Patents

Literature

30results about How to "Faster thermal cycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

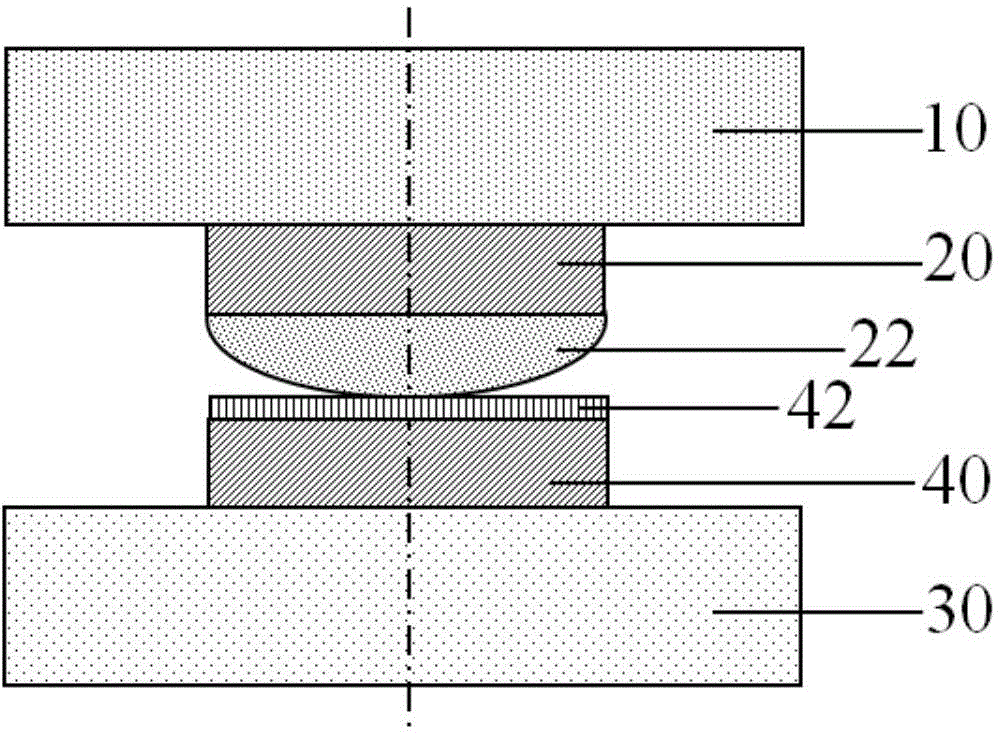

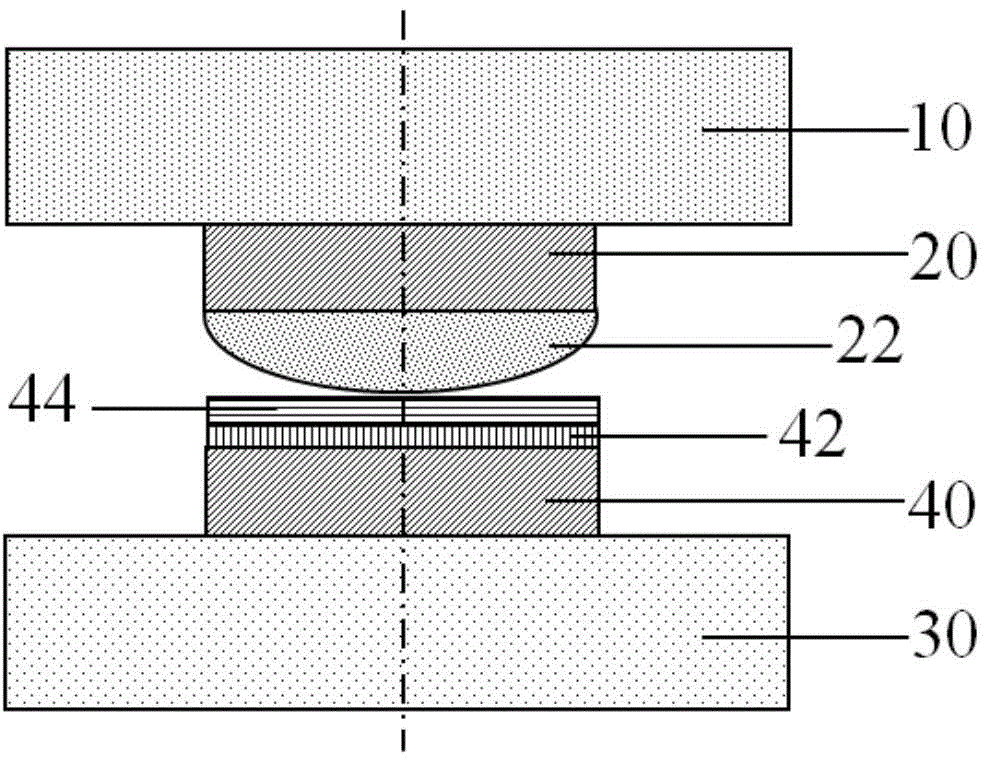

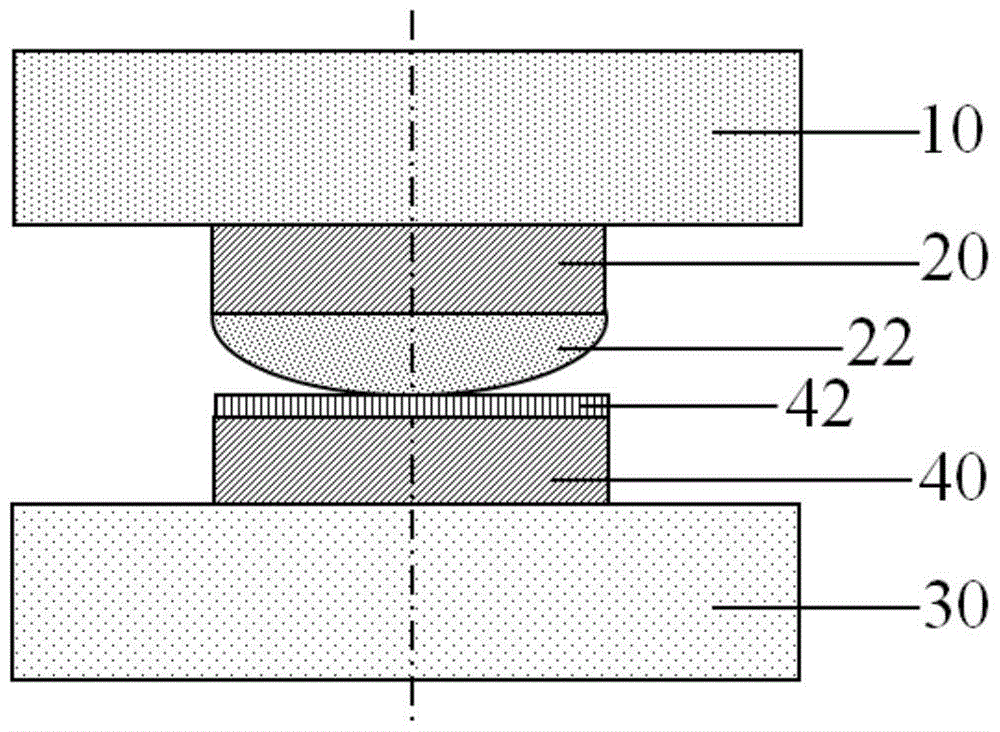

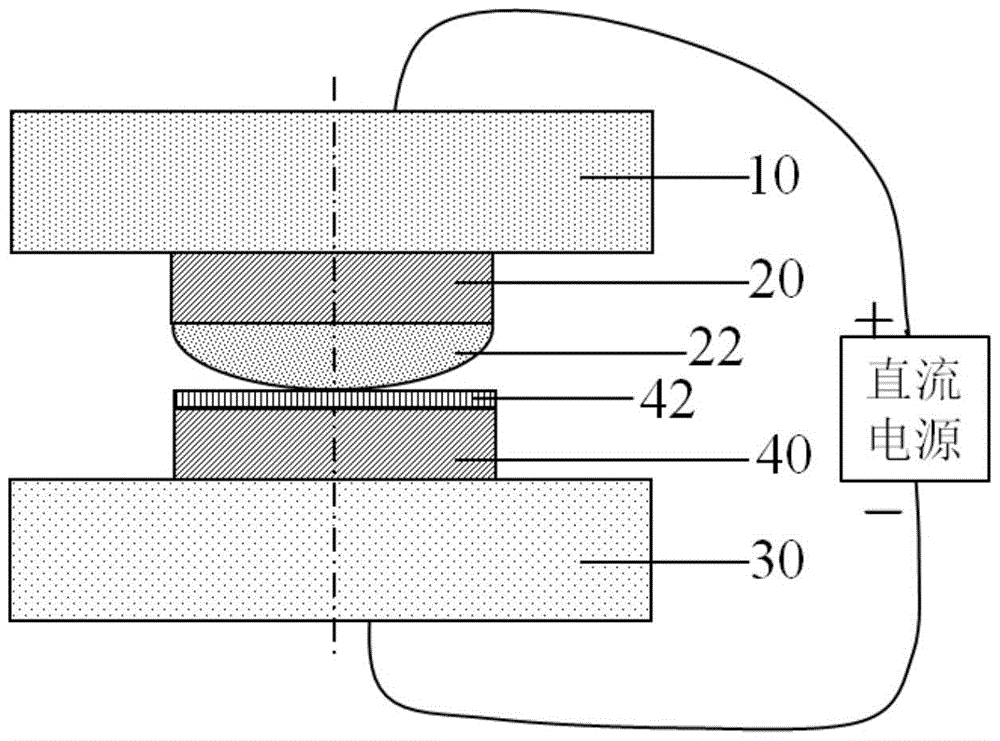

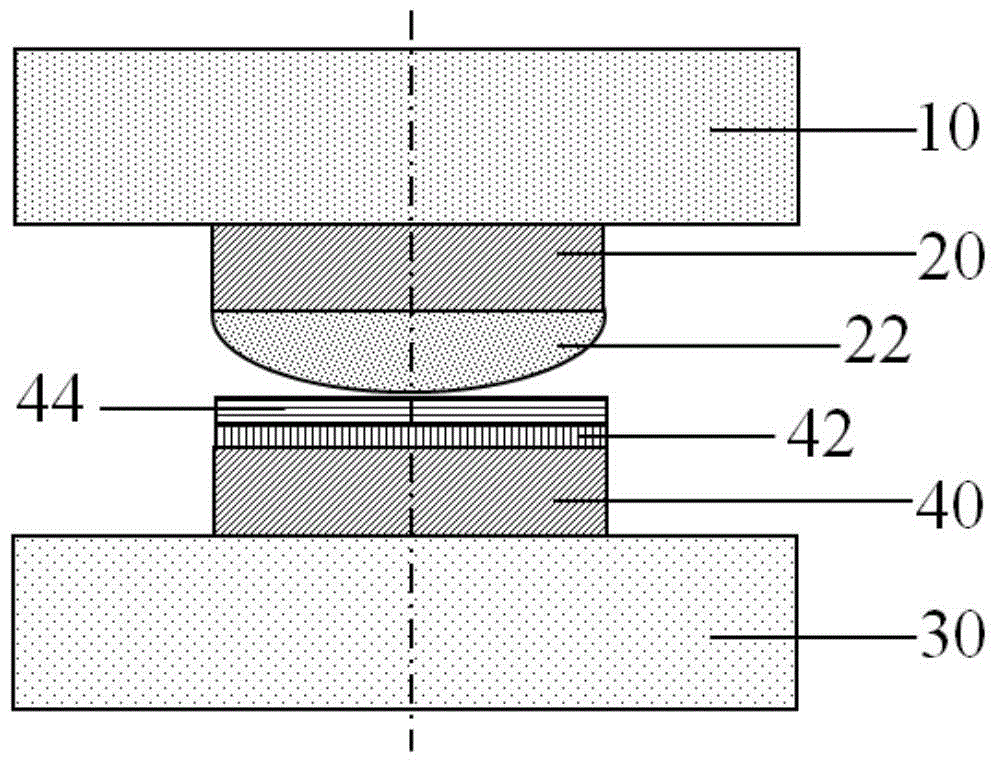

Preparation method and structure of fully intermetallic compound interconnection solder joints

ActiveCN104690383AImprove fatigueFaster thermal cyclingMetal working apparatusSoldering auxillary devicesSingle crystalInterconnection

The invention discloses a preparation method and a structure of fully intermetallic compound interconnection solder joints. The preparation method comprises the following steps: preparing single crystal or preferentially orienting a first metal pad and solder bumps on a first substrate, preparing a second metal pad and a solderable layer on a second substrate, aligning and contacting the solder bumps and the second metal pad one by one to form a combined body, performing soldering reflux on the combined body at a desired temperature, applying direct current with a current density I / S, making the direct current direct from the first metal pad to the second metal pad until all the solder bumps are converted into an intermetallic compound through melting and soldering reaction, forming single-orientation intermetallic compound interconnection solder joints. According to the invention, the method accelerates the formation of the intermetallic compound, significantly improves the manufacturing efficiency, forms single-orientation intermetallic compound, improves the mechanical properties of solder joints and service reliability, is compatible with the semiconductor and packaging technology, and realizes low-temperature interconnection and high-temperature service.

Owner:DALIAN UNIV OF TECH

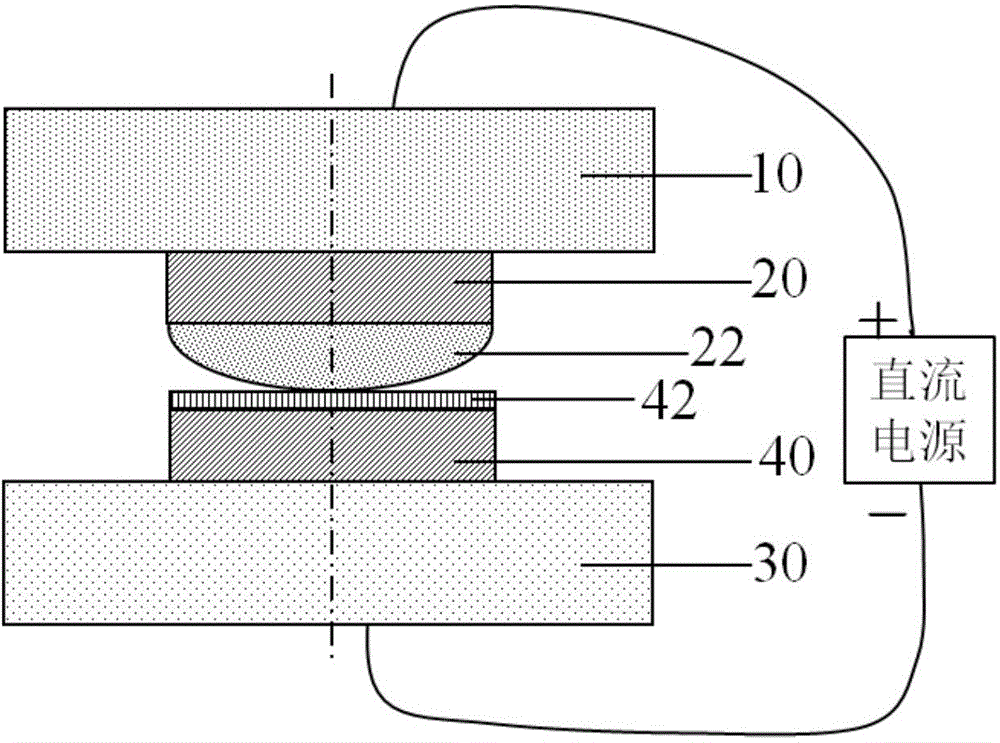

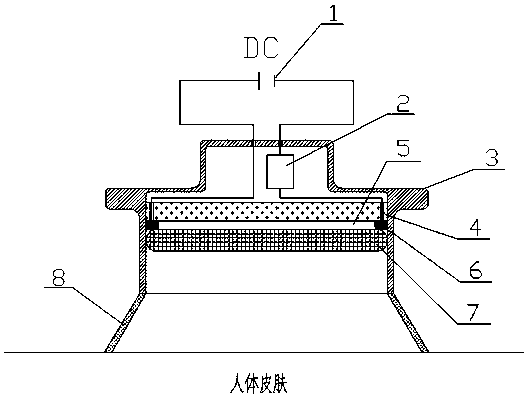

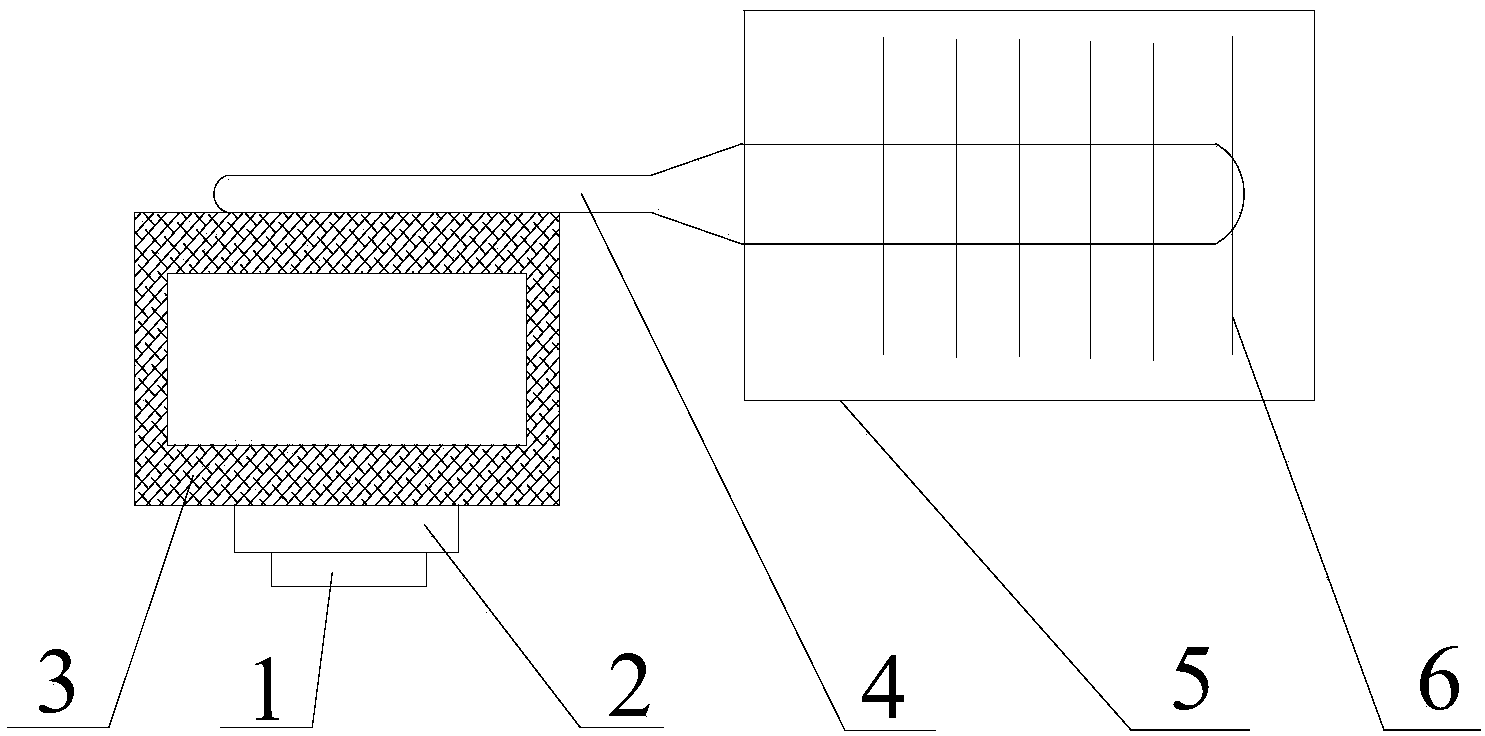

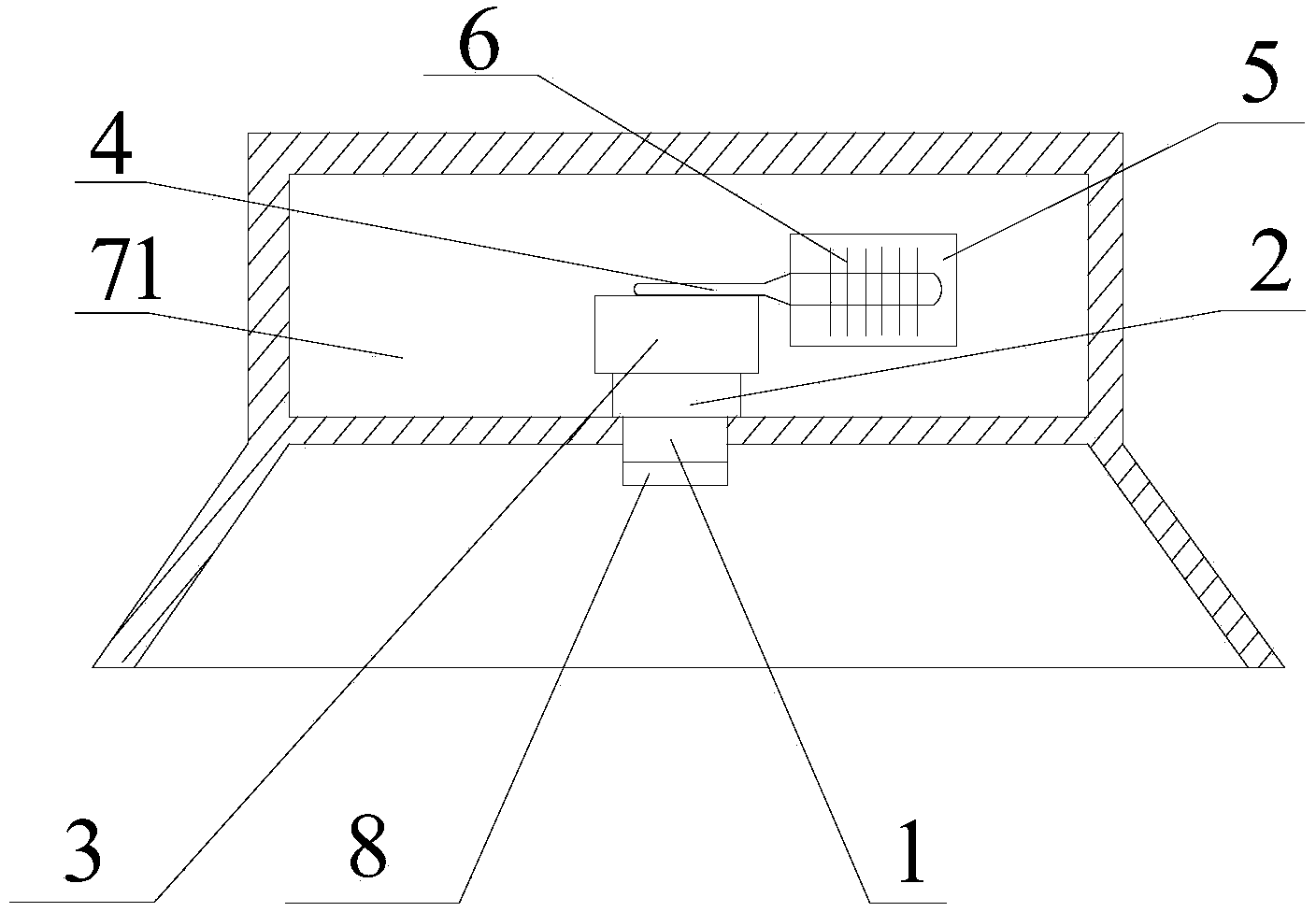

Smokeless graphene heating film moxibustion device

InactiveCN107714447AEasy to operateEffective penetrationDevices for heating/cooling reflex pointsDevices using electromagnetic wavesDiseaseTherapeutic effect

The invention belongs to the field of traditional Chinese medicine physiotherapy instruments, and particularly relates to a smokeless graphene heating film moxibustion device. The moxibustion device is composed of a shell, a direct-current power supply, a direct-current voltage transformation module, electrodes, a graphene heating film, a heat insulation material pad, a suction cup and a moxibustion sheet. The moxibustion device has the functions of clearing and activating the channels and collaterals, promoting qi to activate blood, dispelling dampness and cold, removing swelling and lumps, restoring yang to rescue patients from collapse and preventing diseases to maintain health as traditional moxibustion, and compared with the traditional moxibustion method, the moxibustion device further has the advantages of being free of smoke and ash, clean, environmentally friendly, convenient to use and practical; meanwhile, the moxibustion device has the far infrared wave treatment effect ofgraphene and can accelerate blood circulation, stimulate cell vitality, relax muscles and relieve body aches.

Owner:GUANGXI UNIV OF CHINESE MEDICINE +1

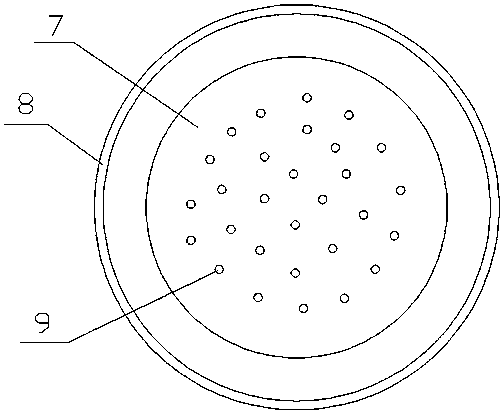

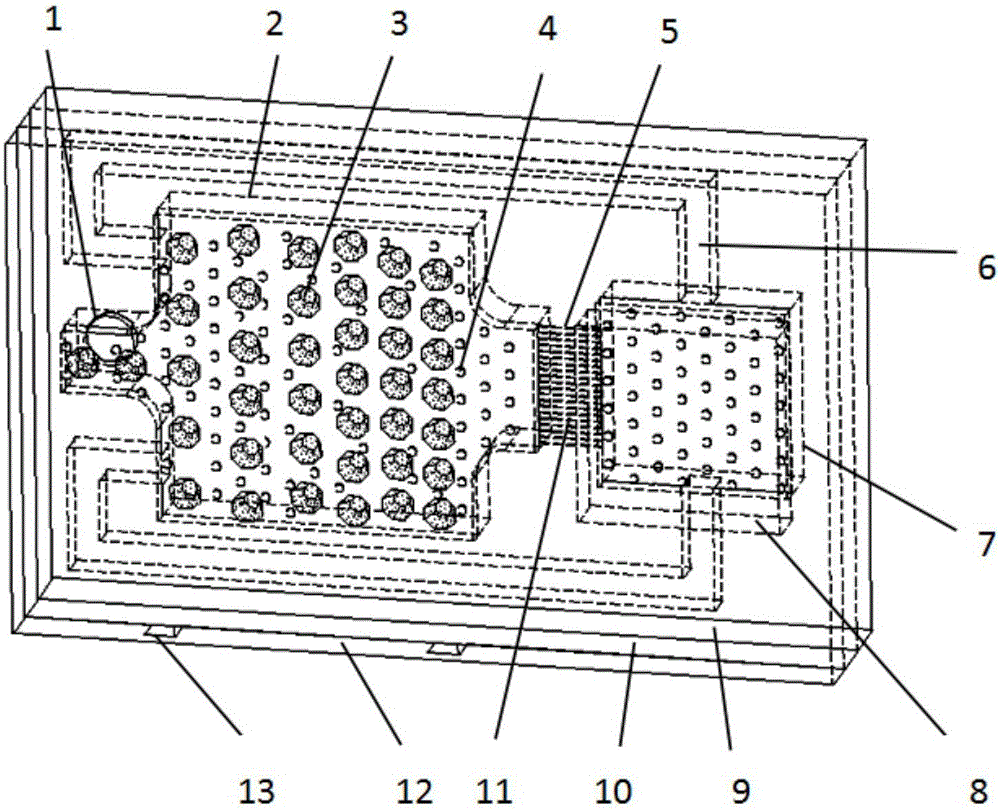

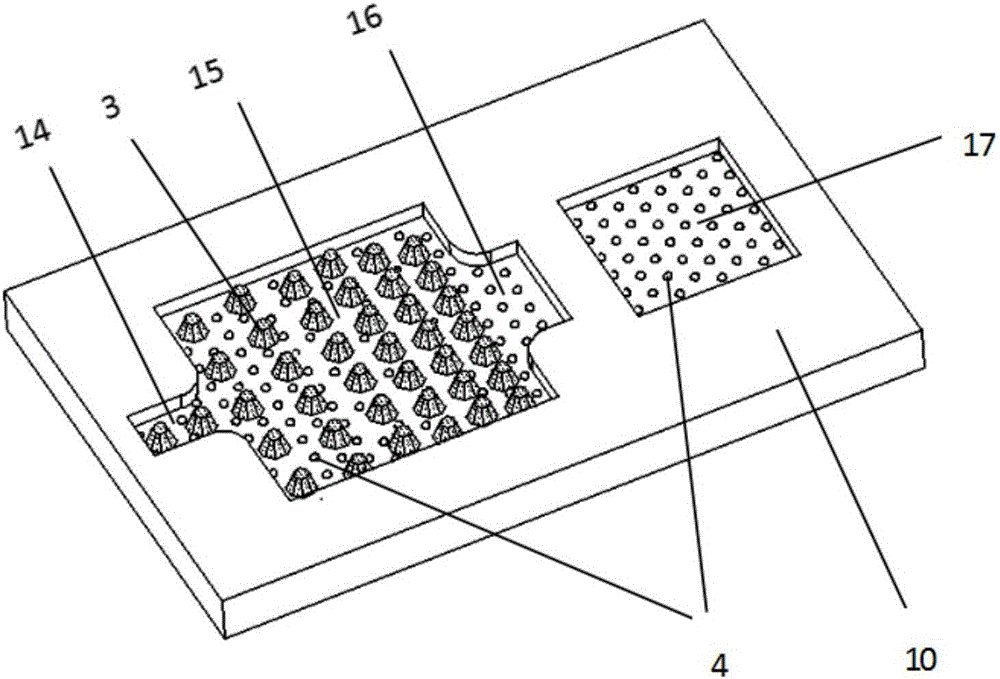

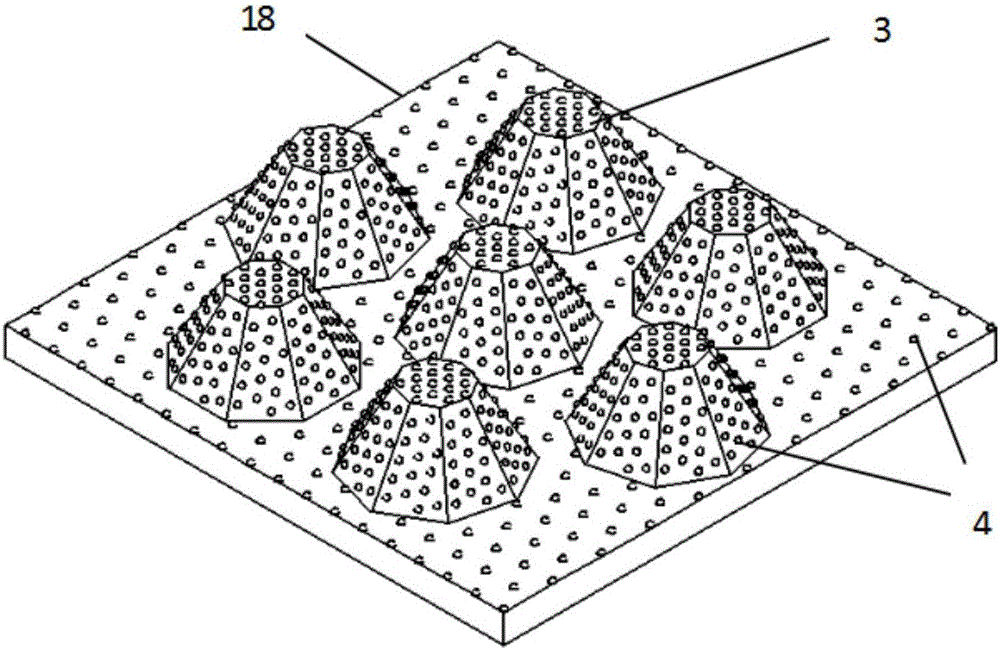

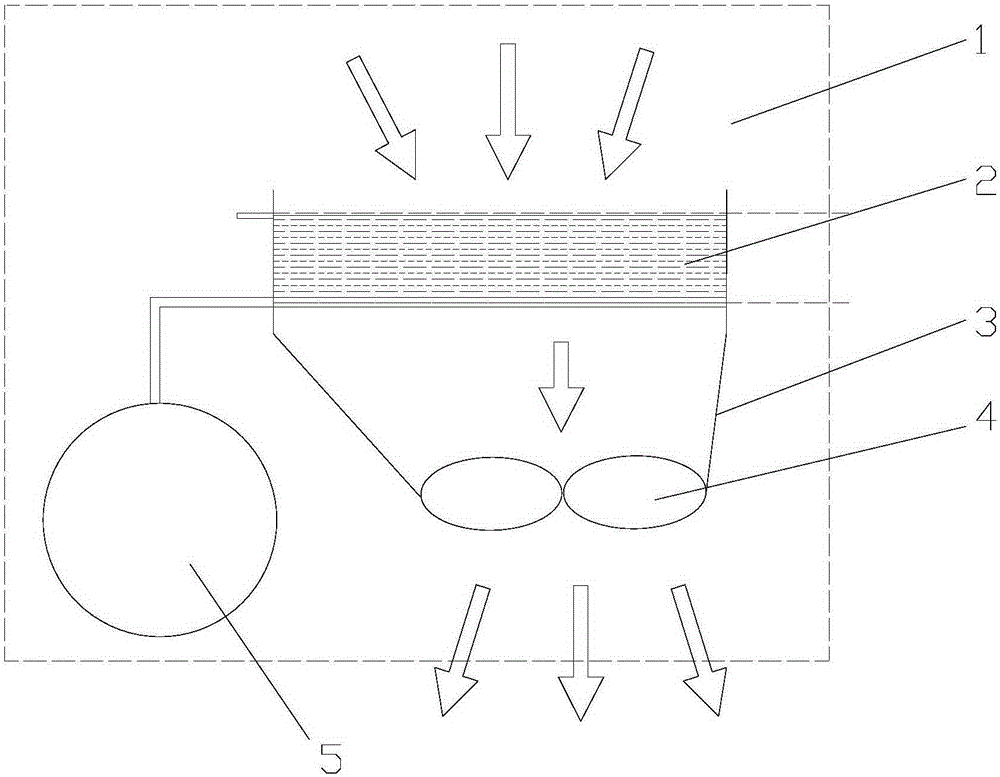

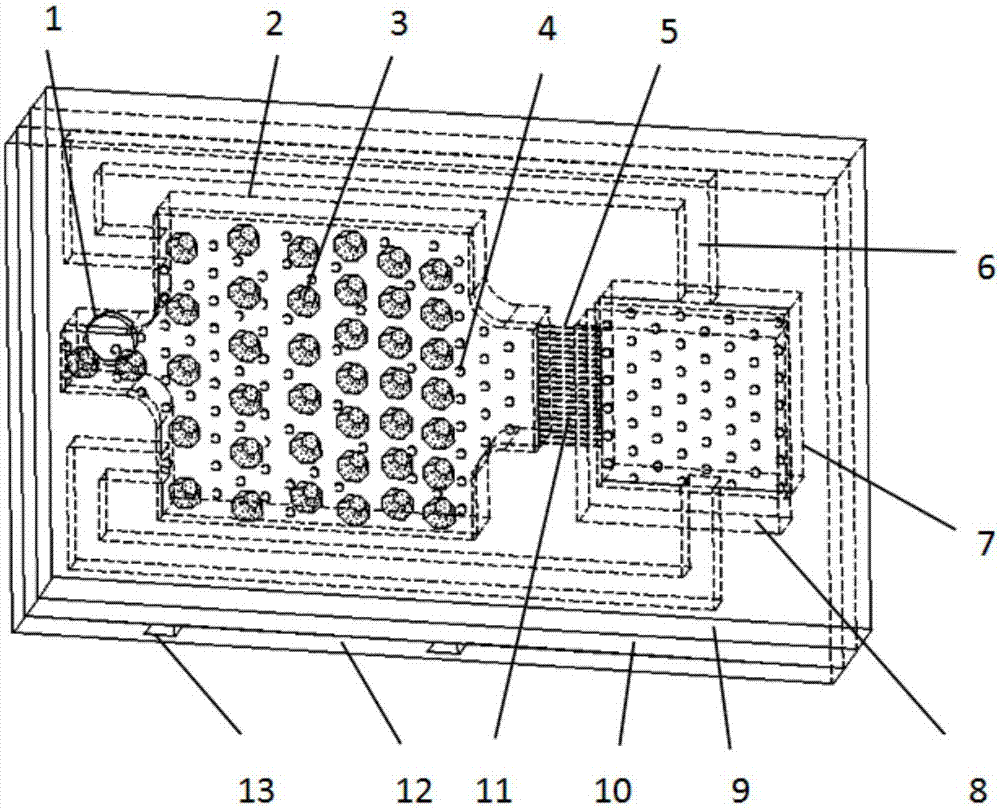

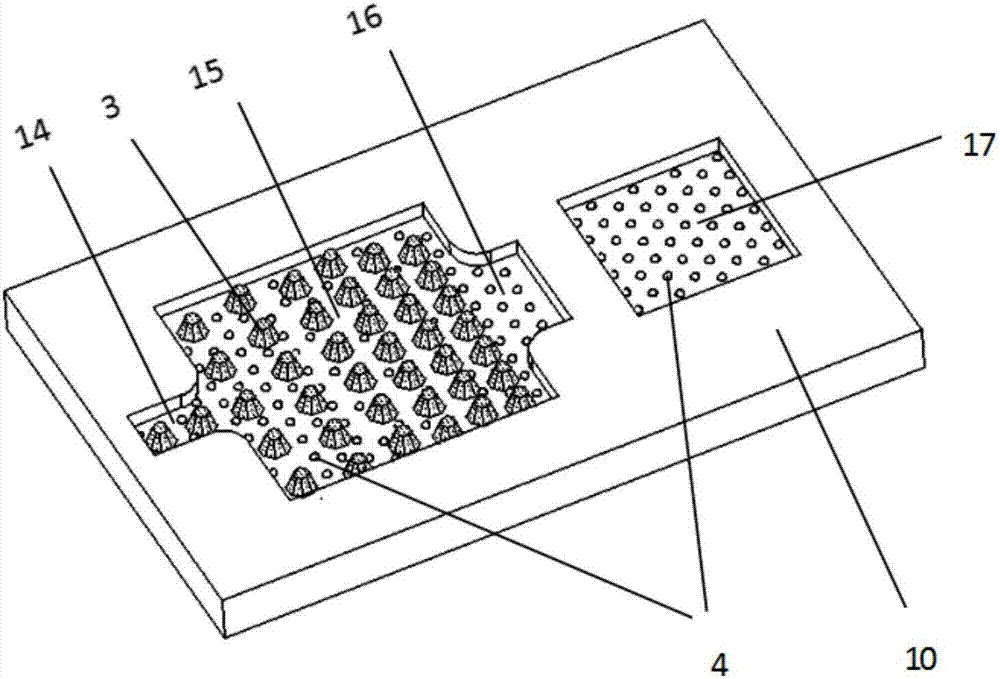

Micro cooler capable of condensing steam into drops and automatically collecting water, and manufacturing method of micro cooler

ActiveCN106017174AIncreased phase change heat transfer coefficientContinuous and fast flowIndirect heat exchangersCooling/ventilation/heating modificationsEngineeringDrop-shaped

The invention relates to a micro cooler capable of condensing steam into drops and automatically collecting water. The micro cooler adopts a three-layer structure of an upper glass plate, a middle silicon slice and a lower glass plate, wherein the upper glass plate and the middle silicon slice are bonded to form a condenser, an evaporator, a liquid pipe and a steam pipe; the lower glass plate and the middle silicon slice are bonded to form a high-temperature chip heat transferring zone and a cooling water pipe. The micro cooler disclosed by the invention adopts a special truncated pyramid-hemisphere type micron-nanometer double-layer heterostructure to modify a silicon condensation surface, so that drop-shaped liquid drops can be quickly formed by the condensation of steam in the condenser, autonomously concentrated close to the liquid pipe, and sent to the evaporator to absorb heat by a large capillary driving force provided by the liquid pipe consisting of a plurality of capillary tubes. The invention further relates to a manufacturing method of the micro cooler. The micro cooler disclosed by the invention has the advantages of being novel in structure, small in size, light in weight, good in stability, and excellent in refrigeration performance.

Owner:ZHEJIANG UNIV OF TECH

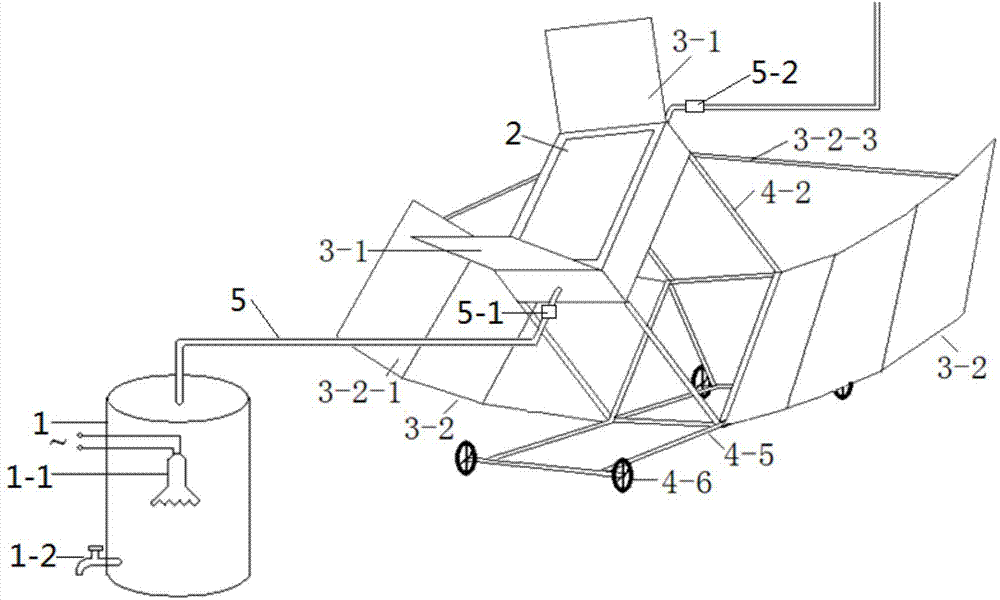

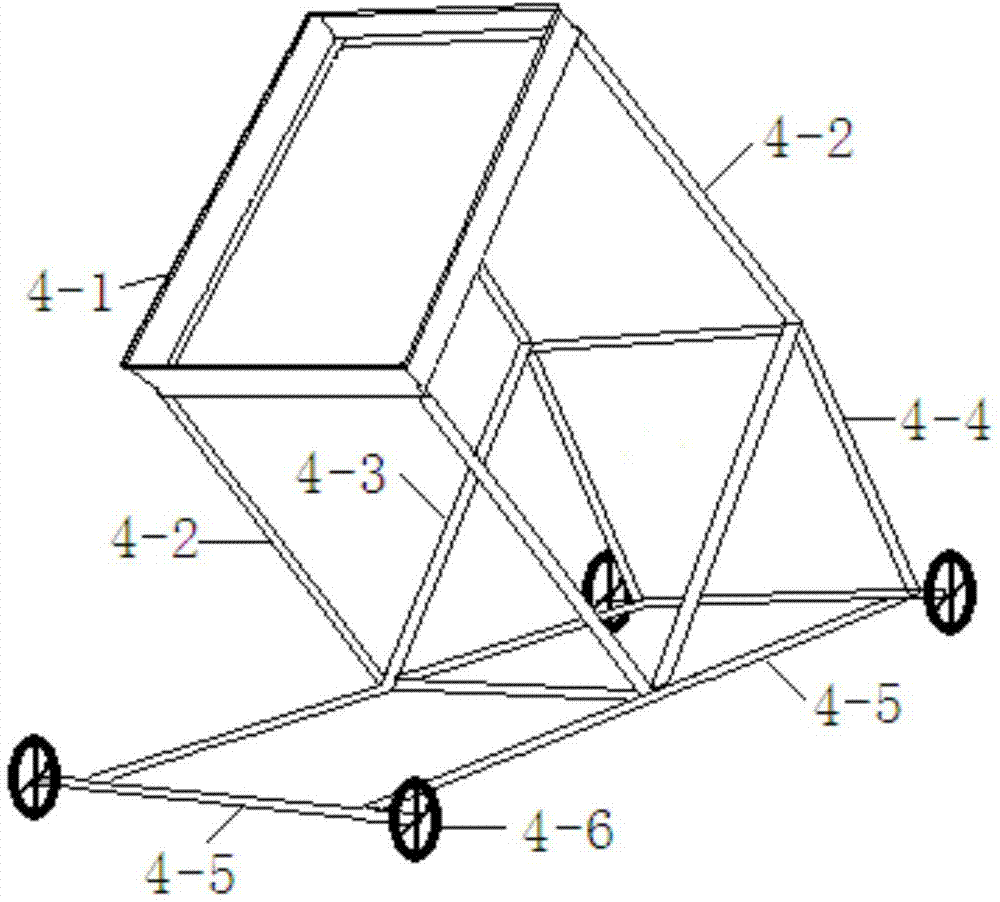

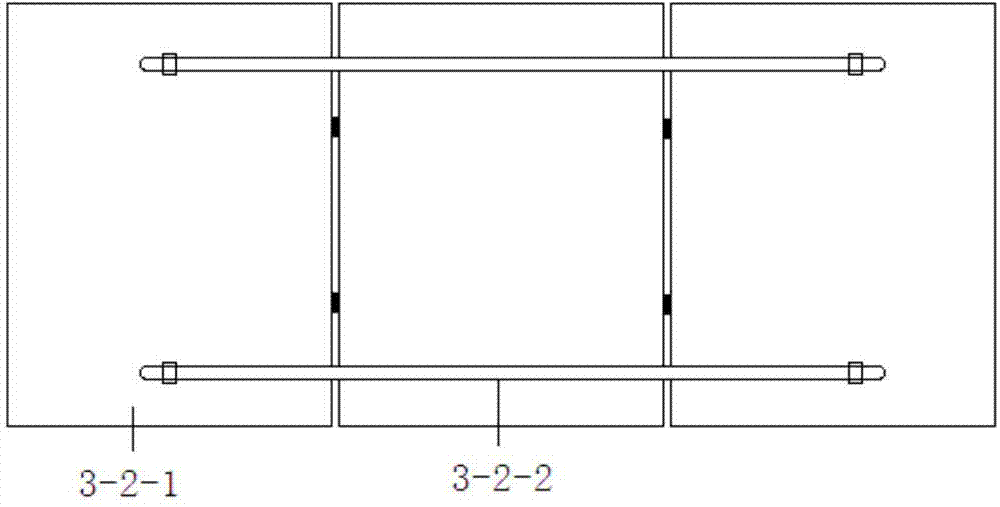

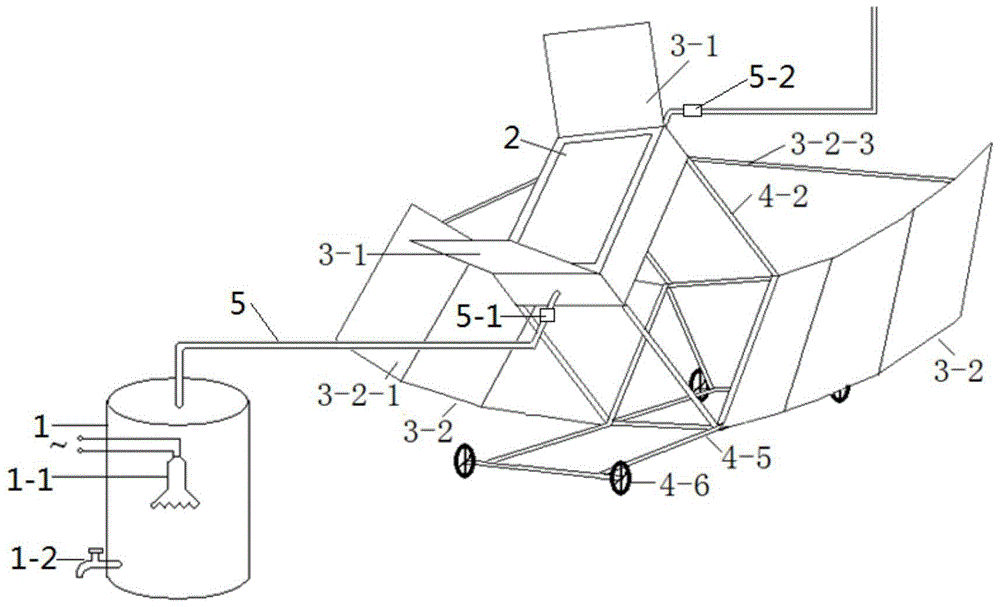

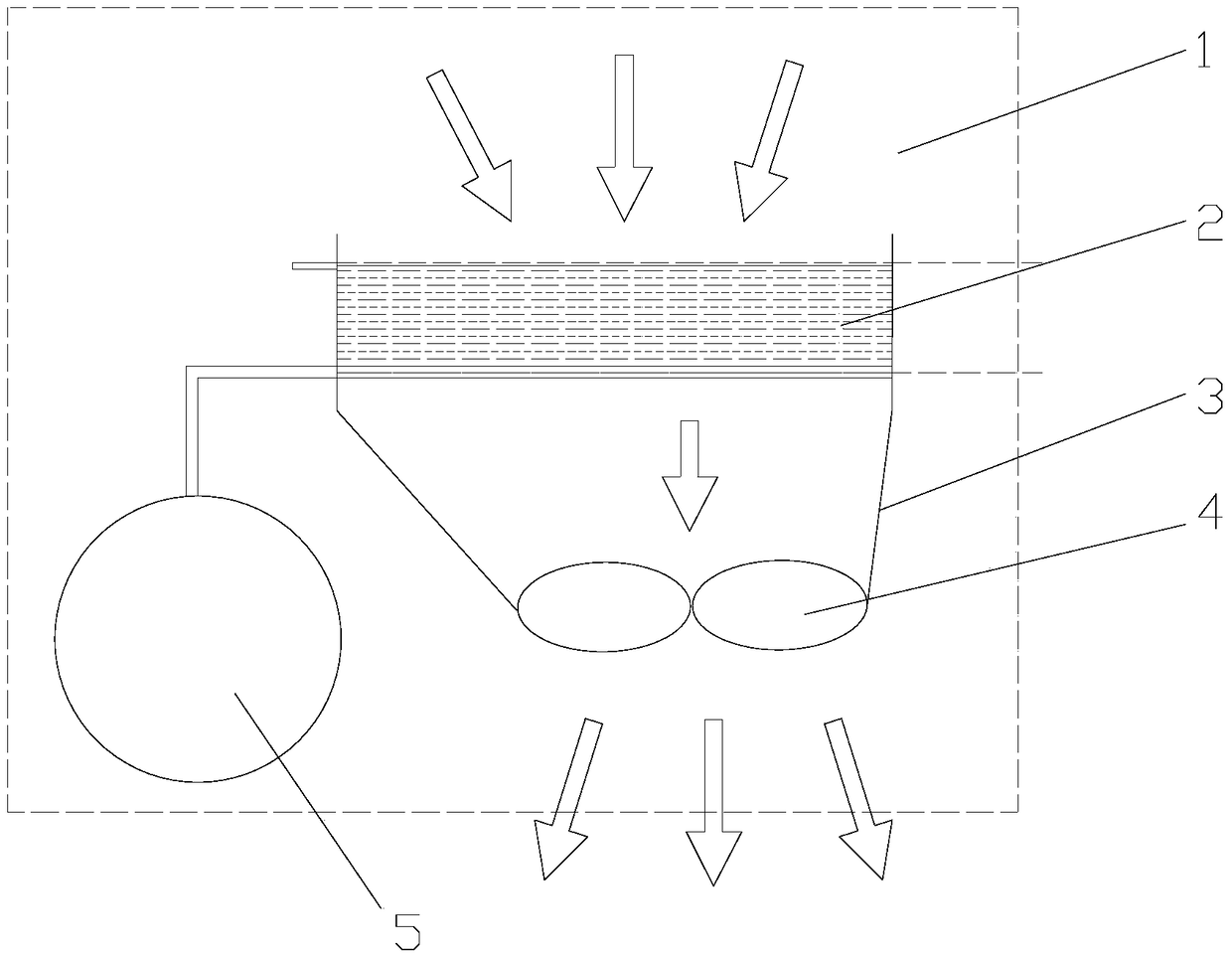

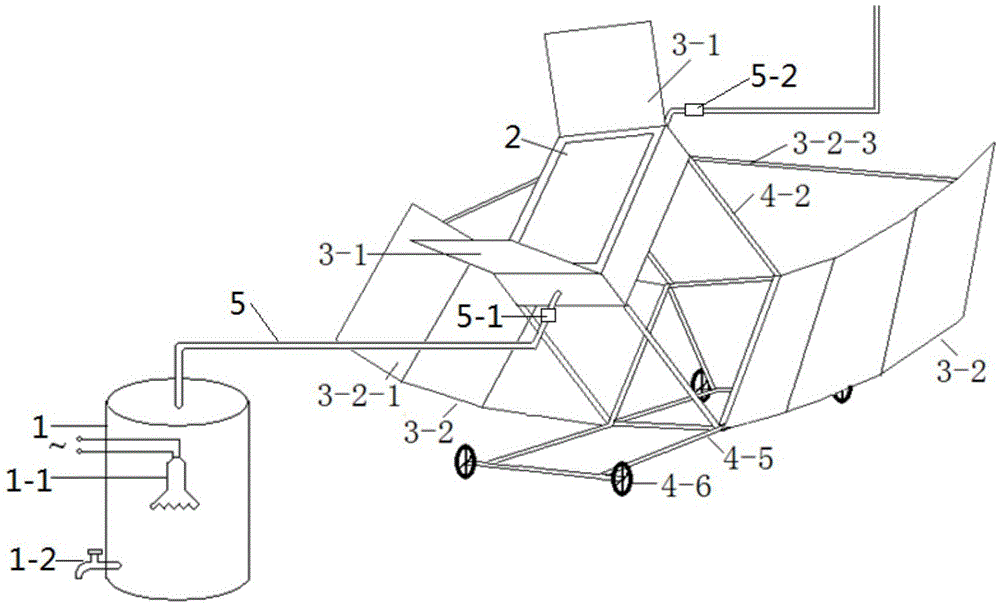

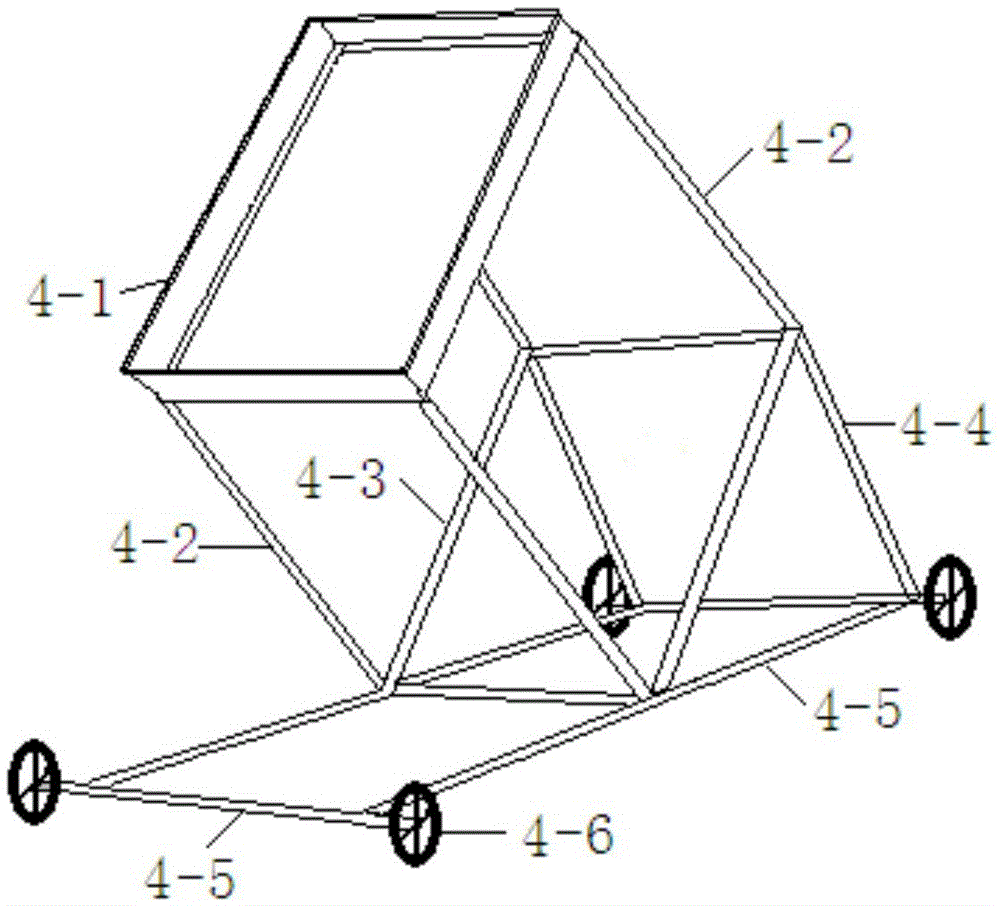

Simple photovoltaic, photothermal and thermoelectric comprehensive utilization system

ActiveCN104729108AIncrease the heating areaIncrease contact areaSolar heating energySolar heat devicesEngineeringThermal water

The invention discloses a simple photovoltaic, photothermal and thermoelectric comprehensive utilization system and belongs to the field of solar energy utilization. The system comprises a supporting frame, a condensation device, a heat collection and power generation module and a hot water collection device, wherein the condensation device and the heat collection and power generation module are installed on the supporting frame, a planar reflector is installed in the condensation device, converged light rays irradiate the outer surface of the heat collection and power generation module, a heat collection water tank is arranged in the heat collection and power generation module, the heat collection water tank is communicated with the hot water collection device through a water delivery pipe, and a photovoltaic module and a thermoelectric module which are used for power generation are arranged on the two sides of the water tank respectively. The internal structure and system composition of the heat collection and power generation module are simplified; the devices are organically combined, so that the functions of photovoltaic power generation, thermoelectric power generation and optical energy heating are achieved, the utilization rate of solar energy is increased, heat collection and power generation efficiency is improved, and cost is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

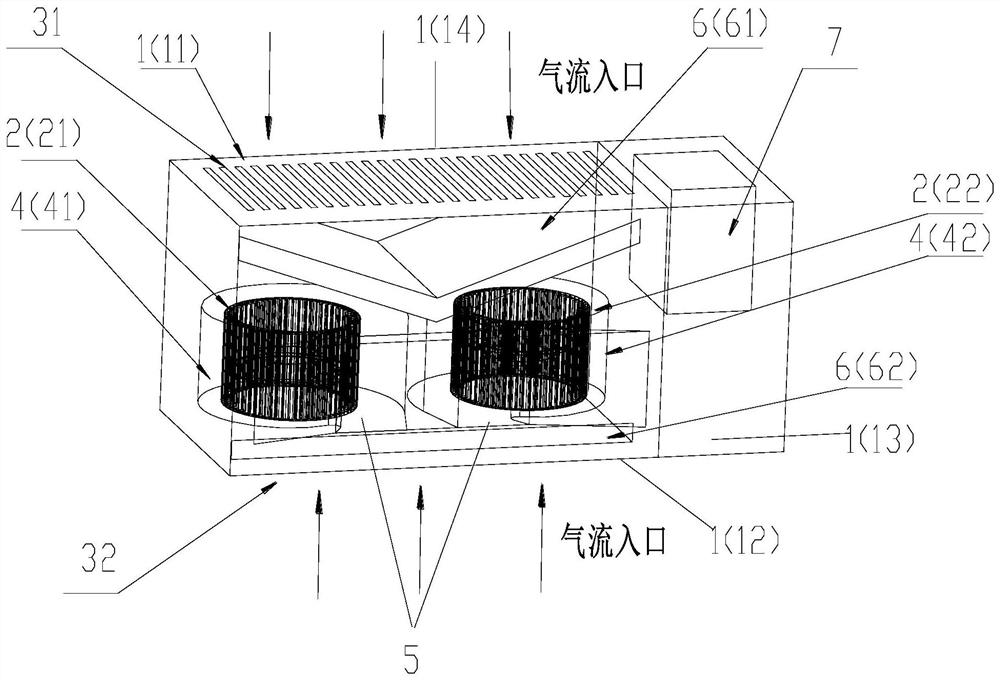

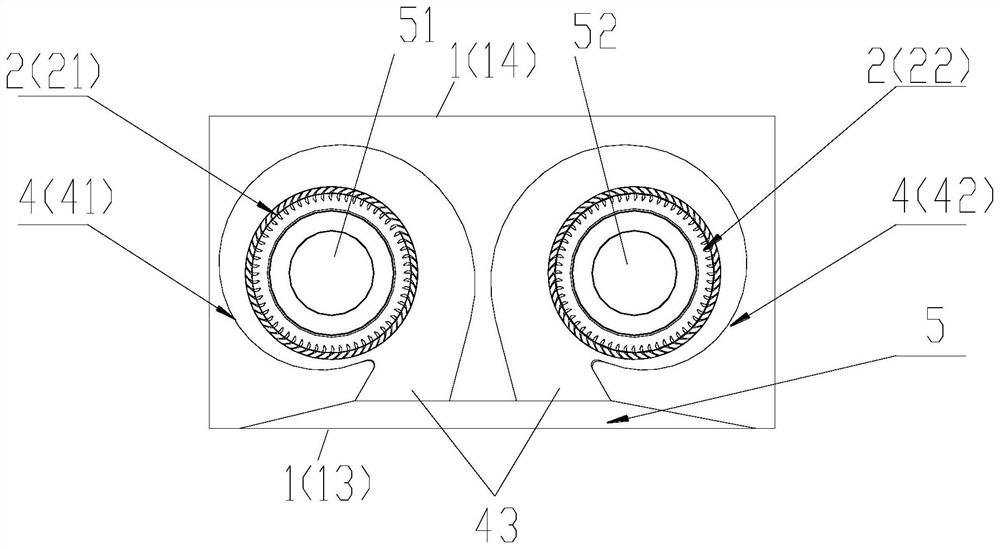

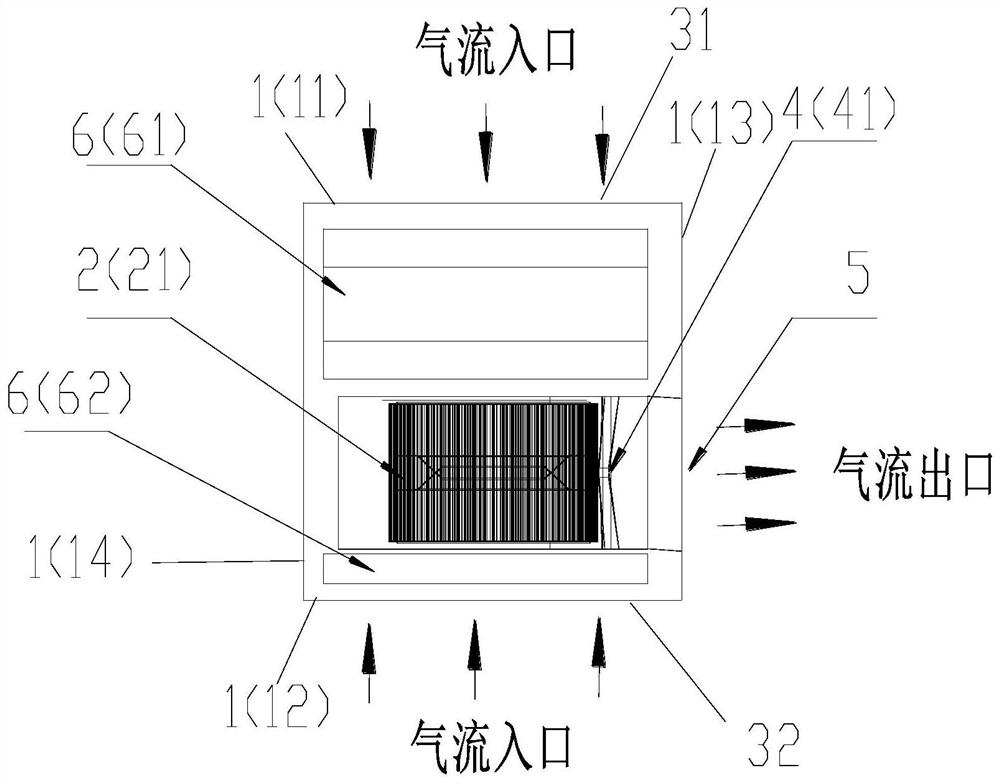

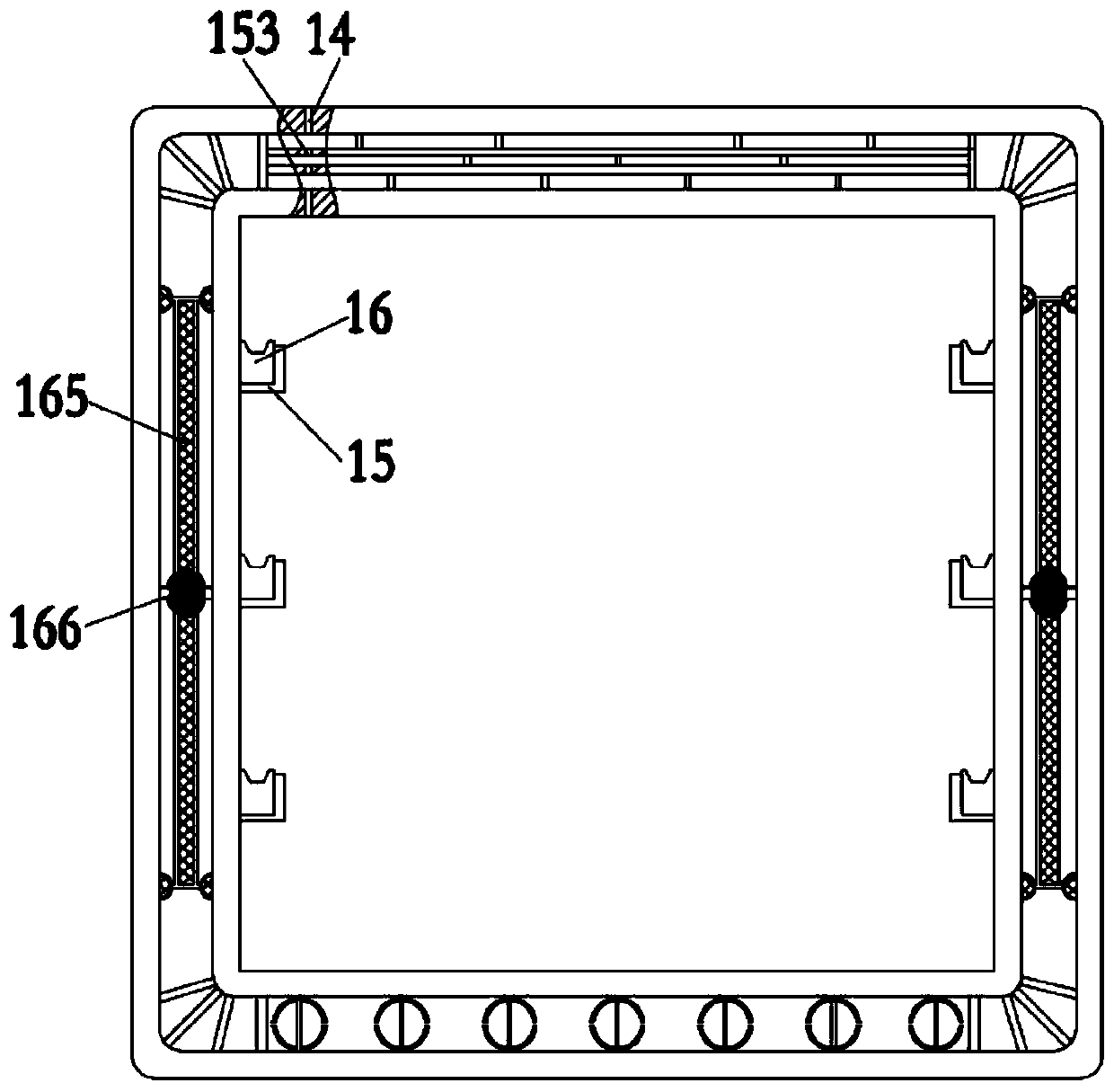

Air conditioner indoor unit, control method and air conditioner

PendingCN112325381AIncrease air volumeRealize the function of air intake from top to bottomMechanical apparatusLighting and heating apparatusAir volumeEngineering

The invention provides an air conditioner indoor unit, a control method and an air conditioner. The air conditioner indoor unit comprises a shell and a fan. The fan is arranged in the shell and is a centrifugal fan. The shell comprises a first side face and a second side face which are oppositely arranged. The first side face and the second side face are both opposite to the axis direction of thecentrifugal fan. A first air inlet is formed in the first side face. A second air inlet is formed in the second side face. According to the air conditioner indoor unit, the control method and the airconditioner, the air inlet area is effectively increased, the air volume of the whole unit can be effectively increased, heat circulation and cold circulation of a room are accelerated, the air conditioner efficiency is improved, power consumption is reduced, and the refrigerating and heating effects of the indoor unit are improved; and the two air inlets are formed in the upper side face and thelower side face correspondingly, a function of up-down air inlet of the air conditioner can be effectively fulfilled, and the air inlet volume of the air conditioner can be remarkably increased through the two air inlets.

Owner:GREE ELECTRIC APPLIANCES INC

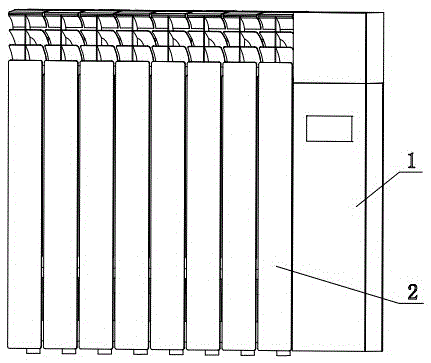

Automatic cycling heater for indoor heating

InactiveCN104713161AFaster thermal cyclingSimple and fast operationLighting and heating apparatusSpace heating and ventilation detailsVoltage regulationCirculating pump

The invention provides an automatic cycling heater for indoor heating. The device comprises a temperature sensor, a controller, a voltage adjusting circuit, a circulation pump and a wireless communication circuit. The temperature sensor, the controller, the voltage adjusting circuit and the circulation pump are sequentially connected. The wireless communication circuit is connected with the controller. By means of the automatic cycling heater for indoor heating, cycling heating can be conducted according to the real-time indoor temperature, the heat cycle is accelerated, and the automatic cycling heater for indoor heating is easy and convenient to operate.

Owner:XIAN GUANGRONG ELECTRICAL

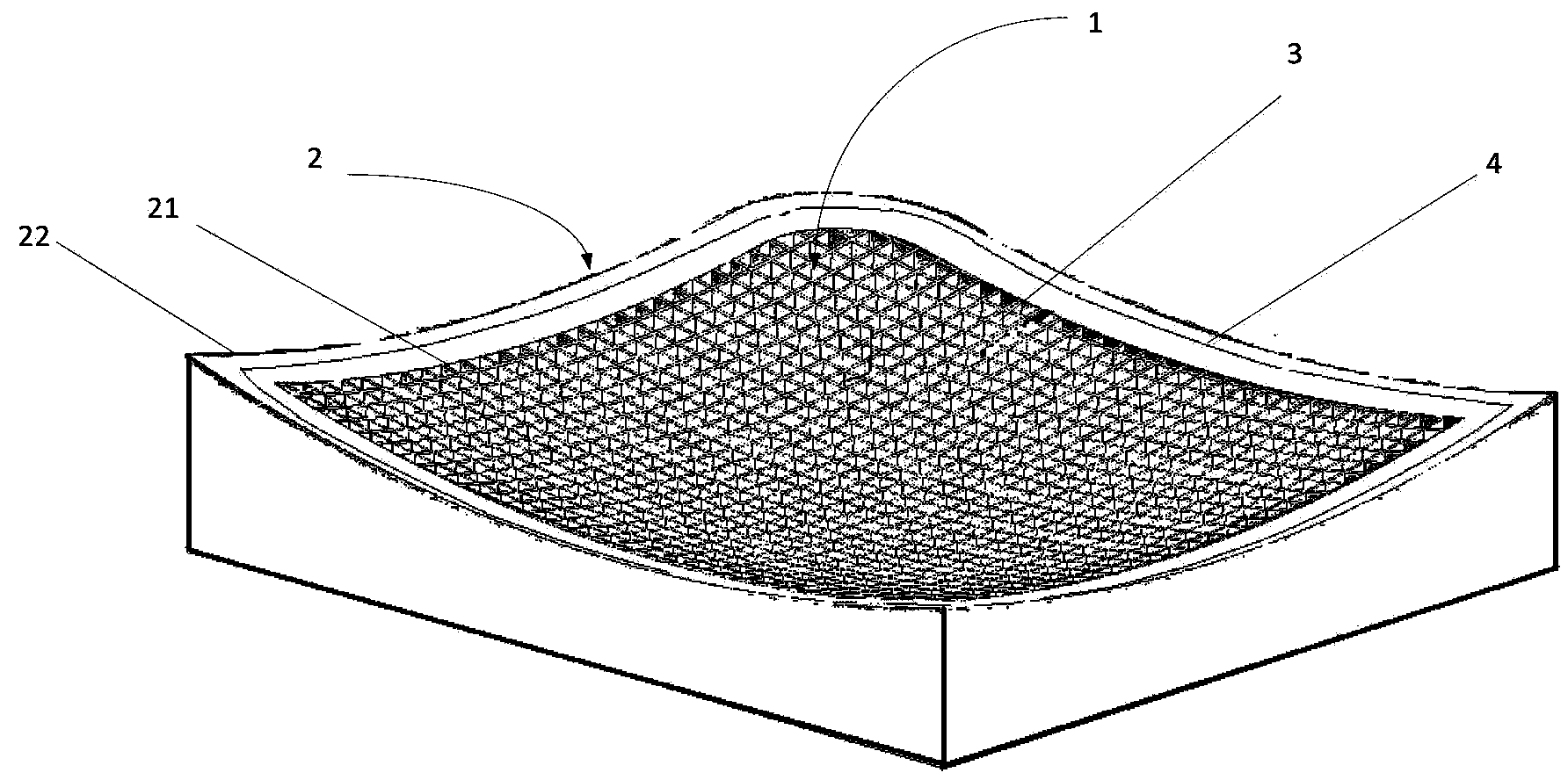

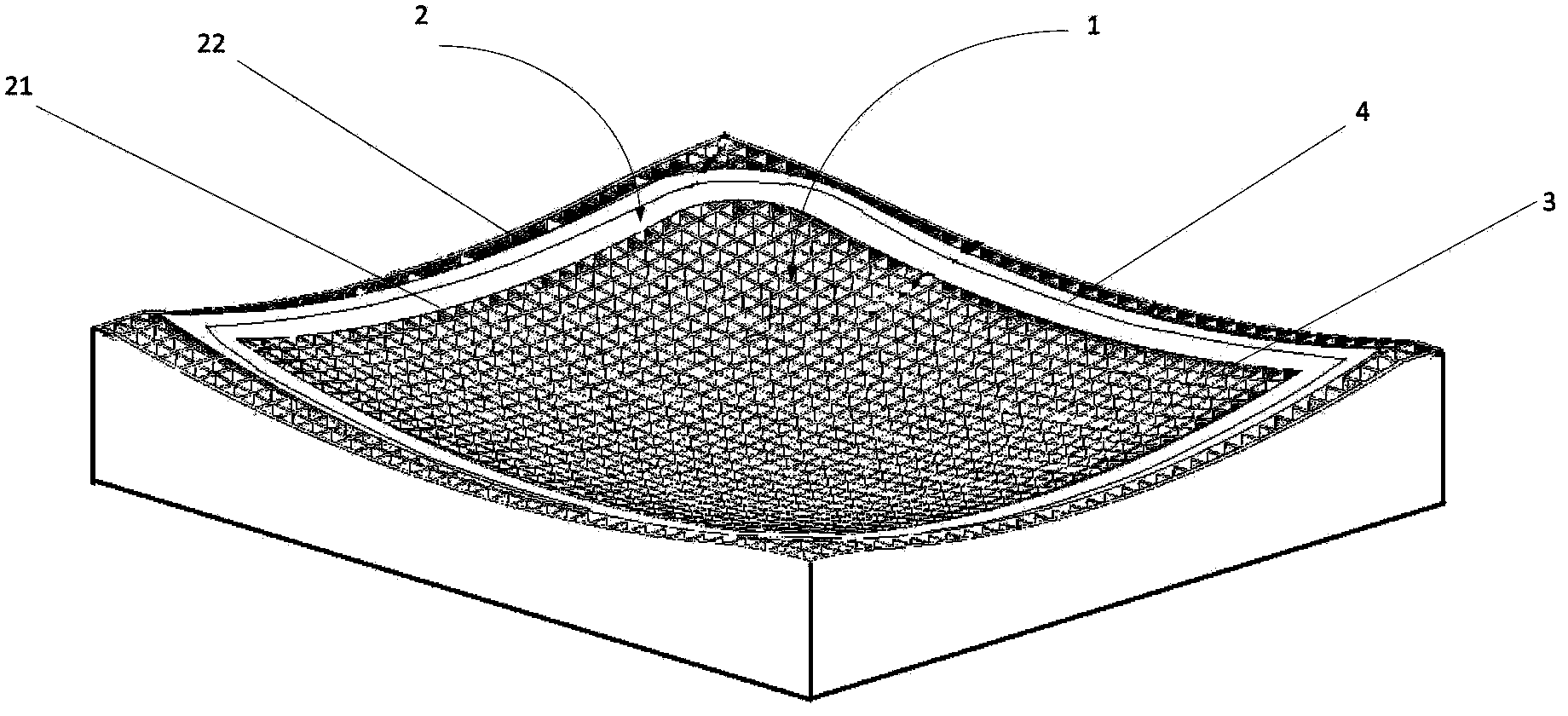

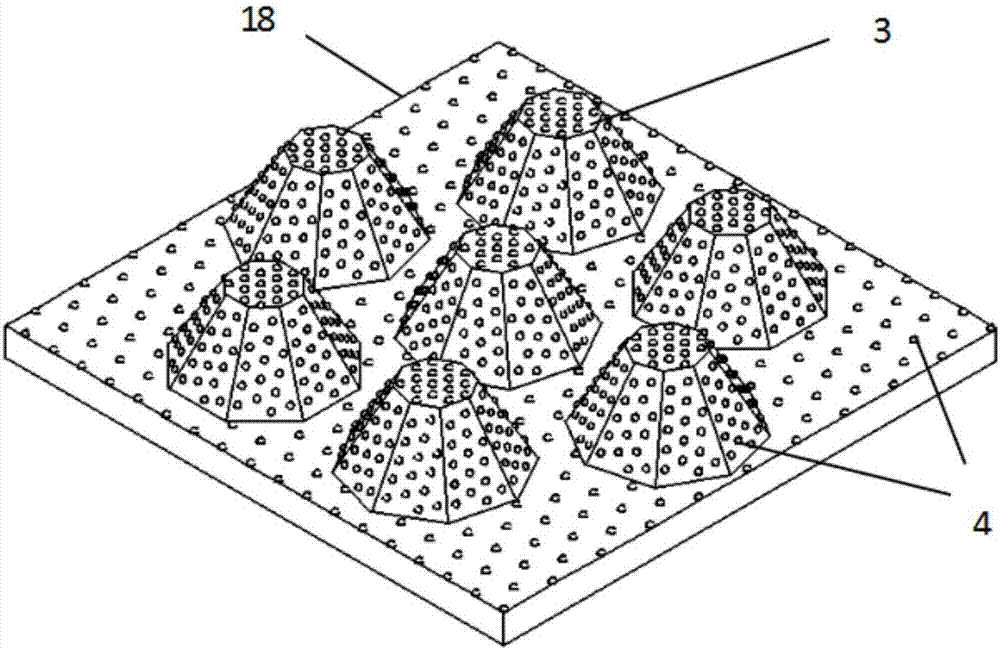

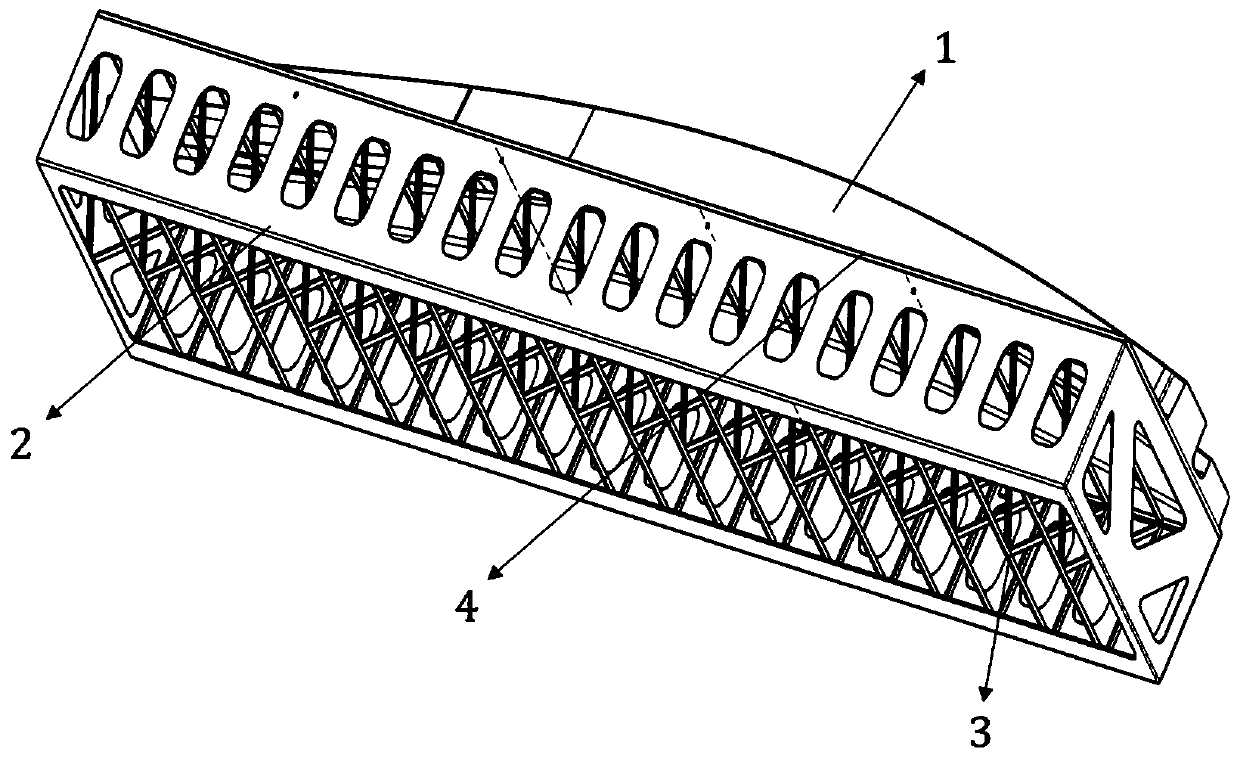

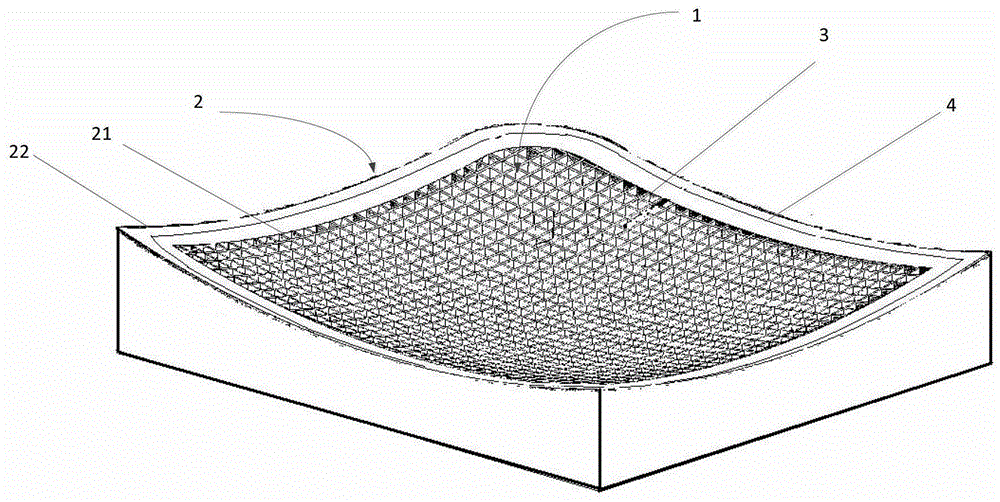

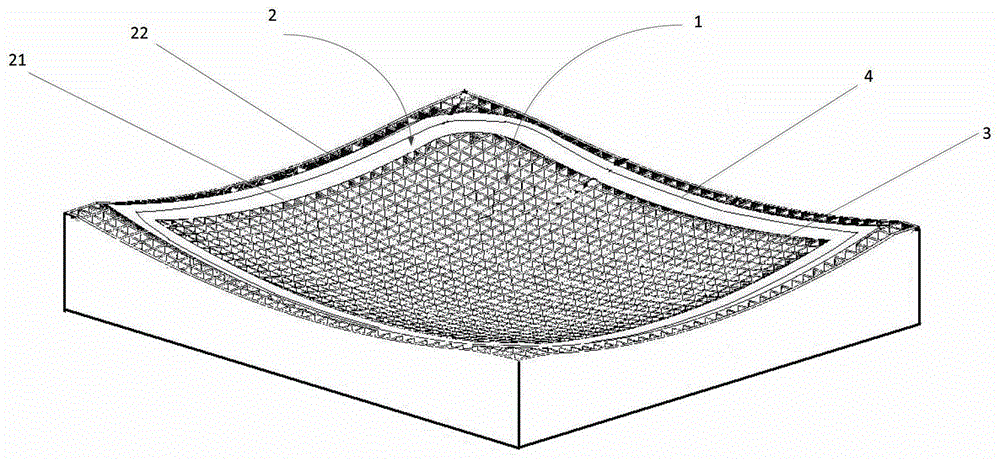

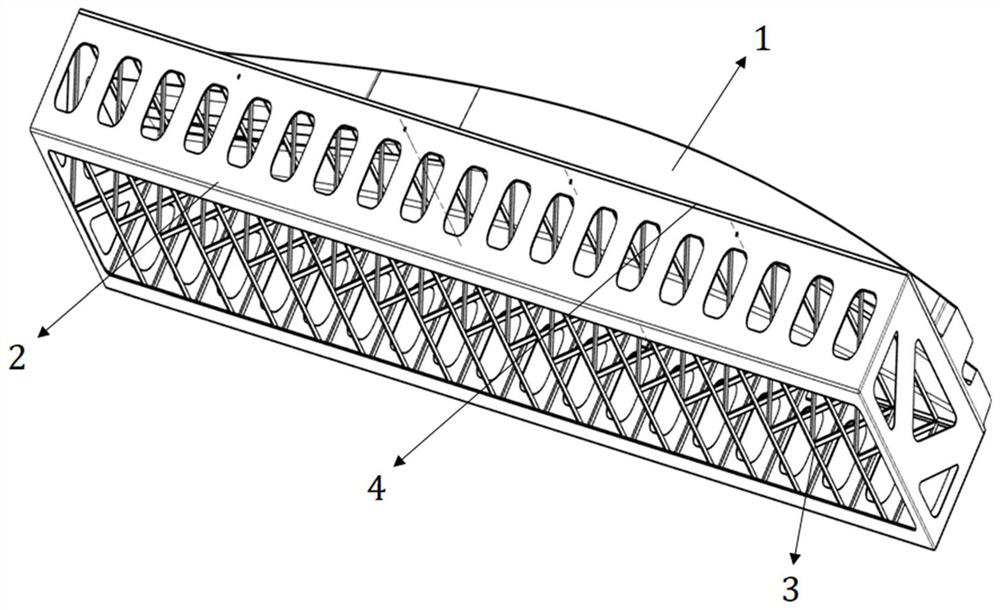

Glass hot-bending die as well as manufacturing method and application thereof

ActiveCN103359919AReduce manufacturing costReduce weightGlass reforming apparatusGlass productionHeat cyclingGlass forming

The invention discloses a glass hot-bending die as well as a manufacturing method and application of the glass hot-bending die, belonging to the technical field of solar energy utilization. The glass hot-bending die comprises a main body and a frame-shaped glass edge hot-bending part, wherein the main body has a plurality of through holes which pass through the upper and lower surfaces of the main body; the frame-shaped glass edge hot-bending part is connected with the main body; a glass forming surface is formed by the upper surface of the frame-shaped glass edge hot-bending part together with the upper surface of the main body. According to the glass hot-bending die, by forming the through holes in the main body part of the glass hot-bending die, materials used by the glass hot-bending die are reduced, the die production cost is lowered, the heat that the die absorbs is reduced, the uniform glass heating and forming in the hot-bending process are facilitated, the radiation of the heat of the die is facilitated, and both the service life of the die is prolonged and the forming precision of glass is ensured; due to the existence of the through holes, the hot-bending die is good in heat circulation in the hot-bending process, a plurality pieces of glass can be hot-bent simultaneously, the production efficiency is greatly improved, and due to the arrangement of the through holes, the weight of the die is reduced, and the die can be conveniently hoisted and transported.

Owner:CHINA BUILDING MATERIALS ACAD +1

Top radiating system of embedded refrigerator

ActiveCN105180564AImprove heat transfer efficiencyCompact structureLighting and heating apparatusRefrigeration devicesRefrigerationRefrigerated temperature

The invention relates to a top radiating system of an embedded refrigerator. The system comprises a condenser, a compressor, a sealed air duct and fans, wherein the condenser, the compressor, the sealed air duct and the fans are arranged on a fixed base plate located on the top of the embedded refrigerator. The condenser is located at the position of an opening in one end of the sealed air duct, and the fans are located at the position of an opening in the other end of the sealed air duct. The compressor is communicated with the condenser through a pipeline. According to the top radiating system of the embedded refrigerator, air on the back face of the refrigerator is sucked into the air duct of the radiating system for heat exchange, and then the air is exhausted from the front face and the periphery of the refrigerator, so that efficient and stable air flowing circulation is formed. On the basis that the space of the embedded refrigerator is saved and the appearance of the embedded refrigerator is beautified, an efficient radiating circulation system is guaranteed. The radiating efficiency of an entire refrigeration assembly of the embedded refrigerator is achieved, and good usability of the refrigerator is guaranteed.

Owner:HEFEI HUALING CO LTD +1

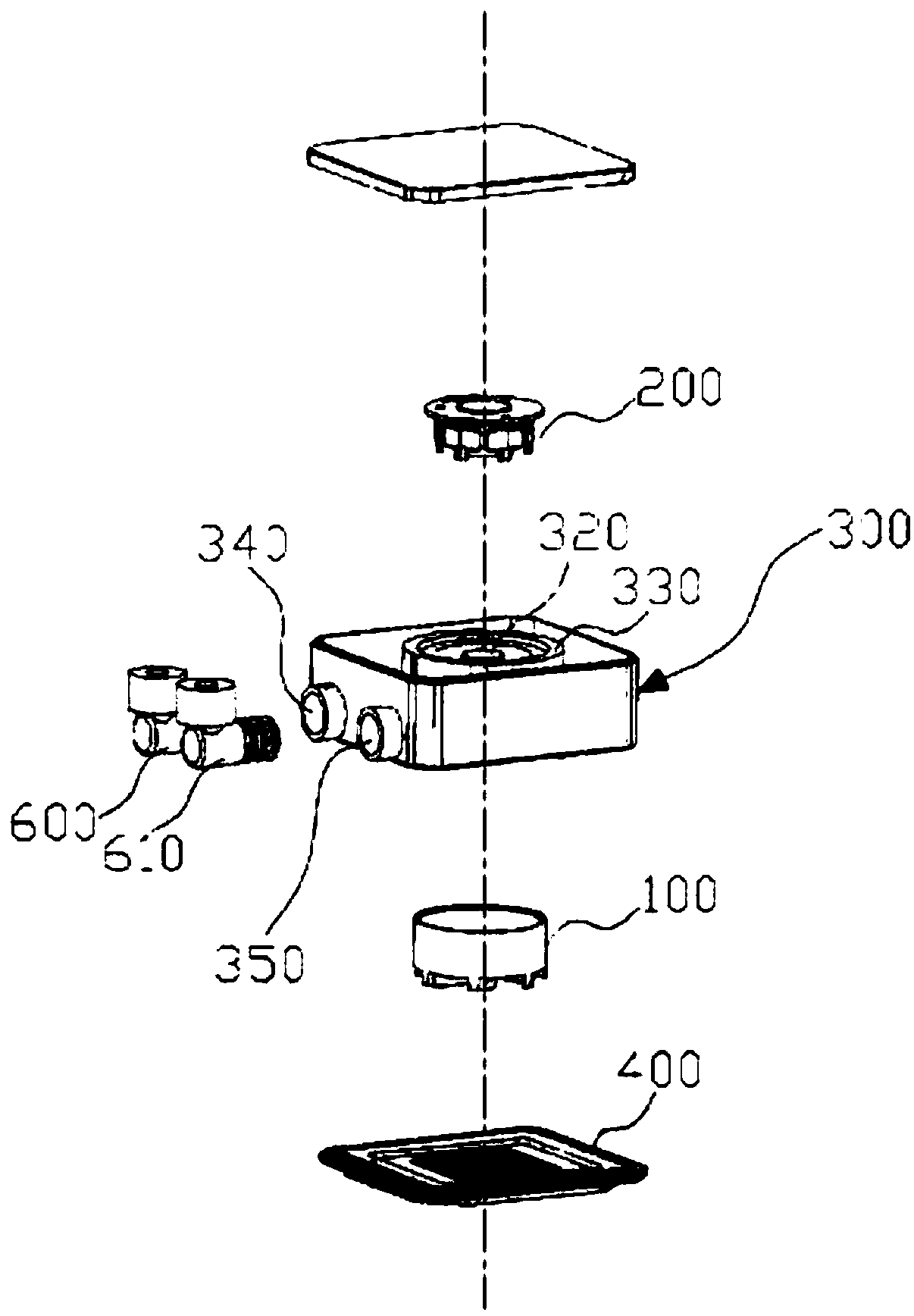

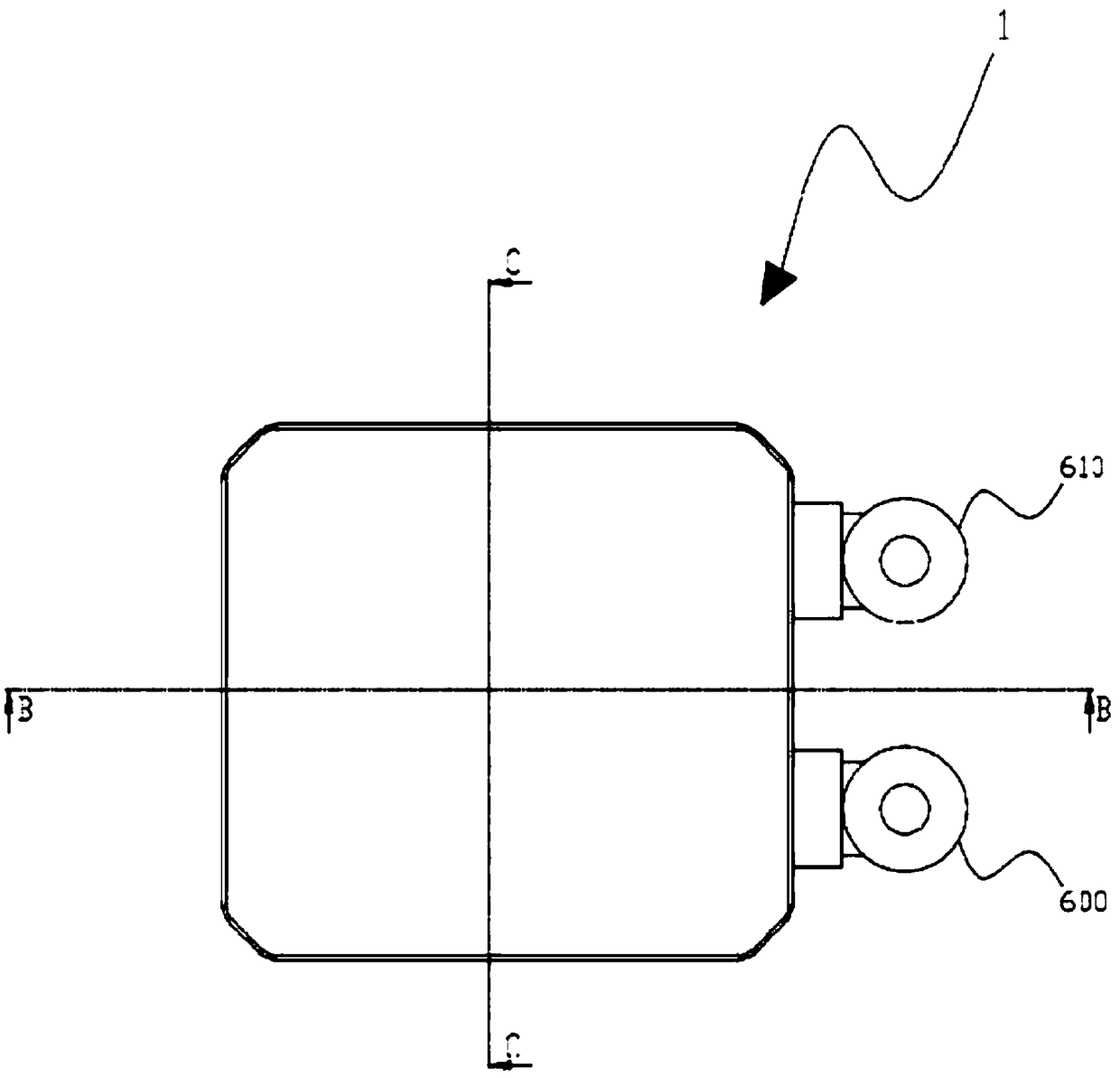

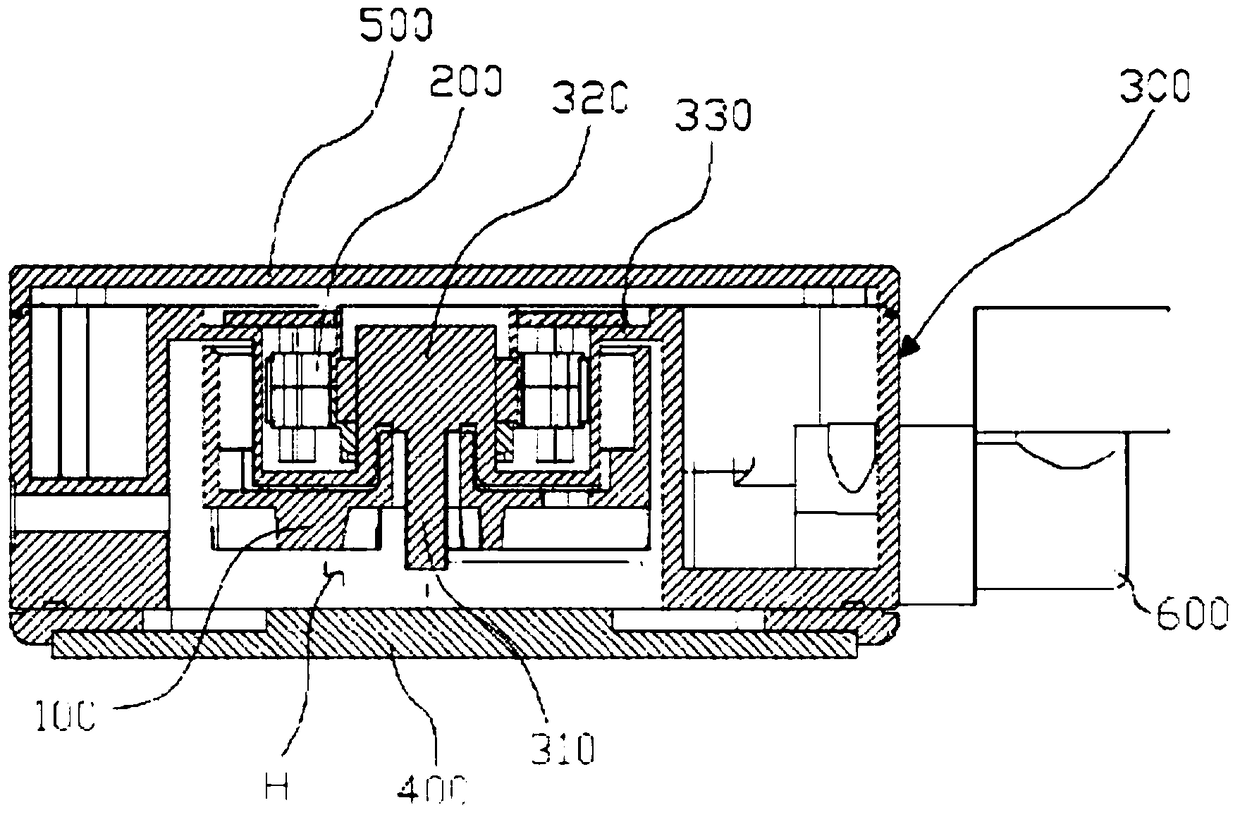

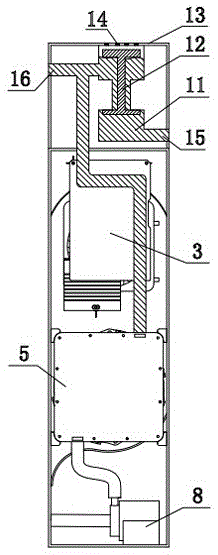

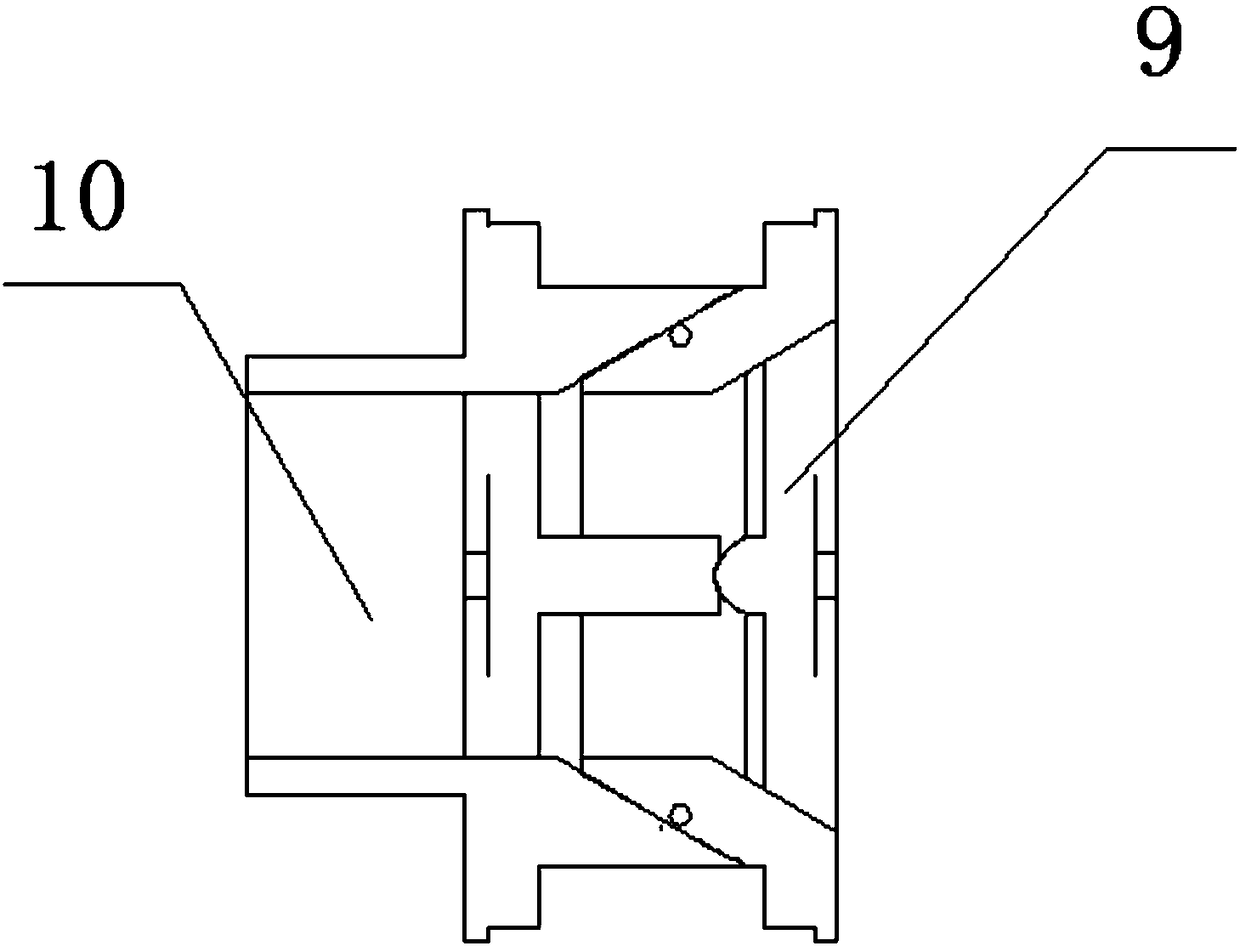

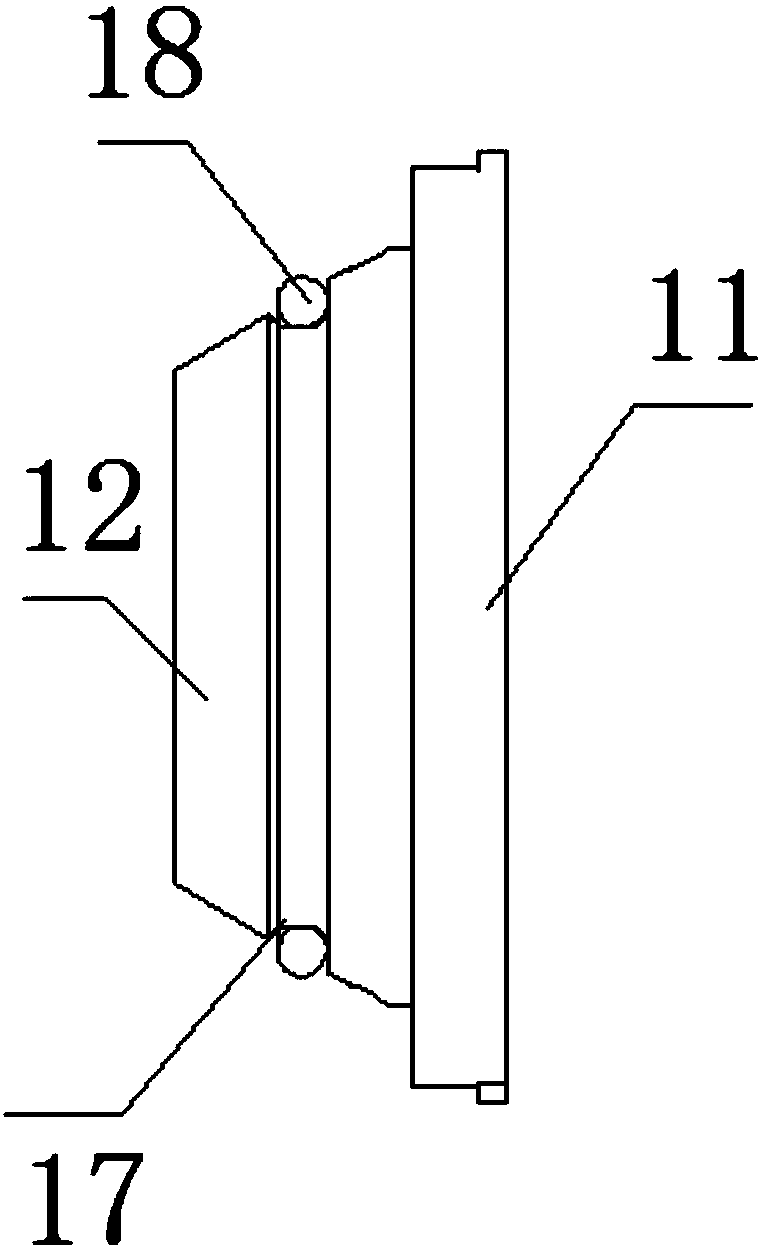

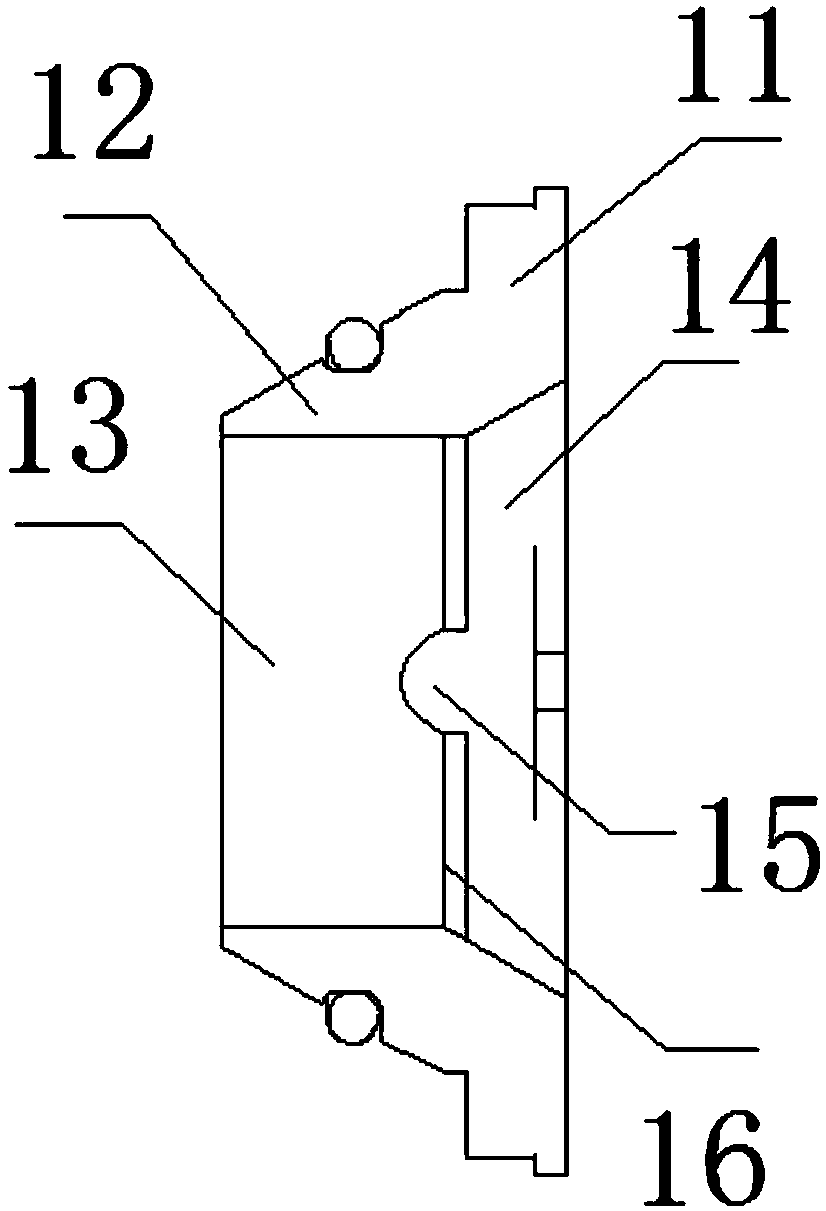

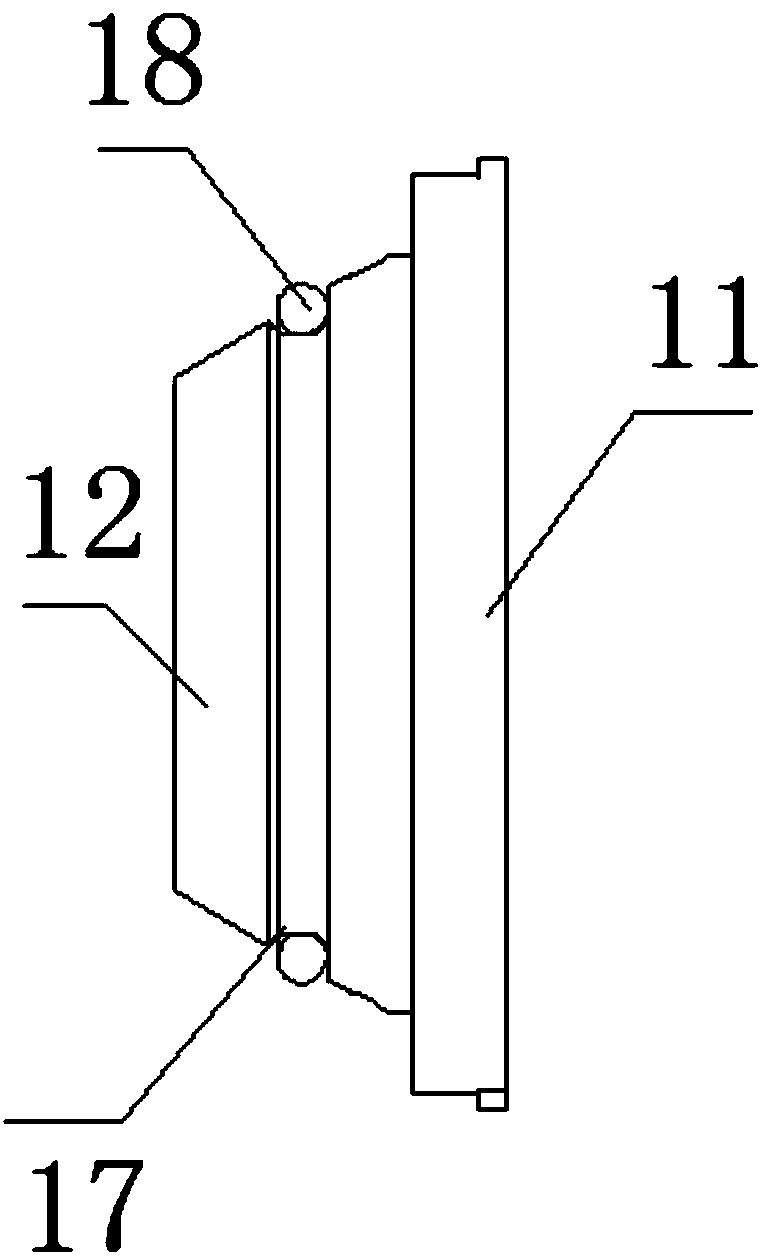

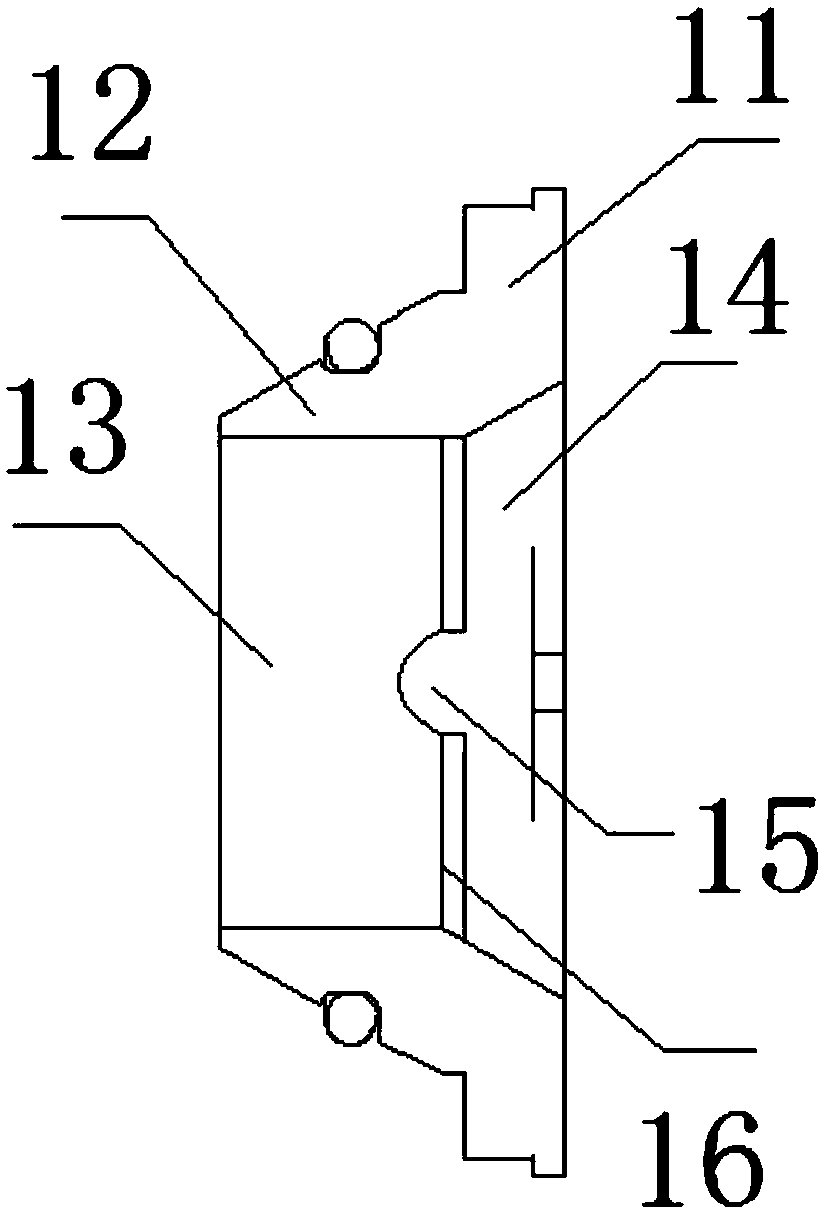

Electronic part cooling device having gas/liquid pump

ActiveCN109076721AMaximize Cooling EfficiencyFaster thermal cyclingSemiconductor/solid-state device detailsSolid-state devicesImpellerEngineering

According to an embodiment of the present invention, a gas / liquid pump can be configured through application of a two-phase cooling system, advantageously maximizing the cooling efficiency. To this end, particularly, an embodiment of the present invention may comprise an electronic part cooling device having a gas / liquid pump, comprising: an impeller positioned on a gas / liquid containing portion that contains a gas / liquid; a motor stator positioned on an outside isolated from the gas / liquid containing portion so as to transfer driving force to the impeller; a sealed injection cover having an impeller shaft formed on one side thereof so as to protrude toward the center of the gas / liquid containing portion such that the impeller is inserted therein, the sealed injection cover having a motorstator insertion rod formed on the other side thereof so as to protrude from an axis of the impeller shaft toward the center of the outside such that the motor stator is inserted therein, the sealed injection cover having an upper plate formed to expand from a periphery of the motor stator insertion rod such that the impeller and the motor stator are isolated from each other, and the sealed injection cover having an entrance and an exit formed on a side surface of the upper plate such that the gas / liquid flows in and out through the same, respectively; a heat transfer base thermally bonded orattached to the lower portion of the impeller along an edge of the upper plate such that the gas / liquid containing portion is formed; an inflow pipe thermally bonded or attached to the entrance such that the gas / liquid flows in through the same; an outflow pipe thermally bonded or attached to the exit such that the gas / liquid flows out through the same; and a condensing portion positioned betweenthe inflow pipe and the outflow pipe so as to condense the gas in the gas / liquid, wherein a vacuum is formed in an inner space defined by a close loop extending through the gas / liquid containing portion, the inflow pipe, the outflow pipe, and the condensing portion.

Owner:ZALMAN TECH CO LTD

A microrefrigerator with droplet condensation and self-collection of water and its manufacturing method

ActiveCN106017174BIncreased phase change heat transfer coefficientContinuous and fast flowIndirect heat exchangersCooling/ventilation/heating modificationsHeterojunctionCapillary Tubing

A drop-like condensation and self-collecting microrefrigerator, with a three-layer structure of an upper glass plate, a middle silicon plate and a lower glass plate, the upper glass plate and the middle silicon plate are combined to form a condenser, an evaporator, a liquid pipe and a steam tube, the lower glass plate and the middle silicon wafer are combined to form a high-temperature chip heat transfer area and a cooling water pipe. The present invention uses a specific frustum-hemispherical micron and nanometer double-layer heterogeneous structure to modify the silicon condensation surface, so that the steam can be rapidly condensed into drop-shaped droplets in the condenser and spontaneously concentrated near the liquid pipe, and at the same time by many The liquid tubes composed of capillary tubes provide a large capillary driving force to absorb heat into the evaporator. The present invention also relates to the manufacturing method of the above-mentioned micro refrigerator. The invention has the advantages of novel structure, small volume, light weight, good stability and excellent refrigeration performance.

Owner:ZHEJIANG UNIV OF TECH

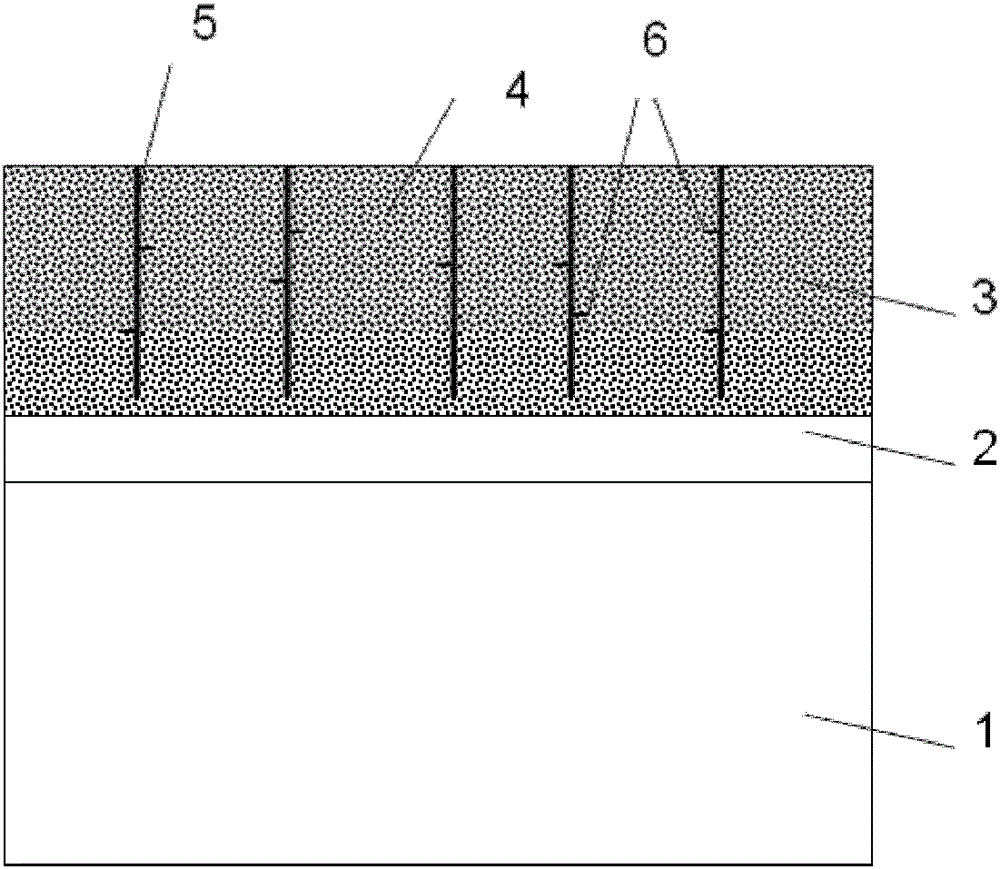

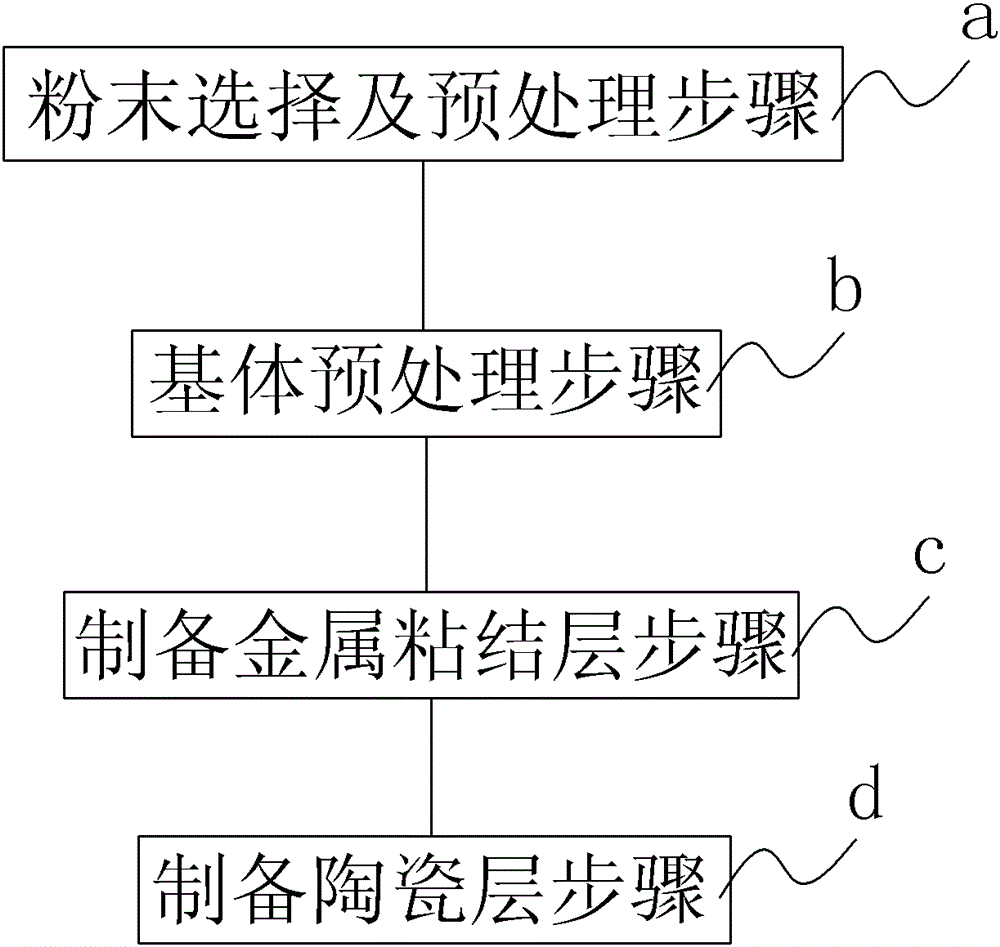

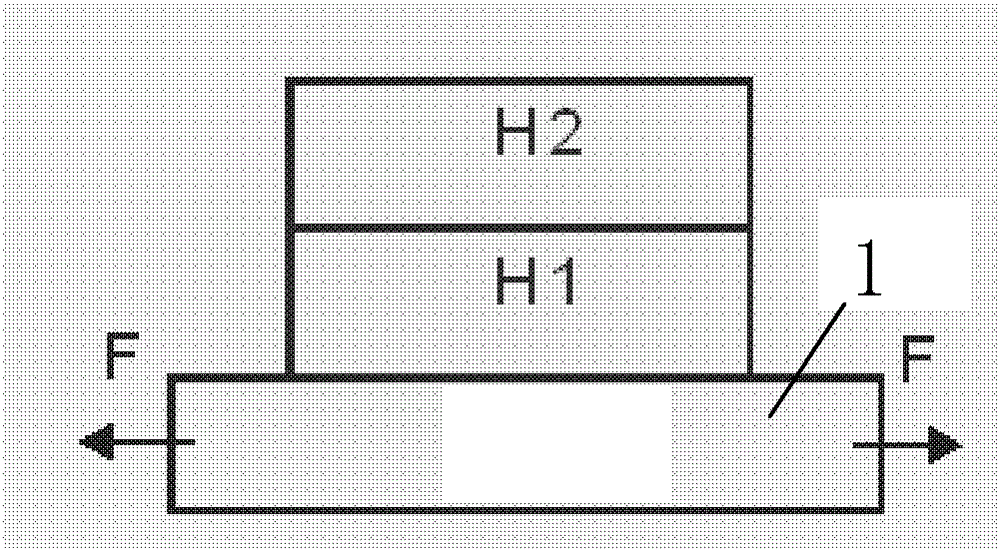

A nano/columnar-like mixed structure thermal barrier coating and its preparation method

ActiveCN103009704BSmall shrinkageGood heat insulationMolten spray coatingCeramic layered productsThermal insulationNanoparticle

The invention relates to a nanometer / columnar-like crystal mixing structure thermal barrier coating and a preparation method thereof. The mixing structure thermal barrier coating is a nanometer / columnar-like crystal mixing structure coating, and comprises a substrate, a metal bonding layer and a ceramic layer, wherein the metal bonding layer and the ceramic layer are sequentially coated on the substrate, the ceramic layer comprises unmelted nanoparticles, nanometer pores, nanometer crystal and ultrafine crystal, and has cracks perpendicular to the substrate, and the cracks form the columnar-like crystal structure. The mixing structure thermal barrier coating preparation method comprises powder selection, a pretreatment step, a substrate pretreatment step, a metal bonding layer preparation step, and a 6-8% YSZ ceramic layer preparation step. The coating disclosed by the present invention has characteristics of high strain tolerance, excellent thermal insulation performance, high bonding strength, high thermal cycle life, and high thermal shock life, such that the thermal barrier coating has a good comprehensive performance.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

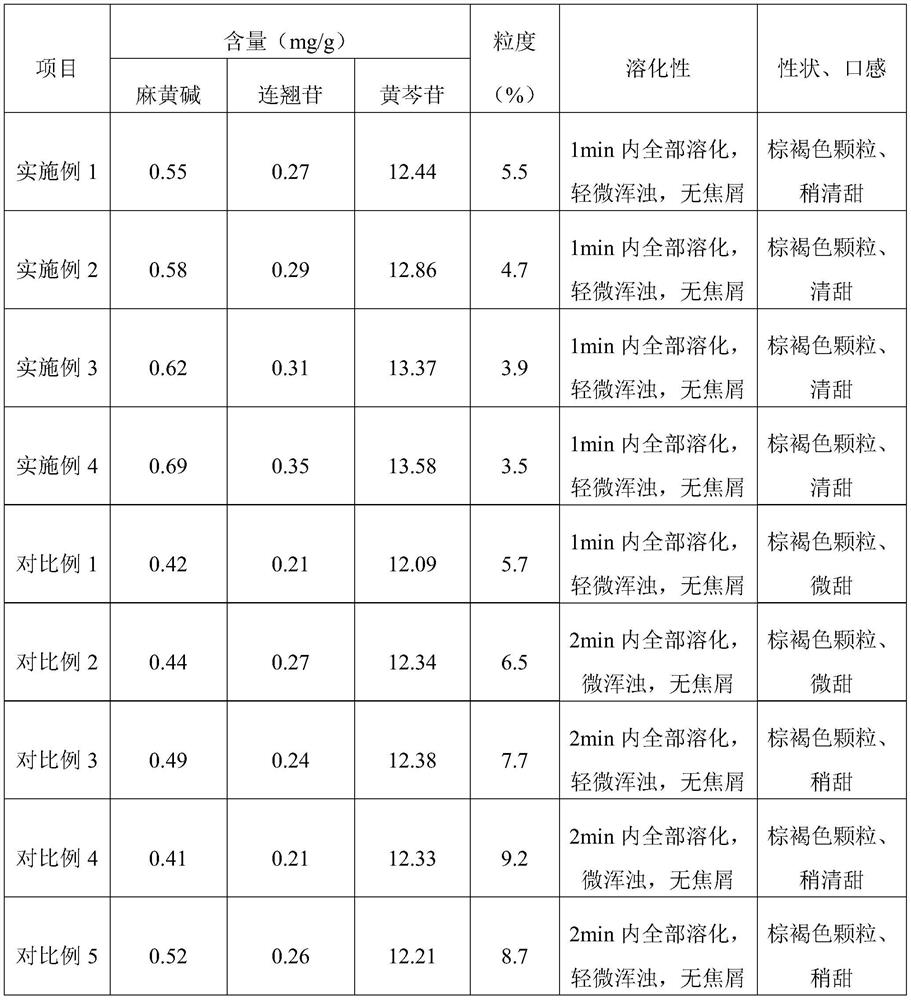

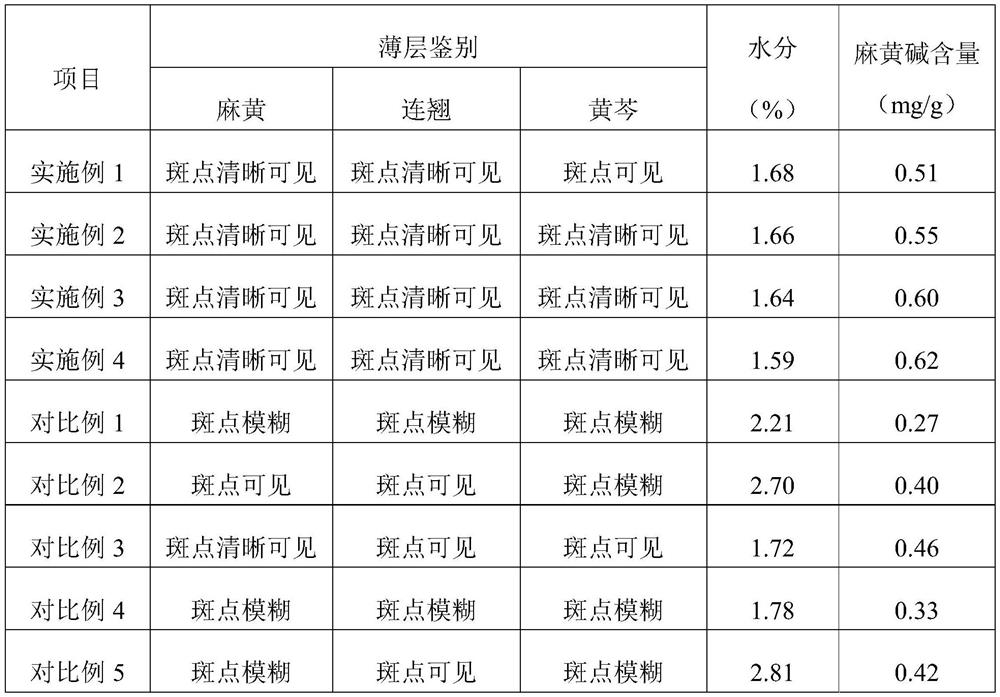

Preparation method of granules for treating infantile lung heat cough and asthma

ActiveCN113384650AEvenly distributedSweet tastePharmaceutical non-active ingredientsGranular deliveryHouttuyniaRadix Ophiopogonis

The invention provides a preparation method of granules for treating infantile lung heat cough and asthma. The preparation method comprises the following steps of: (1) adding liquorice, honeysuckle, semen armeniacae amarae and rhizoma anemarrhenae into hot water for soaking, adding crushed materials of gypsum, radix isatidis, radix ophiopogonis and houttuynia cordata in the boiling process, and filtering after boiling to obtain filtrate 1; (2) crushing ephedra, fructus forsythiae and scutellaria baicalensis, adding hot water for soaking, and filtering after repeated boiling to obtain filtrate 2; (3) performing vacuum concentration on the filtrate 1 and the filtrate 2 to obtain clear paste 1 and clear paste 2, adding mannitol into the clear paste 1, and refrigerating for a long time; and (4) mixing the clear paste 1 and the clear paste 2, preheating with hot air, performing spray drying, adding sodium cyclamate powder, and drying with hot air to obtain the granules. The granules for treating infantile lung heat cough and asthma prepared by the method provided by the invention have fresh and sweet taste, good stability, high content of effective components and good curative effect.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

LED (Light-Emitting Diode) street lamp

InactiveCN103629611ANot easy to affect the encapsulation effectReduce weightPoint-like light sourceLighting heating/cooling arrangementsHeat conductingEngineering

The invention discloses an LED (Light-Emitting Diode) street lamp, which comprises an LED chip and a heat-conducting substrate, wherein the LED chip is connected with the heat-conducting substrate; the heat-conducting substrate is flaky and is arranged on a heat-conducting pedestal; the heated end of a heat tube is arranged on the heat-conducting pedestal; the cooling end of the heat tube is placed in an air convection cavity; the cooling end of the heat tube is provided with radiating fins which are placed vertically. The LED street lamp disclosed by the invention has the advantages of good heat-dissipating effect, light weight, easiness in installation, prevention of safety accidents, uniform illumination and contribution to improving the adaptability of a driver during driving.

Owner:长兴恒动光电有限公司

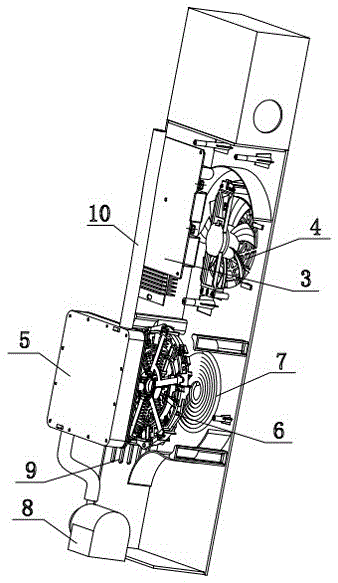

An ih mobile water heating heater

ActiveCN103697528BPromote circulationHeating evenlyLighting and heating apparatusElectric heating systemMovable typeEngineering

The invention relates to a warmer, in particular to an IH movable type water-heating warmer. The IH movable type water-heating warmer is characterized by comprising a heat-radiating device and a control box, wherein the heat-radiating device is formed by connecting a plurality of detachable heating radiators in series, an automatic water adding system is arranged at the upper portion of the control box, a main control plate and a heat-radiating fan is arranged in the middle, and a heating module is arranged at the lower portion. A coupling coil is arranged at the bottom of a heating wire coil and connected with a ground wire and can absorb a magnetic field leaked from the heating wire coil and convert the magnetic field into electric energy to be led to the ground wire and effectively reduce radiation harm on a human body. The heat-radiating fan is arranged in the control box, sucks air from the outside and blows out hot air in the control box, heat-radiating holes are formed in one side facing the heating radiators, and blown-out hot air flows pass through the heating radiators, enable heat of the heating radiators to be radiated indoors and promote indoor heat cycle. The IH movable type water-heating warmer is provided with the automatic water adding system, a movable cover plate is arranged at the top, and exhaust holes are formed in the movable cover plate, so that humidification treatment can be performed on air.

Owner:HANGZHOU SINODOD ELECTRIC

A simple solar energy comprehensive utilization device

ActiveCN104734620BIncrease profitImprove spotlight effectPhotovoltaic supportsSolar heating energyEngineeringThermal water

The invention discloses a simple solar energy comprehensive utilization device, and belongs to the field of solar energy utilization. The simple solar energy comprehensive utilization device comprises a supporting frame, a light condensation device, a heat collection power generation assembly and a hot water collection device, wherein the light condensation device and the heat collection power generation assembly are installed on the supporting frame, a planar reflecting mirror is installed in the light condensation device, converged light is irradiated to the outer surface of the heat collection power generation assembly, a heat collection water tank is arranged in the heat collection power generation assembly, the heat collection water tank is communicated with a hot water collection device through a water conveying pipe, and a photovoltaic assembly for power generation and the photovoltaic thermoelectricity assembly are arranged at the two sides of the water tank respectively. The simple solar energy comprehensive utilization device simplifies the internal structure and system composition of the heat collection power generation assembly, achieves the functions of photovoltaic power generation, thermoelectric power generation and solar heating through organic combination of all devices, improves the utilization rate of solar energy, improves the heat collection and power generation efficiency, and reduces cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

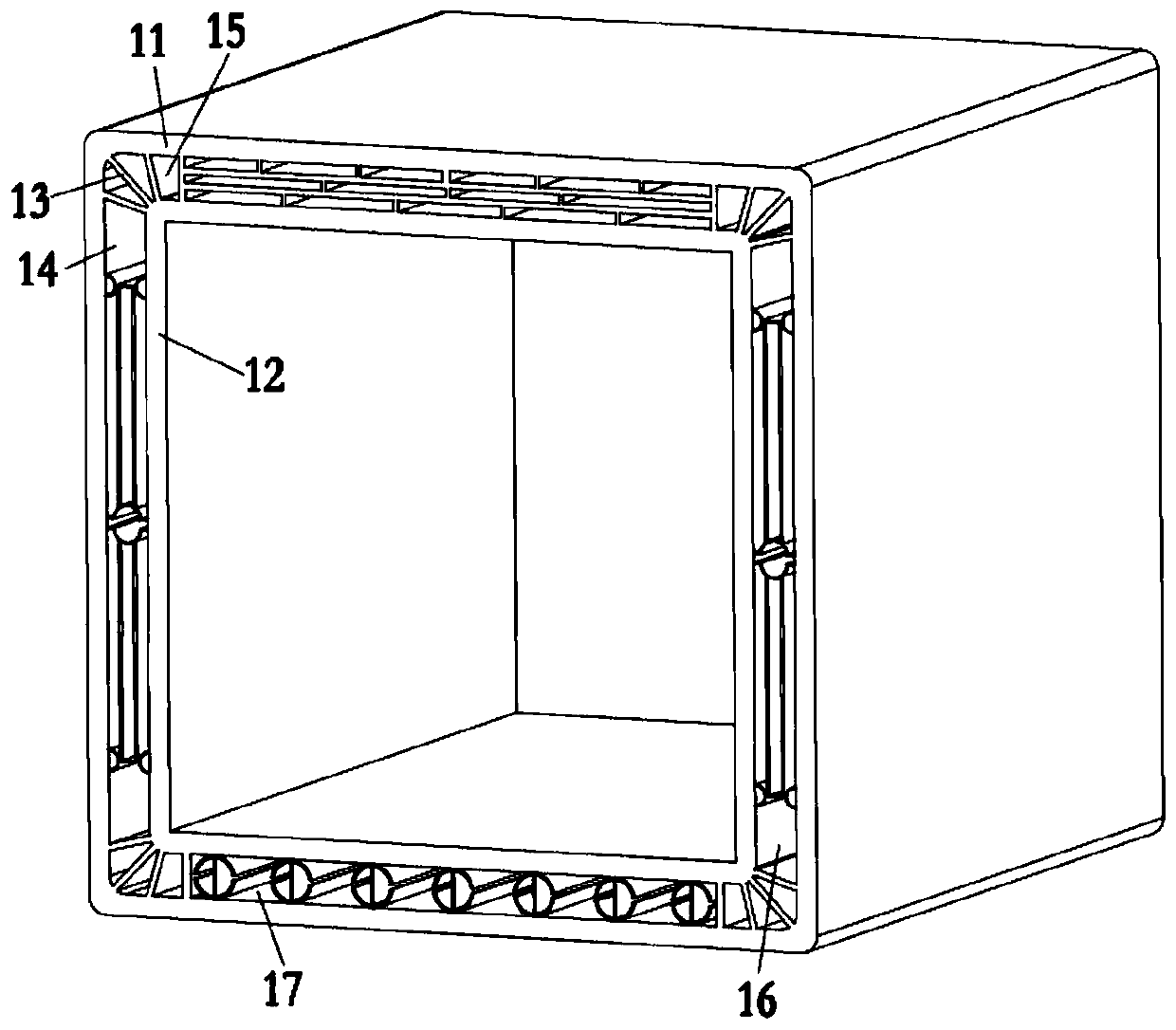

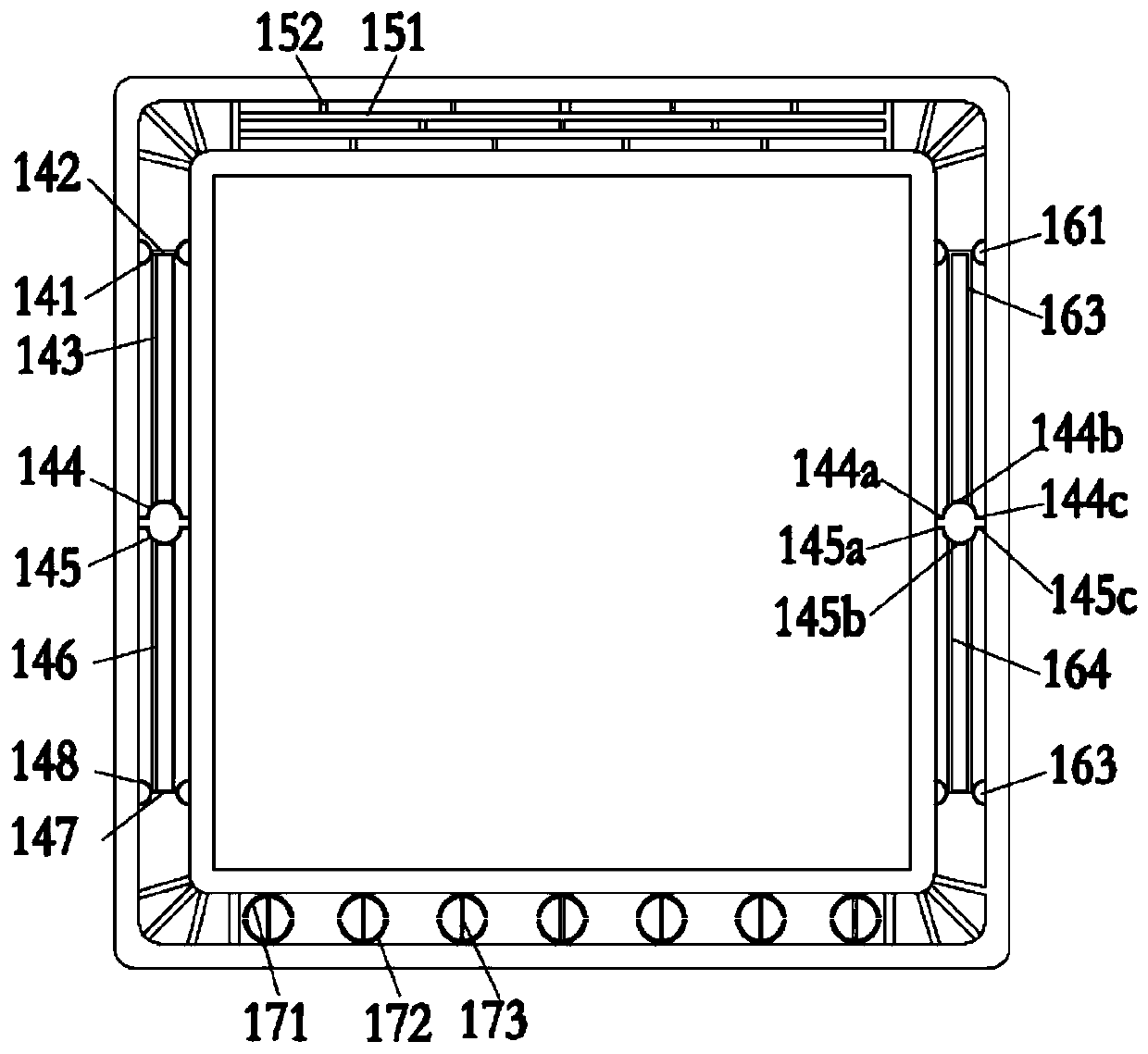

Cabinet heat insulation aluminum alloy profile and heat insulation cabinet

InactiveCN110840111AReduce breedingReduce installation costsLavatory sanitoryFurniture partsEngineeringMechanical engineering

The invention discloses a cabinet heat insulation aluminum alloy profile comprising an inner frame body and an outer frame body; four corners of the inner frame body and four corners of the outer frame body are connected to form a left accommodating cavity, a top accommodating cavity, a right accommodating cavity and a bottom accommodating cavity in a first frame body, wherein first transverse ribs, first vertical ribs, first arc-shaped connecting parts, second arc-shaped connecting parts, second vertical ribs, second transverse ribs, second arc-shaped ribs and the like are arranged in the left accommodating cavity and the right accommodating cavity to form a first sealing cavity, a second sealing cavity, a third sealing cavity and a fourth sealing cavity, and first heat insulation layersare arranged in the sealing cavities so that heat loss is reduced, and energy conservation and environmental protection are achieved.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

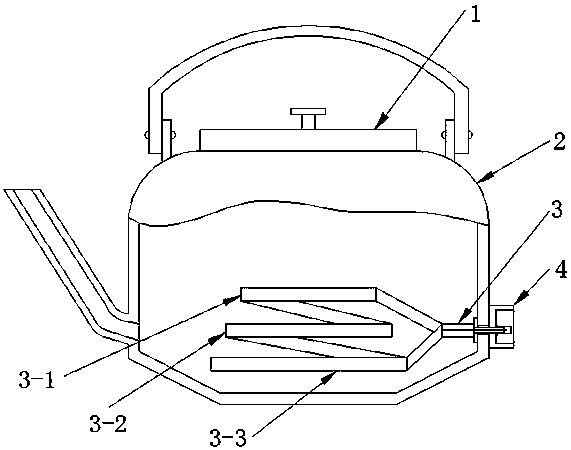

Energy-saving electric kettle

InactiveCN108065767AIncrease contact areaAvoid churnWater-boiling vesselsCooking vessel constructionsEngineeringHeat losses

The invention provides an energy-saving electric kettle. The energy-saving electric kettle comprises a kettle body and a kettle lid; an electric heating tube is installed at the lower portion of an inner cavity of the kettle body; conical surface transition is adopted for the bottom of the kettle body and the side wall of the kettle body, so that the lower portion of the kettle body is of a big-end-up structure; the electric heating tube is spiral, one connecting end is led from the lower end of the spiral electric heating tube, another connecting end is led from the upper end of the spiral electric heating tube, and the spiral electric heating tube is in matched connection with a socket arranged on the outer wall of the kettle body; the spiral electric heating tube is of an encircling structure formed by three layers of circular electric heating tube bodies. According to the energy-saving electric kettle, a traditional electric heating tube is changed into the three-layer spiral heating tube, so that the contact area of the heating tube and water is increased in the heating process, the energy consumption is reduced, the heat loss is prevented, and the heat efficiency is improved;conical surface transition is designed at the bottom of the kettle body, it is guranateed that the volume of water at the upper portion in the kettle body is larger than that of water at the lower portion in the kettle body, water at the bottom can rise easily, water at the upper portion can fall easily, and thus thermal circulation is promoted.

Owner:谈颜

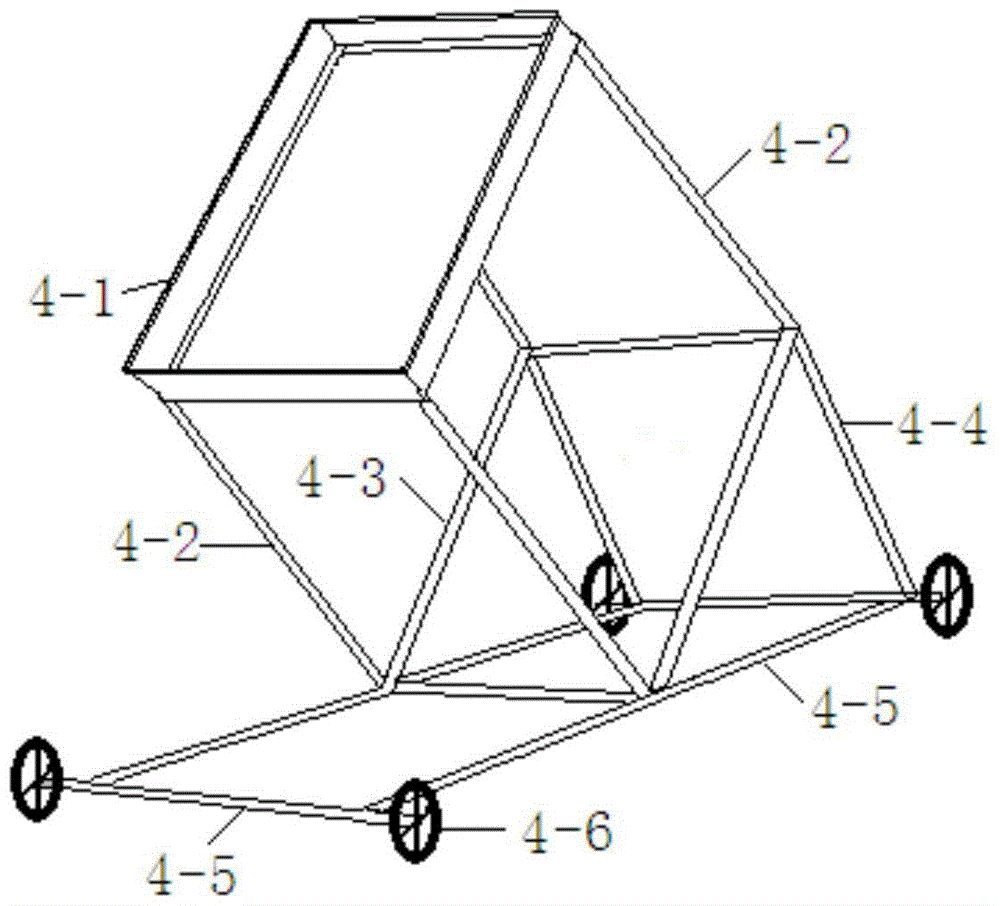

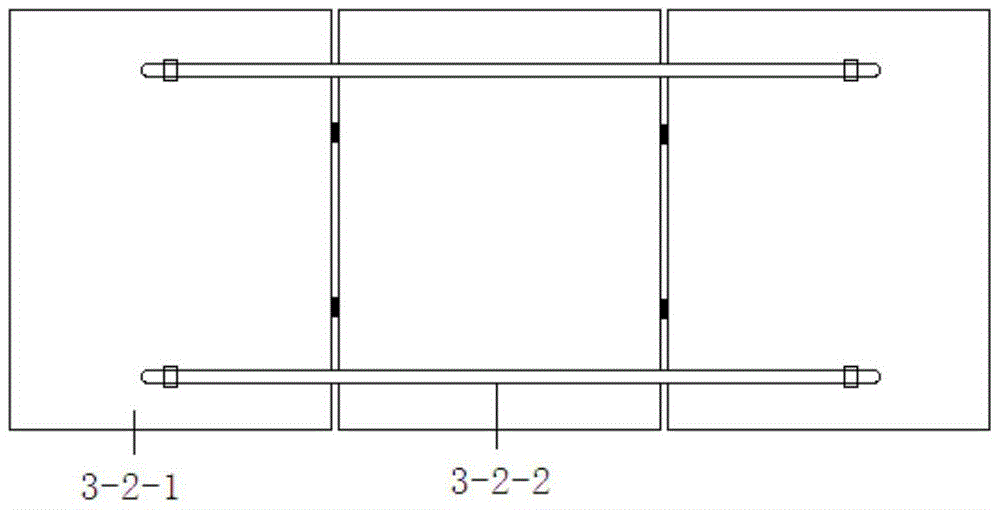

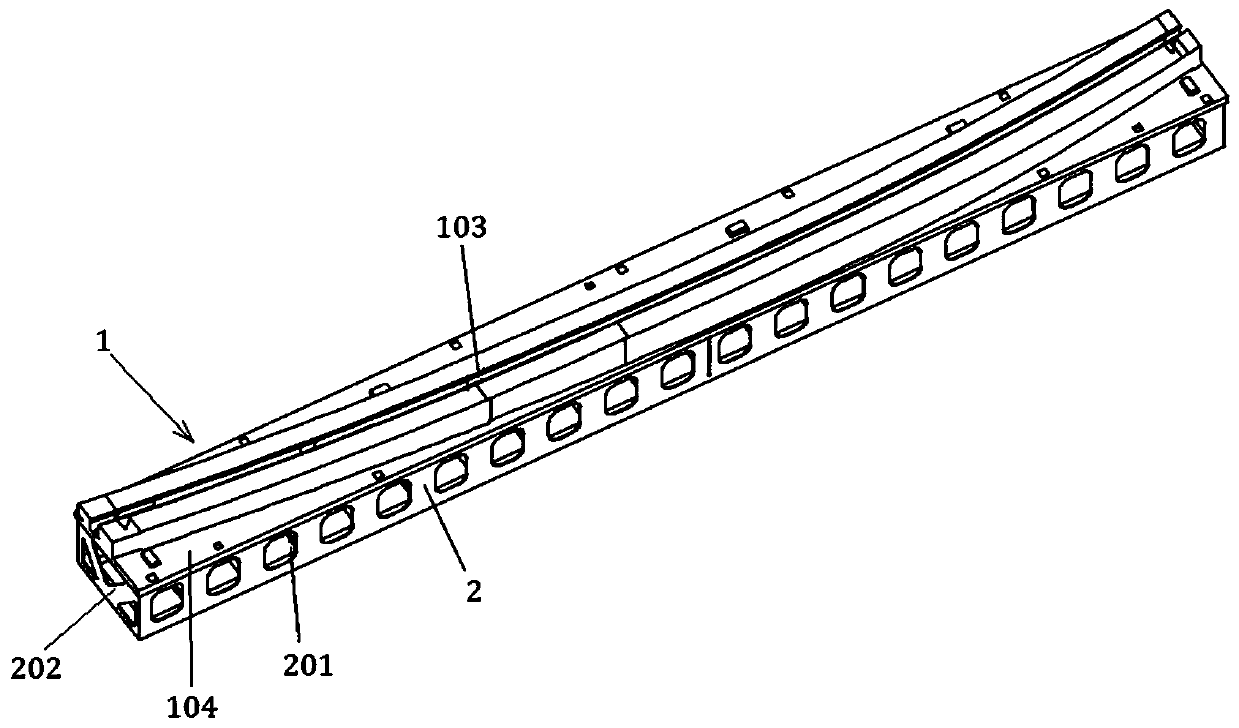

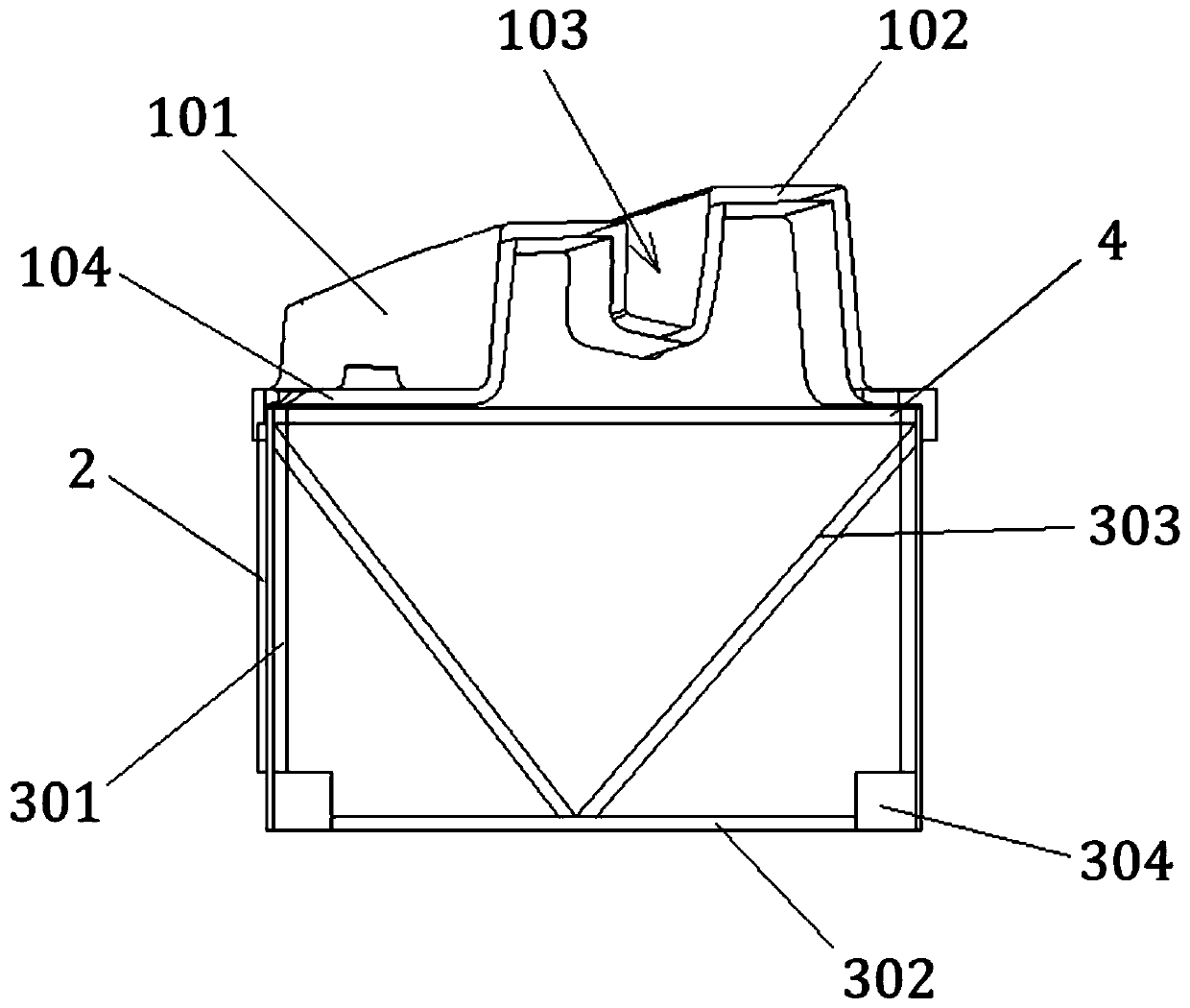

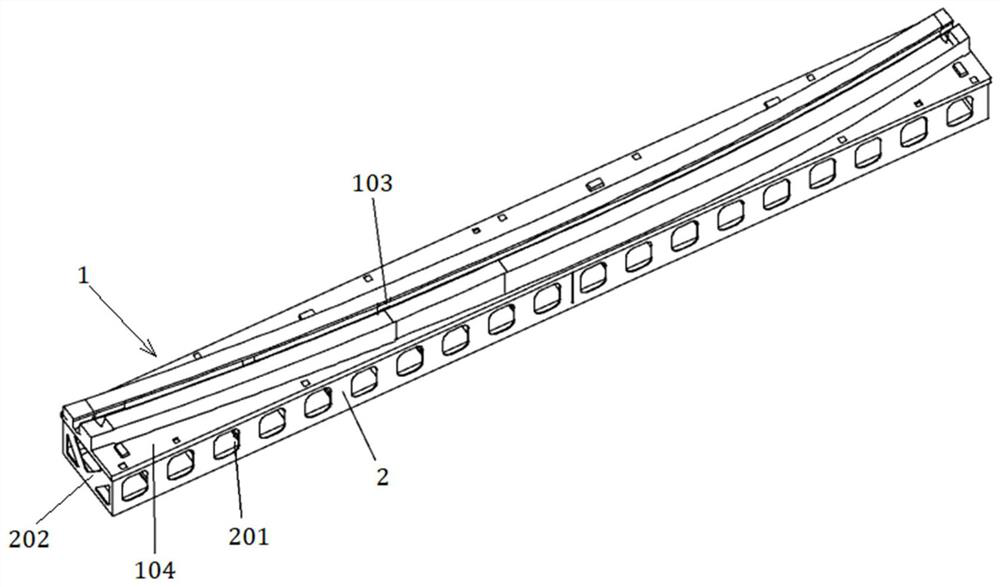

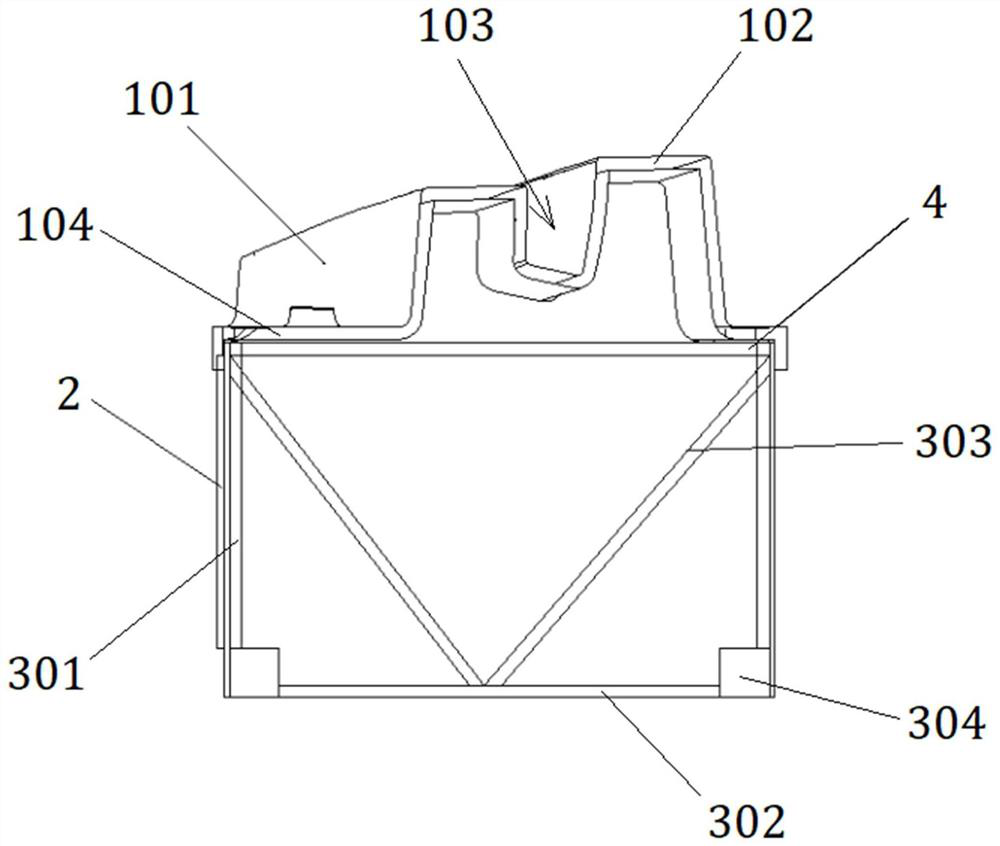

Mold and hot-pressing tank forming process equipment

ActiveCN111452261AStable supportReduce lengthwise deformationDomestic articlesProcess equipmentBraced frame

The invention relates to the technical field of hot-pressing tank forming processes, in particular to a mold and hot-pressing tank forming process equipment. The mold comprises a mold body and a supporting framework. A cavity matched with a prefabricated beam is constructed on the mold body. The supporting framework is fixed to the side, away from the cavity, of the mold body, and multiple supporting frame units are connected in the supporting framework in the length direction of the mold body at intervals. By means of the mold, the technical problem that existing hot-pressing tank forming process molds cannot meet the requirements that the shrinking percentage of the mold and product materials is consistent and the cost is low can be solved.

Owner:CRRC QINGDAO SIFANG CO LTD

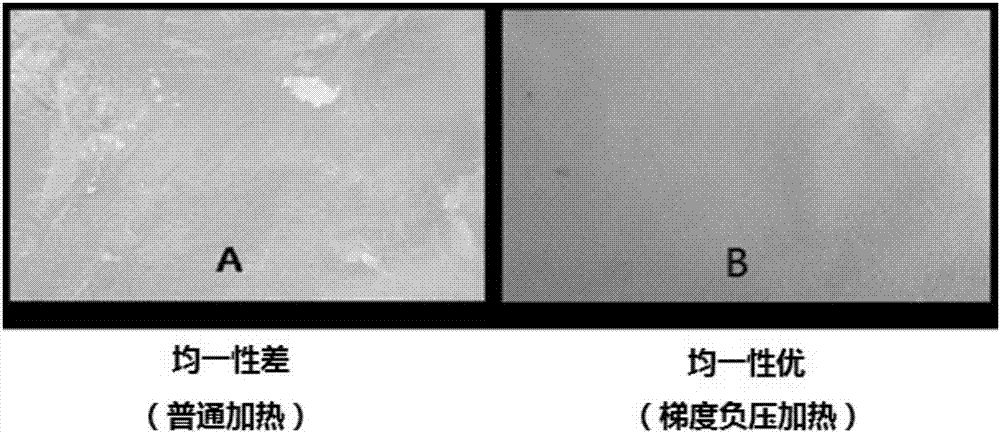

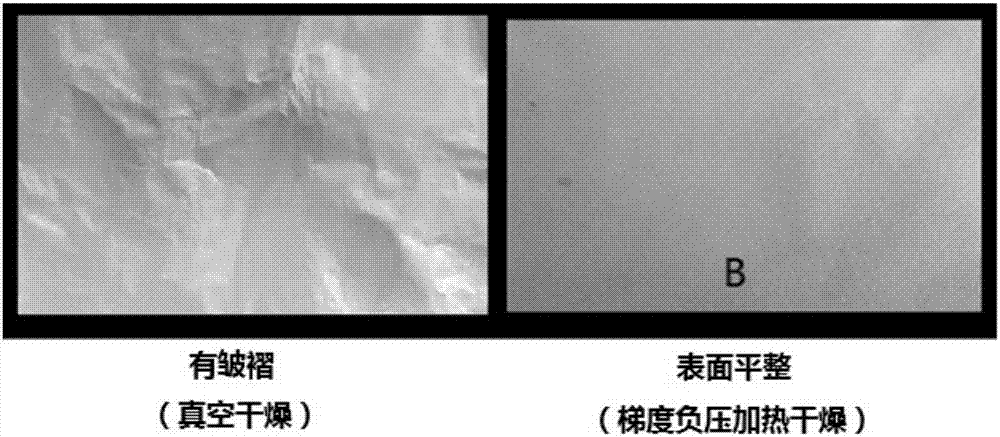

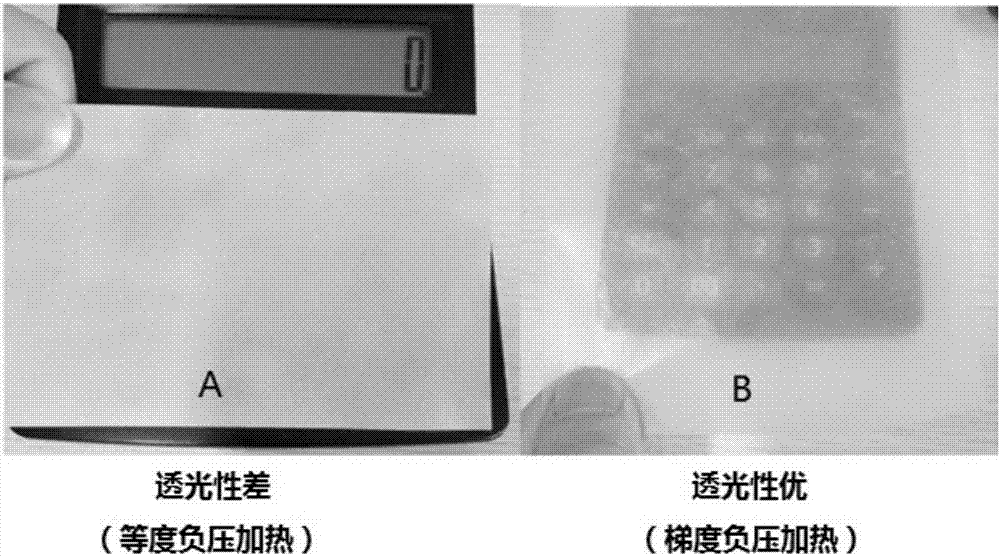

A kind of bacterial cellulose dry film and its preparation method and application

The invention provides a bacterial cellulose dry film as well as a preparation method and application thereof. The preparation method comprises the following steps of: pretreating a bacterial cellulose wet film; and performing gradient negative pressure heating molding to obtain the bacterial cellulose dry film. A gradient negative pressure is adopted to ensure that fibers cannot be flocculated, and the water in the wet film is removed as quickly as possible through heat transmission. The result shows that when the whole wet film is in a gradient negative pressure state, the atmospheric pressure on every part of the wet film is uniform and constant to provide a stable and uniform negative pressure environment for the wet film, and a continuous and stable heating temperature ensures rapid shaping of the wet film and the flatness and pressed density of the wet film after shaping. Due to a pumping action, the diffusion rate of the water in the wet film is increased, thereby promoting thermal circulation and greatly improving the heat treatment efficiency. The prepared dry film is good in uniformity and flatness, good in transparency, good in property of attaching to a skin when applied in the medical field, is stable in product quality, is easy to store, is light and thin, is convenient to pack and transport, and can be widely applied to various products with high added values.

Owner:SHAN DONG NAMEIDE BIOTECHNOLOGY CO LTD

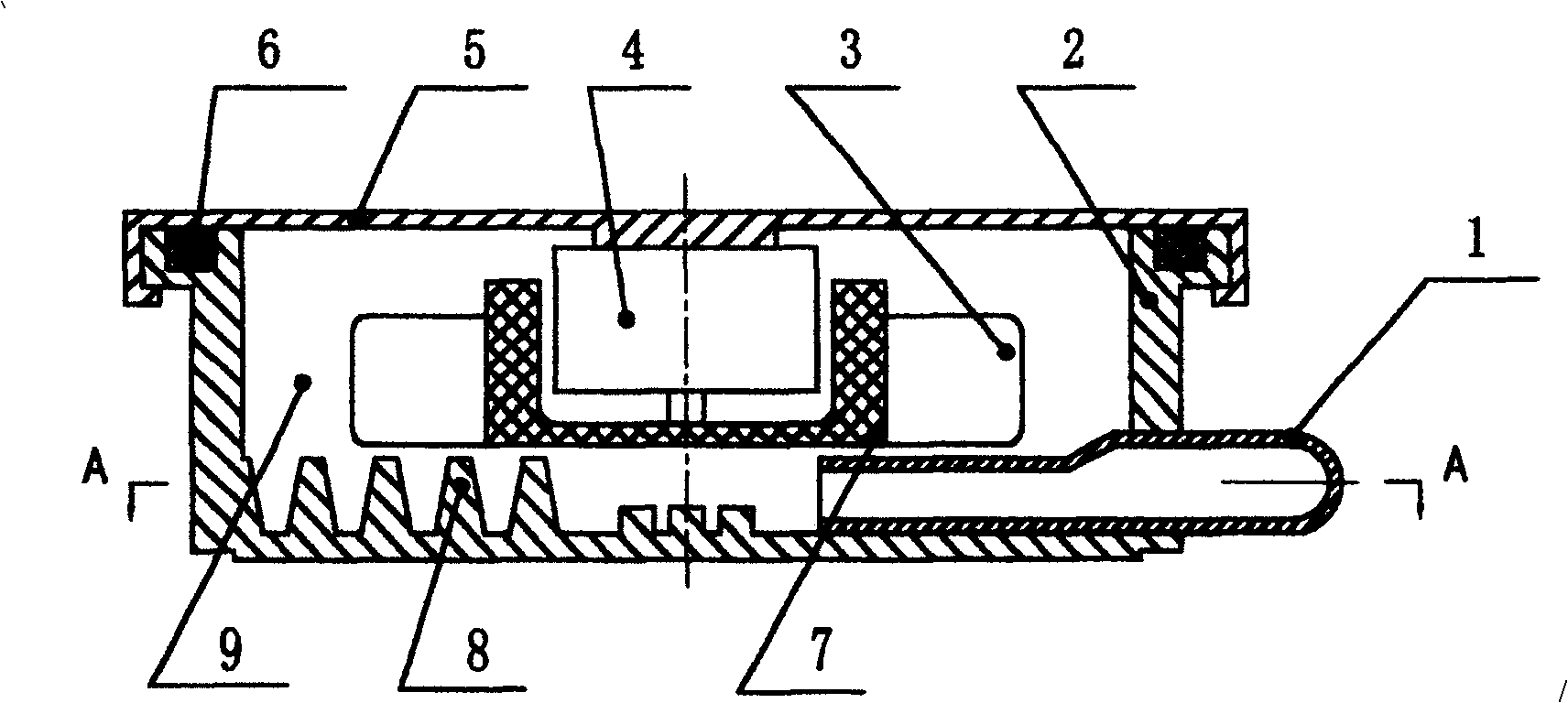

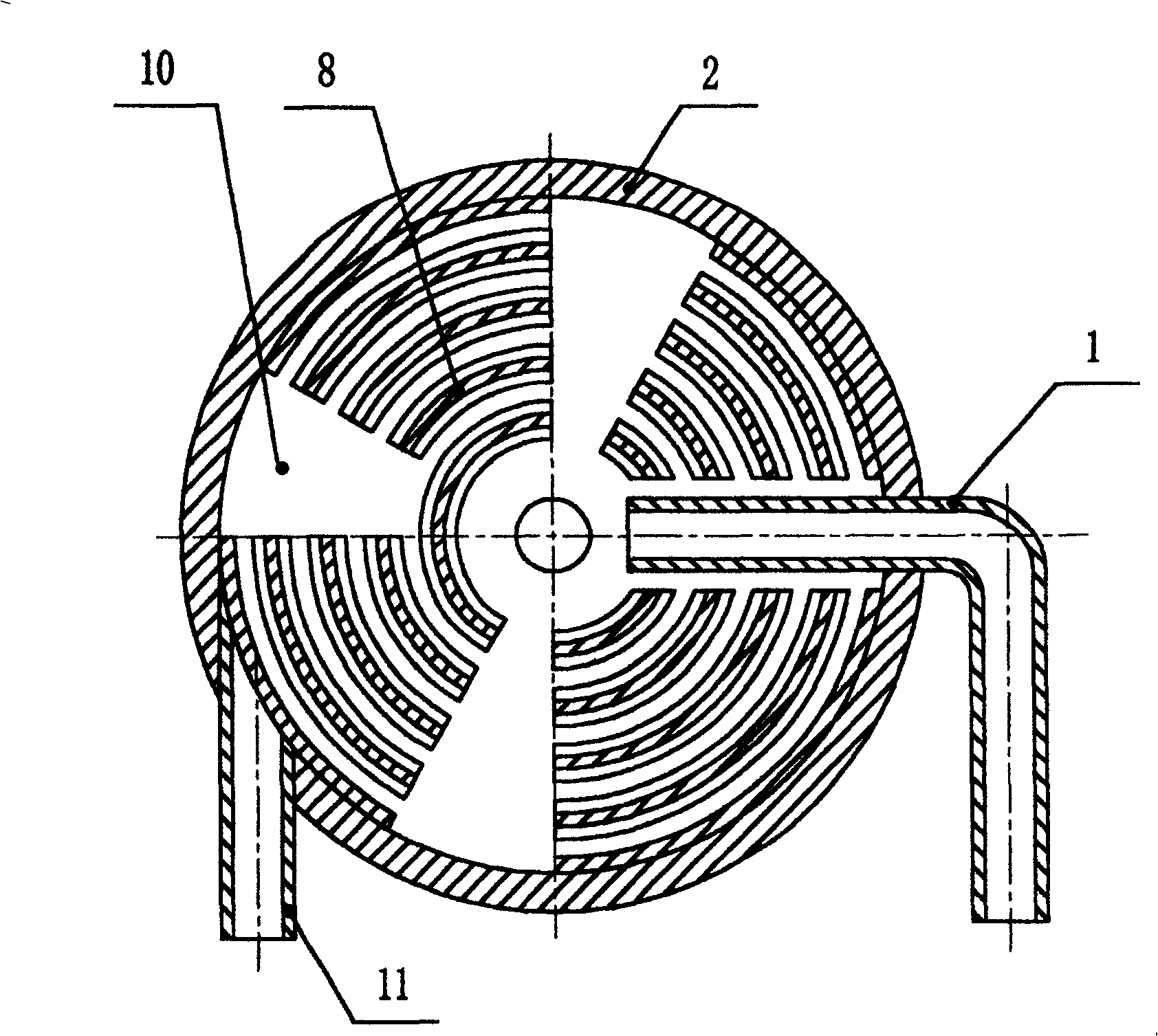

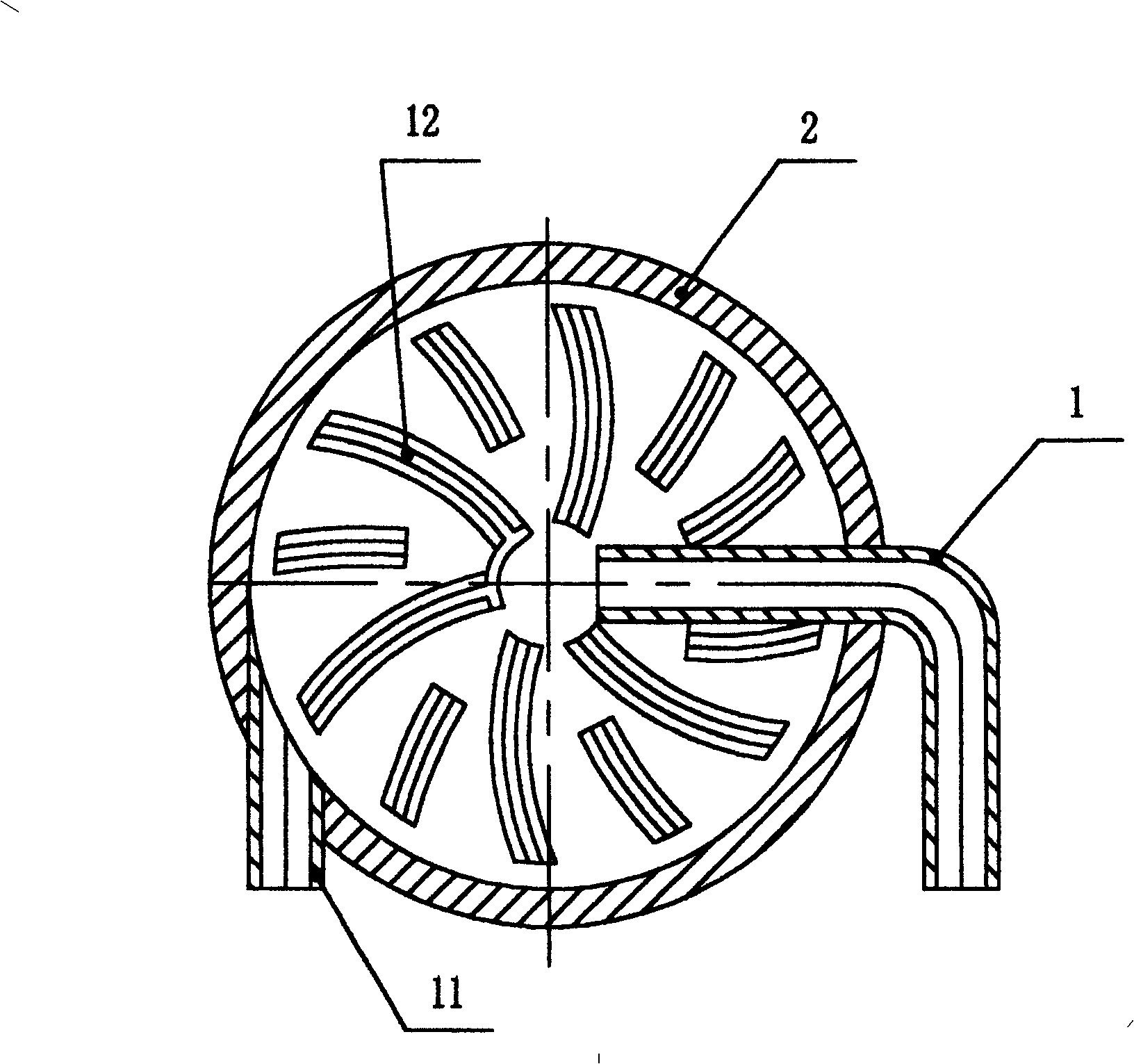

Miniature heat-collecting pump

InactiveCN100453823CAvoid strandedFaster thermal cyclingPump componentsPump installationsImpellerEngineering

Owner:张炜 +1

An Embedded Refrigerator Top Cooling System

ActiveCN105180564BImprove heat transfer efficiencyCompact structureLighting and heating apparatusRefrigeration devicesRefrigerationRefrigerated temperature

The invention relates to a top radiating system of an embedded refrigerator. The system comprises a condenser, a compressor, a sealed air duct and fans, wherein the condenser, the compressor, the sealed air duct and the fans are arranged on a fixed base plate located on the top of the embedded refrigerator. The condenser is located at the position of an opening in one end of the sealed air duct, and the fans are located at the position of an opening in the other end of the sealed air duct. The compressor is communicated with the condenser through a pipeline. According to the top radiating system of the embedded refrigerator, air on the back face of the refrigerator is sucked into the air duct of the radiating system for heat exchange, and then the air is exhausted from the front face and the periphery of the refrigerator, so that efficient and stable air flowing circulation is formed. On the basis that the space of the embedded refrigerator is saved and the appearance of the embedded refrigerator is beautified, an efficient radiating circulation system is guaranteed. The radiating efficiency of an entire refrigeration assembly of the embedded refrigerator is achieved, and good usability of the refrigerator is guaranteed.

Owner:HEFEI HUALING CO LTD +1

Preparation method for structured phospholipids based on enzyme reactor

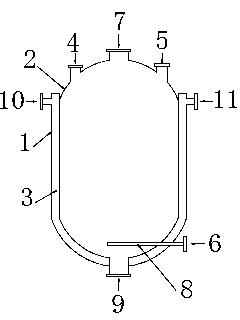

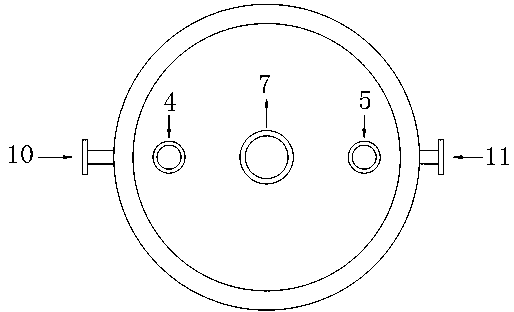

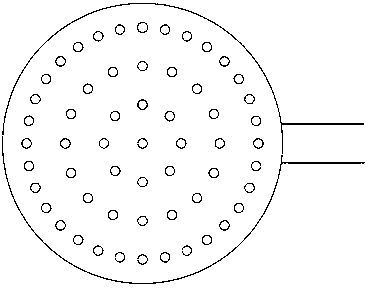

InactiveCN102827887BHigh catalytic efficiencyPromote circulationEnzyme production/based bioreactorsFermentationPhospholipinPhospholipase

The invention discloses a method for preparing textured phospholipids based on an enzyme reactor. The invention provides a textured phospholipid enzymatic reactor, which comprises a reaction tank and an outer jacket. The reaction tank has a material inlet, an enzyme adding port, an air inlet, an air distributor, an air outlet, and a material outlet. The outer jacket has a Cooling water inlet and cooling water outlet. The reaction material enters the reaction tank from the material inlet at a feed speed of 1-2m / s, the catalytic enzyme enters the reaction tank from the enzyme feeding port according to the ratio of 10-20% of the phospholipid mass, and the purified air enters the reaction tank from the air inlet, and the purified air passes through The air distributor becomes dispersed uniform small air bubbles, and the air flow rate is 1-3m / s; after the reaction, the material flows out from the material outlet, and the flow rate is 1-2m / s. The textured phospholipid enzymatic reactor of the present invention has simple structure, low cost, large effective reaction volume, and is suitable for large-scale industrial production of textured phospholipids; the textured phospholipid enzymatic reactor and the reaction method of the present invention can promote the production of reaction materials Full circulation, convenient and effective control of the reaction, significantly increase the conversion rate of unsaturated fatty acids.

Owner:GUANGZHOU CITY POLYTECHNIC +1

Glass hot bending mold and its manufacturing method and application

ActiveCN103359919BReduce manufacturing costReduce weightGlass reforming apparatusGlass productionHeat cyclingGlass forming

The invention discloses a glass hot-bending die as well as a manufacturing method and application of the glass hot-bending die, belonging to the technical field of solar energy utilization. The glass hot-bending die comprises a main body and a frame-shaped glass edge hot-bending part, wherein the main body has a plurality of through holes which pass through the upper and lower surfaces of the main body; the frame-shaped glass edge hot-bending part is connected with the main body; a glass forming surface is formed by the upper surface of the frame-shaped glass edge hot-bending part together with the upper surface of the main body. According to the glass hot-bending die, by forming the through holes in the main body part of the glass hot-bending die, materials used by the glass hot-bending die are reduced, the die production cost is lowered, the heat that the die absorbs is reduced, the uniform glass heating and forming in the hot-bending process are facilitated, the radiation of the heat of the die is facilitated, and both the service life of the die is prolonged and the forming precision of glass is ensured; due to the existence of the through holes, the hot-bending die is good in heat circulation in the hot-bending process, a plurality pieces of glass can be hot-bent simultaneously, the production efficiency is greatly improved, and due to the arrangement of the through holes, the weight of the die is reduced, and the die can be conveniently hoisted and transported.

Owner:CHINA BUILDING MATERIALS ACAD +1

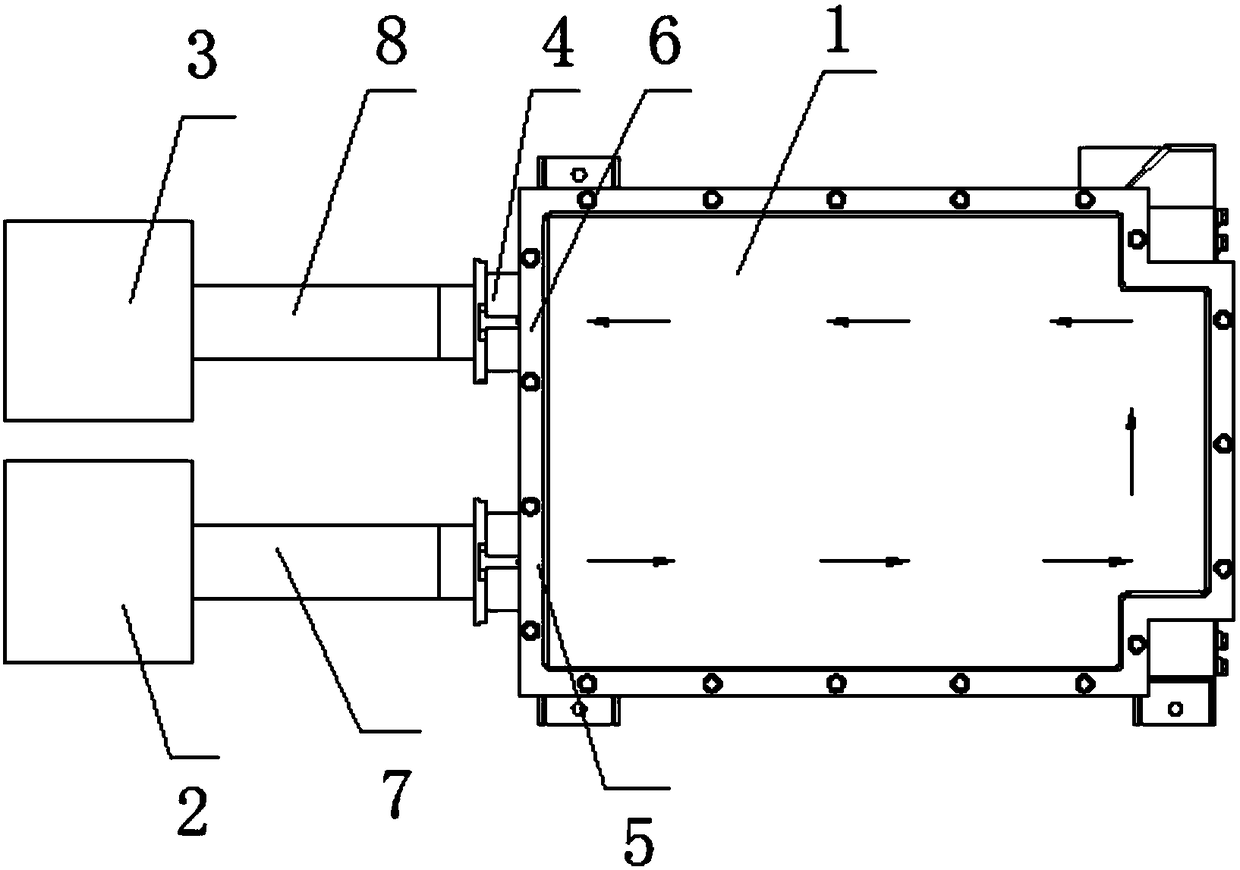

A new type of air-cooled air duct quick connection mechanism

The invention relates to a novel air cooling duct fast connecting mechanism which comprises an inner locking connection terminal and an outer locking connection terminal, wherein the inner locking connection terminal is composed of a first base and a first locking connection seat; a circle of sealing groove is formed in the outer wall of the first locking connection seat; a sealing ring is arranged in the sealing groove; and the outer locking connection terminal is composed of a second locking connection seat and a third locking connection seat. According to the novel air cooling duct fast connecting mechanism, the first locking connection seat of the inner locking connection terminal is fixed to the second locking connection seat of the outer locking connection terminal in a snap-in manner, and mutual communication among a first channel, a second channel, a third channel and a fourth channel is realized to enable a first positioning lug and a second positioning lug to be mutually pressed, thus the installation problem of an air port and an air port matching end is solved, the sealing performance is good, and the speed of interior thermal cycle of a battery pack is accelerated.

Owner:SYST ELECTRONICS TECH ZHENJIANG CO LTD +1

A preparation method and structure of an all-intermetallic compound interconnection solder joint

ActiveCN104690383BHave a single orientationImprove fatigueMetal working apparatusSoldering auxillary devicesPower flowSingle crystal

Owner:DALIAN UNIV OF TECH

A new battery pack air cooling system

Owner:SYST ELECTRONICS TECH ZHENJIANG CO LTD +1

A simple photovoltaic-photothermal-thermoelectric comprehensive utilization system

ActiveCN104729108BIncrease the heating areaIncrease contact areaSolar heating energySolar heat devicesEngineeringThermal water

The invention discloses a simple photovoltaic, photothermal and thermoelectric comprehensive utilization system and belongs to the field of solar energy utilization. The system comprises a supporting frame, a condensation device, a heat collection and power generation module and a hot water collection device, wherein the condensation device and the heat collection and power generation module are installed on the supporting frame, a planar reflector is installed in the condensation device, converged light rays irradiate the outer surface of the heat collection and power generation module, a heat collection water tank is arranged in the heat collection and power generation module, the heat collection water tank is communicated with the hot water collection device through a water delivery pipe, and a photovoltaic module and a thermoelectric module which are used for power generation are arranged on the two sides of the water tank respectively. The internal structure and system composition of the heat collection and power generation module are simplified; the devices are organically combined, so that the functions of photovoltaic power generation, thermoelectric power generation and optical energy heating are achieved, the utilization rate of solar energy is increased, heat collection and power generation efficiency is improved, and cost is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

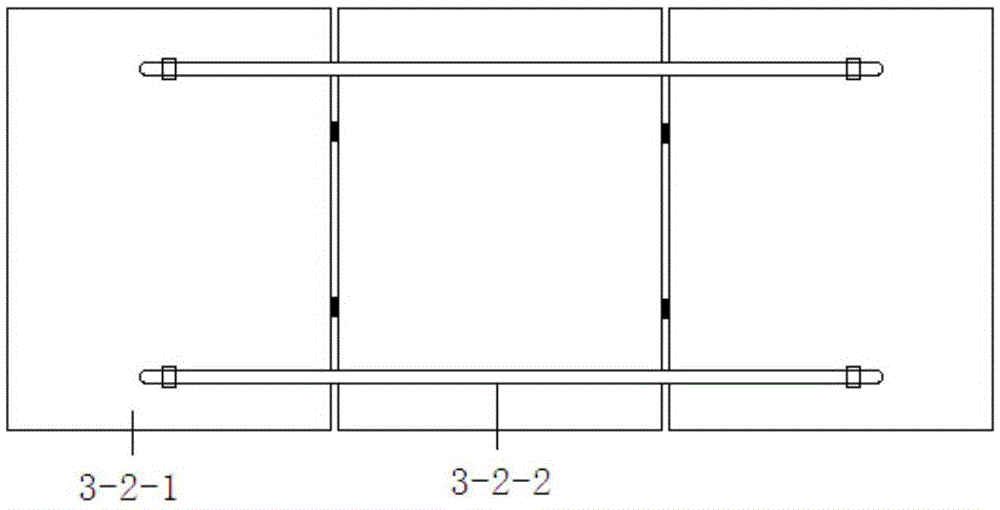

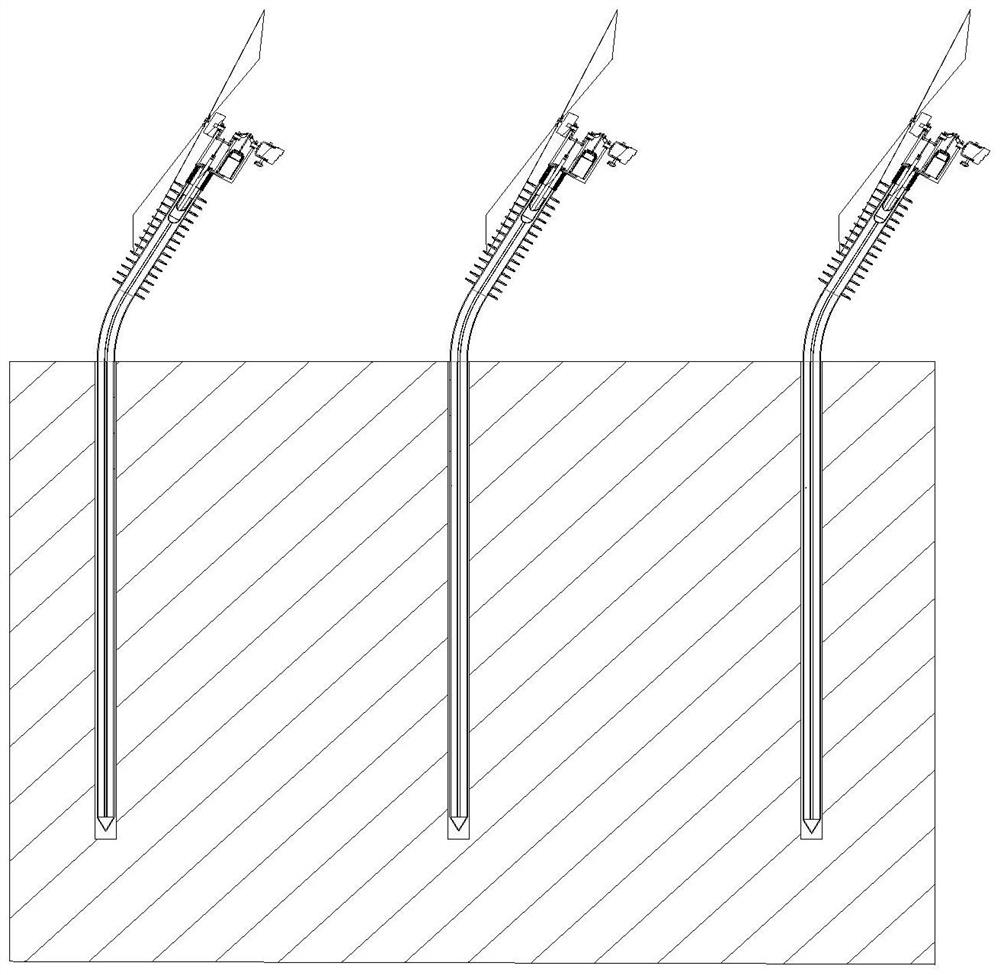

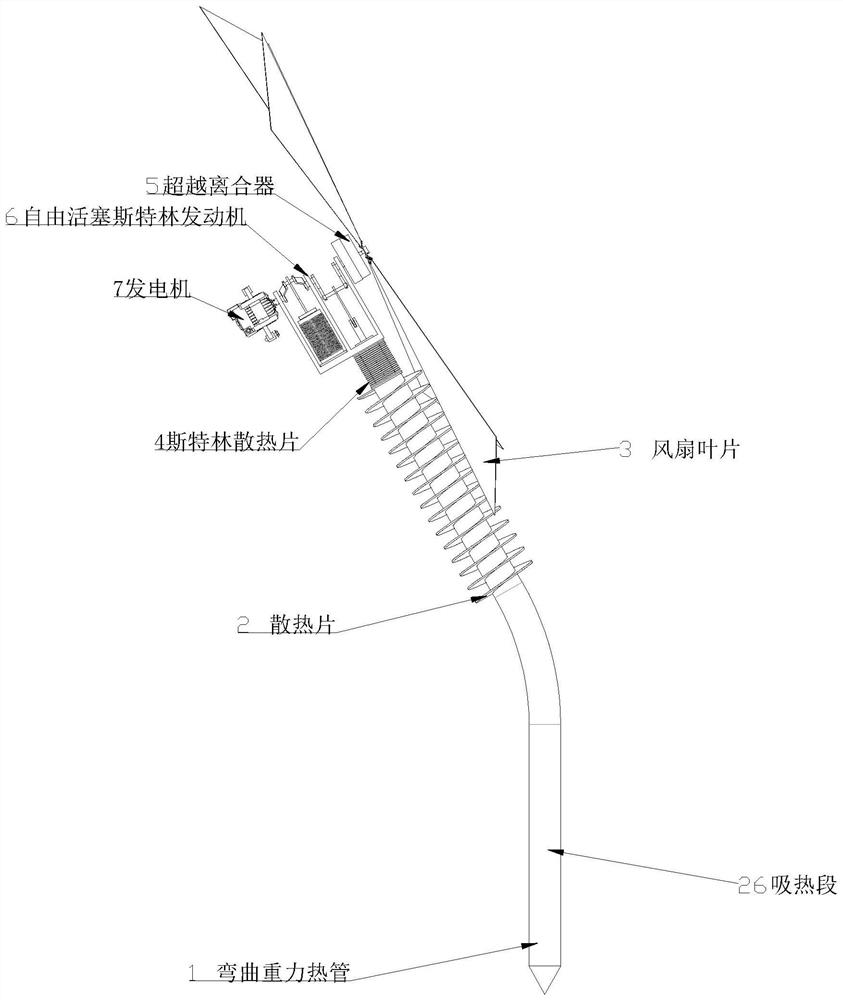

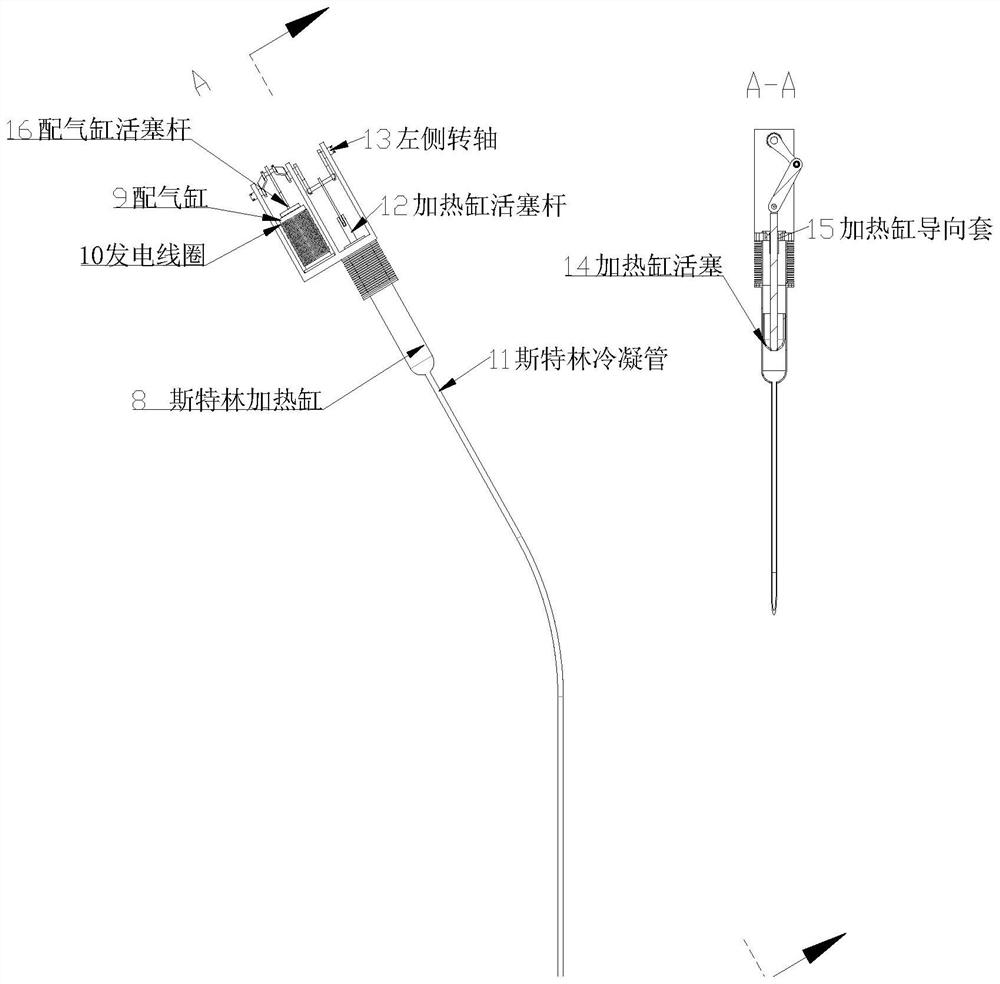

Device for waste dump accumulated temperature treatment and heat energy and wind energy cooperative power generation and heat dissipation

PendingCN114576033AImprove cycle efficiencyFaster thermal cyclingIndirect heat exchangersWind energy generationWaste dumpEngineering

The invention relates to the field of waste dump treatment, in particular to a waste dump accumulated temperature treatment and heat energy and wind energy synergistic power generation and heat dissipation device which comprises a bent gravity assisted heat pipe, the bent gravity assisted heat pipe comprises a heat absorption section and a heat dissipation section, and the top end of the bent gravity assisted heat pipe is connected with a Stirling heating cylinder. Stirling piston frames are installed at the top ends of the Stirling heating cylinders, heating cylinder rotating rods and air distribution cylinder rotating rods are installed on the Stirling piston frames on the two sides respectively, air distribution cylinder rotating rod movable pins are connected between the air distribution cylinder rotating rods, the air distribution cylinder rotating rod movable pins are connected with air distribution cylinder piston rods, and air channels are formed in the lower portions of the Stirling piston frames. Thermal circulation of the bent gravity assisted heat pipe can treat accumulated temperature in the gangue dump, and the Stirling engine can accelerate thermal circulation of the bent gravity assisted heat pipe and convert excess energy into electric energy at the same time. The wind power device can utilize wind energy to accelerate movement of the Stirling engine so as to accelerate heat circulation of the bent gravity assisted heat pipe, and meanwhile excess energy is converted into electric energy.

Owner:SOUTHEAST UNIV

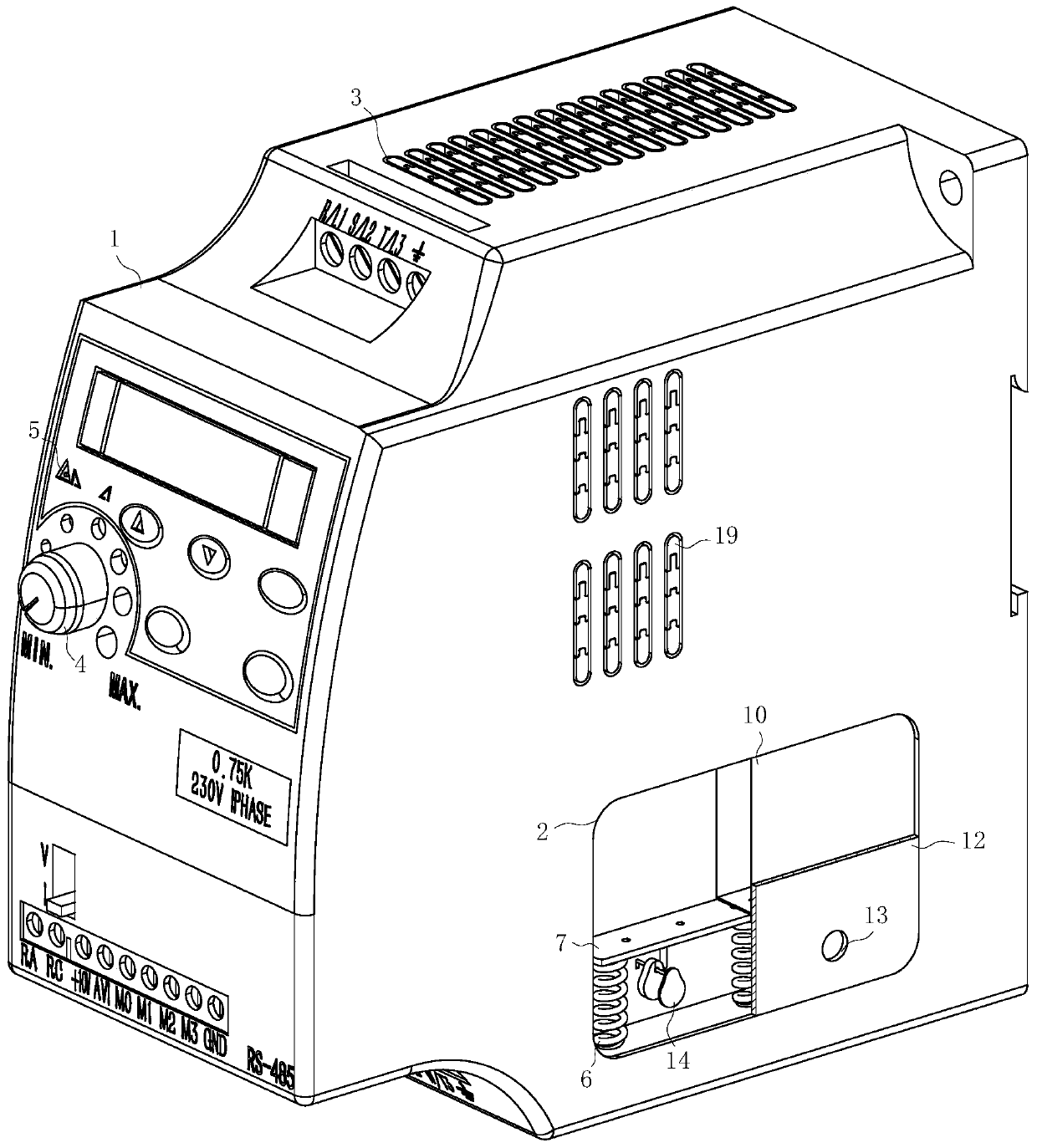

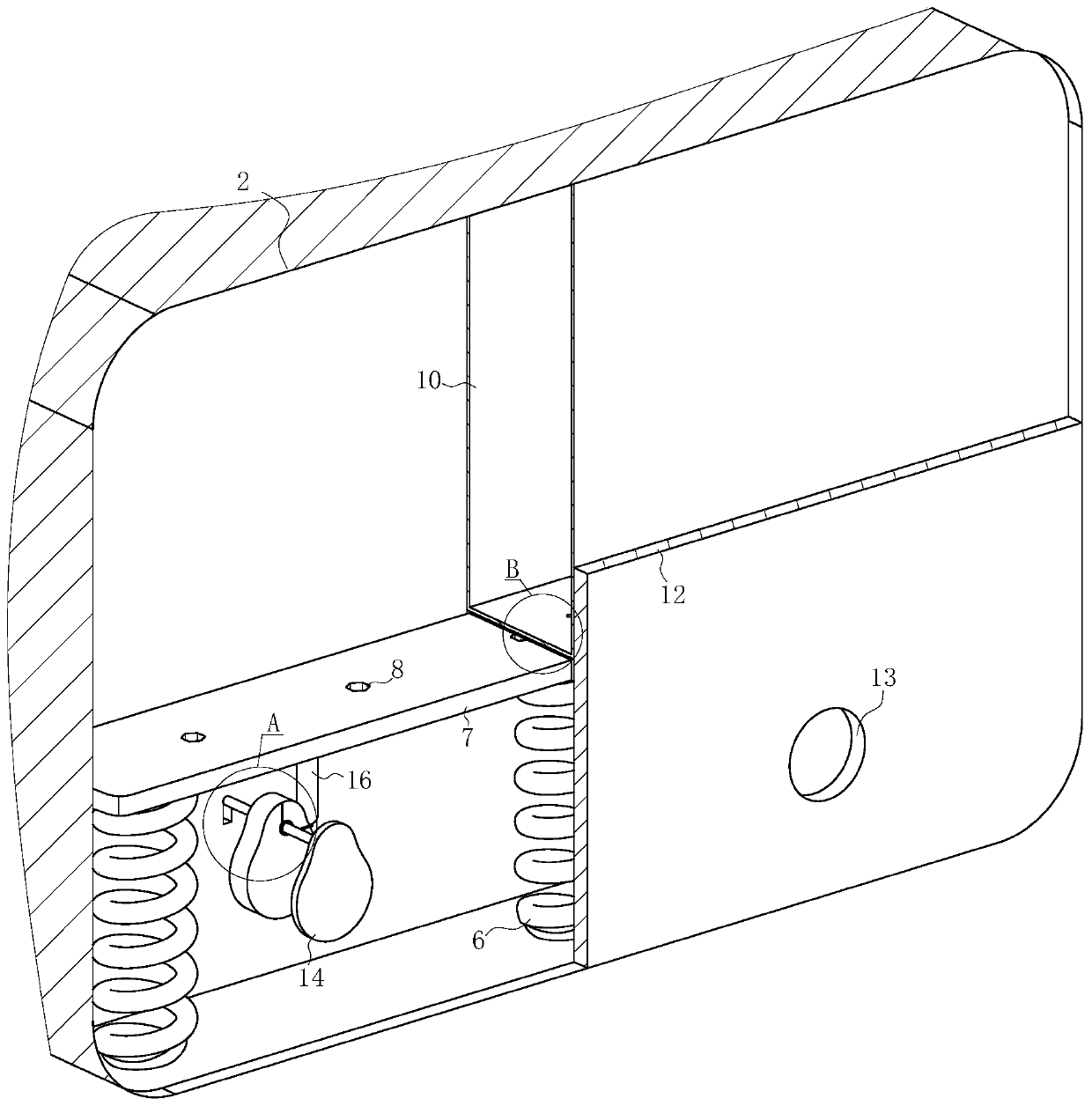

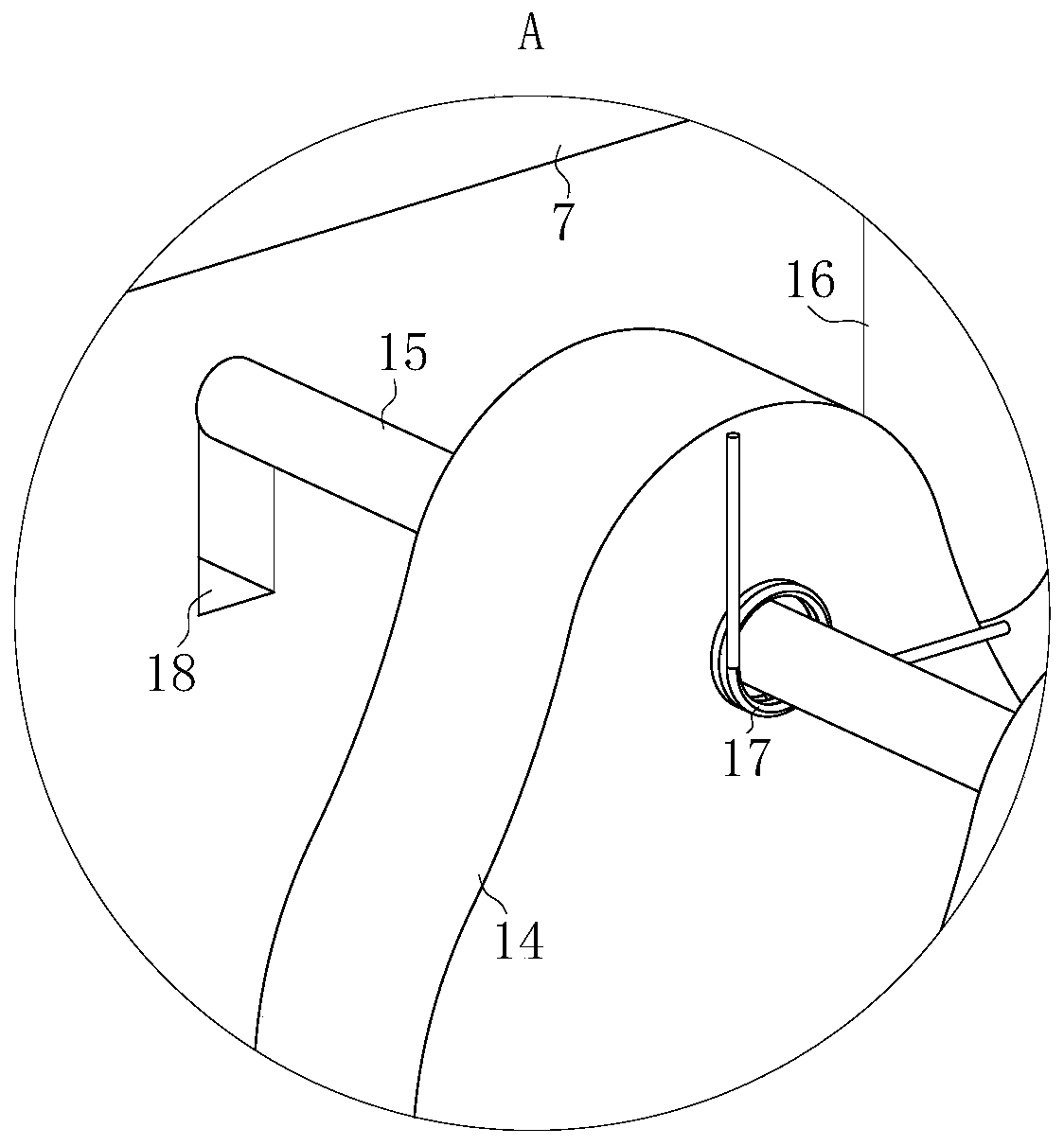

A kind of frequency conversion speed regulator for AC permanent magnet synchronous motor with direct current power supply for mining

ActiveCN110504820BGuaranteed working environmentImprove reliabilityAC motor controlElectric motor controlFrequency conversionPermanent magnet synchronous motor

The invention belongs to the technical field of variable frequency speed regulation control, and specifically relates to a variable frequency speed regulator for an AC permanent magnet synchronous motor of a mining DC power supply, including a speed governor, and the speed governor includes a vibration chamber, a heat dissipation chamber, and a speed regulation knob and the adjustment button, one set of the vibrating spring is located at the bottom of the vibrating chamber, the lower end of the vibrating spring is fixedly connected to the vibrating chamber, and the upper end of the vibrating spring is fixedly connected to the pressing plate; The vibration chamber is fixedly connected, and there are air guide holes on the air-collecting airbag and the elastic membrane; the sealing plate is located on the side of the vibration chamber, and the sealing plate is used to seal the vibration chamber. There are air inlet holes on the sealing plate, and two sets of cams are arranged along the rotating shaft. The cam is fixedly connected with the rotating shaft, and the upper surface of the cam far away from the air inlet hole is provided with a push rod, which is fixedly connected with the pressure plate; the rotating shaft is fixedly connected with a torsion spring, and the rotating shaft is connected in the height-adjusting chamber in rotation; a rotating plate is hinged in the heat dissipation chamber; The gas entering the governor is kept dry and clean, ensuring the working environment inside the governor.

Owner:ANHUI UNIV OF SCI & TECH

Mold and autoclave forming process equipment

ActiveCN111452261BStable supportReduce lengthwise deformationDomestic articlesProcess equipmentShrinkage rate

The invention relates to the technical field of autoclave forming technology, in particular to molds and autoclave forming process equipment. The mold comprises: a mold body configured with a cavity matching the prefabricated beam body; and a support frame fixed on the side of the mold body away from the cavity, and the inside of the support frame is connected along the longitudinal direction of the mold body at intervals. a supporting frame unit. The mold can solve the technical problem that the existing hot-pressing pot molding process mold cannot meet the requirements of consistent shrinkage ratio of the mold and product materials and low cost.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com