Process of producing cold re-treading rubber

A manufacturing method and tread rubber technology, which is applied in the field of cold retread manufacturing, can solve problems such as high temperature damage, poor tread wear resistance, and aging of the carcass, and achieve high vulcanization pressure, high rubber adhesion, and vulcanization temperature. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

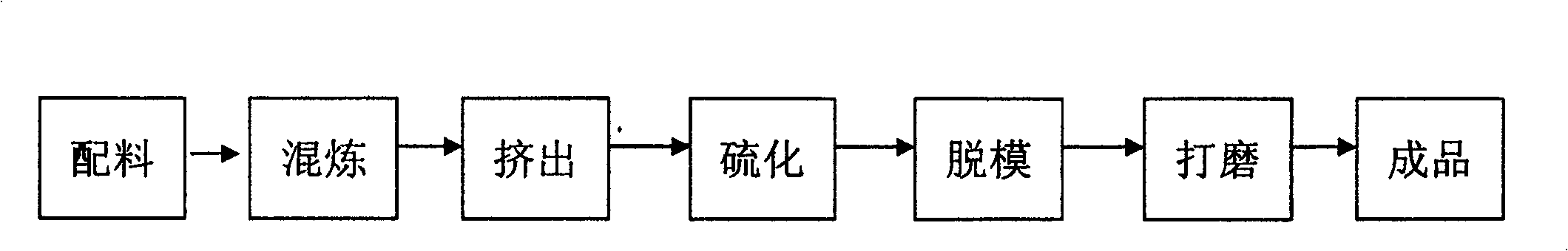

[0016] A kind of manufacture method of cold retread tread compound, such as figure 1 As shown, the following steps are taken:

[0017] a. Ingredients: weigh the raw materials according to the formula;

[0018] b. Mixing: Mix the weighed raw materials in the internal mixer according to the process, control the mixing temperature below 90°C, and then cool with cooling water to make a mixed rubber;

[0019] c. Extrusion: Control the extrusion temperature below 80°C, the thickness is 14-20mm, and extrude the mixed rubber to the required thickness on the extruder;

[0020] d. Vulcanization: Control the vulcanization pressure to 13-15MPa, time to 20-30min, and temperature to 145-165°C, put the extruded film into a specific mold, and put it into a flat vulcanizer for vulcanization.

[0021] e. Demoulding: remove the vulcanized adhesive tape from the mold;

[0022] f. Grinding: Grinding the working surface of the tread rough;

[0023] g. Finished product: inspection, marking, pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com