Motion controller

A technology of stroke controller and stroke, applied in the direction of using feedback control, using optical devices to transmit sensing components, etc., can solve the problems of high labor intensity, low work efficiency, troublesome maintenance, etc., and achieve maintenance-free, low cost, and control reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

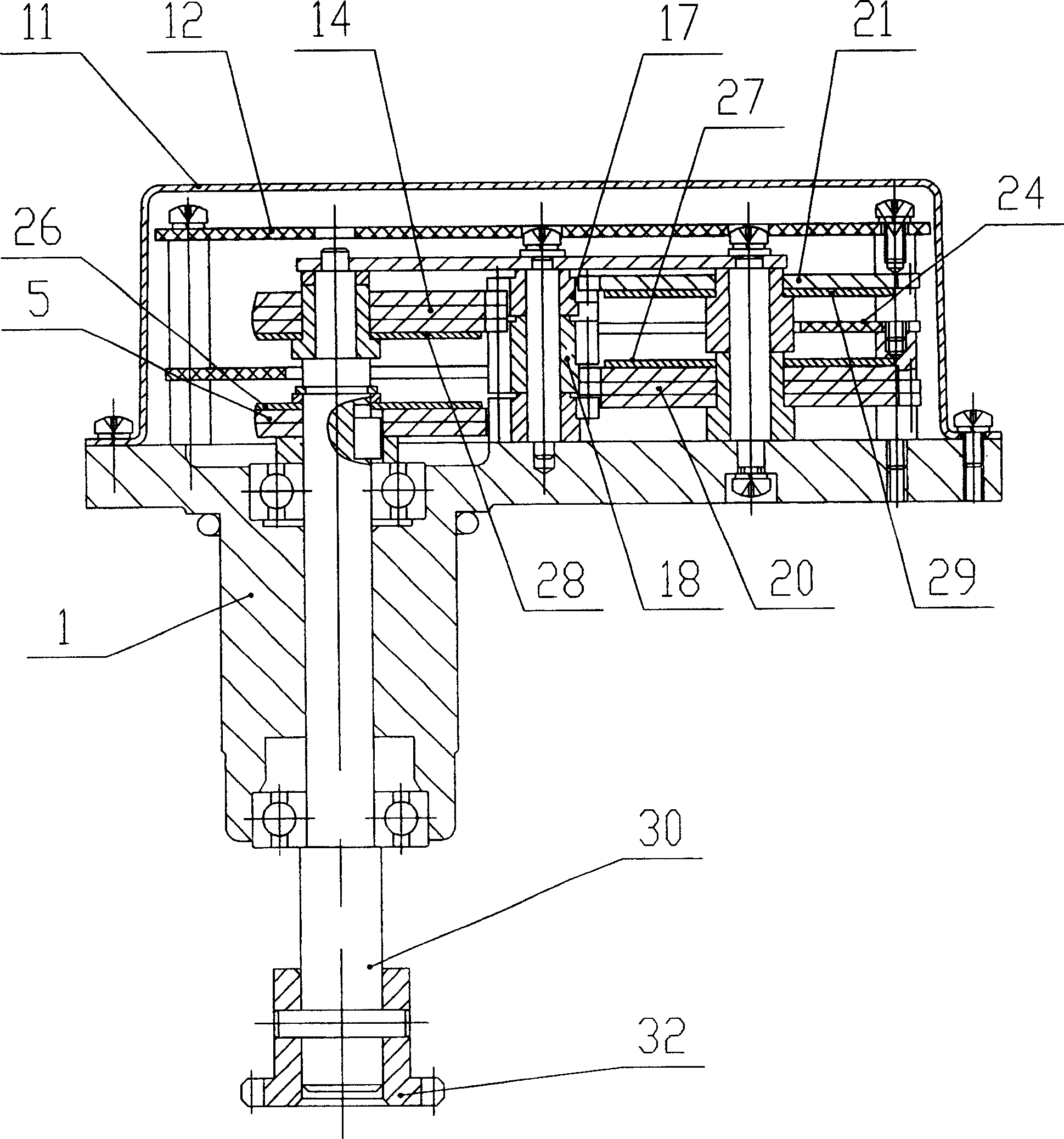

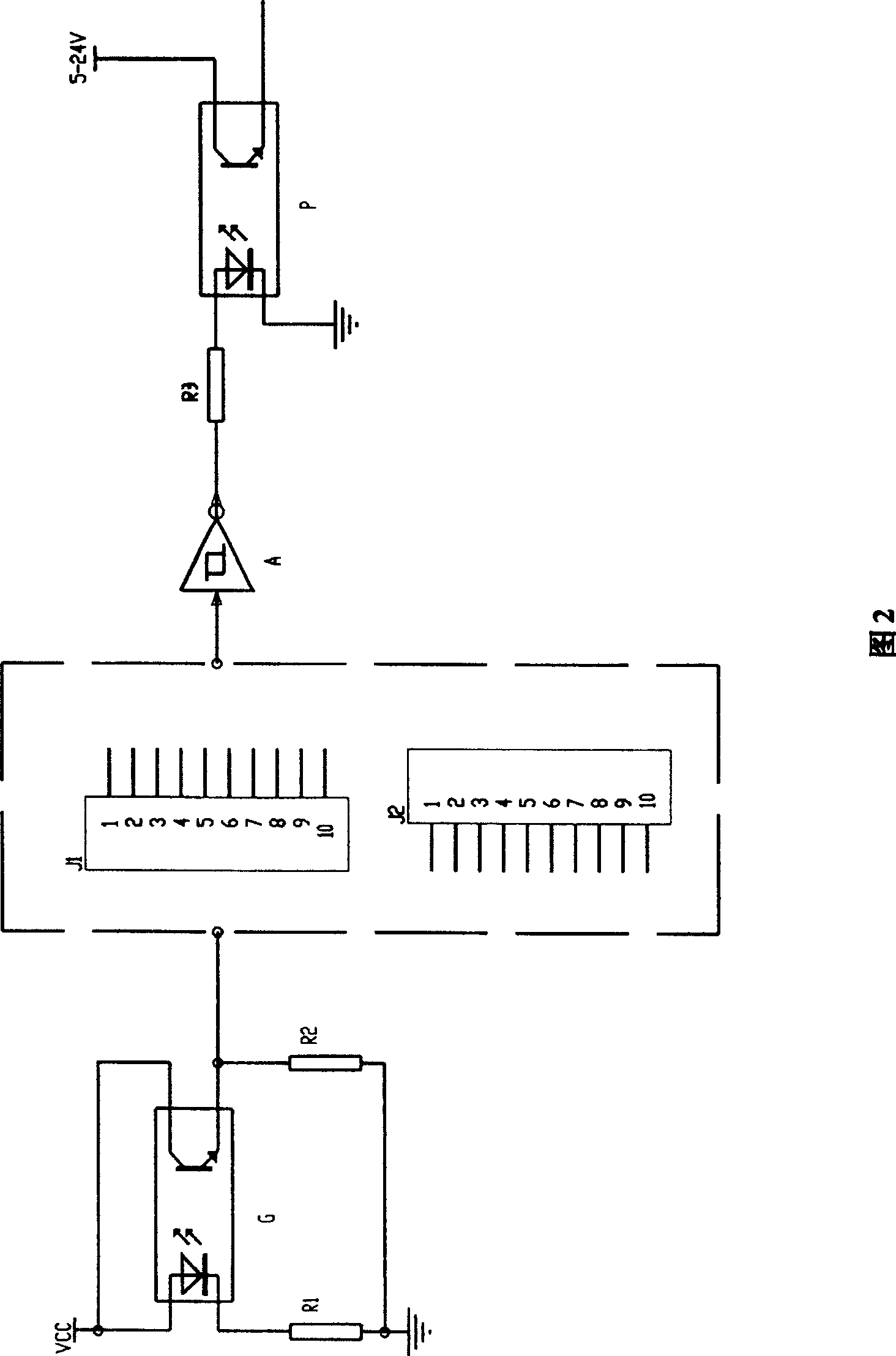

[0012] See figure 1 A stroke controller of the present invention includes a stroke input shaft 30, a stroke input gear 32, a base 1, and a control circuit composed of a photoelectric sensor code taking circuit and a level conversion circuit. The stroke output shaft 30 is fixedly attached to the stroke Input gear 32, bottom counting gear 5, the first to fourth code disc 26 is fixed on the bottom counting gear 5, the gear meshing with the bottom counting gear 5 drives the bottom counting gear 20 to rotate, on the bottom counting gear 20 The 5th to 8th code disc 27 is fixed, and the gear 18 meshing with the bottom counting gear 20 drives the top counting gear 14 to rotate. The 9th to 12th code disc 28 is fixed on the top counting gear 14 to count with the top layer. The gear 17 meshed with the gear 14 drives the top counter gear 21 to rotate, and the 13th to 16th bit code disc 29 is fixed on the top counter gear 21. When the stroke output shaft 30 drives the code disc to rotate, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap