Manufacturing method of spring core of elastic glasses foot

A manufacturing method and technology for glasses legs, which are applied in the field of glasses, can solve the problems such as difficulty in controlling the gap size of the spring core, insufficient diagonal size accuracy, unsuitability for mass production, etc., achieving easy control of the gap size, low production cost, and the The effect of high angular dimension accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

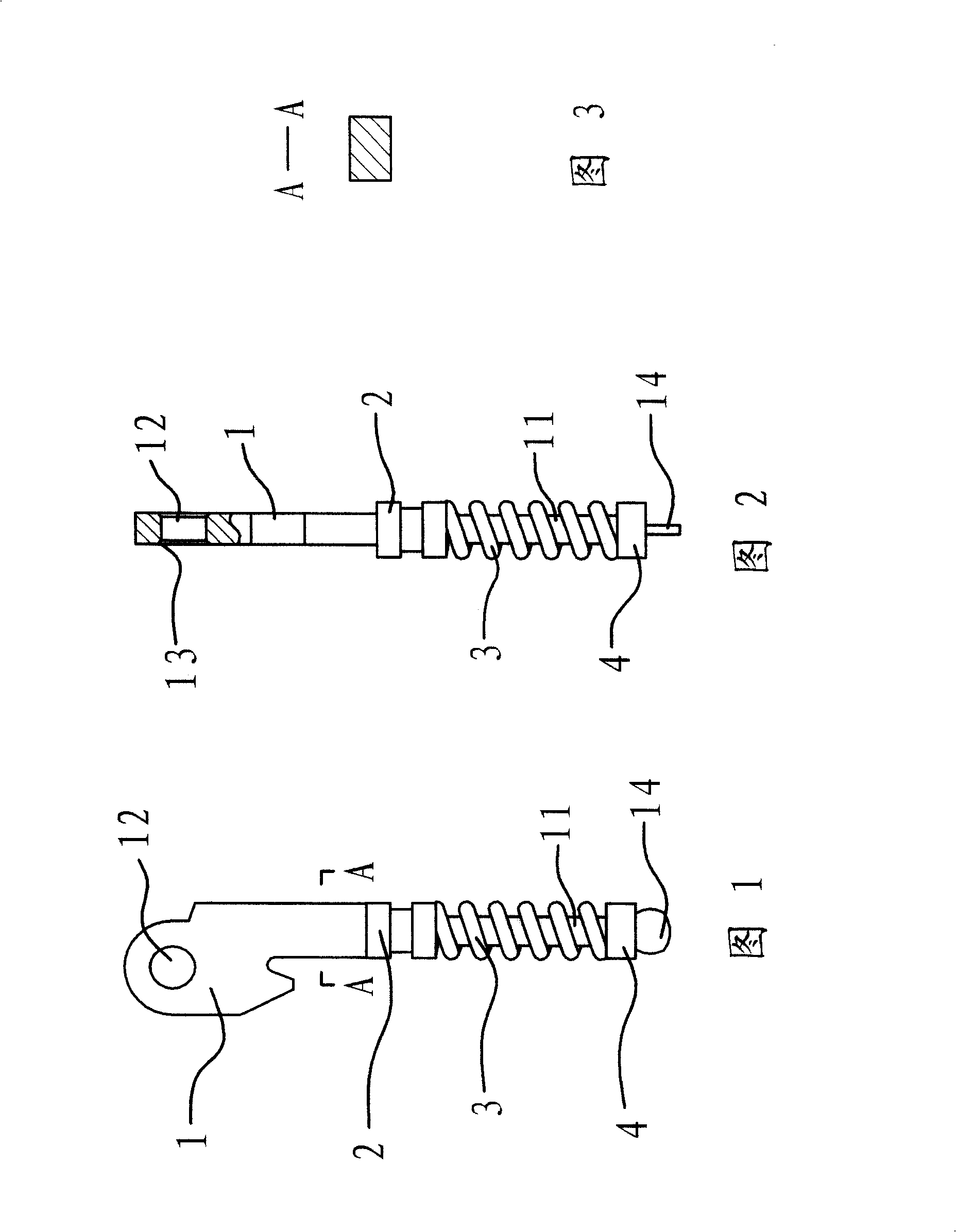

[0038] As shown in Fig. 1 and Fig. 2, the spring core for elastic spectacle legs made by the present invention comprises parts such as core body 1, grooved tubule 2, helical compression spring 3, sealing tubule 4; The spring 3 and the tail-sealing small tube 4 are sequentially set on the core body 1. The tail of the core body 1 forms a stopper 14 after being flattened and rounded. The upper end of the core body 1 is drilled with a small hole 12, wherein the spring core The diagonal dimension accuracy is relatively high, as shown in Figure 3.

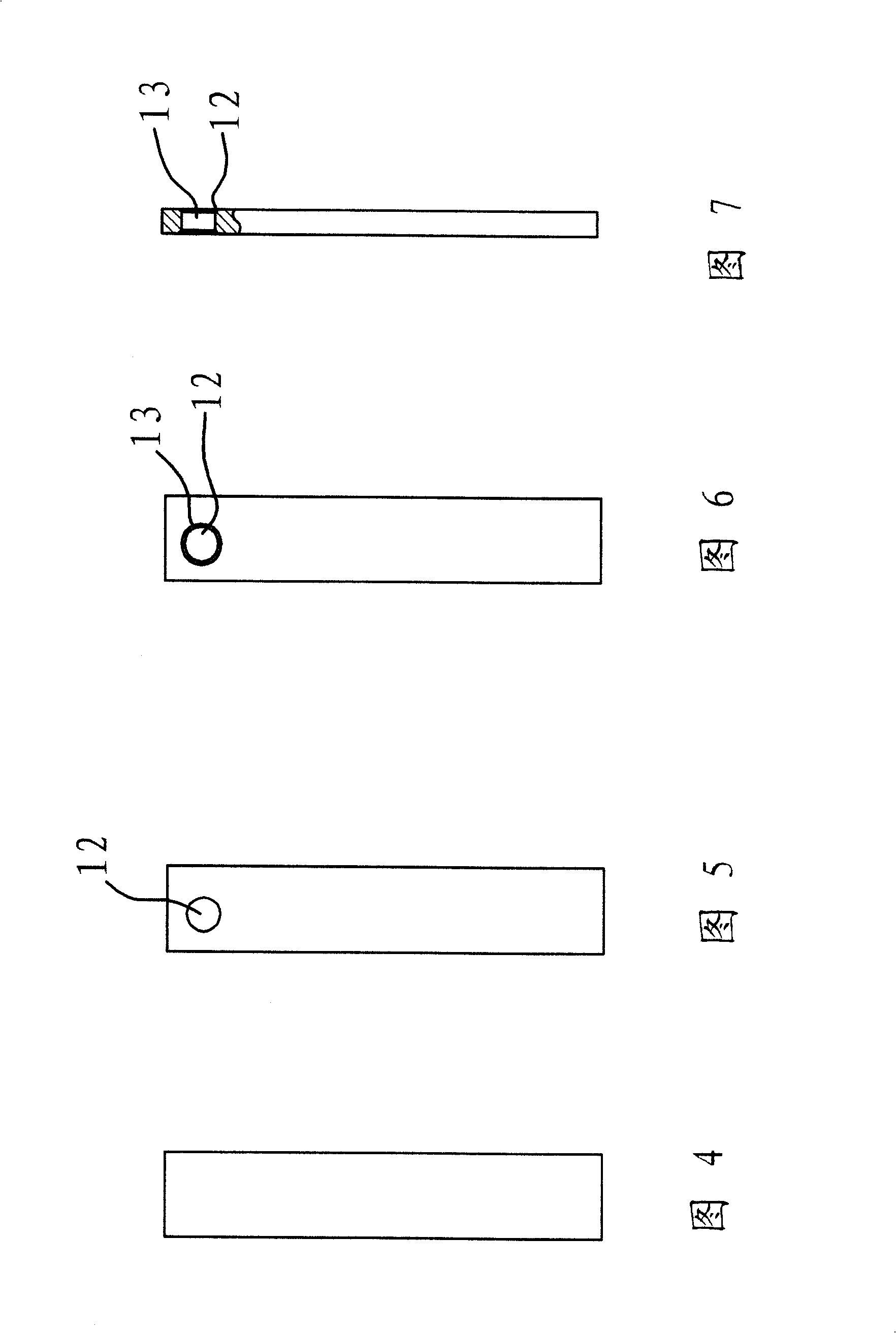

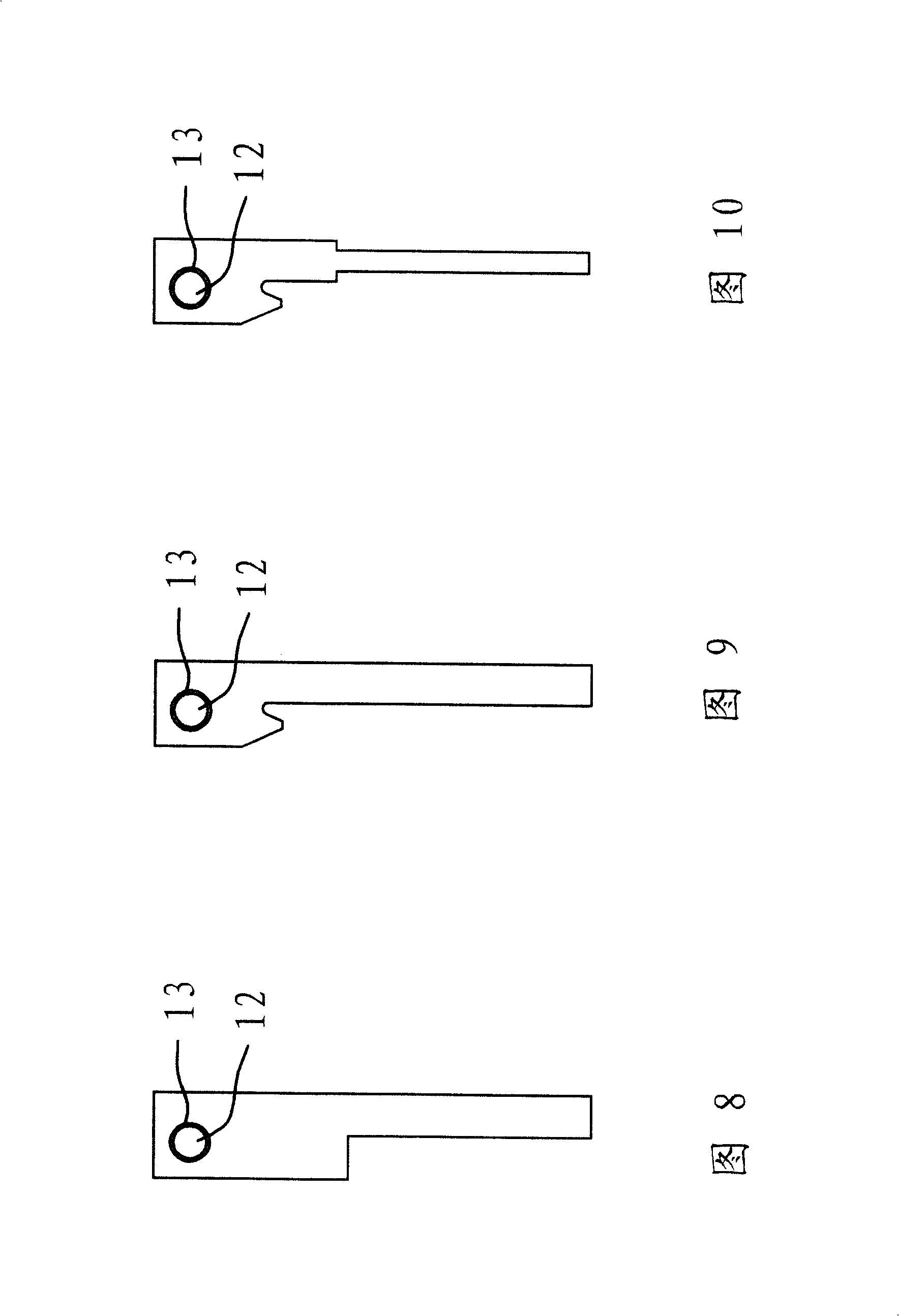

[0039] According to the thickness of the spring core used for elastic spectacle feet, choose zinc white copper or stainless steel plate, and use the punching method to cut the plate into the length and width of the core body 1 blank, and then put the core body 1 blank into the ultrasonic cleaning and vibrating machine Internal coarse vibration; at this time, the schematic diagram of the front structure of the core body 1 is shown in FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com