Double-ring tribranched chain contraction and enlargement type parallel structure

A zoom-type, three-branched technology, which is applied in the direction of manipulators, program-controlled manipulators, and manufacturing tools, can solve the problems of insufficient high rigidity, small position and attitude work space, etc., so as to save the reducer, good motion accuracy, The effect of reducing size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

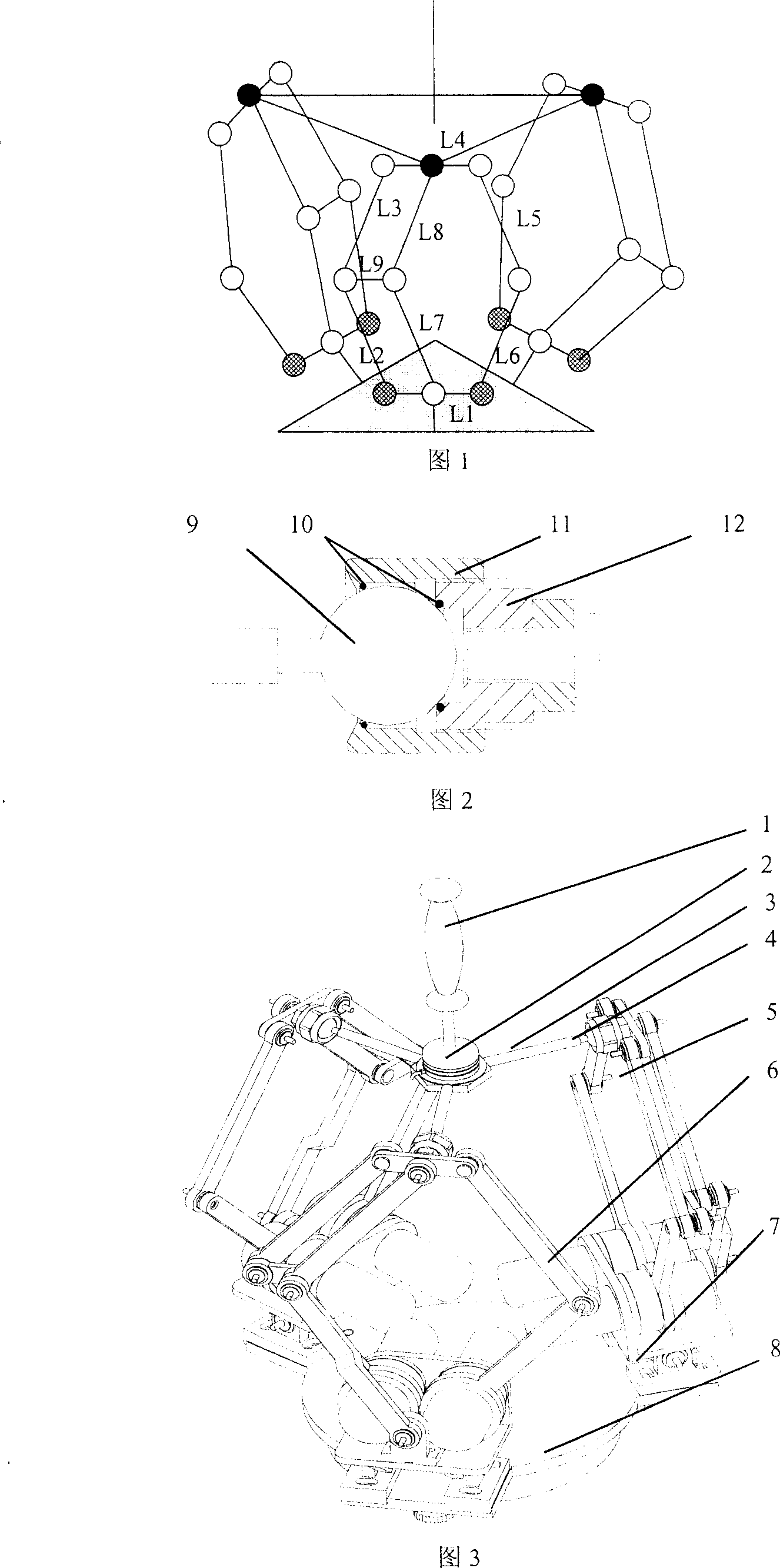

[0016] Combined with Fig. 3, the composition of the parallel main hand includes the lower platform 8, the upper platform 3 and three branch chains connected between the upper and lower platforms. The center of the three branch chains is symmetrically distributed. The rod is composed of a pantograph mechanism 5 connected by a rotating pair, the lower swing rod is connected to the lower platform through a rotating pair, the pantograph mechanism is connected to the upper platform through a ball hinge 4, and two drive motors 6 are installed at both ends of the horizontal rod at the bottom of the pantograph mechanism. A handle 1 is arranged in the middle of the upper platform, and a force sensor 2 is installed at the joint between the handle and the upper platform. Referring to FIG. 2 , the composition of the ball pair includes: a ball 9 , a ball 10 , a collar 11 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com