Parallel cross operation method of critical continuous conducting mode power factor corrector

A technology of power factor correction and critical continuity, applied in the direction of output power conversion devices, instruments, electrical components, etc., can solve the problems of complex implementation, uniform interleaving of inductive current, and increase in the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

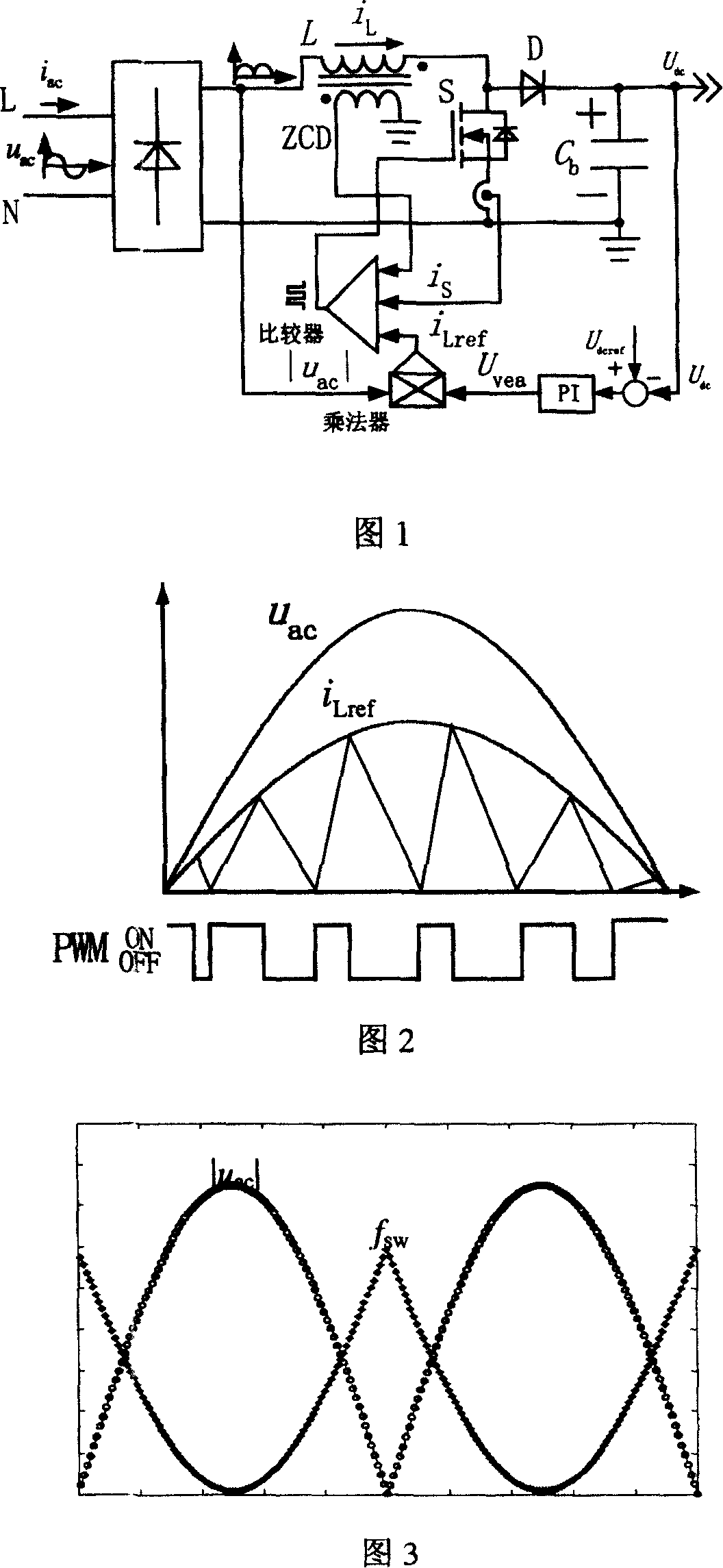

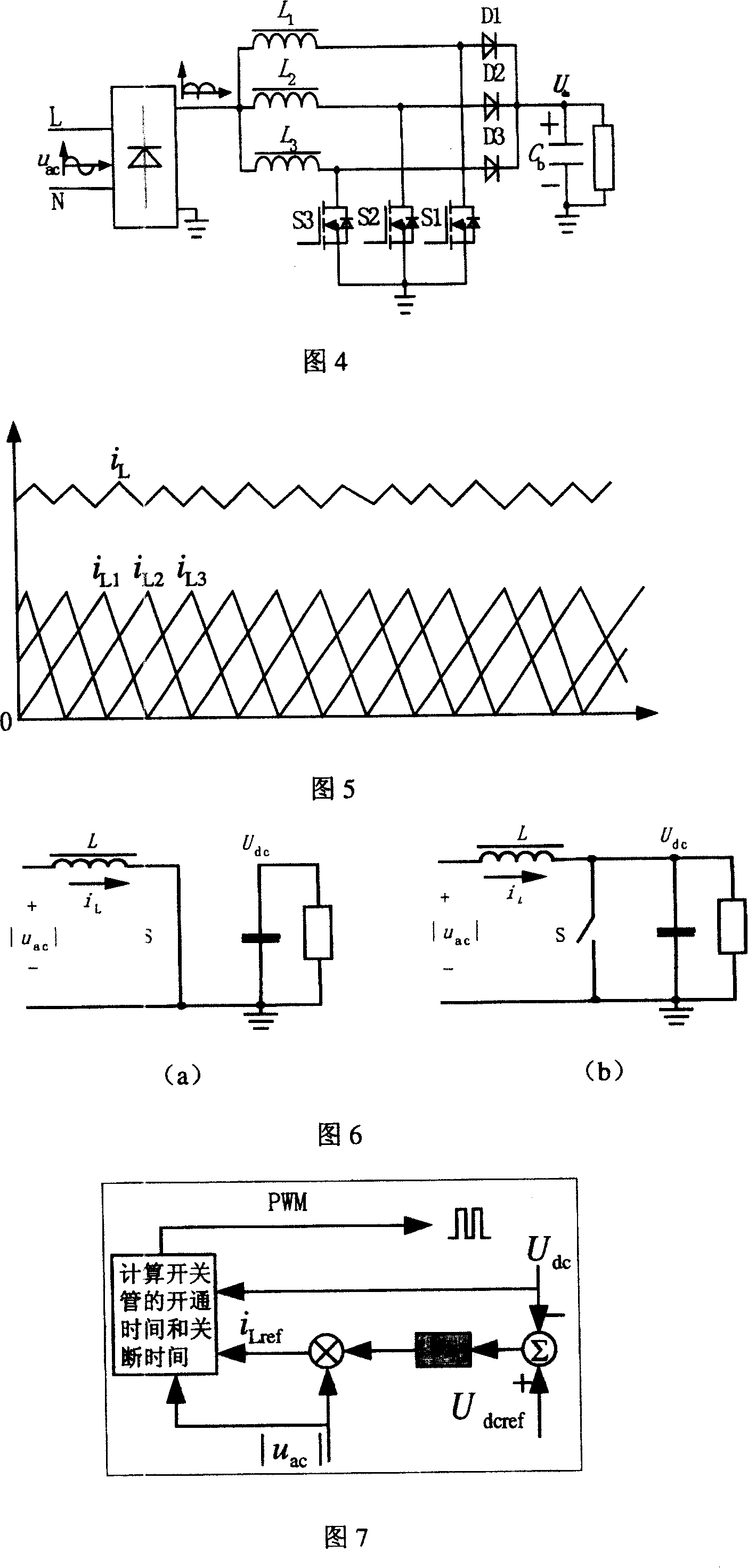

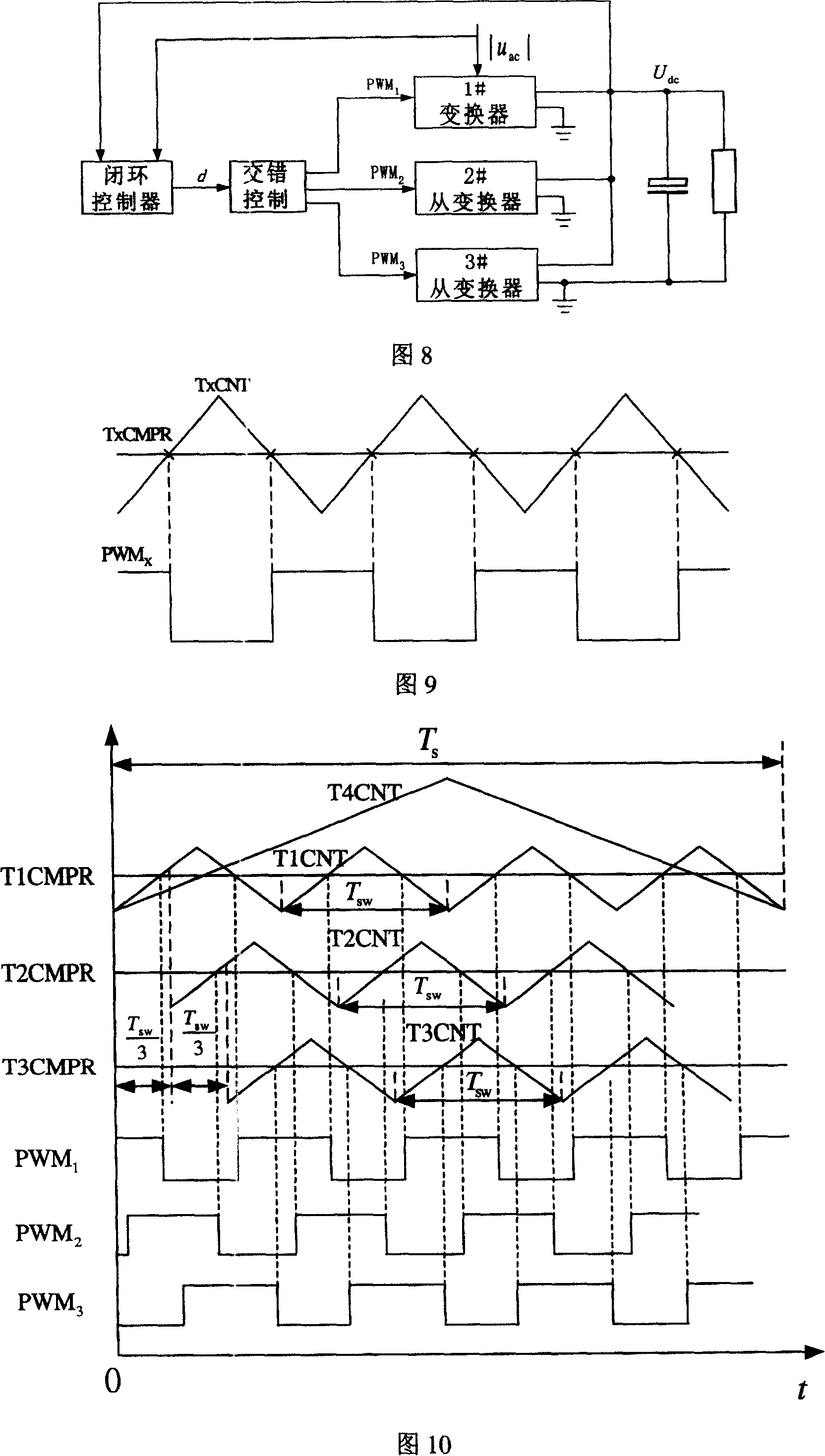

[0053] The deadbeat controller proposed by the present invention is obtained based on two operating modes of the BCM Boost APFC converter. The two operating modes of the BCM Boost APFC converter are shown in Figure 6, and the proposed deadbeat control scheme is shown in Figure 7 shown. The proposed parallel and interleaved operation scheme of multiple BCM Boost converters based on a single DSP realized by variable sampling frequency is shown in Figure 8, Figure 9 and Figure 10.

[0054] In the working mode shown in Figure 6(a), the inductor current i L = | u ac | L t on , In the working mode shown in Figure 6(b), i L = U dc - | ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com