A microrefrigerator with droplet condensation and self-collection of water and its manufacturing method

A technology of droplet condensation and micro-refrigerator, which is applied in the direction of cooling/ventilation/heating transformation, indirect heat exchangers, electrical equipment structural parts, etc., can solve the problem of low cooling effect, achieve continuous and rapid flow, accelerate heat The effect of improving circulation and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

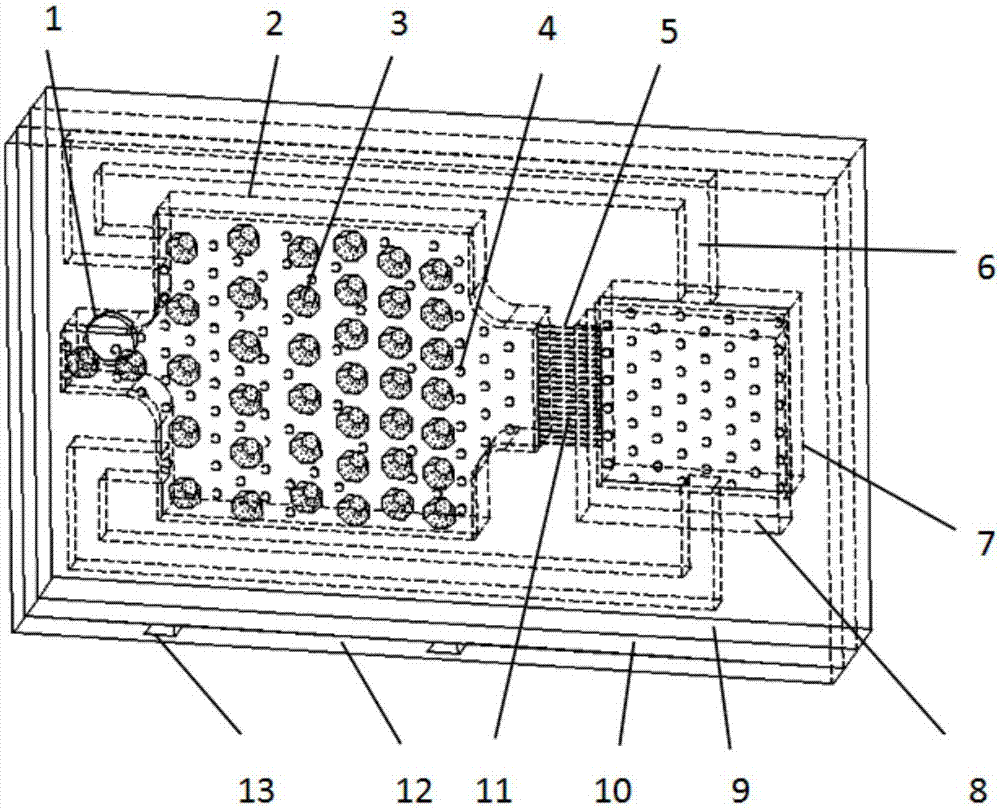

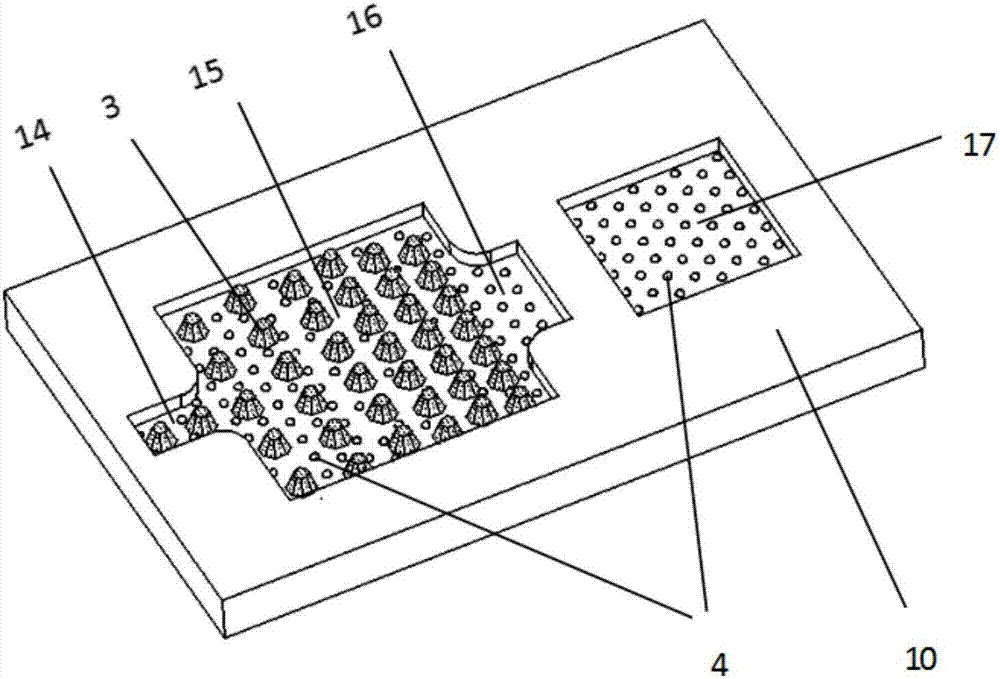

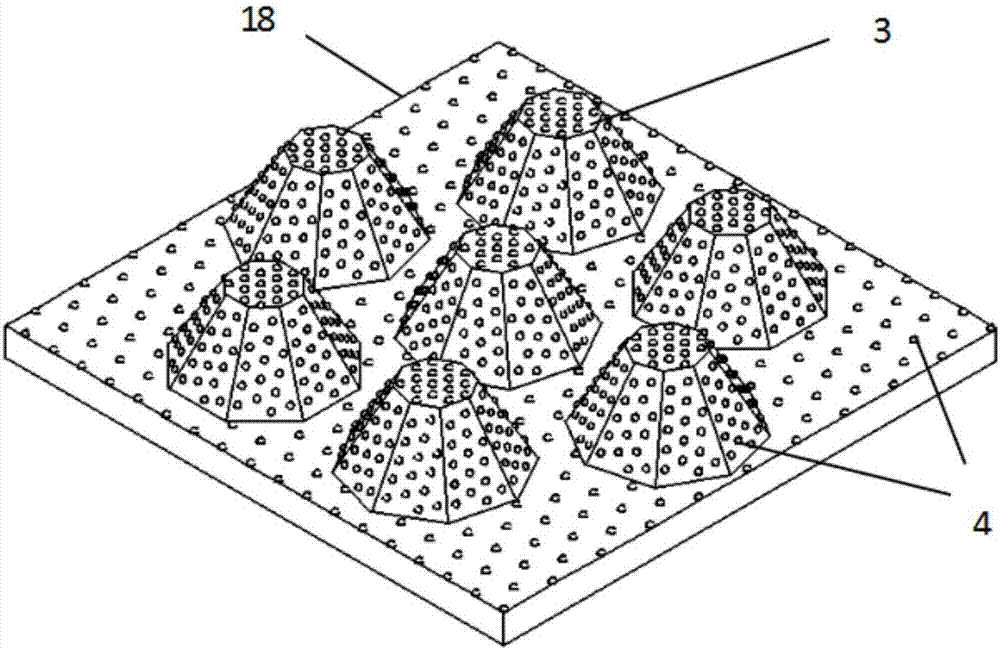

[0037] Such as figure 1 Shown, a kind of dropwise condensation of the present invention and self-collecting water microrefrigerator comprise upper glass plate (9), middle silicon chip (10) and lower glass plate (12) three-layer structure, described upper glass plate (9) ) and the middle silicon wafer (10) are combined to form a condenser (2), an evaporator (7), a steam pipe (6) and a liquid pipe (5), and the lower glass plate (12) and the middle silicon wafer (10) The high-temperature chip heat transfer zone (8) and the cooling water pipe (13) are formed by bonding together. Among them, the liquid tube (5) is composed of twenty parallel capillaries (11), and the liquid tube composed of multiple capillaries (11) greatly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com