Oil smoke waste gas sample collecting and determining method and sample collecting device in nylon spinning

A collection device and oil fume technology, which is applied in the direction of measuring device, sampling device, color/spectral characteristic measurement, etc., can solve the problem that there are few analysis and researches on the exhaust gas of nylon spinning oil fume, and there is no determination method and emission standard of oil fume exhaust gas from nylon spinning. and other problems, to achieve the effect of simple and reliable sampling method, small deviation of analysis results, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

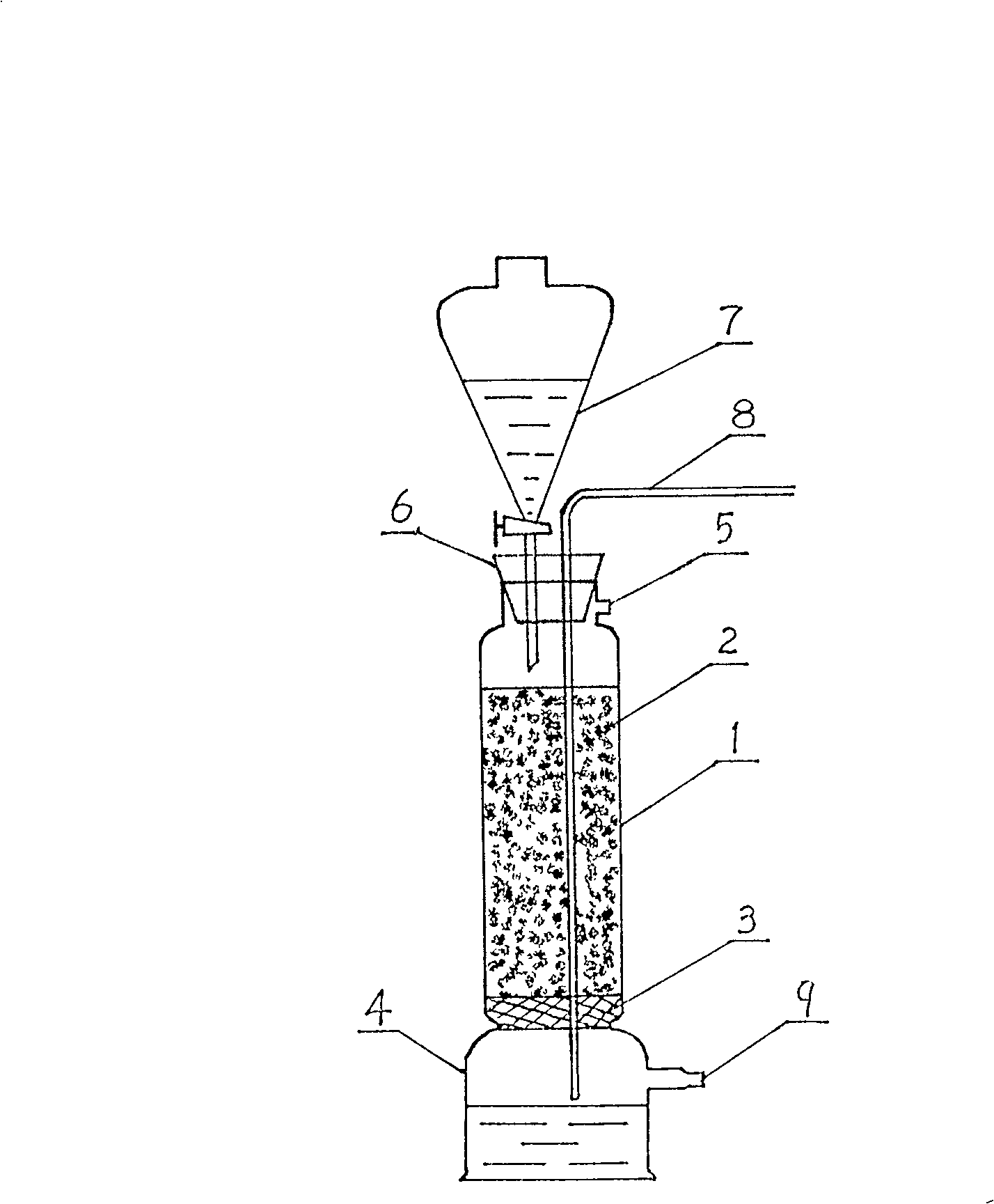

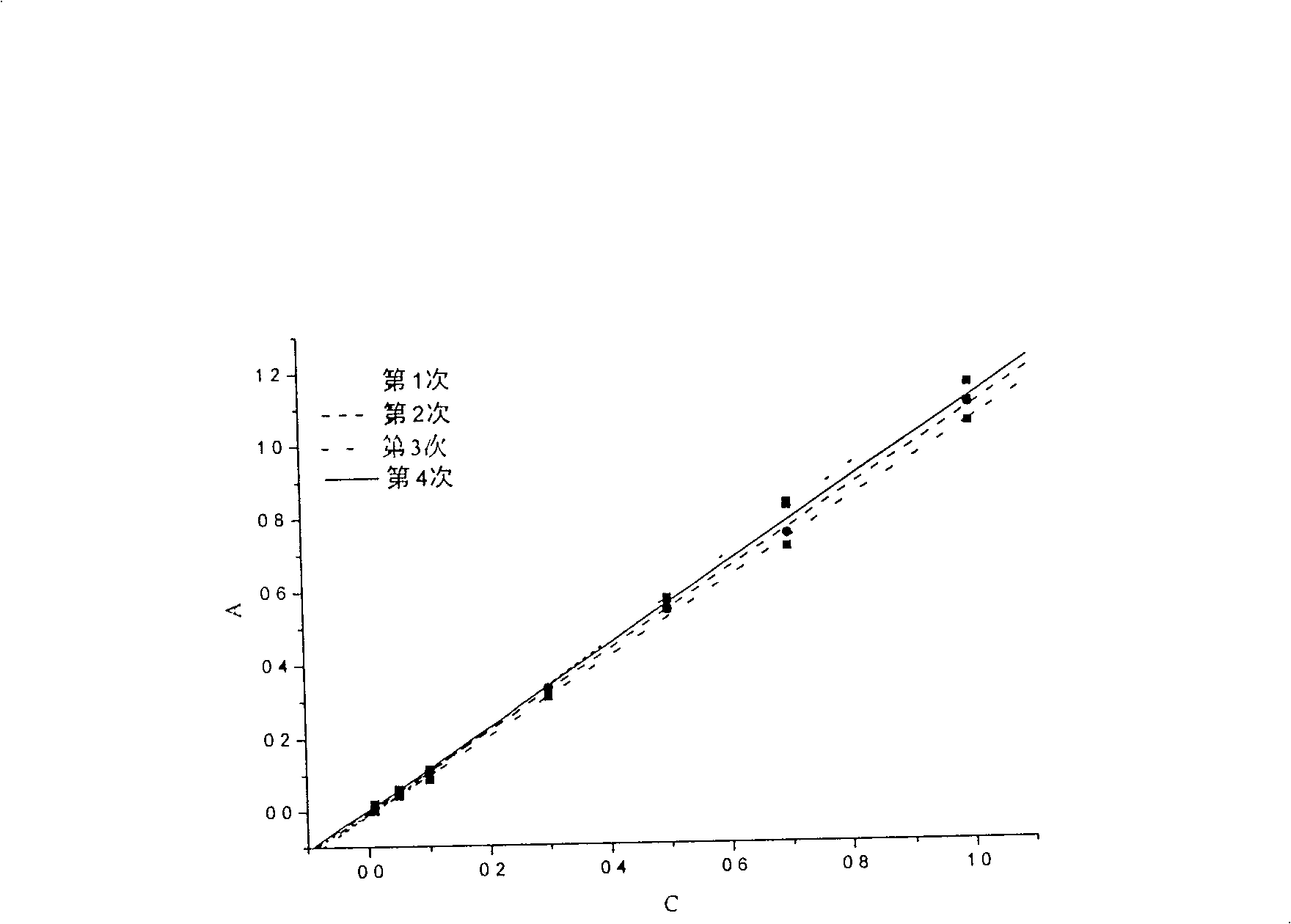

[0022] Embodiment 1, the collection and determination method of nylon spinning oil fume waste gas sample, make the oil fume waste gas to be measured pass through the ceramic (Φ3mm) packing layer in the waste gas sample collection device at a uniform speed from bottom to top, and simultaneously make carbon tetrachloride from top to bottom The exhaust gas is absorbed through the packing layer at a uniform speed, the flow rate of oily fume exhaust is 5L / min, the absorption time is 10min, and the absorption liquid is fixed to a volume of 100ml. Gained absorbing solution takes carbon tetrachloride as blank, and uses infrared spectrophotometer at 3400cm -1 -2400cm 1 Scan between them, measure the absorbance value, and compare the working curve to get the concentration of the oil fume exhaust gas to be tested.

[0023] The sample collection device includes a transparent glass tube 1 with built-in ceramic (Φ3mm) filler 2, and the aspect ratio of the glass tube is 20 / 1. A stainless s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com