Light-storing film, modified coating and preparation method

A modified coating and light storage technology, which is applied in coatings, fireproof coatings, film/sheet adhesives, etc., can solve the problems of poor solvent absorption, high temperature resistance, and non-printing, etc., to achieve strong absorption, Strong adhesion, convenient laser engraving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of modified coating 1 comprises the steps:

[0026] (1) First add ethyl acetate into the mixing tank, then add butyl acetate, cyclohexanone, fluorine-modified acrylic leveling agent, polyester resin, and hydroxy acrylic resin in order while stirring, and then use 900-1100r / min Stir for 10-15min;

[0027] (2) Add curing agent to the mixing tank after stirring in step (1), stir at 900-1100r / min for 8-12min, pass through a 250-350 mesh sieve to obtain the modified coating 1.

[0028] A method for preparing a light-storing film: the modified coating 1 is coated on the surface of the PET layer 2 by a roll coater, the thickness of the coating knife edge is 180-220um, the coating speed is 5-15m / min, and the coating temperature is 65-150°C .

Embodiment 1

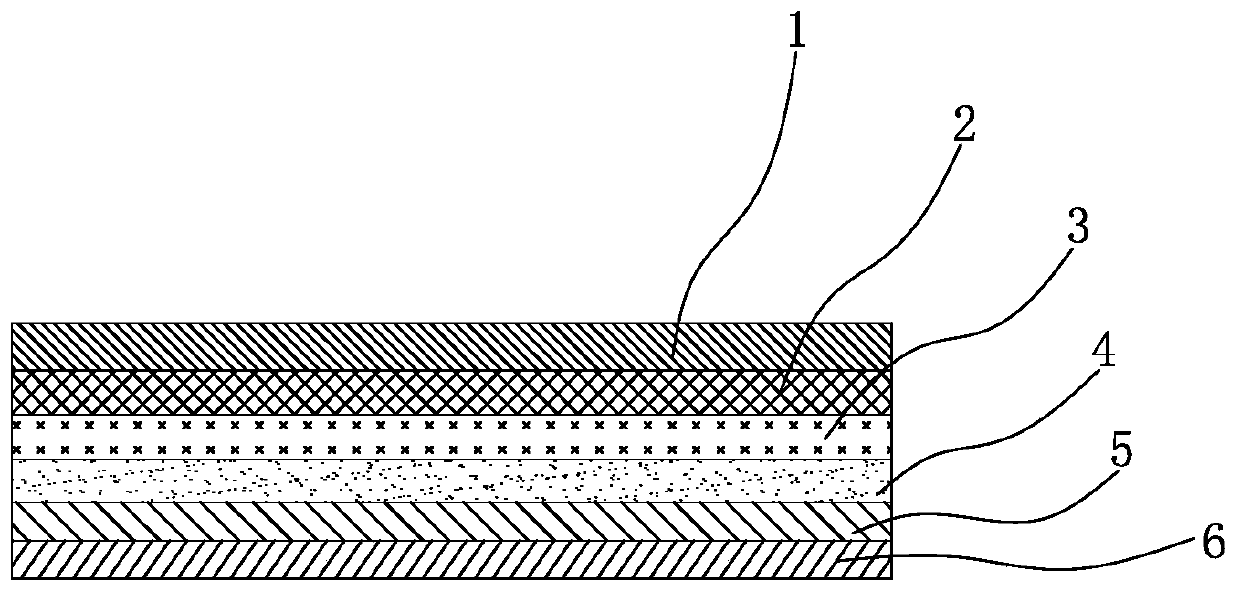

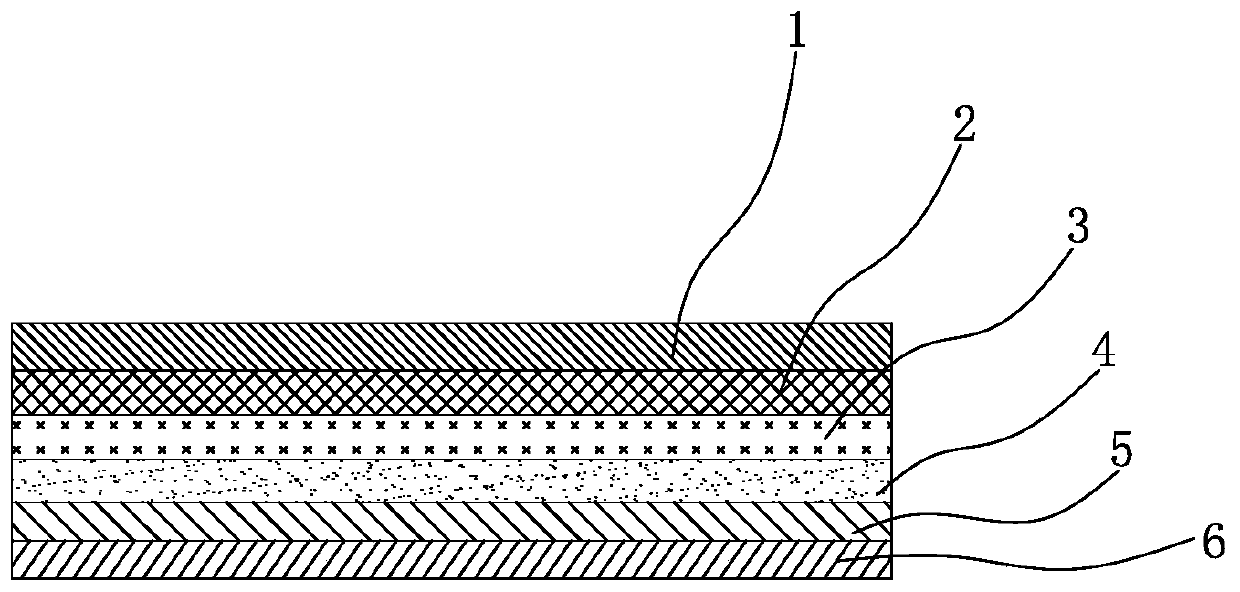

[0030] A light-storage film, including a modified coating 1, a PET layer 2, a light-storage layer 3, a white glue light-shielding layer 4, a pressure-sensitive adhesive layer 5, and a release layer 6 arranged sequentially from top to bottom. Specifically, further, The thickness of modified coating 1 is 8um.

[0031] Modified coating 1, including the following raw materials in parts by weight: 47 parts of hydroxyl acrylic resin, 5 parts of saturated polyester resin, 15 parts of ethyl acetate, 17 parts of butyl acetate, 3 parts of cyclohexanone, 4.5 parts of curing agent, fluid Leveling agent 0.1 part.

[0032] Specifically, the curing agent is aliphatic polyisocyanate based on hexamethyl diisocyanate, and further, the curing agent is curing agent N3390 produced by Dongguan Encyclopedia Chemical Co., Ltd.

[0033] The leveling agent is a fluorine-modified acrylic leveling agent, specifically, the fluorine-modified acrylic leveling agent is a commercially available product.

[...

Embodiment 2

[0039] A light-storage film, including a modified coating 1, a PET layer 2, a light-storage layer 3, a white glue light-shielding layer 4, a pressure-sensitive adhesive layer 5, and a release layer 6 arranged sequentially from top to bottom. Specifically, further, The thickness of modified coating 1 is 12um.

[0040] Modified coating 1, including the following raw materials in parts by weight: 50 parts of hydroxyl acrylic resin, 4 parts of saturated polyester resin, 10 parts of ethyl acetate, 20 parts of butyl acetate, 5 parts of cyclohexanone, 5 parts of curing agent, fluid 0.3 parts of leveling agent.

[0041] Specifically, the curing agent is aliphatic polyisocyanate based on hexamethyl diisocyanate, and further, the curing agent is curing agent N3390 produced by Dongguan Encyclopedia Chemical Co., Ltd.

[0042] The leveling agent is a fluorine-modified acrylic leveling agent, specifically, the fluorine-modified acrylic leveling agent is a commercially available product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com