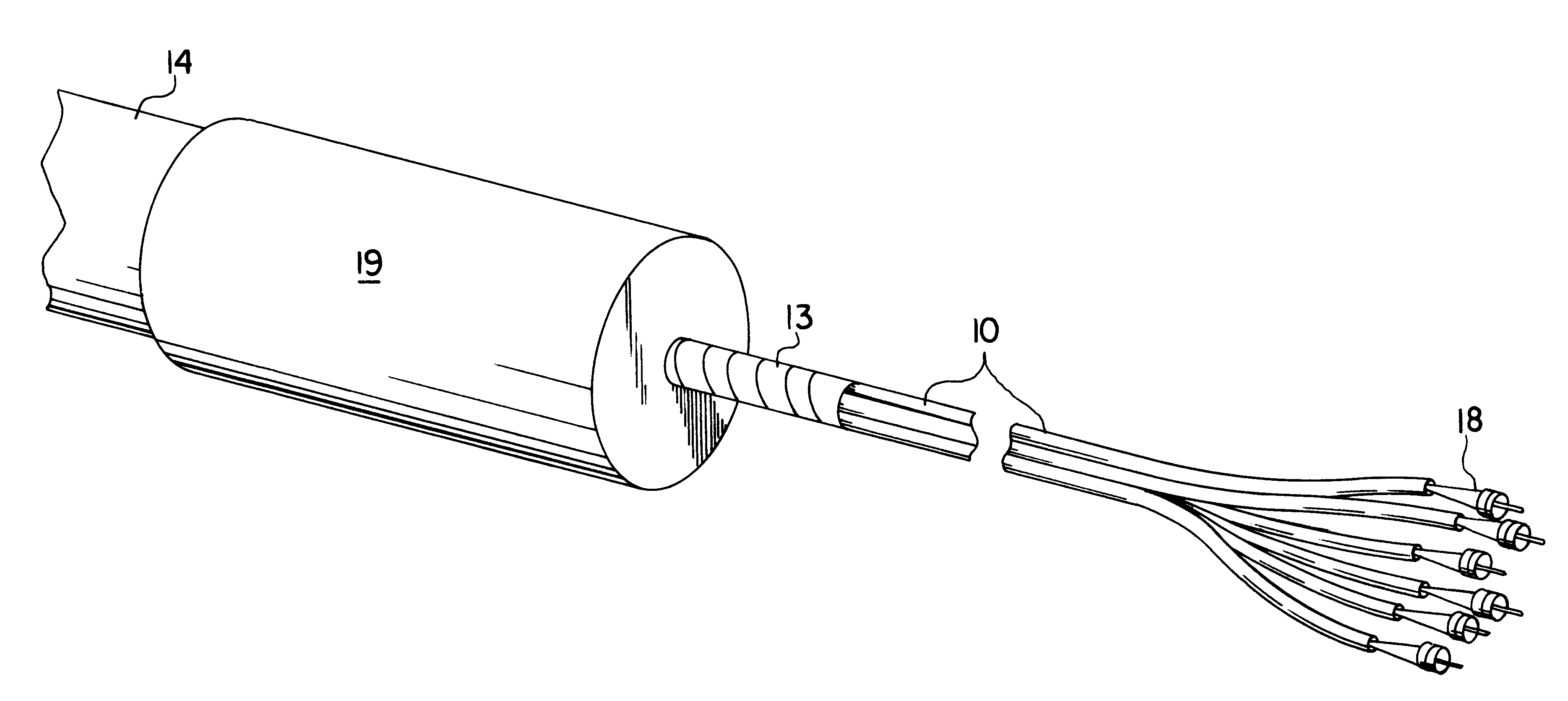

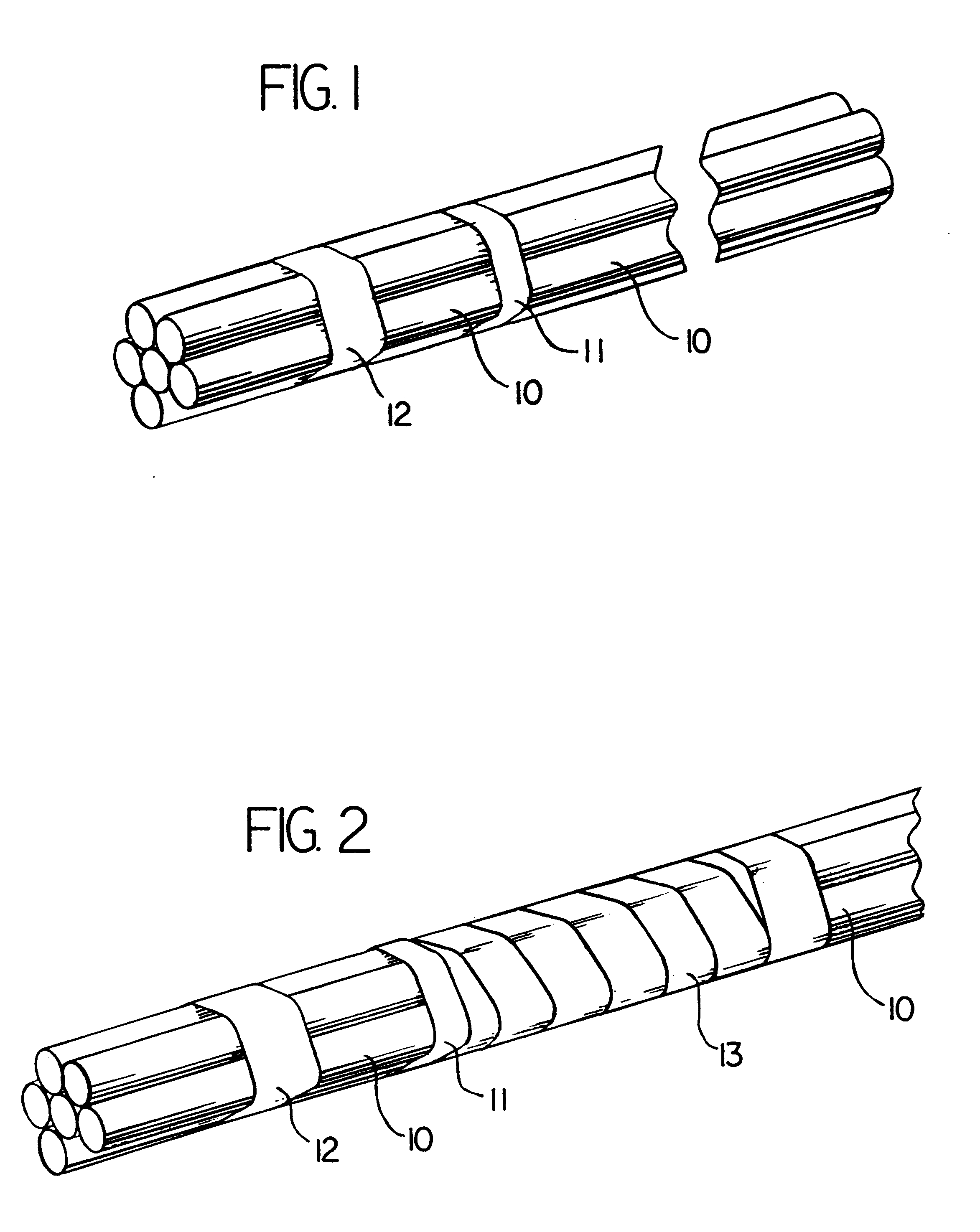

An array of flexible tubes 10 are bundled as shown in FIG. 1 by two strips 11, 12 of heat shrinkable material which are preferably 1 / 4 inch wide. Tubes 10 are preferably made of a lightweight, low friction, highly flexible plastic such as Teflon.RTM. plastic. Strips 11, 12 are placed 3 / 16th of an inch apart. Strip 12 is located around 1 / 4 inch from one end of tubes 10.

After strips 11, 12 have cooled, spiral wrap material 13 is placed over the bundle of tubes 10, with one edge over strip 11 and the remainder proceeding in the direction opposite strip 12.

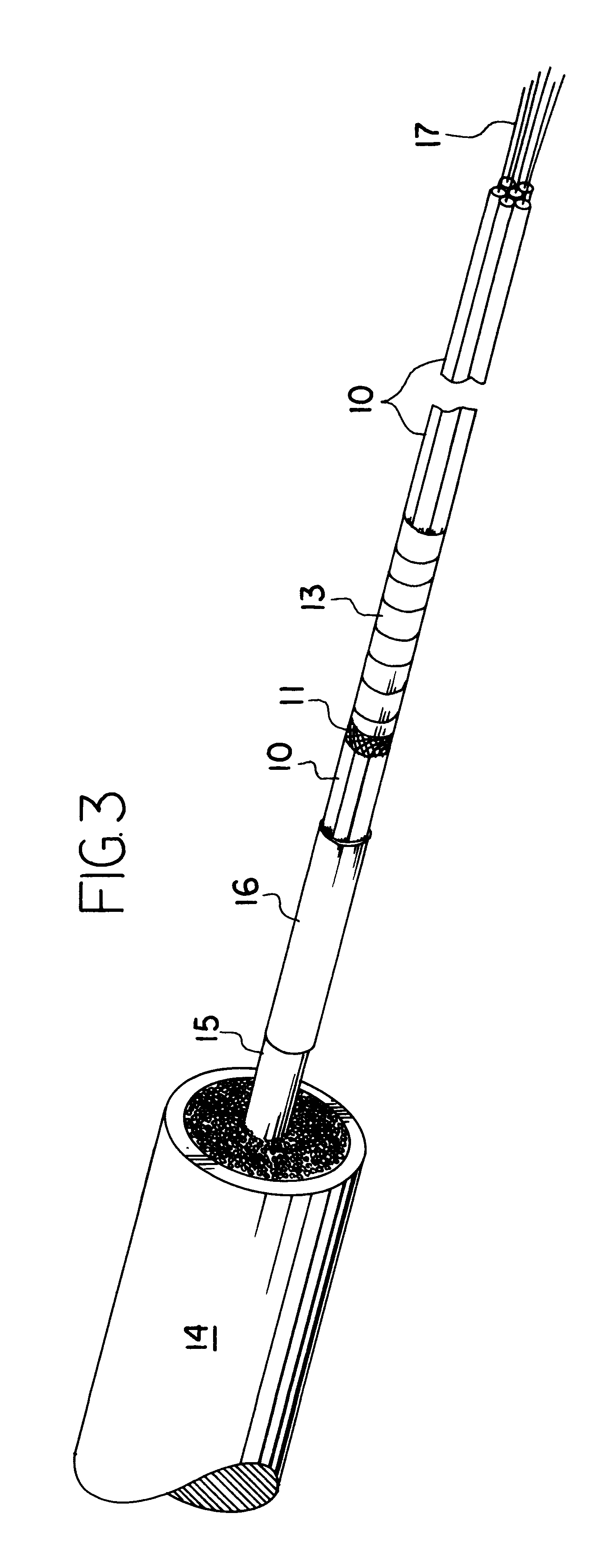

A light waveguide cable is then prepared as shown in FIG. 3. After one end of cable jacket 14 has been cut back, a buffer tube 15 including light waveguides 17 extends a short distance. Each fight waveguide 17 is threaded through a flexible tube 10, with an optical coupler 18 being placed on the distal end of each fight waveguide 17. As shown in FIG. 4, tubes 10 extend to meet the rear of couplers 18. A protective boot on each coupler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com