Electrical housing with non-integral cable outlet port member

a non-integral, housing technology, applied in the installation of electric cables, substation/switching arrangement details, lighting conductors, etc., can solve the problems of frequent breakage of the opposing fingers which make up the anti-tensioning device, cost and time-consuming practice, etc., and achieve the effect of convenient formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]While the invention has been described in connection with what is presently considered to be the most practical and preferred embodiment, it is to be understood that the invention is not to be limited to the disclosed embodiments but, on the contrary, is intended to cover various modifications and equivalent arrangements included within the spirit and scope of the appended claims, which scope is to be accorded the broadest interpretation so as to encompass all such modifications and equivalent structures as is permitted under the law.

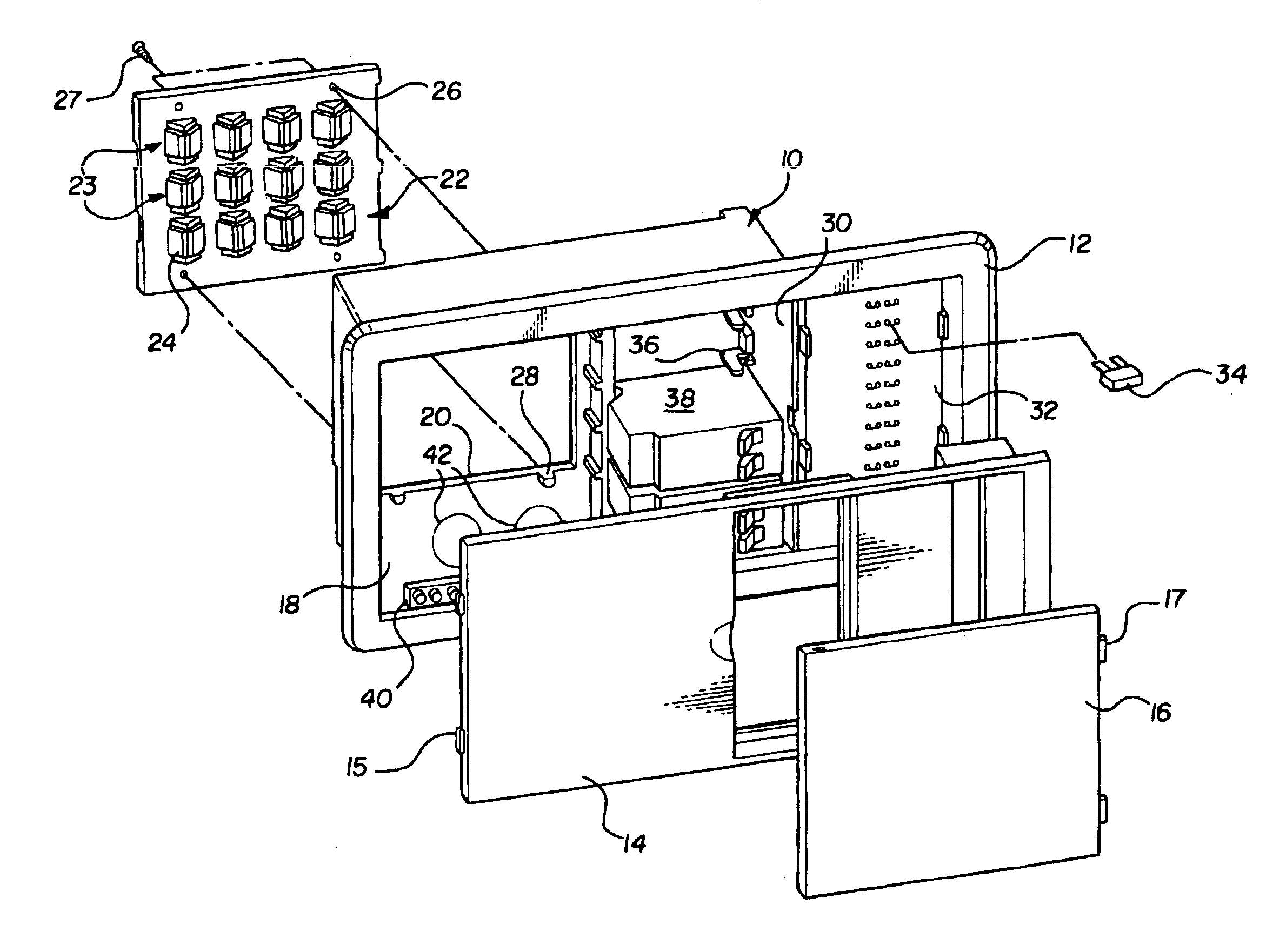

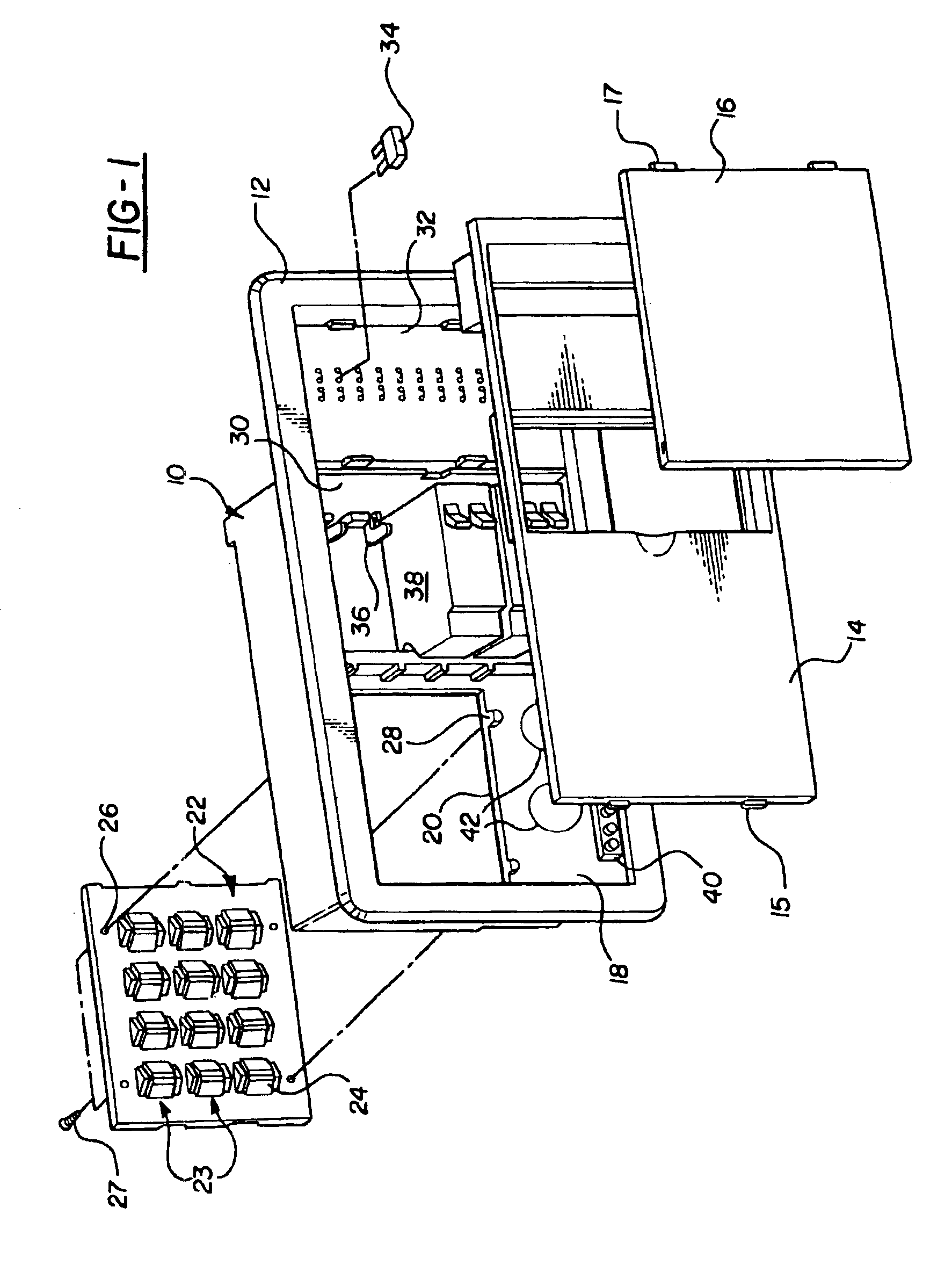

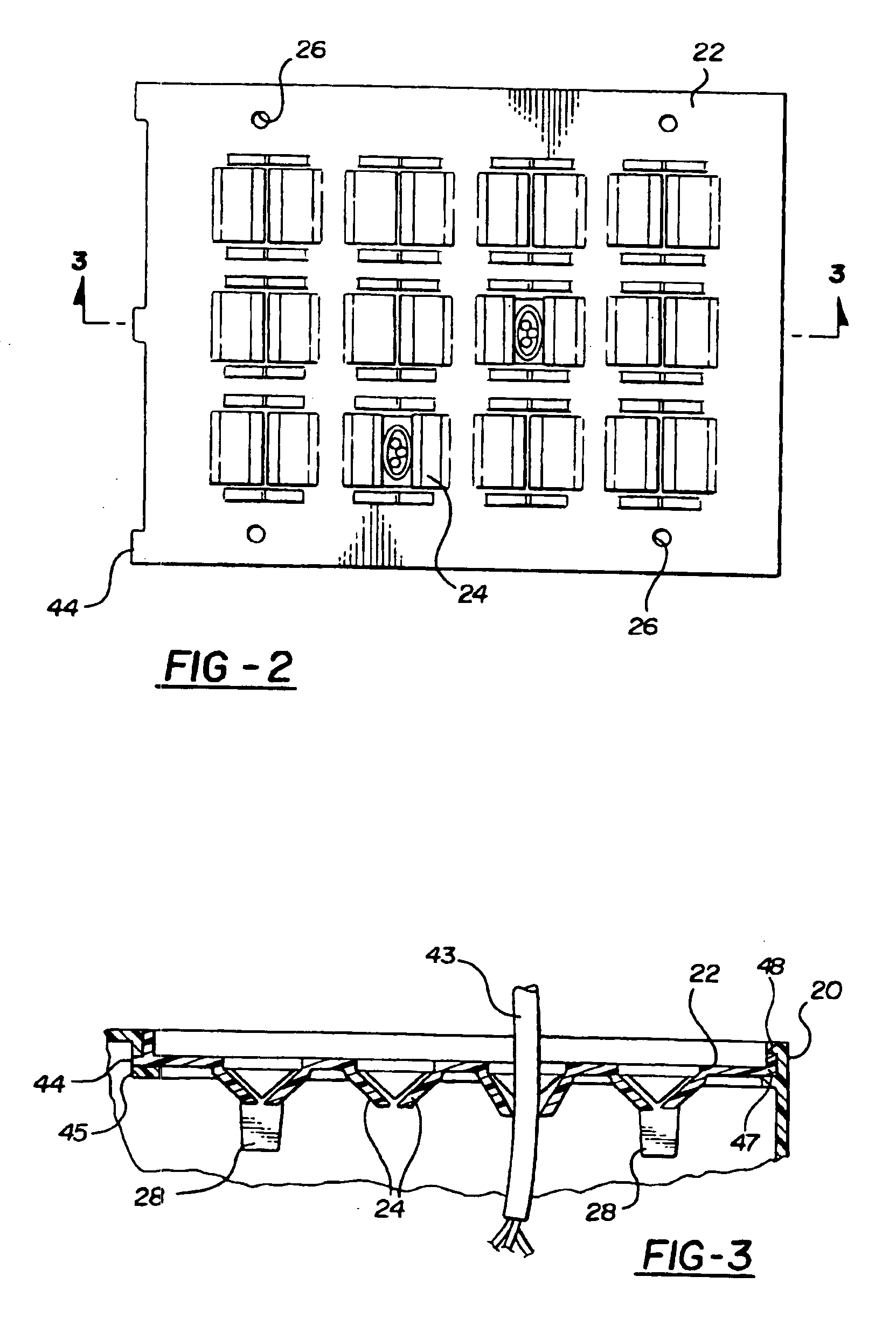

[0020]Referring now to FIGS. 1 through 3, a molded plastic housing 10 of the size, weight, and configuration suitable for use as an electrical distribution center in recreational vehicles is shown. The housing 10 is injection molded from a suitable phenolic resin to exhibit a decorative and functional front peripheral flange 12, a separate snap-in cover 14 having edge tabs 13 and an access patch 16 having edge tabs 17 which cooperates with the rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com