Elastomeric composition

A technology of elastomers and compositions, applied in the field of low-permeability elastomer compositions, which can solve the problems of natural rubber loss of ideal properties, loss of processing properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

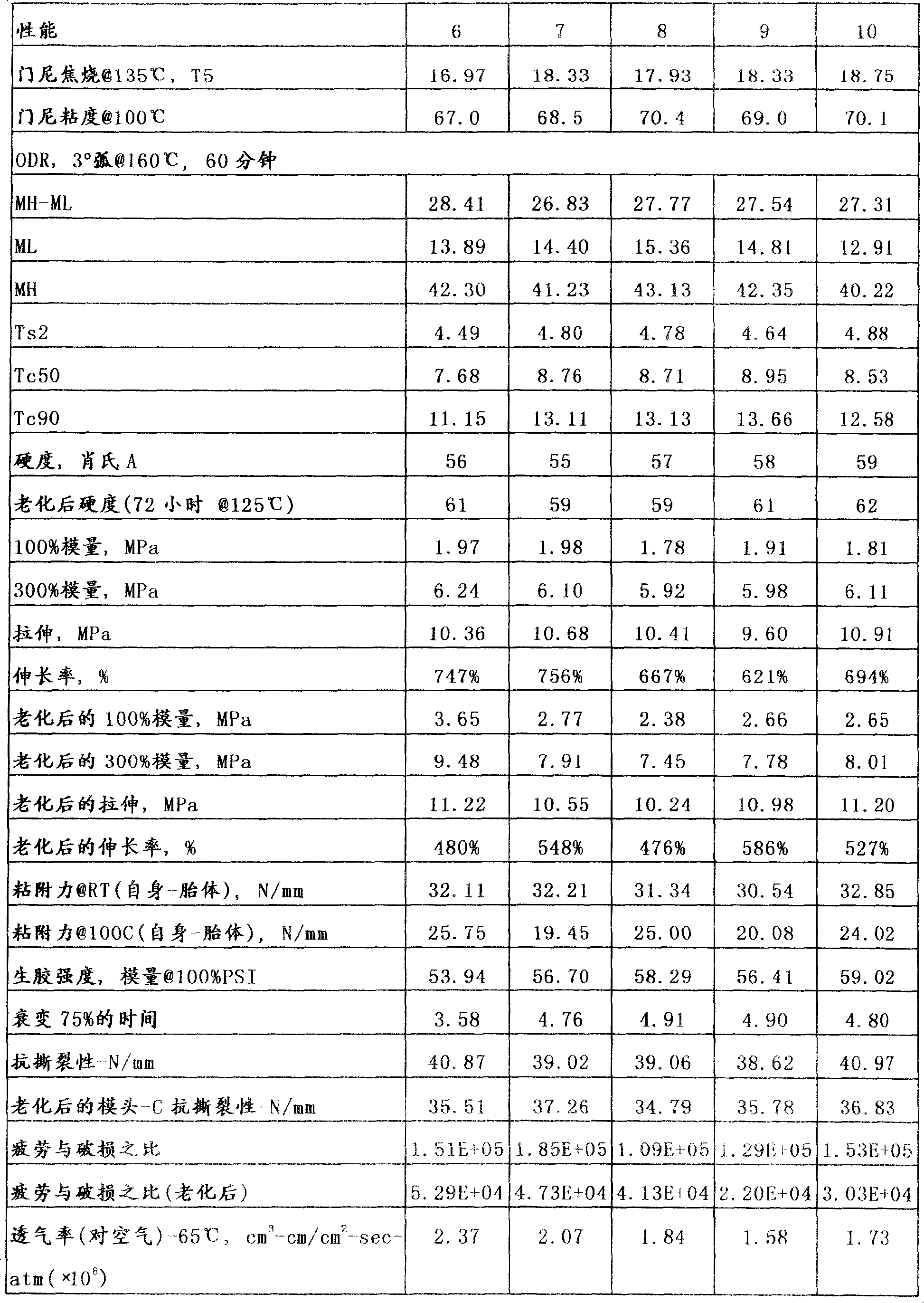

[0095] Compositions 1-15 (Tables 3-5) illustrate the benefits of incorporating polybutene processing oils in blends of isobutylene copolymers containing halomethylstyrene moieties. Compositions 1, 6 and 11 represent halogenated isobutylene-p-methylstyrene copolymers containing varying amounts of halogenation and varying amounts of p-methylstyrene (PMS) (see Table 3). Incorporation of PARAPOL TM The compositions have improved air permeability while improving or maintaining processing properties such as green strength and fatigue-to-breakage ratio (Tables 6-8).

[0096] Compositions 16-21 (Table 9) illustrate the benefits of incorporating polybutylene processing oils in blends of isobutylene-based polymers such as HSSB with another rubber such as natural rubber and exfoliated clay. Composition 16 is HSSB only (SBB-6222, 100phr), composition 17 is natural rubber and PARAPOL only TM (90phr SBB, 10phr natural rubber). Typically, halogenated rubbers such as HSSB have a desirably ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap