Method for operation of fast running knitting machine

A technology of knitting machines and driving devices, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of complex and expensive machines, and achieve the effects of improving resolution, fast implementation, and simplifying data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

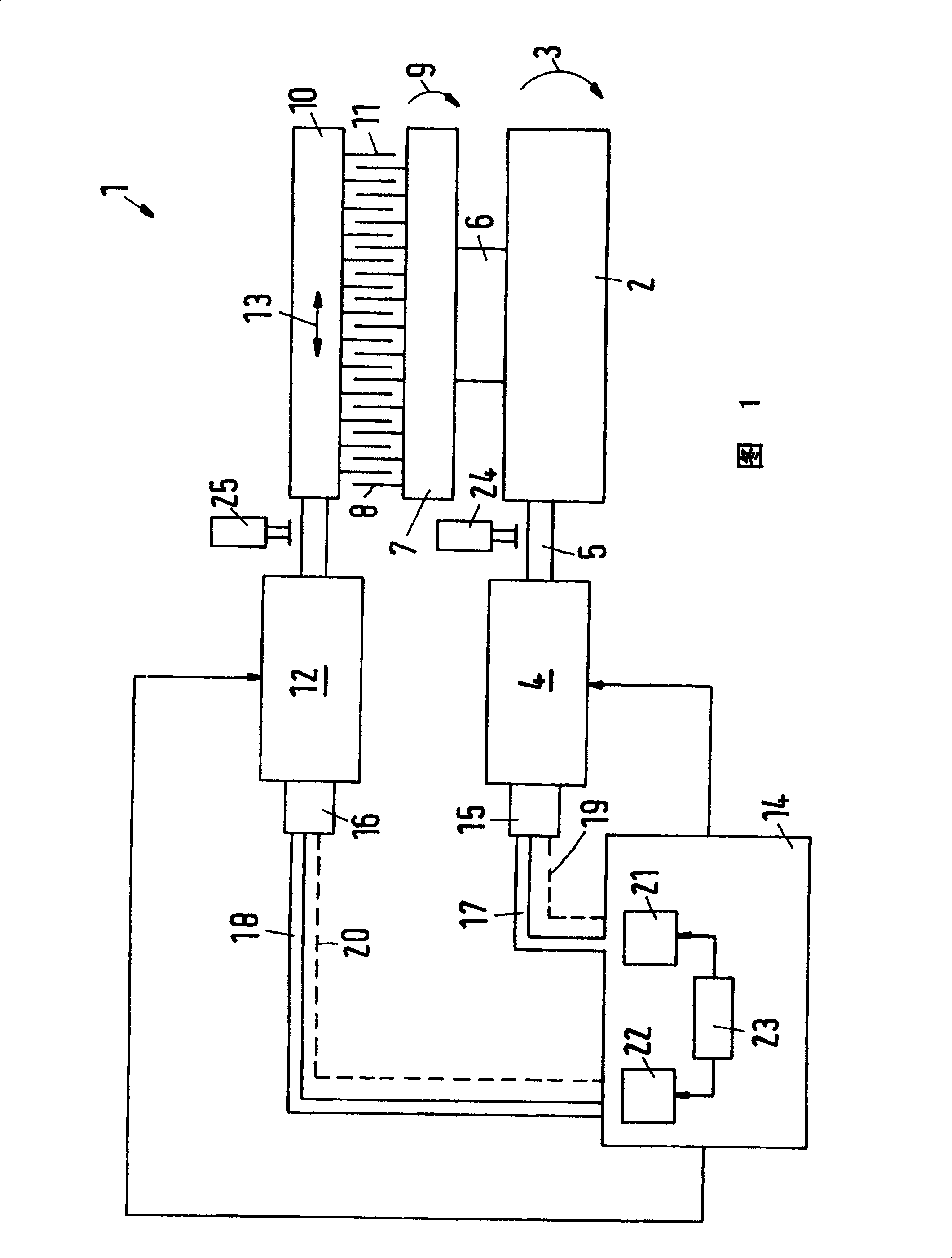

[0021] The chain knitting machine 1 has a main shaft 2 which is rotatably driven in the direction of the arrow 3 . To generate the rotational movement, the main shaft 2 is provided with a drive 4 , for example an electric motor, which is connected to the main shaft 2 via a clutch 5 .

[0022] The spindle 2 is connected to a working needle bar 7 via a coupling joint 6 which is only schematically shown. The working needle mattress carries a number of working needles 8 and is deflected back and forth in the direction of the double arrow 9 .

[0023] A leg barre 10 has a plurality of comb needles 11 which, in the shown case, are located in the seams between the working needles 8 . The bar 10 is connected to a drive 12 which reciprocates the bar 10 laterally in the direction of the double arrow 13 . Now, during operation, the movement of the working needle 8 (pivoting movement) and the movement of the comb needles 11 (linear movement) are brought into such agreement with one anot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com