Axle gear box shifting retaining mechanism

An axle gearbox and locking mechanism technology, applied in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of off-gear, inconvenient precise adjustment, large wear of steel balls and grooves, etc. Achieve the effect of ensuring the reliability of the limit, improving the reliability of the limit, and reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

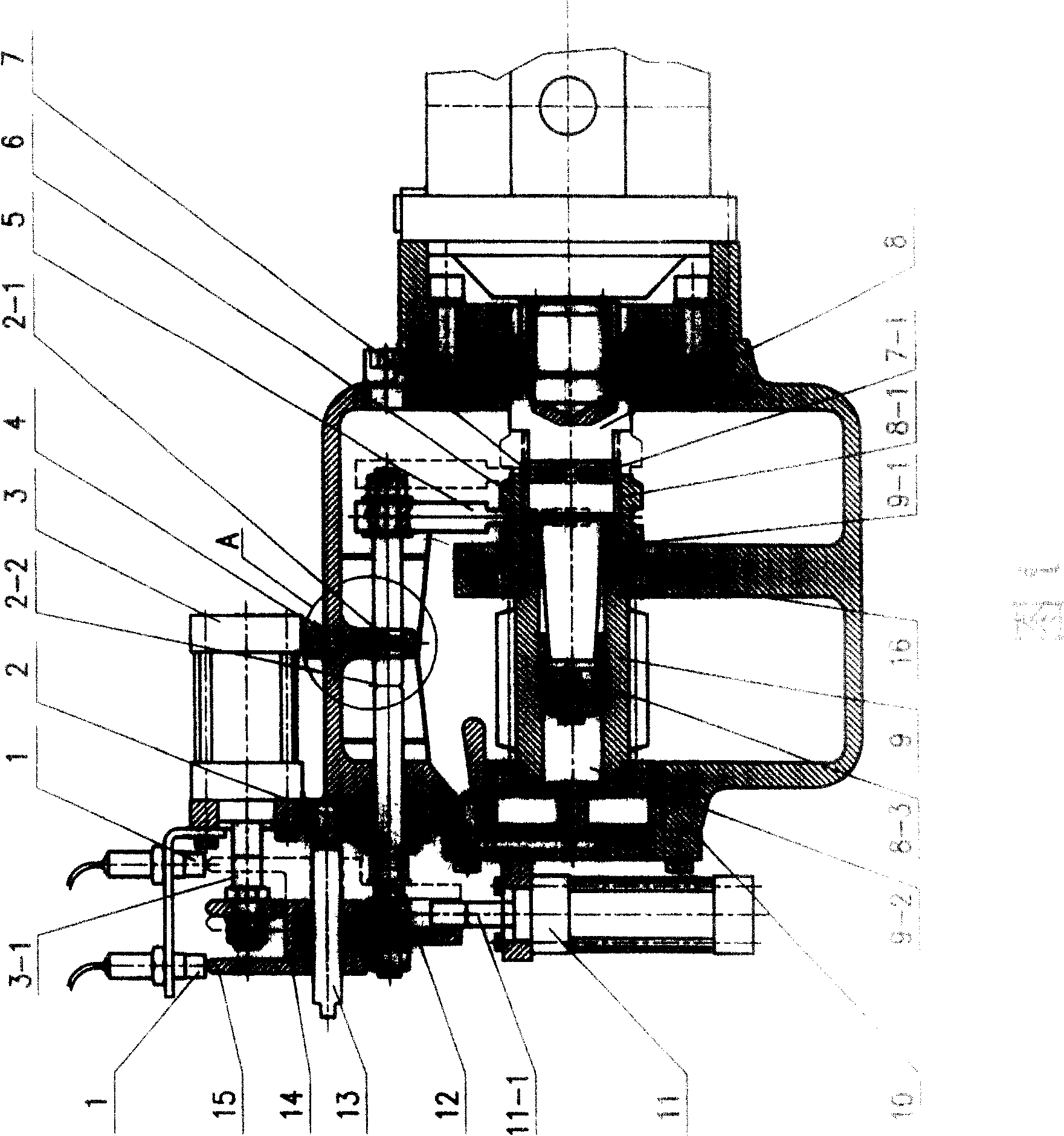

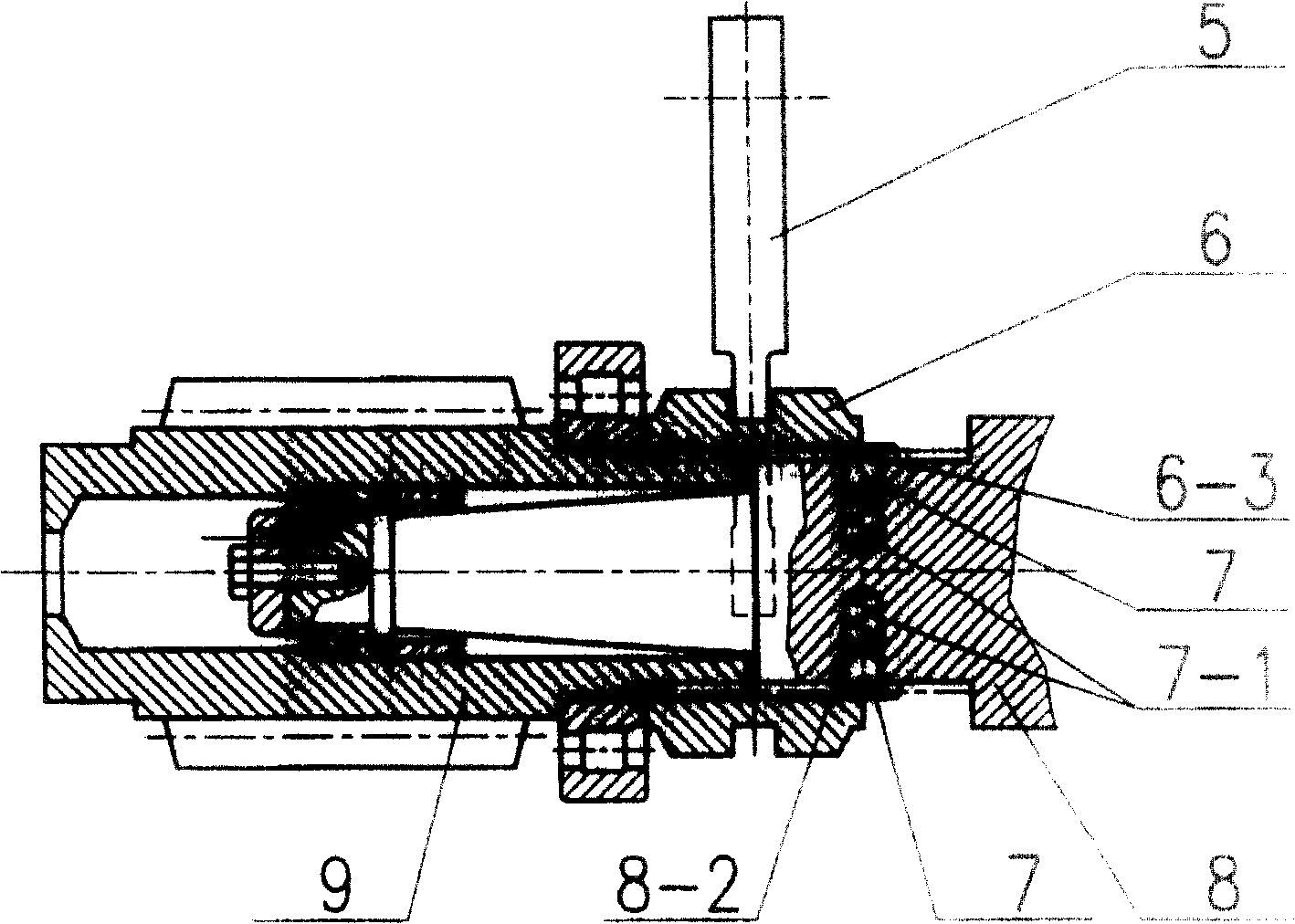

[0020] A gear shifting and locking mechanism for an axle gear box, through the engagement and disengagement of the splines inside the meshing sleeve and the splines outside the spline shaft, gear shifting and disengagement are realized; To achieve "clutch", the power source of the shift mechanism is compressed air.

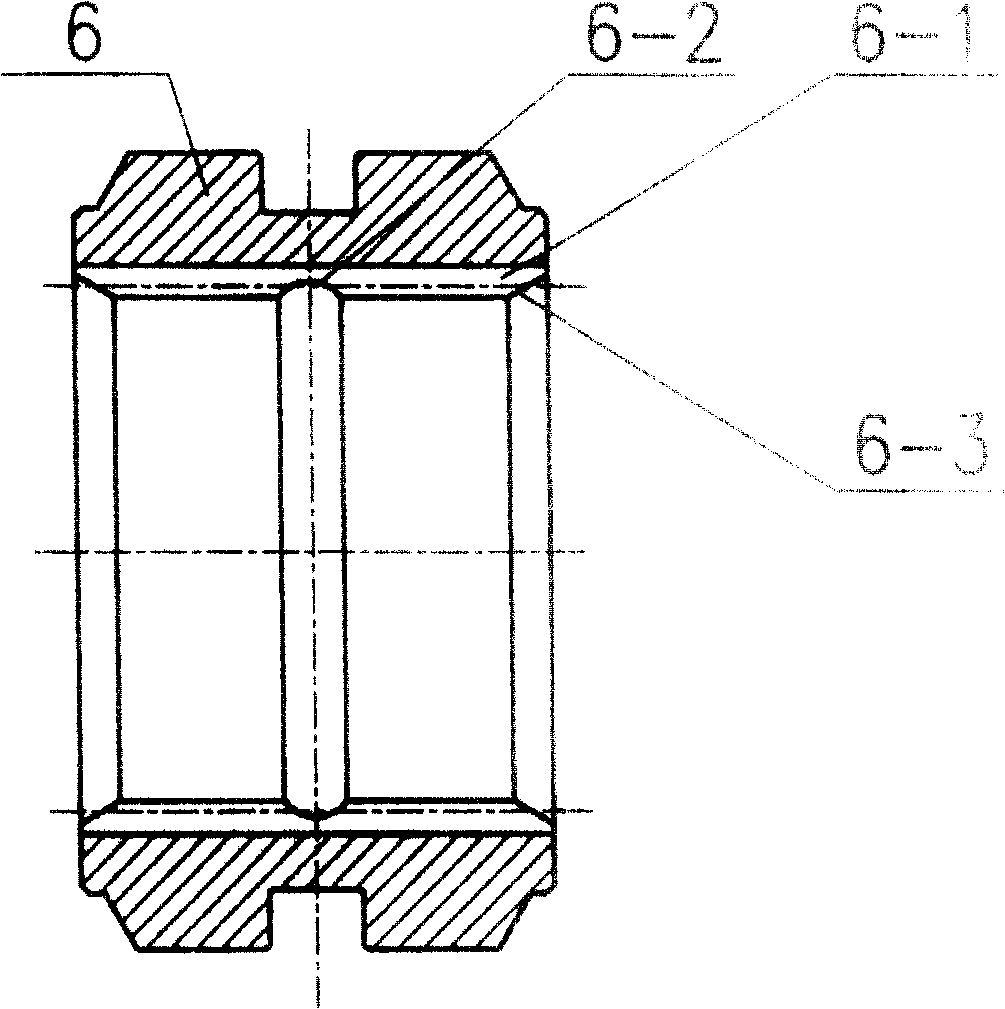

[0021] Figure 1~ Figure 5 As shown, the present invention includes a toggle cylinder 3, a shift fork 5 connected with the shift fork rod 2, and a spline shaft 8 built in the inner hole of the engagement sleeve 6, and is characterized in that: the surface of the shift fork rod 2 is provided with gears Groove 2-1 and neutral groove 2-2, in the hole at the corresponding position on the top of the gearbox, there are spring 4-2 and steel ball 4-1 with adjustable pre-compression force, which constitute the locking mechanism of shift fork lever 2 ; The end of the engaging sleeve 6 is provided with a shifting groove or a shifting surface 6-3, the inner hole wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com