Electronic part cooling device having gas/liquid pump

A technology of electronic parts and cooling devices, which is applied to the structural parts of electrical equipment, electrical components, electrical solid devices, etc., can solve the problems of rapid circulation of fluids that cannot act, and achieve the effect of promoting thermal circulation and maximizing cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In describing the present invention, when it is judged that the detailed description of related known functions or structures may unnecessarily obscure the gist of the present invention, the detailed description will be omitted. In addition, the terms (terminology) used in this specification are used in order to express the preferred embodiment of this invention appropriately, and therefore may differ according to the intention of a user, an operator, or the common practice of the field to which this invention belongs. Therefore, this term should be defined based on the contents of the entire specification. The same reference numerals attached to the respective figures denote the same structures.

[0024]

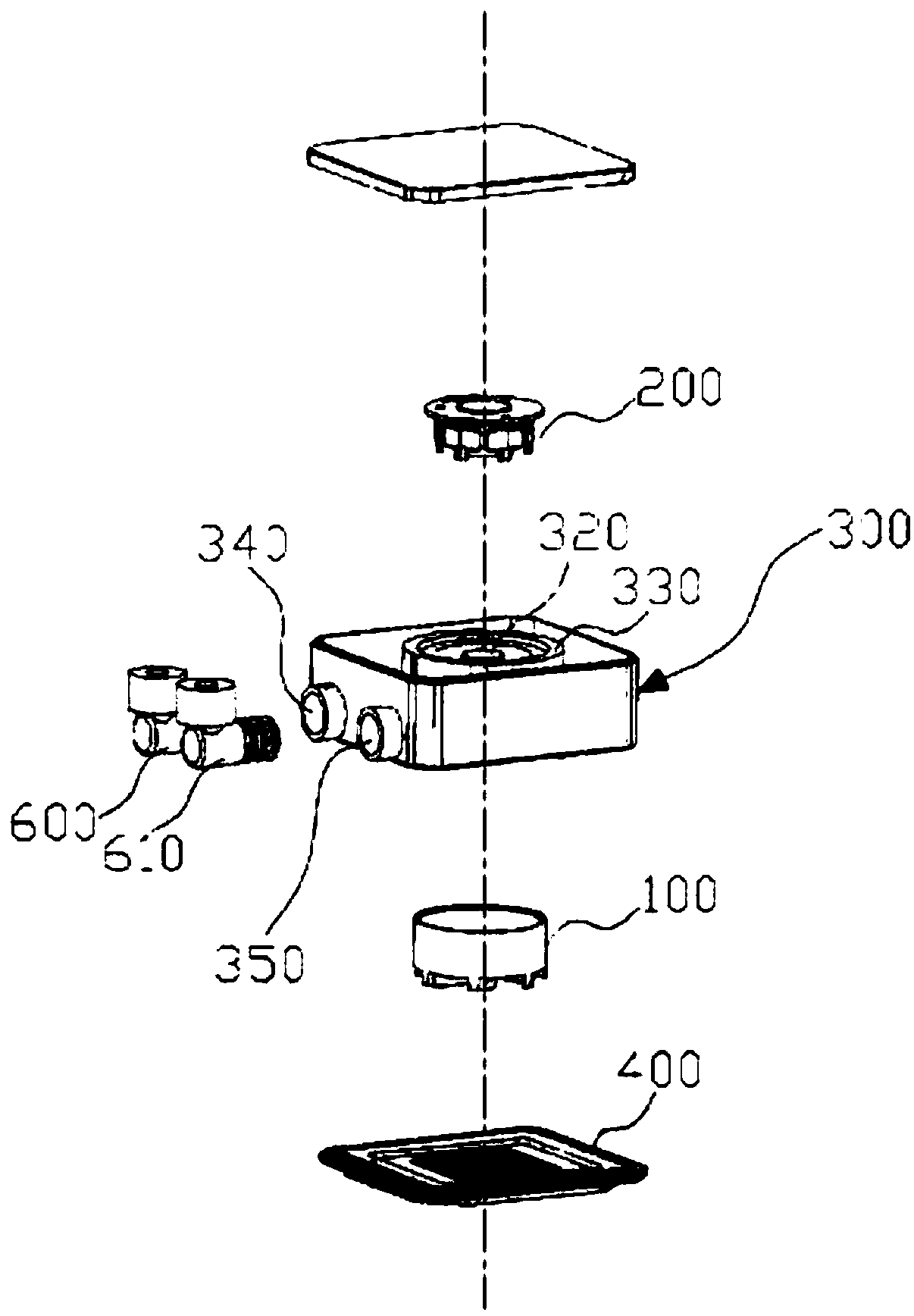

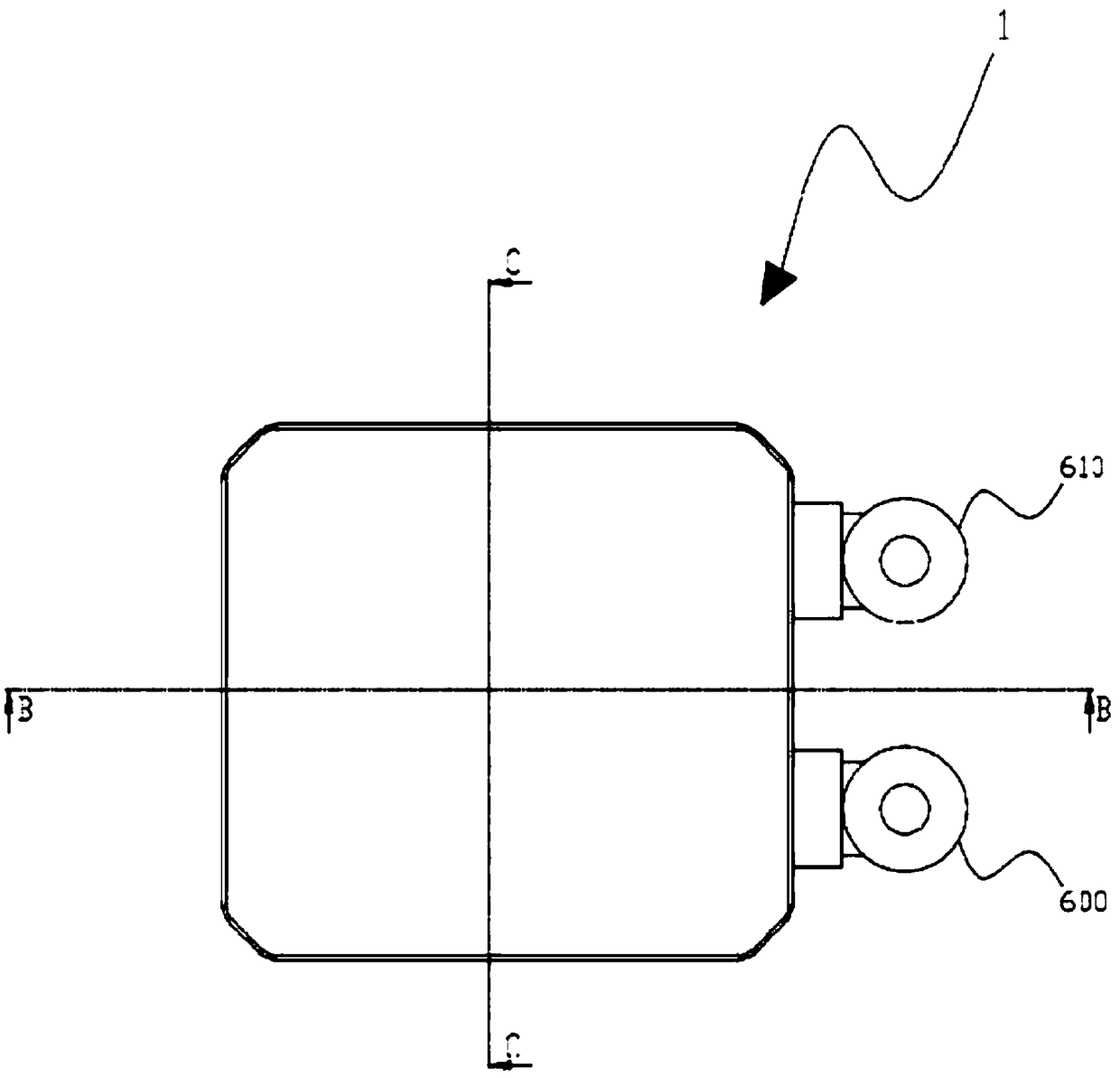

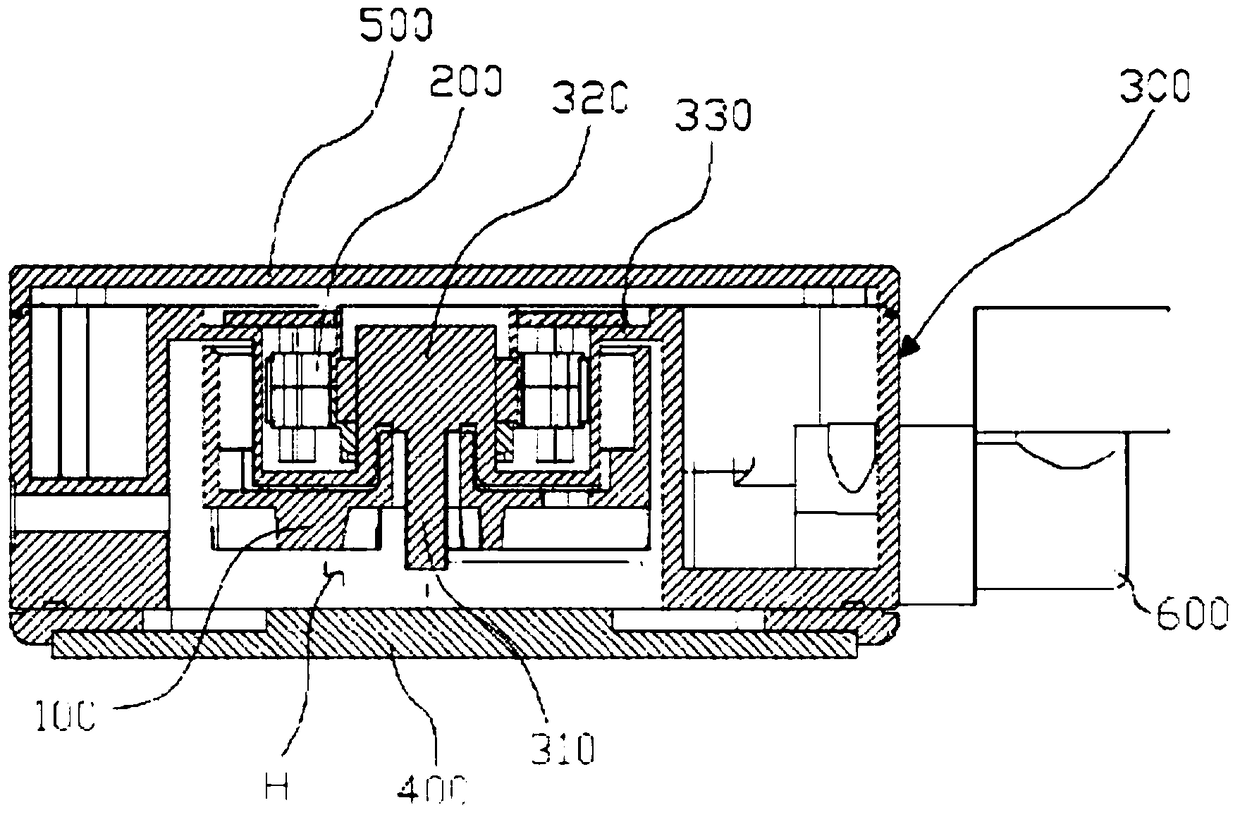

[0025] figure 1 is an exploded perspective view illustrating a structure of an electronic component cooling device according to an embodiment of the present invention, figure 2 It is a top view of the electronic component cooling device according to one embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com