Suction jet pump

A jet pump and suction type technology, applied in the field of suction jet pump, can solve the problem of low delivery coefficient of the suction jet pump, and achieve the effect of simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

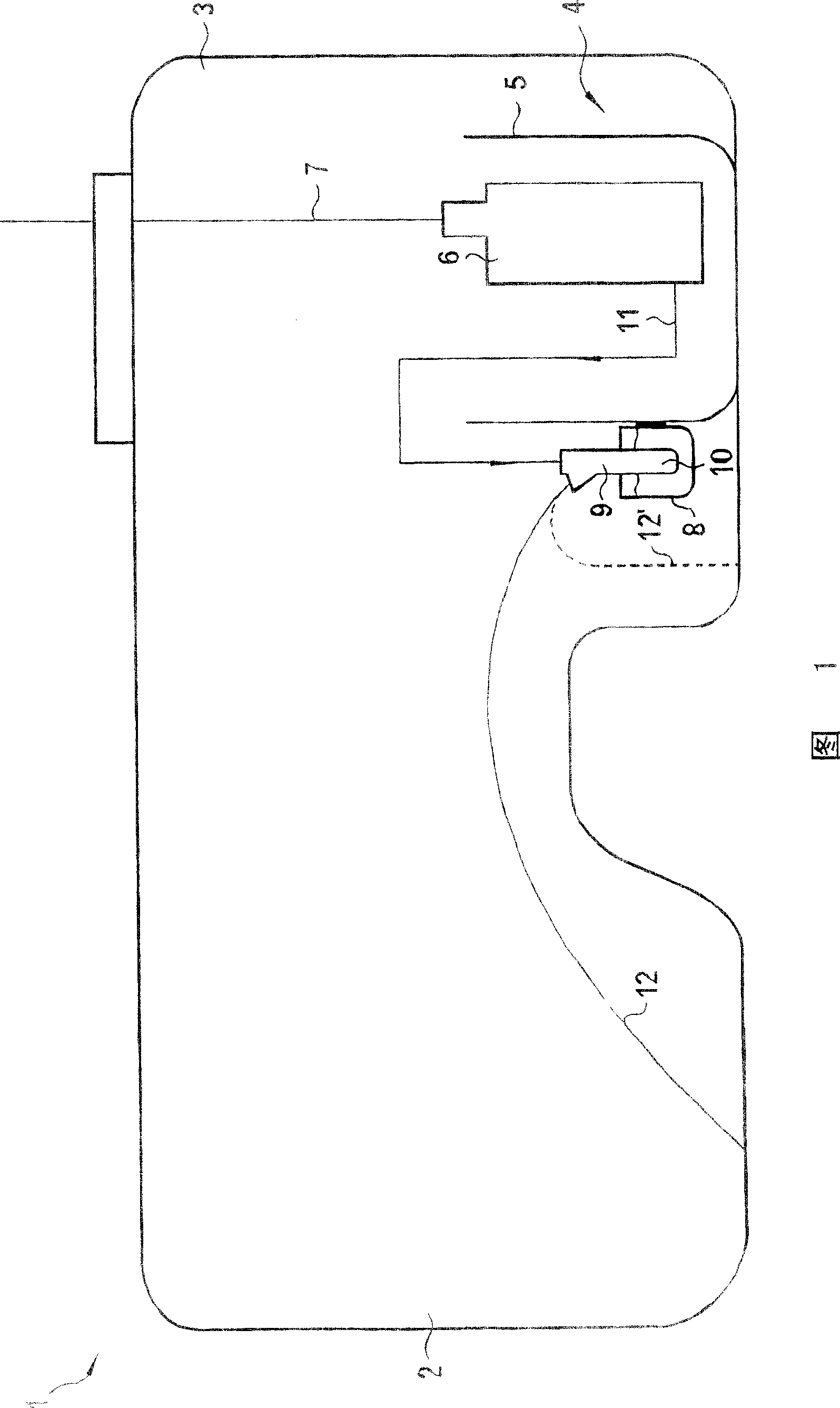

[0020] FIG. 1 shows a fuel tank 1 comprising two chambers 2 , 3 . A delivery unit 4 is fixed in the fuel tank 1 , which comprises a splash guard cylinder 5 and a fuel pump 6 arranged in the splash guard cylinder 5 . The fuel delivered by the fuel pump 6 is led to the internal combustion engine via a forward line 7 , not shown in the figure. A tank 8 is fixed to the outer wall of the splash cylinder 5 . The suction jet pump 9 is arranged relative to the tank 8 such that the mixing tube 10 of the suction jet pump 9 protrudes into said tank. Fuel is supplied from fuel pump 6 to suction jet pump 9 via line 11 . Another line 11 extends from the suction jet pump 9 into the other chamber 2 . Fuel is delivered via line 12 out of chamber 2 into chamber 3 or directly into the splash cylinder 5 .

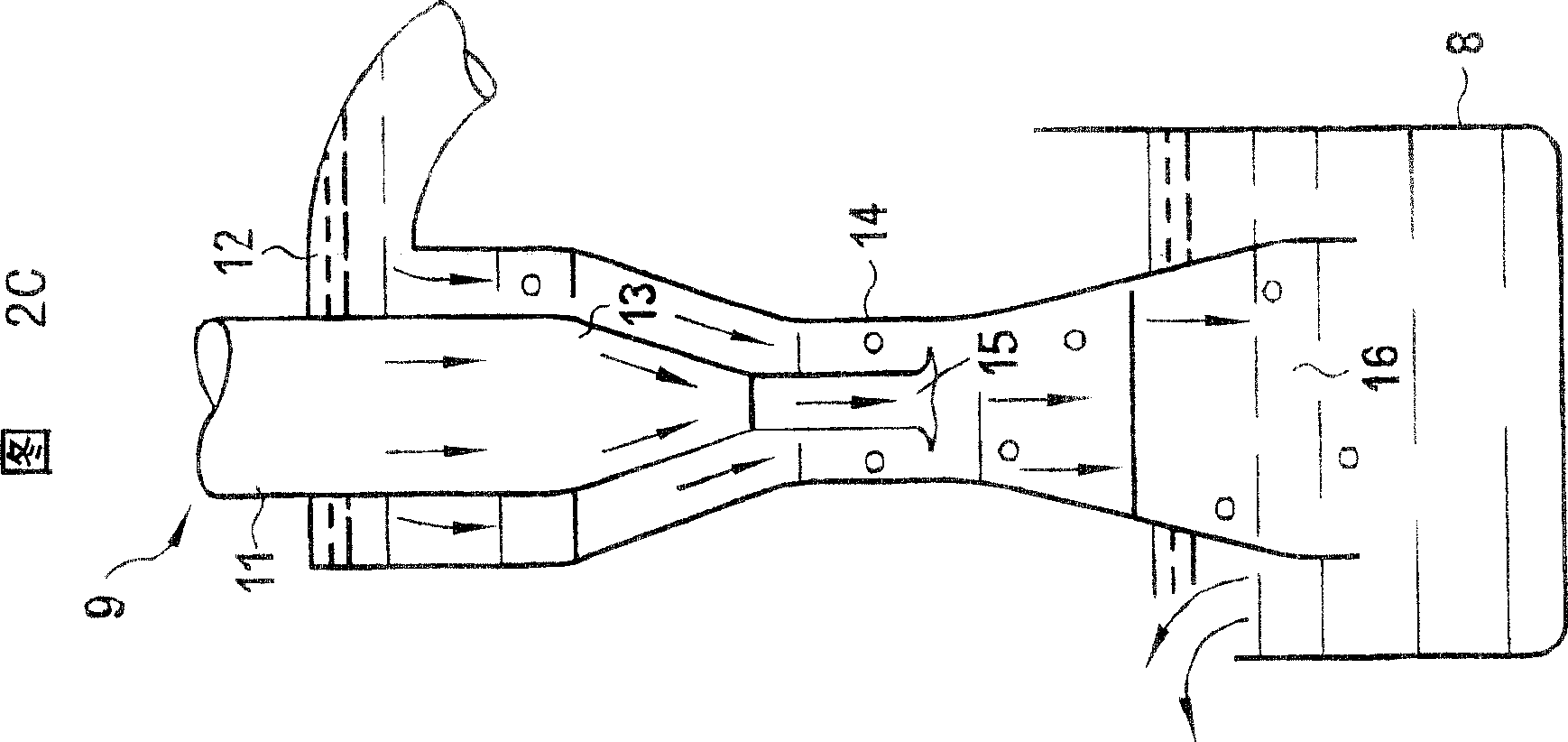

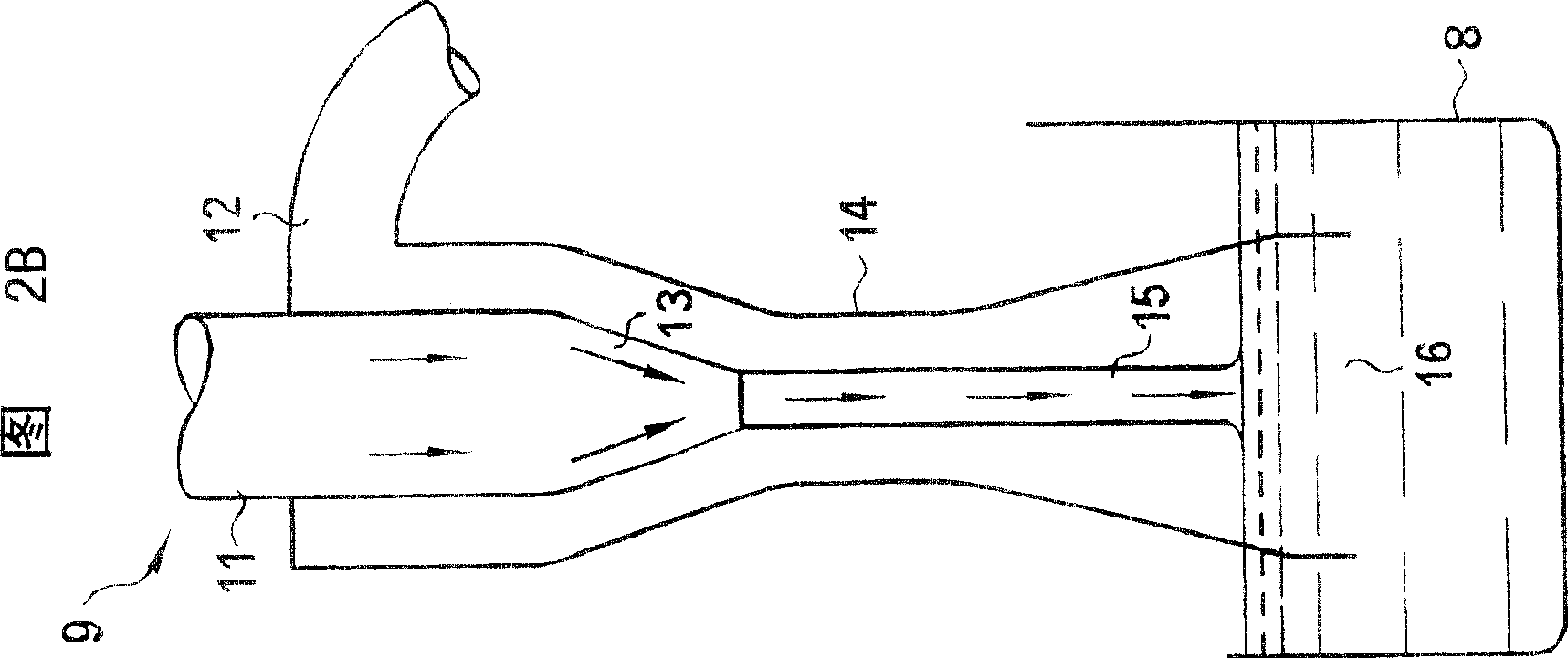

[0021] The suction jet pump 9 shown in FIGS. 2 a - c comprises a propulsion jet nozzle 13 , a mixing tube 14 , suction line 12 and a tank 8 . A propulsion jet 15 is supplied to the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com