Internal and external element correcting method of star sensor

A technology of a star sensor and a calibration method, applied in the field of aerospace measurement, can solve the problems of calibration method error, affecting the estimation accuracy of the internal parameters of the star sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

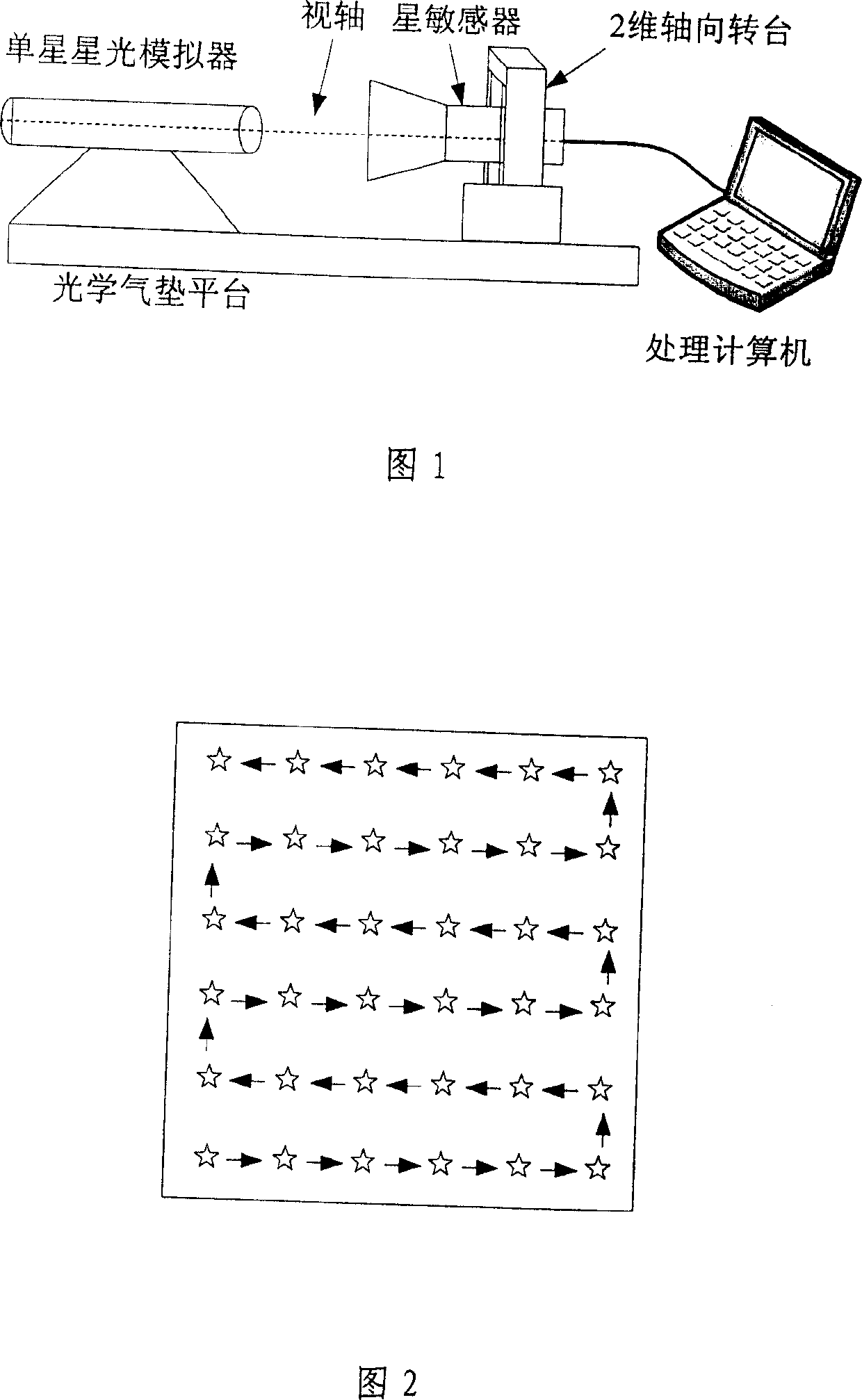

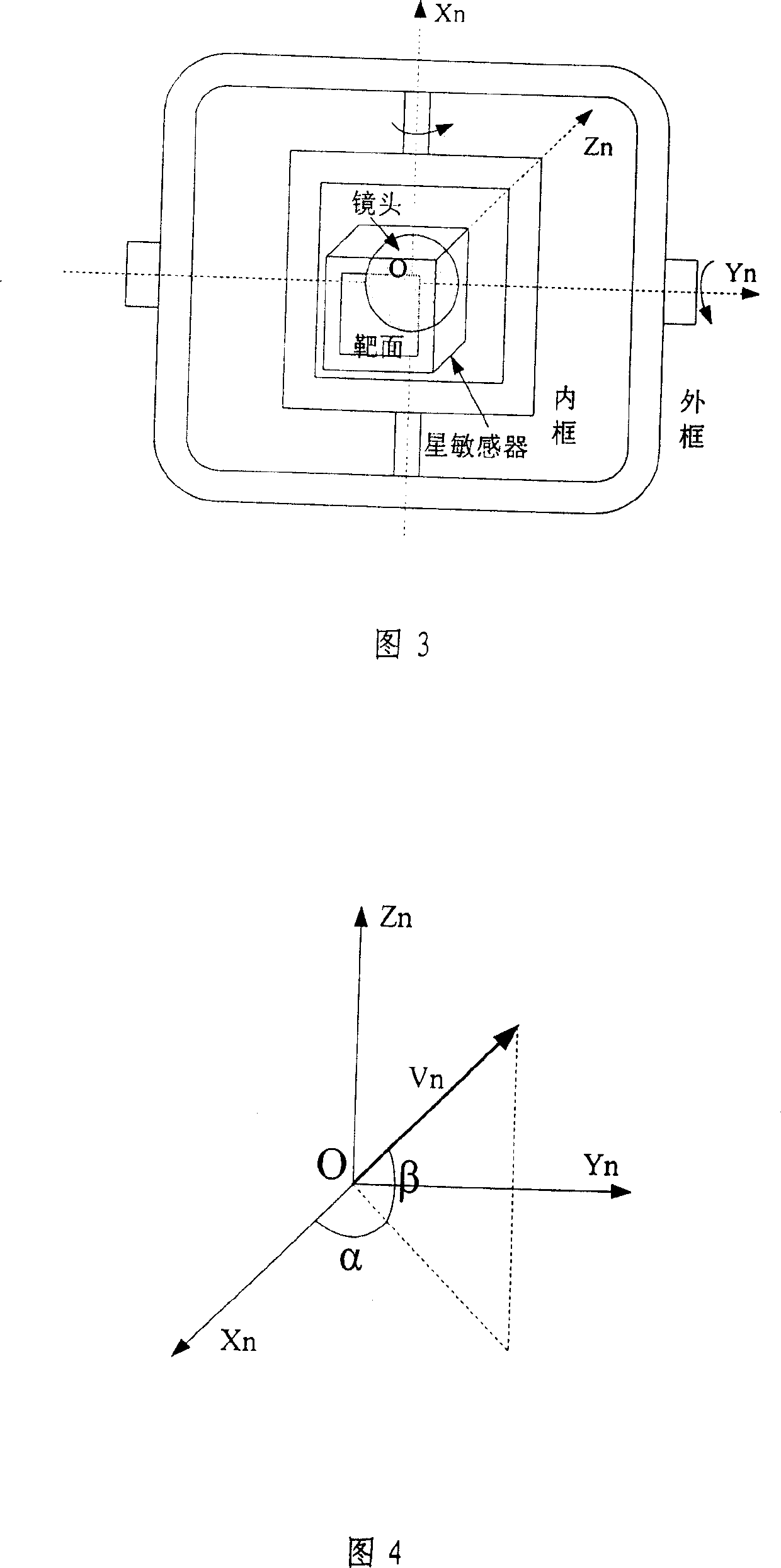

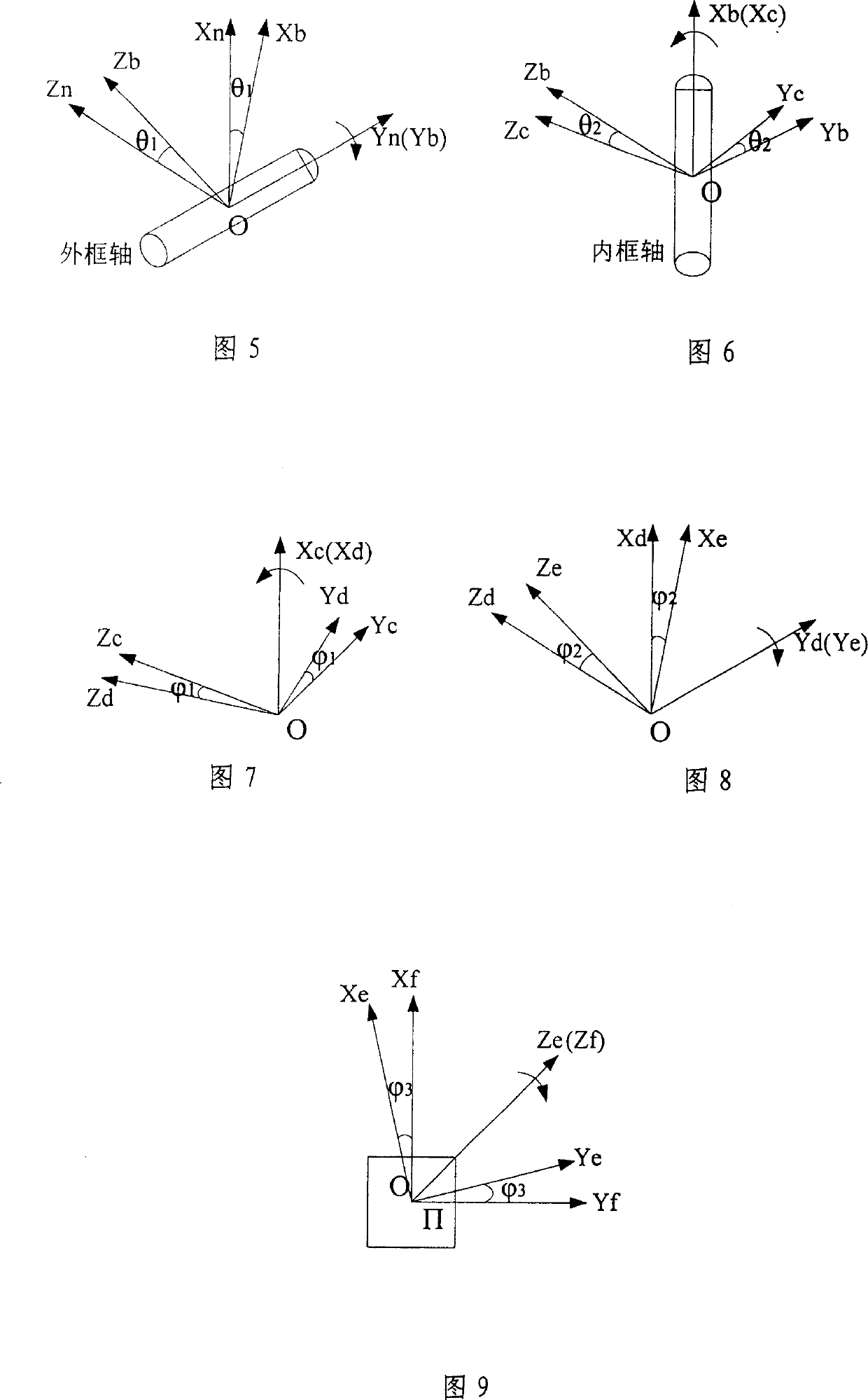

Embodiment Construction

[0104] The present invention will be described in further detail below. The invention proposes a joint modeling method for the internal parameters and external parameters of the star sensor calibration system, and uses the nonlinear least square method and collinear formula to iteratively calculate the internal parameters and external parameters of the star sensor calibration system. This method can separate the internal parameters and external parameters of the star sensor calibration system, making the final internal parameters of the star sensor more accurate. At the same time, the external world coordinate system of the star sensor calibration system is established in the calibration process, so that the star sensor coordinate system can be easily drawn to the optical cube coordinate system that is fixedly connected with the star sensor, and it will be used for future star sensor installation. Orientation measurements while on board the spacecraft provide the basis. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com