Miniature heat-collecting pump

A heat-collecting and miniature technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of rising chip heat, increased leakage current, increased installation and maintenance costs, etc., to improve heat collection capacity, reduce installation space, The effect of enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

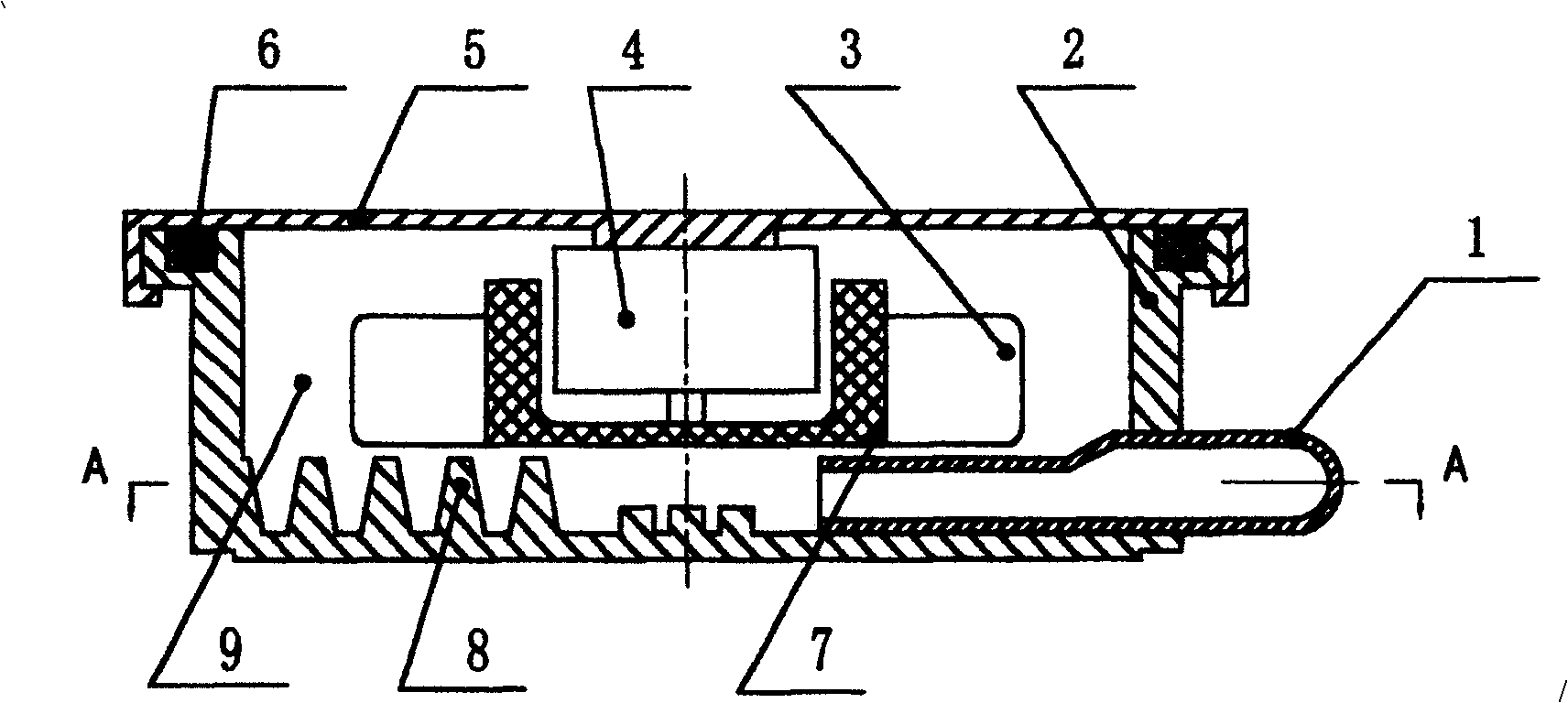

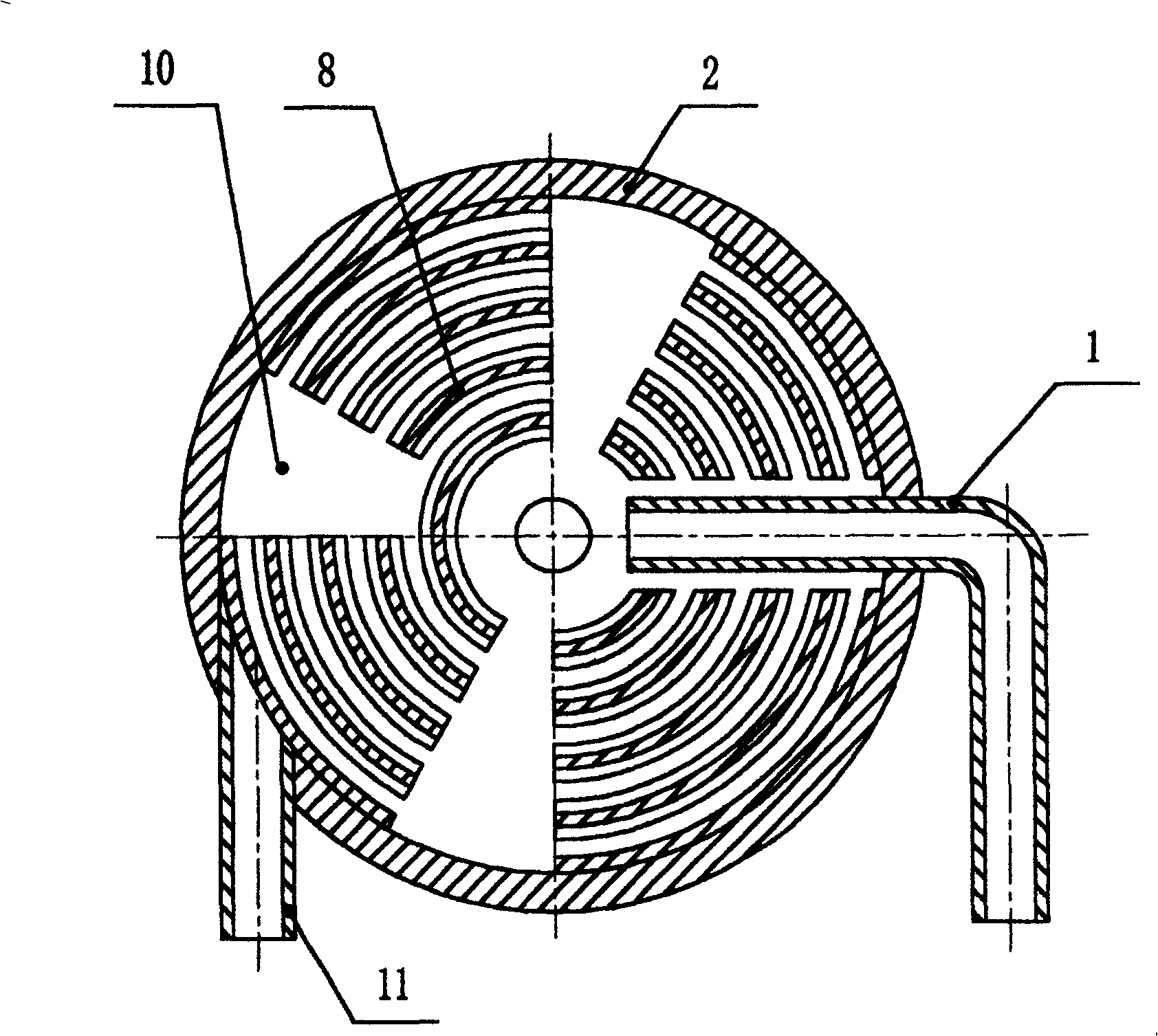

[0029] Such as figure 1 , figure 2 As shown, the micro-collector heat pump includes a water inlet pipe 1, a pump body 2, blades 3, a motor 4, a pump cover 5, a sealing ring 6, an impeller 7, and a water outlet pipe 11, and the pump cover 5 is fixedly connected with the pump body 2. A sealing ring 6 is arranged between the pump cover 5 and the pump body 2, the cavity between the pump cover 5 and the pump body 2 is a water chamber 9, and the pump body 2 is provided with a water inlet pipe 1 and an outlet pipe 11, and the water inlet pipe 1 and the outlet pipe The water pipes 11 communicate with the water chamber 9 respectively. The water inlet pipe 1 is located on the side of the pump body 2 near the bottom, and the outlet of the water inlet pipe 1 is located at the inner middle of the bottom of the pump body; Inside, the motor 4 is fixedly connected to the pump cover 5, and the output of the motor 4 is fixedly connected to the impeller 7. There are four blades 3 on the impell...

example 2

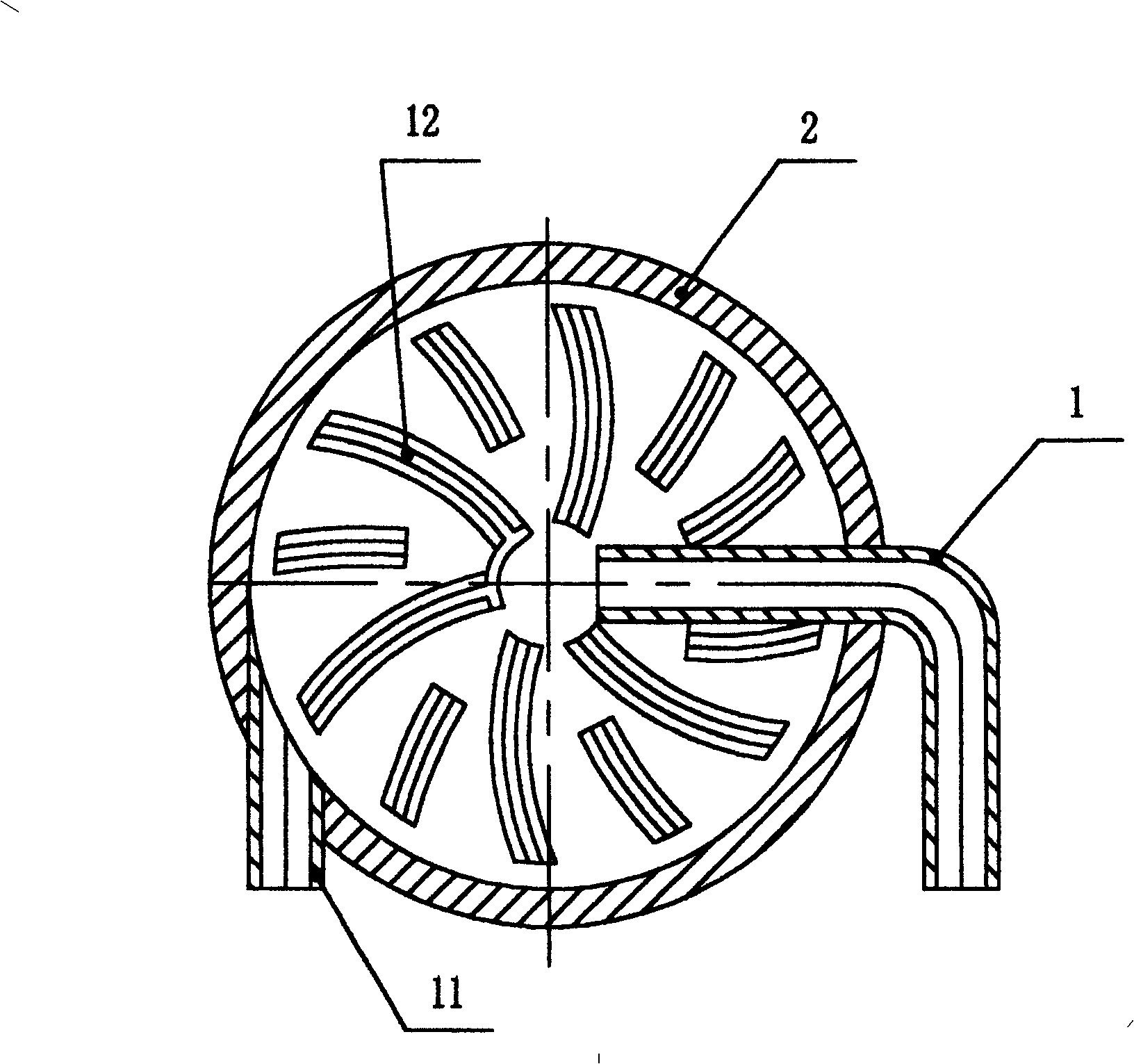

[0031] Such as figure 1 , image 3 As shown, the micro-collector heat pump includes a water inlet pipe 1, a pump body 2, blades 3, a motor 4, a pump cover 5, a sealing ring 6, an impeller 7, and a water outlet pipe 11, and the pump cover 5 is fixedly connected with the pump body 2. A sealing ring 6 is arranged between the pump cover 5 and the pump body 2, the cavity between the pump cover 5 and the pump body 2 is a water chamber 9, and the pump body 2 is provided with a water inlet pipe 1 and an outlet pipe 11, and the water inlet pipe 1 and the outlet pipe The water pipes 11 communicate with the water chamber 9 respectively, the water inlet pipe 1 is located at the side of the pump body 2 near the bottom, the outlet of the water inlet pipe is located at the inner middle of the bottom of the pump body; the motor 4, the impeller 7 and the blade 3 are located in the water chamber 9 , the motor 4 is installed on the pump cover 5, the output of the motor 4 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com