Device angle for regulating of vehicle light

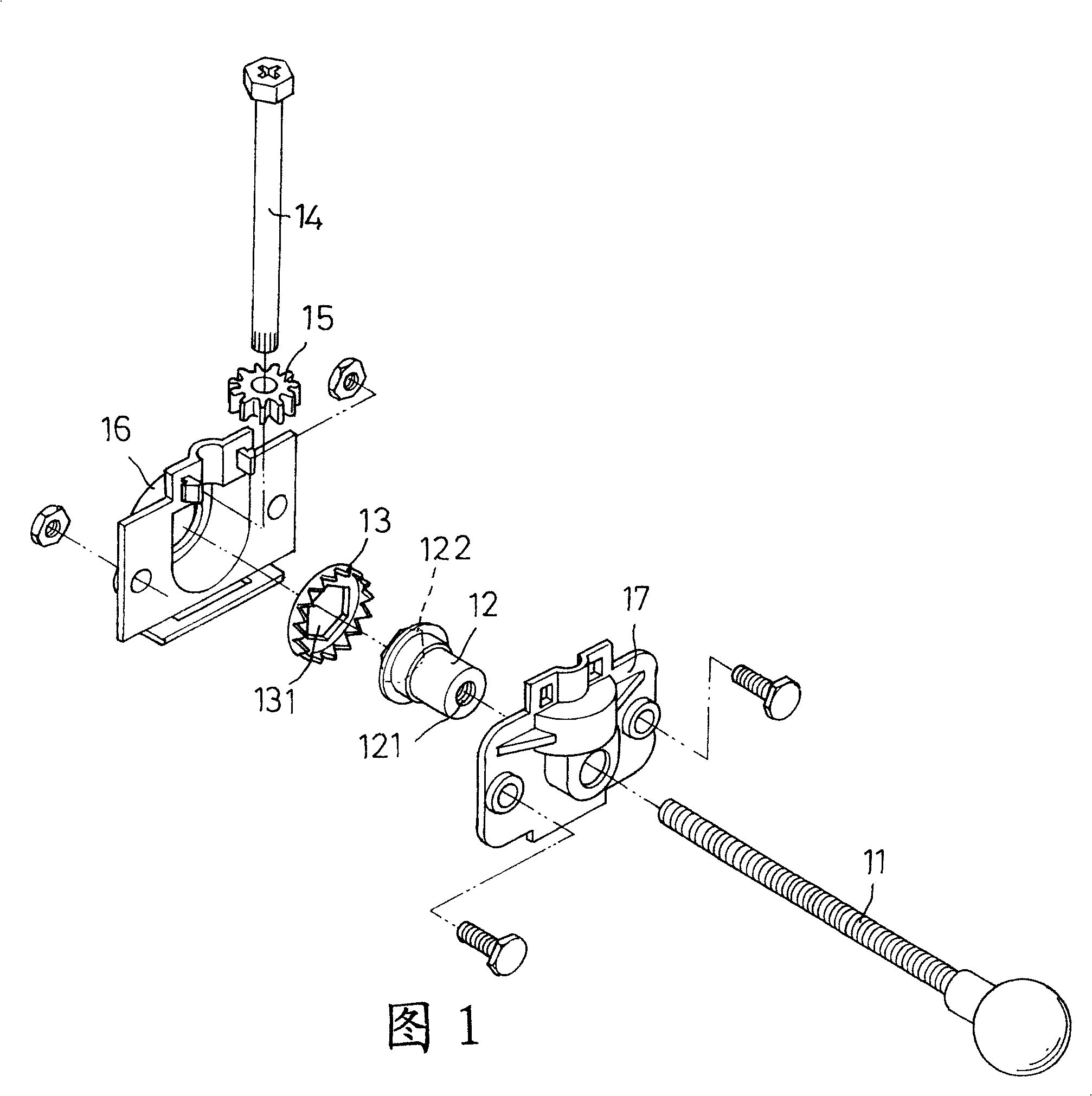

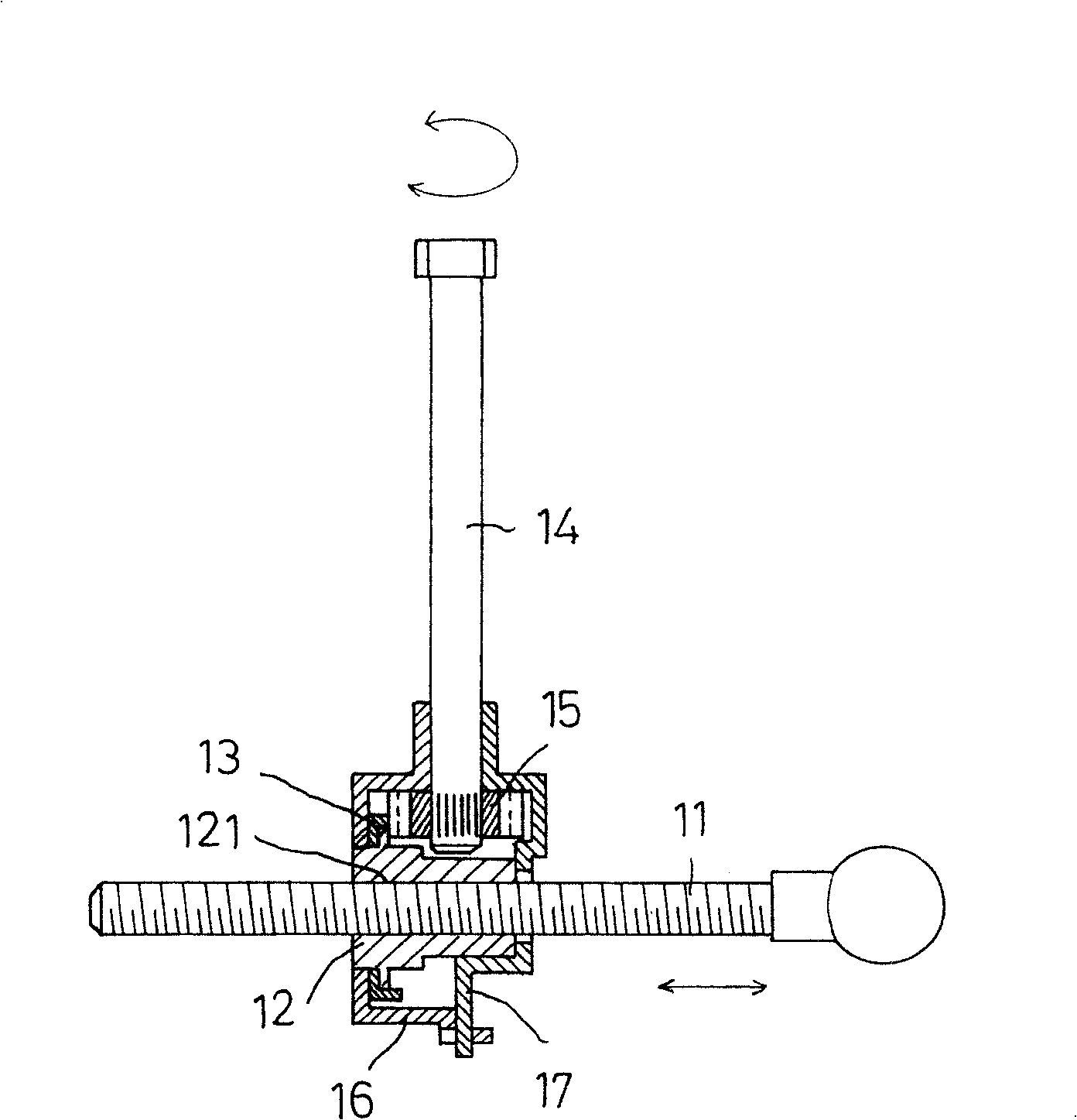

A technology for angle adjustment device and car lamp, which is applied to lighting device, transmission device, friction transmission device, etc., can solve the problems of inability to accurately set the displacement stroke of screw 11, occupying space, and low adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

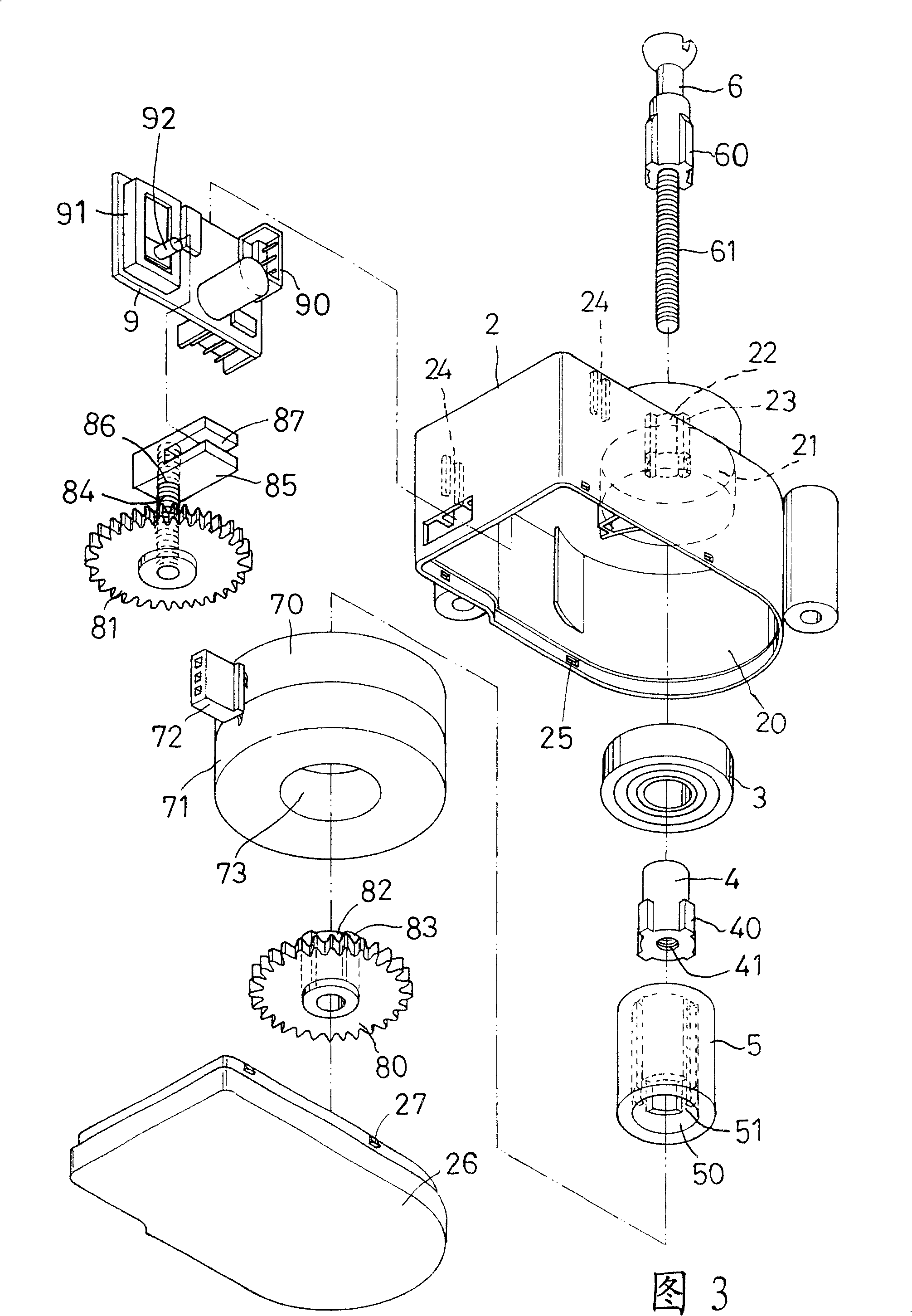

[0015] First of all, please refer to Fig. 3, the present invention is mainly provided with a casing 2, the casing 2 is provided with a chamber 20, the chamber 20 is provided with an alcove 21, and the alcove 21 is provided with a perforation 22 , the peripheral wall of the perforation 22 is provided with several positioning slots 23, the inner wall of the chamber 20 is oppositely provided with two slots 24, the wall surface of the casing 2 is provided with several embedded holes 25, and the bottom of the casing 2 is covered. There is a bottom cover 26, and several inlays 27 are arranged on the wall surface of the bottom cover 26; a bearing 3 is arranged in the alcove 21 of the casing 2; a connecting piece 4 is arranged under the bearing 3, and the connecting piece 4 One end of the connecting piece is set on the bearing 3, the peripheral wall of the connecting piece 4 is provided with several convex bodies 40, and the center of the connecting piece 4 is provided with a screw hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com