Preparation method for structured phospholipids based on enzyme reactor

An enzyme reactor and phospholipid-constructed technology, which is applied in the field of textured phospholipid preparation, can solve problems such as difficult control, low conversion rate, and unsuitability for large-scale production, and achieve low production cost, high conversion rate, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

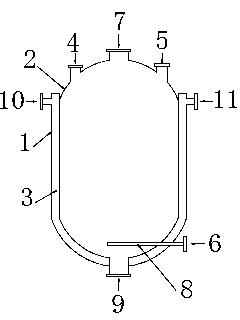

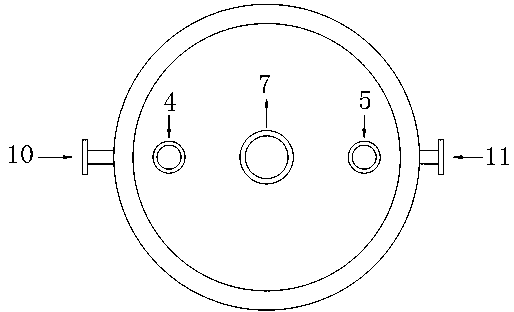

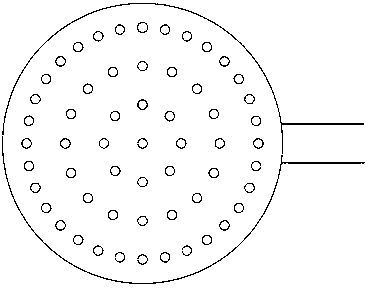

[0028] as attached figure 1 As shown, the present invention is based on a new enzymatic reactor (1), and the reactor (1) includes a reaction tank (2) and an outer jacket (3). The reaction tank (2) is cylindrical, and the top and bottom are both hemispherical. The height of the reaction tank (2) is 6m, and the diameter is 3m. The inner diameter of the material inlet (4) at the top of the reaction tank (2) is 10cm, the inner diameter of the enzyme adding port (5) at the top of the reaction tank (2) is 25cm, and the inner diameter of the air outlet (7) is 12cm. There is an air inlet (6) at the bottom of the reaction tank (2). The inner diameter of the air inlet (6) is 5cm. 8) Small holes with an inner diameter of 2cm are evenly distributed on the surface, and the distribution density of small holes is 200 / m 2 , the inner diameter of the bottom material outlet (9) of the reaction tank (2) is 15cm. The outer jacket (3) is wrapped on the outside of the reaction tank (2), and the ...

Embodiment 2

[0035] This embodiment provides a textured phospholipid enzymatic reactor (1), and the reactor (1) includes a reaction tank (2) and an outer jacket (3). The reaction tank (2) is cylindrical, and the top and bottom are both hemispherical. The height of the reaction tank (2) is 8m, and the diameter is 3m. The inner diameter of the material inlet (4) at the top of the reaction tank (2) is 20cm, the inner diameter of the enzyme adding port (5) at the top of the reaction tank (2) is 40cm, and the inner diameter of the air outlet (7) is 15cm. There is an air inlet (6) at the bottom of the reaction tank (2). The inner diameter of the air inlet (6) is 10cm. 8) Small holes with an inner diameter of 3cm are evenly distributed on the surface, and the distribution density of small holes is 200 / m 2 , the inner diameter of the bottom material outlet (9) of the reaction tank (2) is 20cm. The outer jacket (3) is wrapped on the outside of the reaction tank (2), and the inner diameters of the...

Embodiment 3

[0042] This embodiment provides a textured phospholipid enzymatic reactor (1), and the reactor (1) includes a reaction tank (2) and an outer jacket (3). The reaction tank (2) is cylindrical, and the top and bottom are both hemispherical. The height of the reaction tank (2) is 8m, and the diameter is 3m. The inner diameter of the material inlet (4) at the top of the reaction tank (2) is 15 cm, the inner diameter of the enzyme adding port (5) at the top of the reaction tank (2) is 30 cm, and the inner diameter of the air outlet (7) is 15 cm. There is an air inlet (6) at the bottom of the reaction tank (2), and the inner diameter of the air inlet (6) is 10cm, and the air inlet (6) is connected to a ring-shaped air distributor (8) with the same size as the inner diameter, and the air distributor (8 ) are uniformly distributed with small holes with an inner diameter of 3cm, and the distribution density of small holes is 300 / m 2 , the inner diameter of the bottom material outlet (9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com