Cooling circuit of oil cooler for vehicle

a technology of oil cooler and cooling circuit, which is applied in the direction of mechanical equipment, machines/engines, lubricant mounting/connection, etc., can solve the problems of limited oil cooler series structure, insufficient oil cooling only by heat radiation in the oil pan, and relatively decreased cooling efficiency, so as to achieve the effect of maximizing cooling efficiency and providing higher flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Hereinafter, exemplary embodiments of the present invention will now be described in detail with reference to the attached drawings.

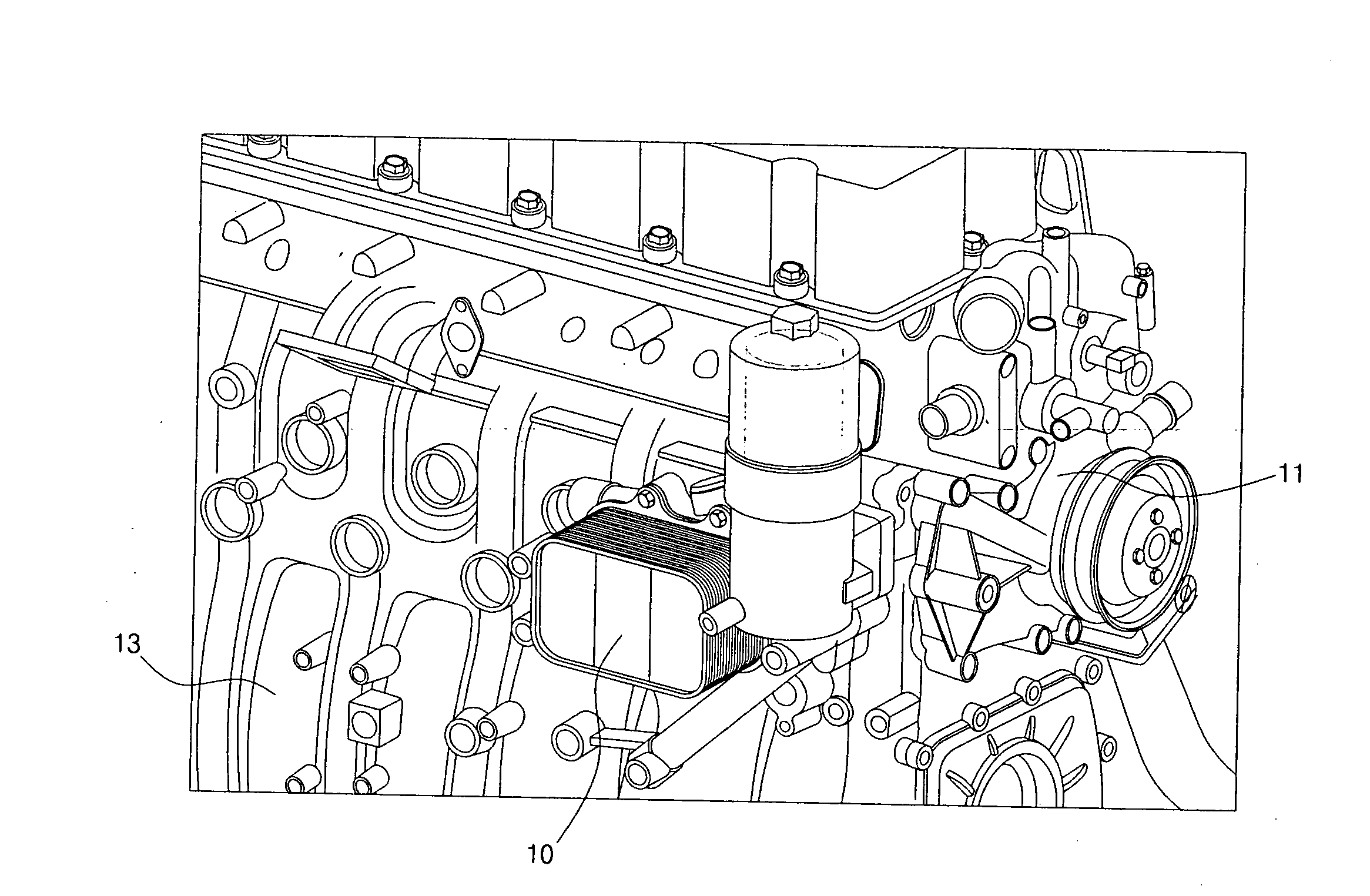

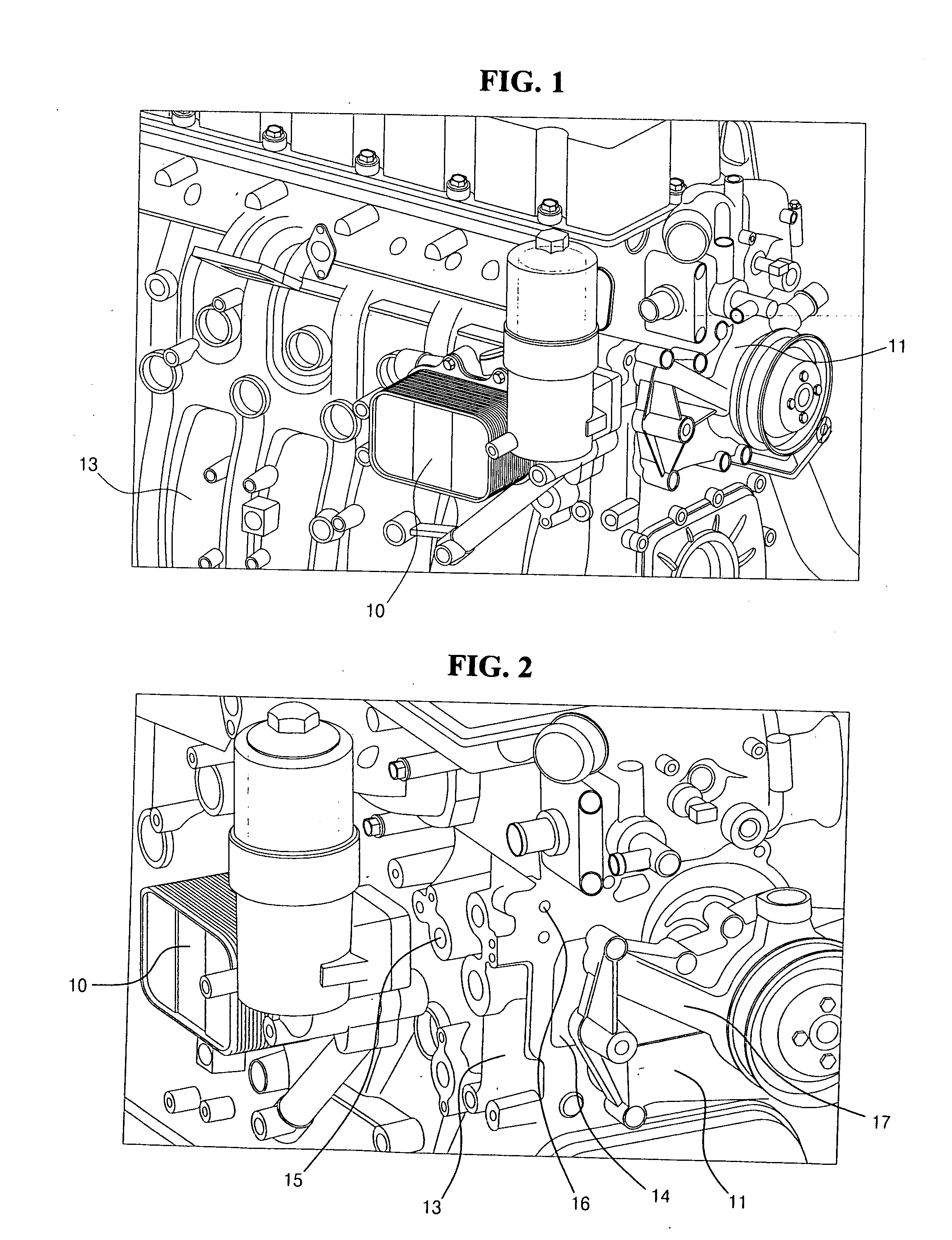

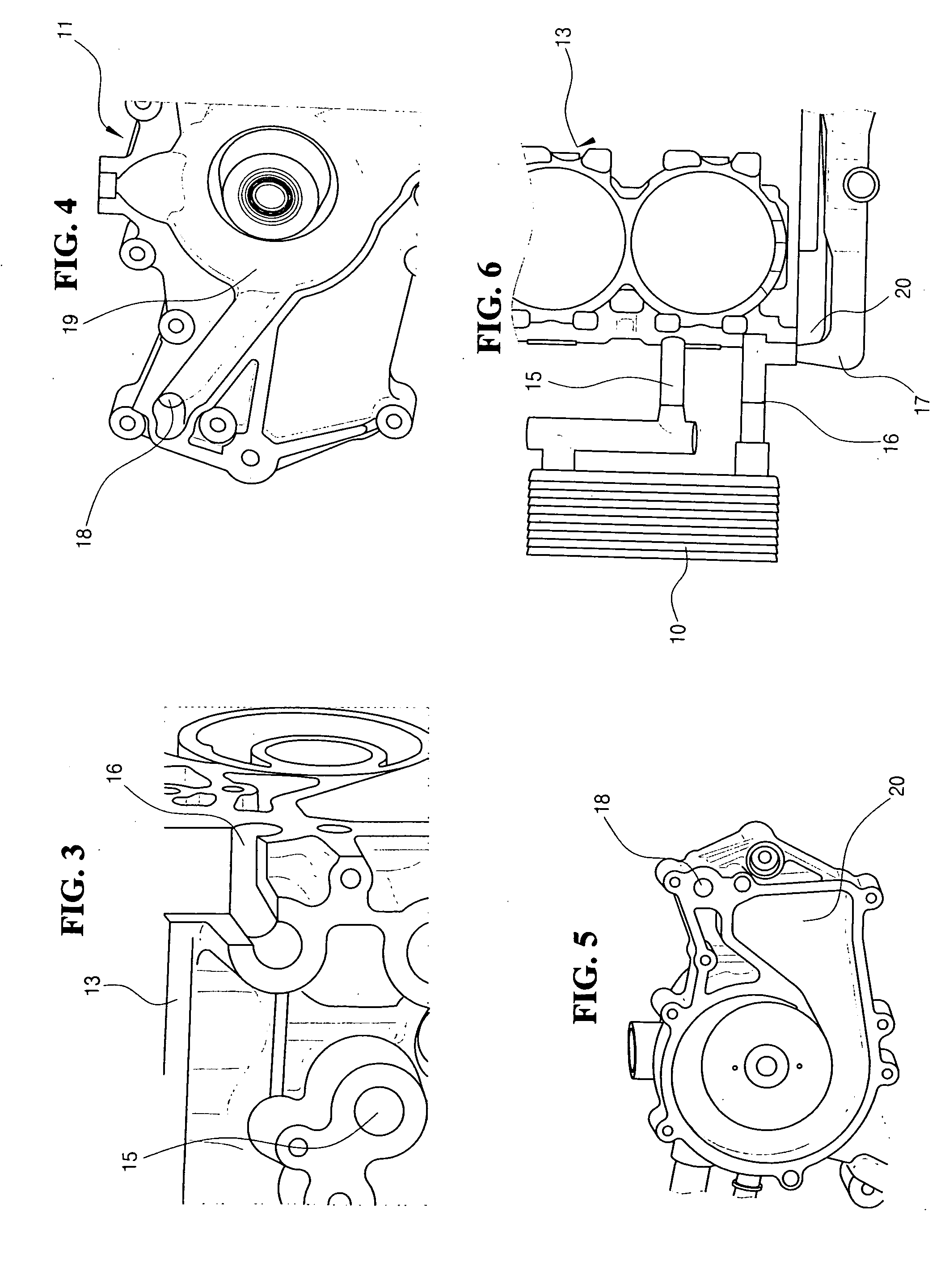

[0021]Referring to FIGS. 1-3, a cooling circuit of an oil cooler 10 comprises a cooling water inlet 14 formed in a cylinder block 13, through which a cooling water flowing in a radiator 12 is introduced via a water pump 11, and an oil cooler inlet 15 established to supply the cooling water introduced into the cylinder block 13 to the oil cooler 10.

[0022]Moreover, the cooling circuit of the oil cooler 10 further comprises an oil cooler outlet 16, arranged in parallel to the oil cooler inlet 15, through which the cooling water supplied to the oil cooler 10 to cool the oil cooler 10 only is provided to the cylinder block 13.

[0023]For the configuration of the cooling circuit of the oil cooler 10, a path 17 for collecting cooling water is established, though which the cooling water heated via the heat exchange with the oil cooler 10 is collected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com