High ignition rate piezoelectric lighter

A technology of ignition rate and lighter, which is applied in the direction of combustion ignition, igniter with fuel, combustion method, etc., can solve the problems of poor ignition rate of finished products, low assembly efficiency, manual thread trimming, etc., and it is easy to achieve the gap size and small deviation , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

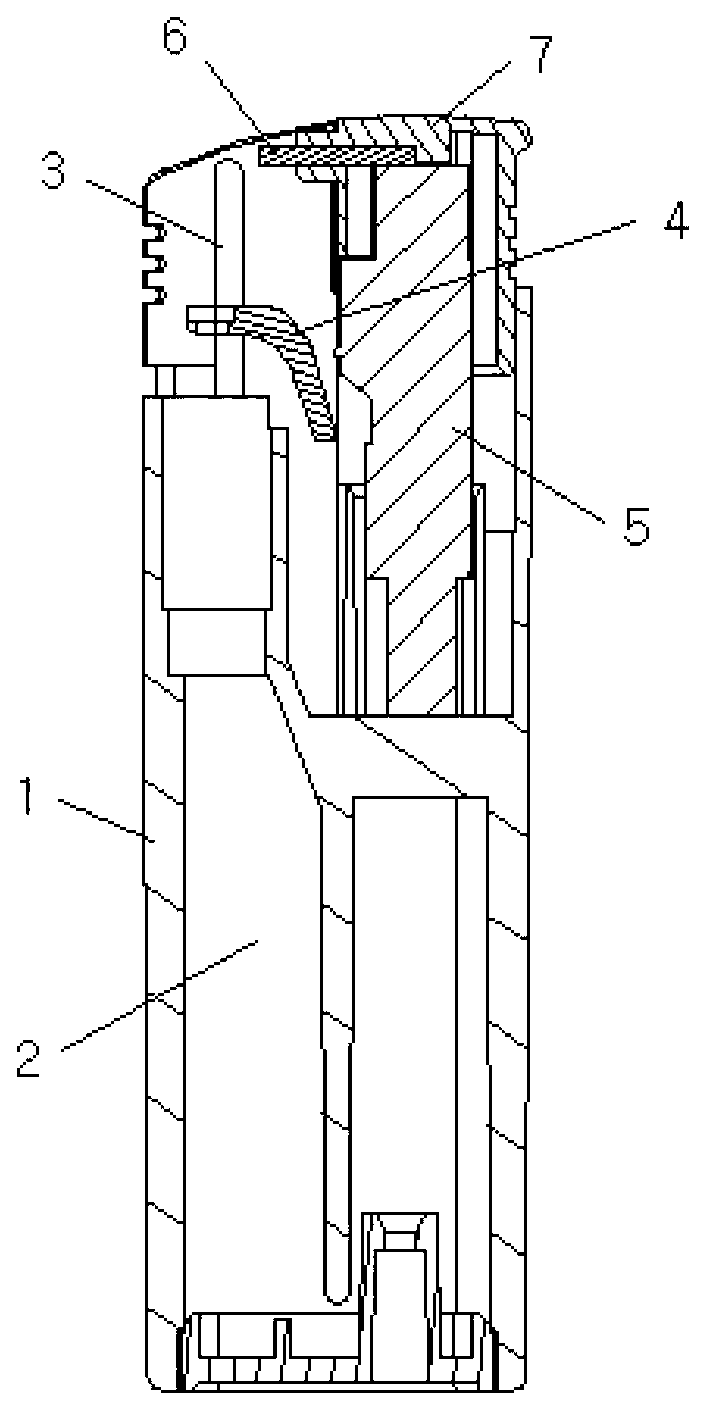

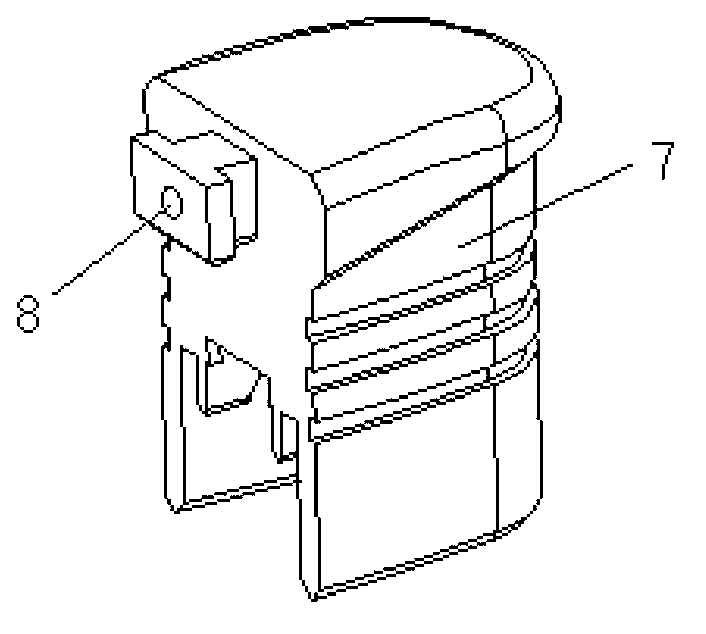

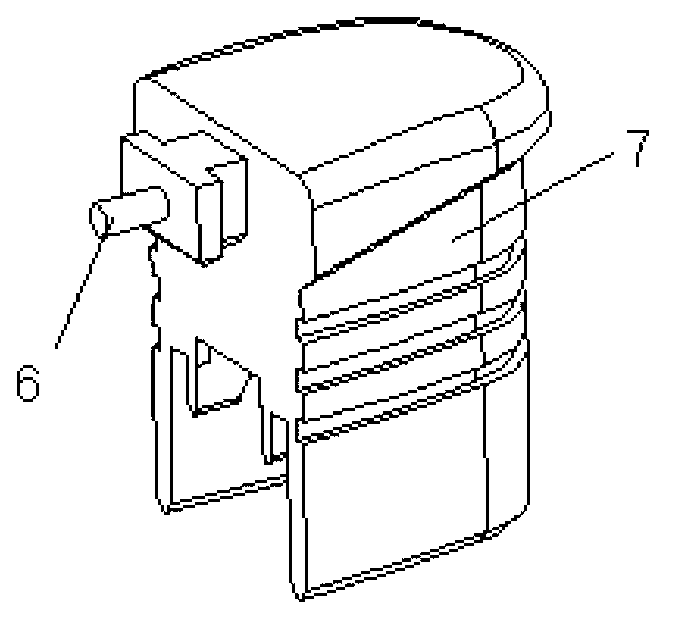

[0017] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0018] Such as Figure 1-Figure 3 As shown, a high ignition rate piezoelectric lighter provided by the embodiment of the present invention includes a lighter body 1 and a piezoelectric body 5 installed on the lighter body;

[0019] The lighter body 1 is provided with a gas cavity 2, and is provided with a gas nozzle 3 communicating with the gas cavity 2, and a rocker 4 for controlling the opening and closing of the gas nozzle 3, for pressing the rocker 4 and the piezoelectric body 5's ignition and laying of hands 7;

[0020] The gas nozzle 3 and the rocker 4 are conductors, one end of the rocker 4 is connected to the gas nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com