Product line of flexible assembly for manufacturing railway vehicle

A technology of flexible tooling and railway vehicles, which is applied in the direction of manufacturing tools, metal processing, positioning devices, etc., can solve the problems of increasing production cycle, increasing cost, affecting efficiency, etc., and achieve the effect of improving quality, improving automation, and quick production transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

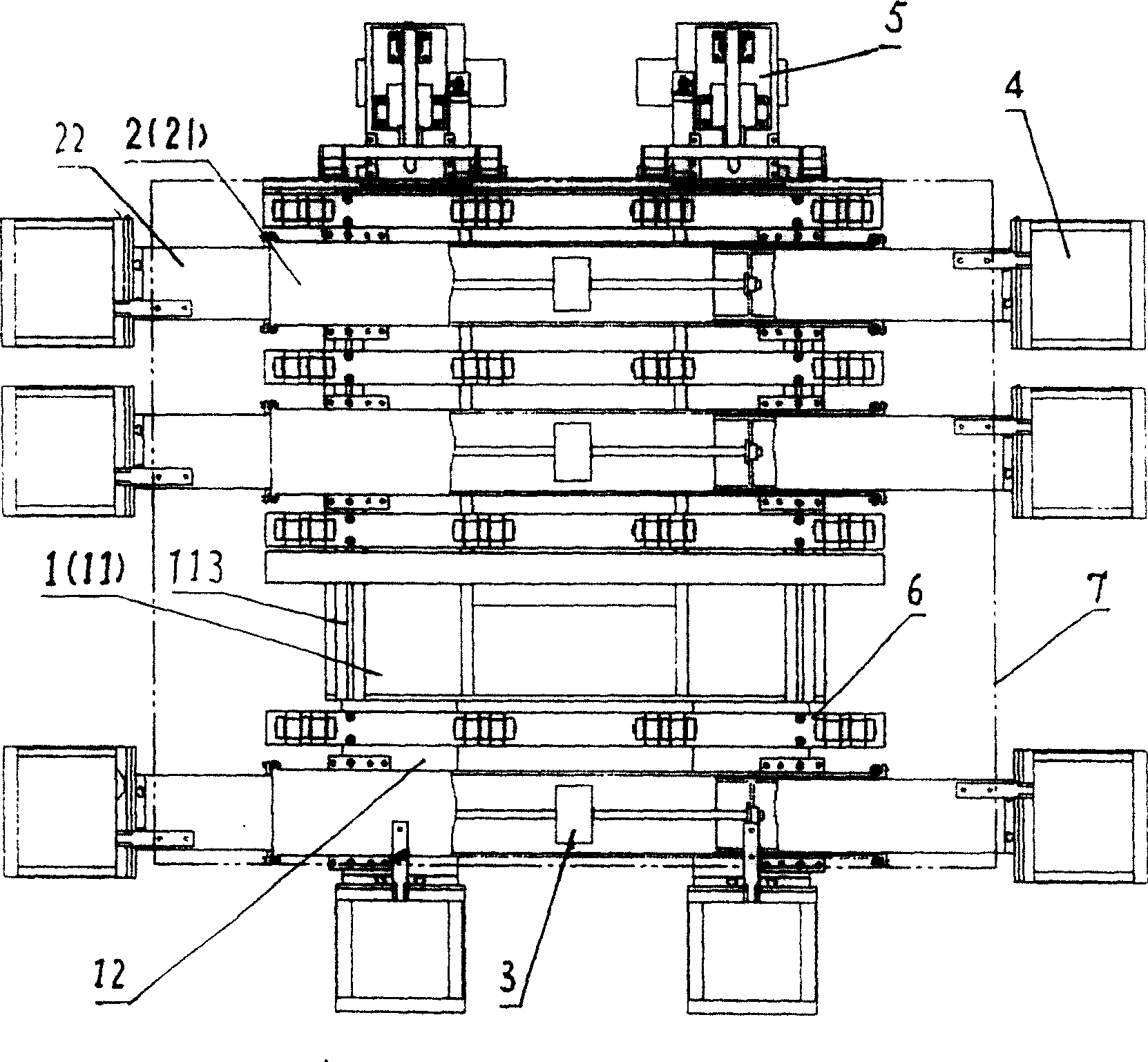

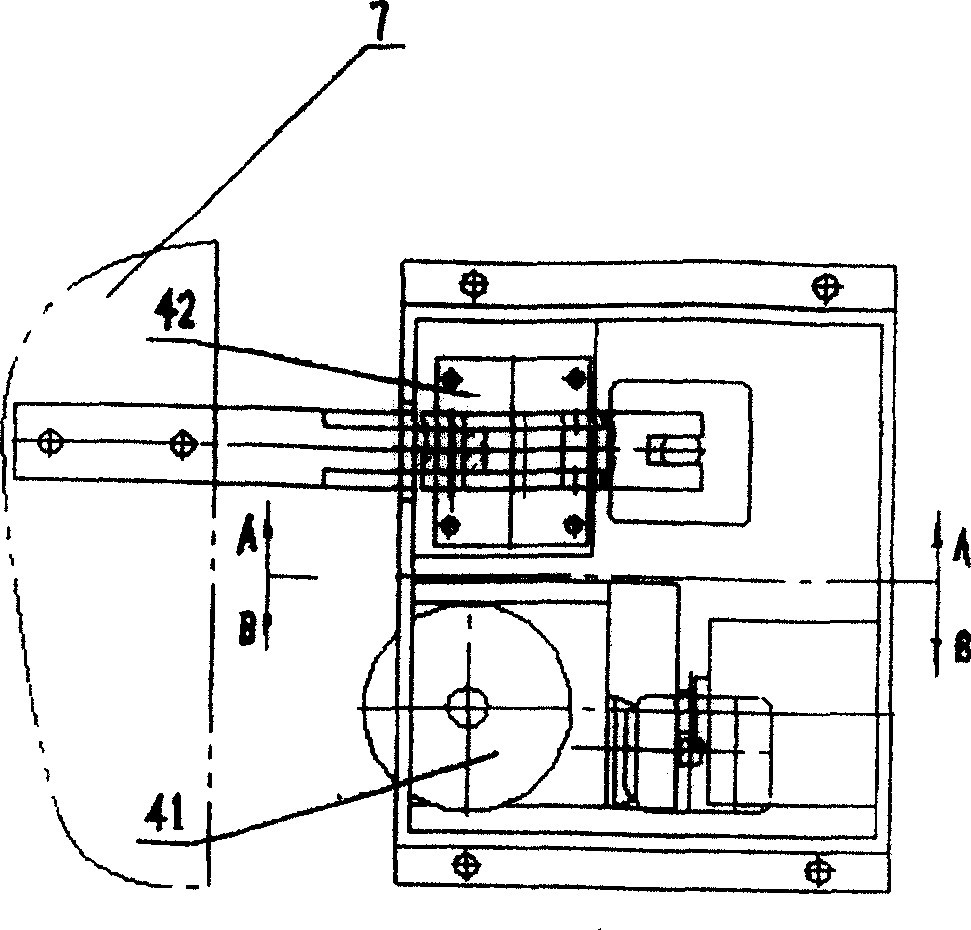

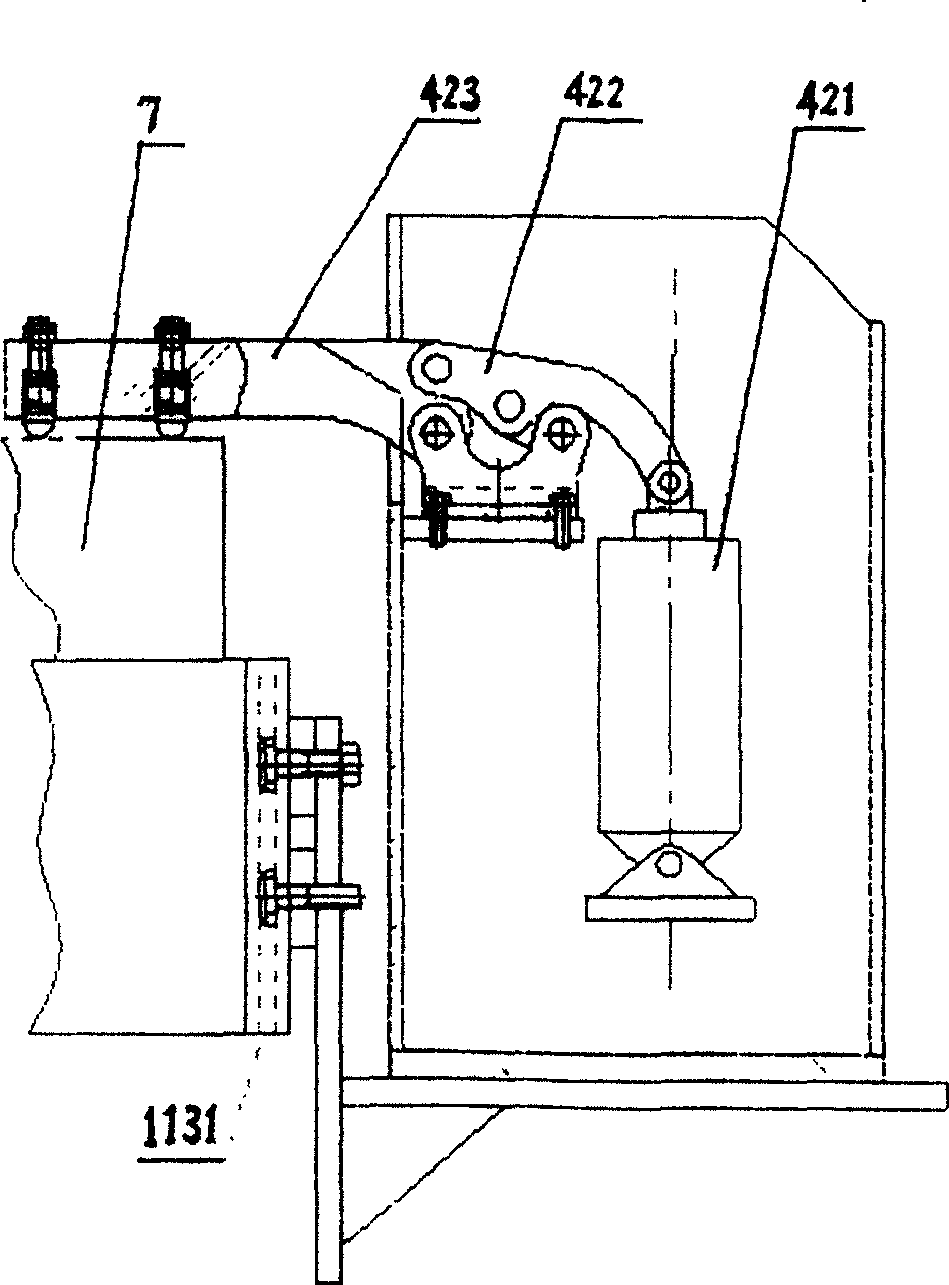

[0015] like figure 1 As shown, the present invention consists of a longitudinal beam 1 and a crossbeam 2 to form a load-bearing platform. The workpiece 7 is placed on the platform. And coaxially built-in inner beam 22 with it, the inner and outer longitudinal beams and beam sections are square holes or rectangular holes, and the outer longitudinal beam 11 is provided with a T-shaped groove plate 113 for fixing the beam 2. The end of the inner longitudinal beam 12 and the middle section of the inner cross beam 22 are provided with a worm gear reducer 3, and the two ends of the worm are respectively connected with one end of the inner longitudinal beam 12 and the two ends of the inner longitudinal beam 22, when the worm rotates forward and reverse , then drive the extension and retraction of the inner longitudinal beam 12 and the inner longitudinal beam 12 to achieve the change of the length of the longitudinal beam 1 and the cross beam 2 . The crossbeam 2 can also move along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com