Camera device

A camera device and camera element technology, applied in installation, image communication, instruments, etc., can solve the problems of increased movement, limited compactness, increased weight, etc., and achieve compactness, light weight, and large travel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

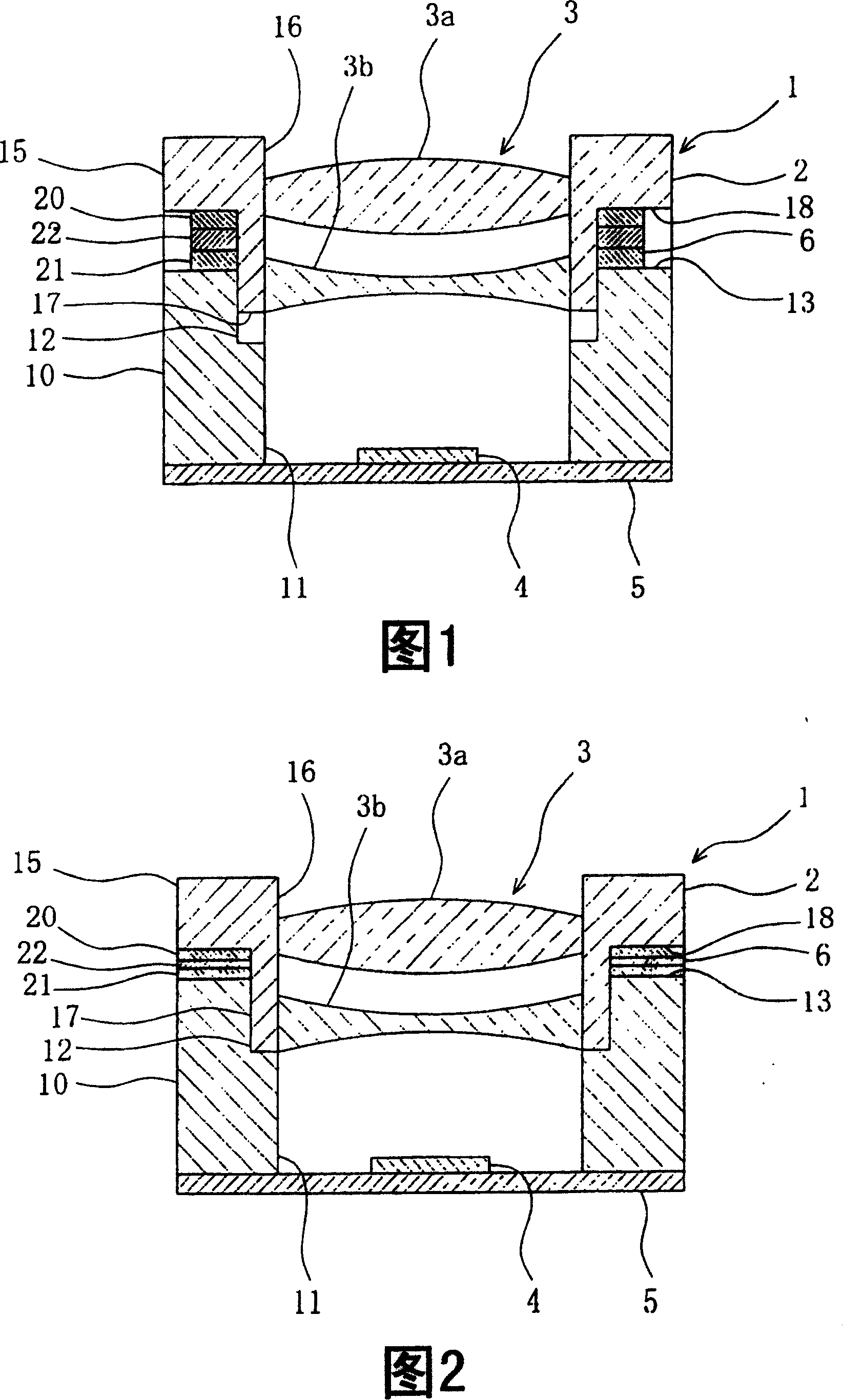

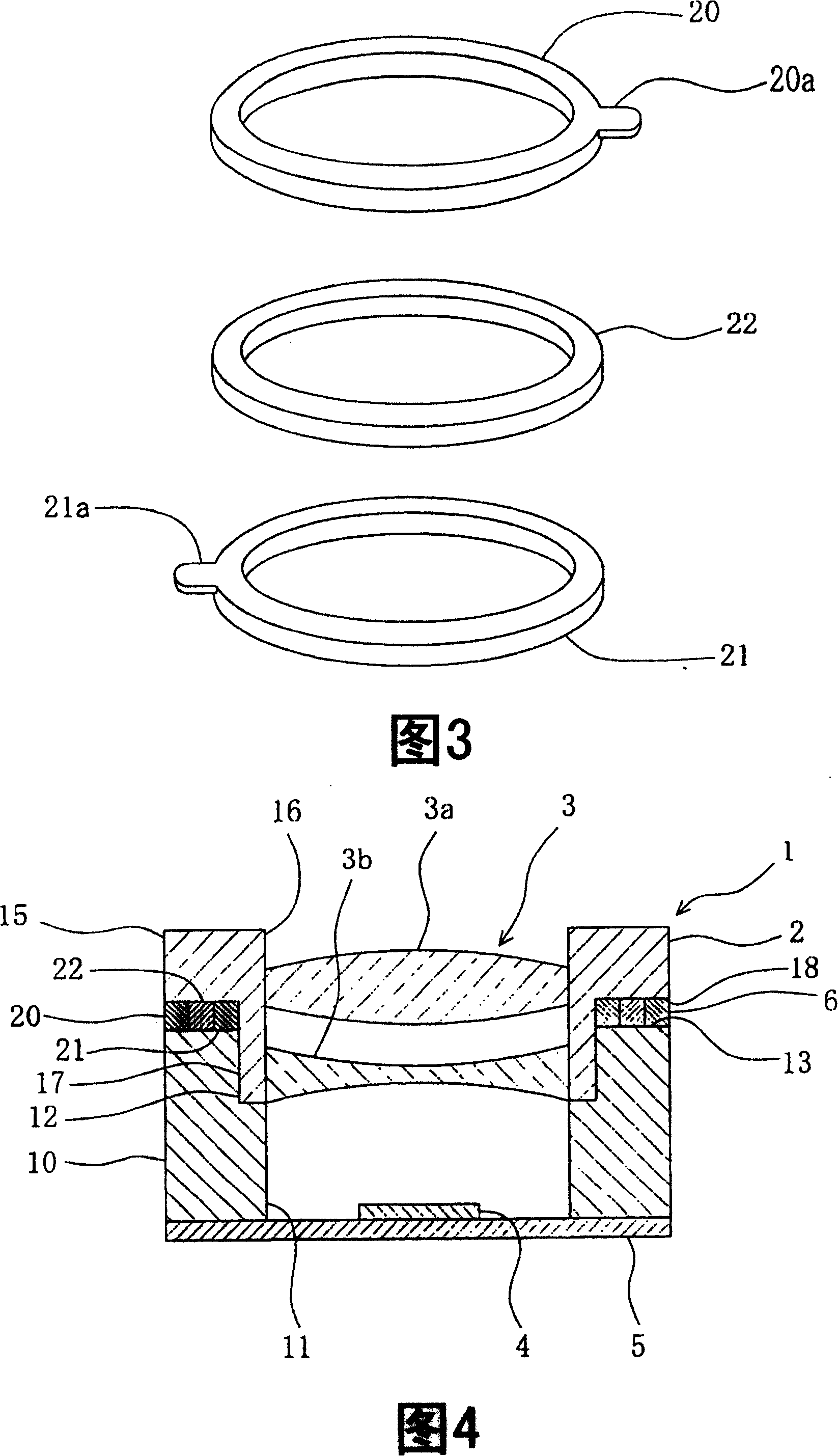

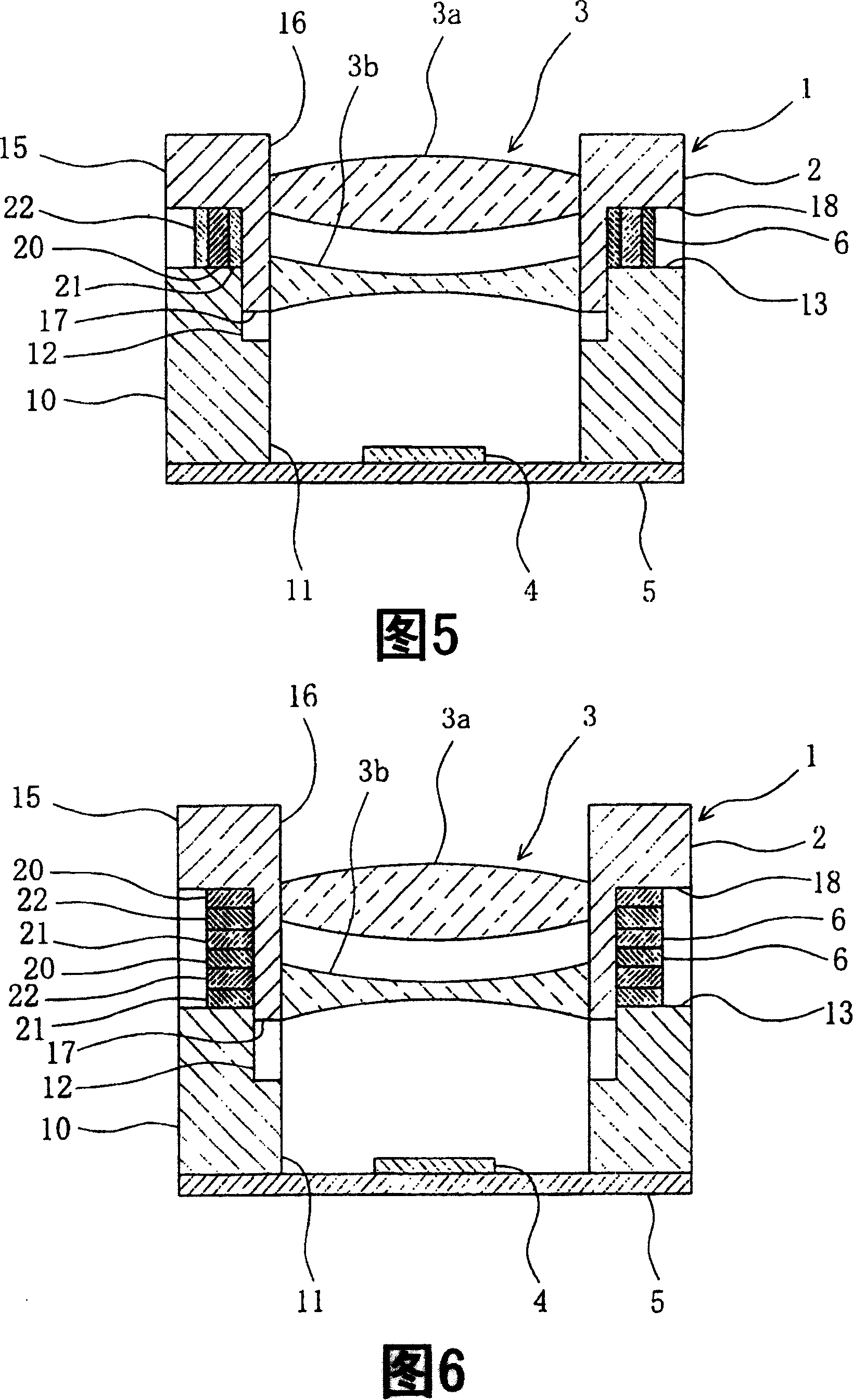

[0027] Embodiments of the present invention will be described in detail below according to the accompanying drawings. FIG. 1 is a longitudinal sectional view of an imaging device 1 of this embodiment. As shown in the figure, the imaging device 1 of this embodiment integrally constitutes a lens group 3 housed in a lens barrel 2 and an imaging element 4 that receives light transmitted through the lens group 3, and the lens group 3 faces each other along the optical axis direction. A device that freely moves around the imaging element 4.

[0028] The imaging element 4 is a photoelectric conversion element such as a CCD or a CMOS, and is arranged on a flat substrate 5 . The lens barrel 2 is provided on the substrate 5 so as to surround the imaging element 4 , is formed in a cylindrical shape, and accommodates the lens group 3 inside. The lens group 3 in this embodiment includes a convex lens 3a and a concave lens 3b. However, a single lens may be accommodated in the lens barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com