Shutter device

A shutter device and slat technology, which is applied to door/window protection devices, shutters/movable grilles, windows/doors, etc., can solve the problems of time-consuming and labor-intensive lifting of slats, and achieve convenient lifting and low weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] specific implementation

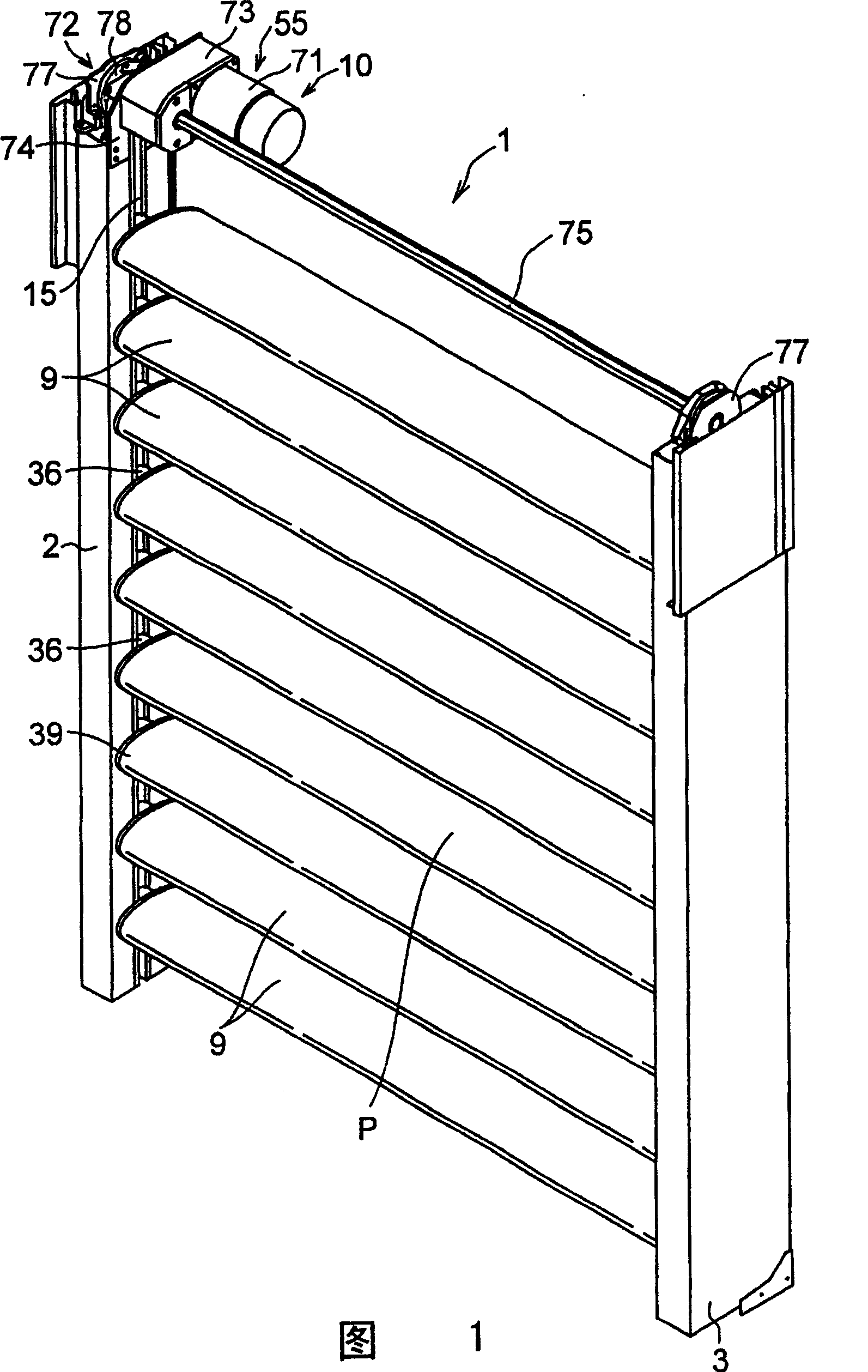

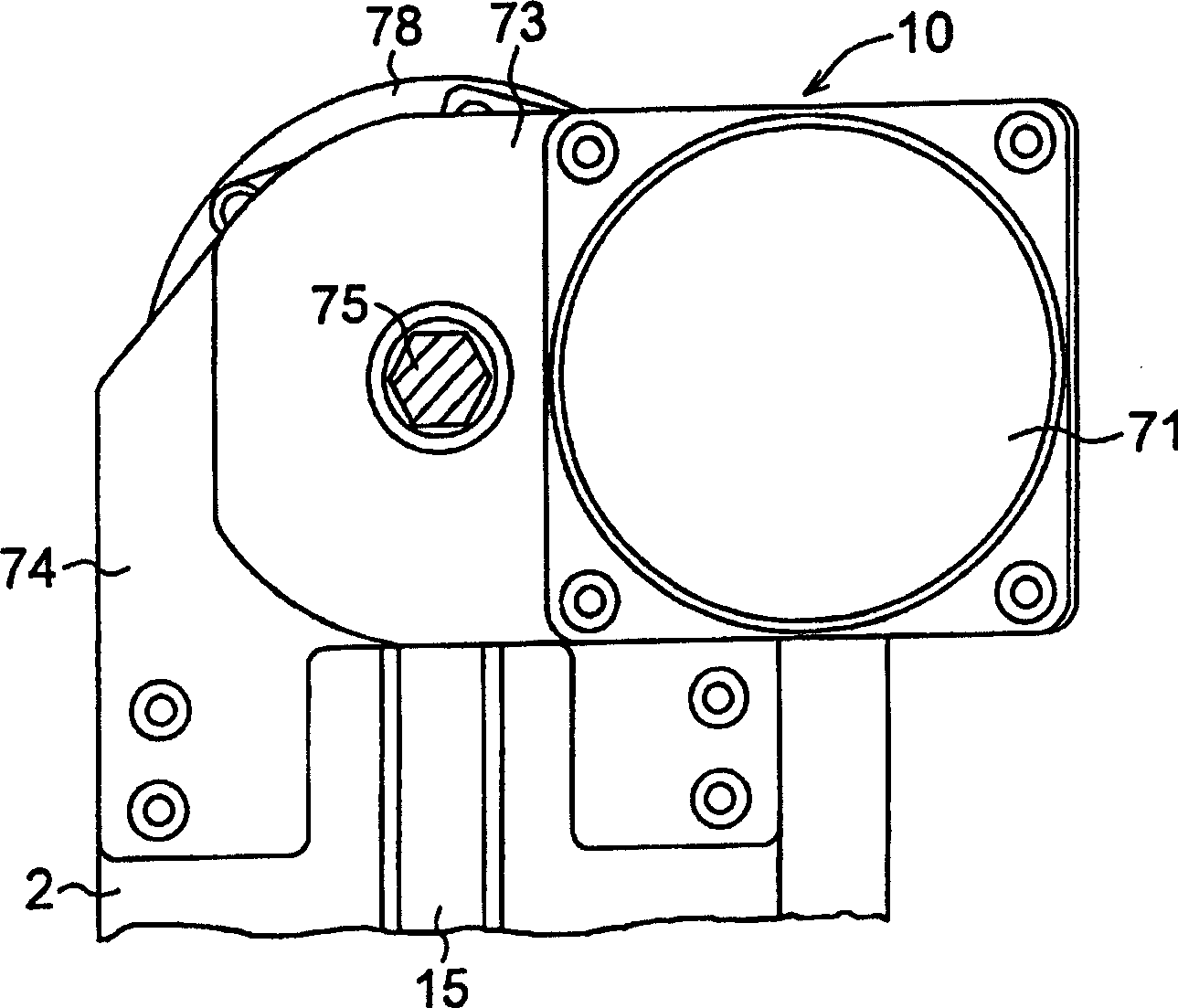

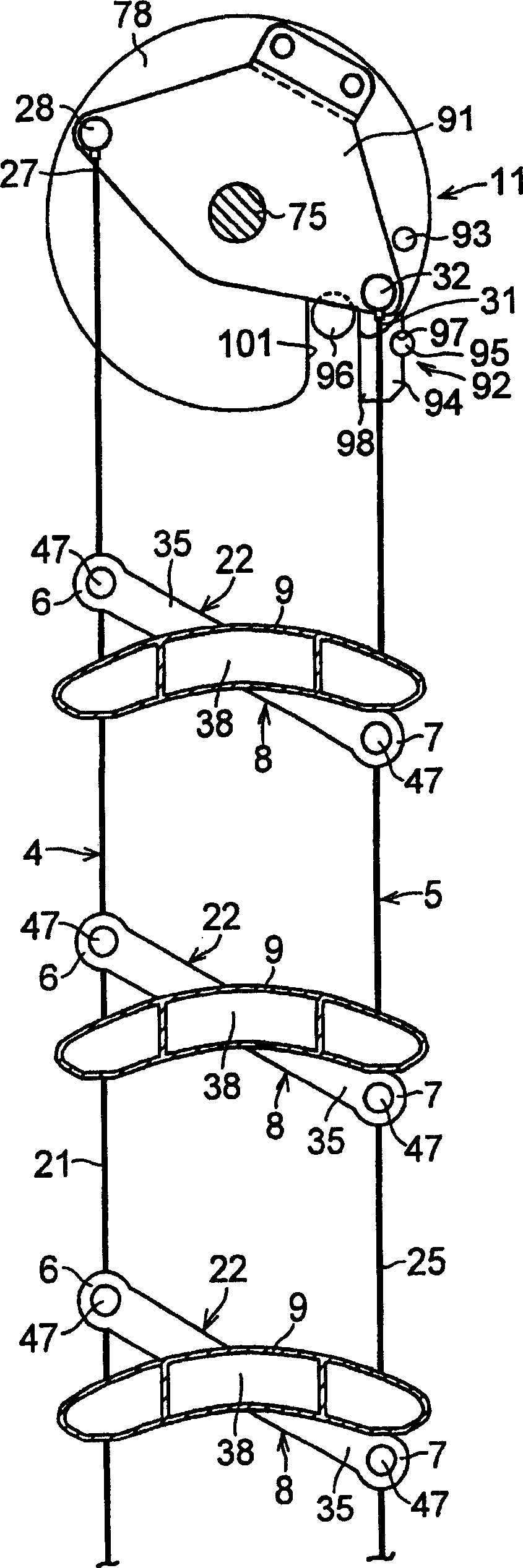

[0042] In Figures 1 to 6, a window shutter device 1 according to the present embodiment comprises a pair of mullions 2 and 3; a connecting mechanism 4; a plurality of slat supporting mechanisms 8, each of which ends 6 connected to the connecting mechanism 4, While the other end 7 is connected to the connecting mechanism 5; a plurality of slats 9, each supported by a corresponding slat supporting mechanism 8, and juxtaposed in the opening P between the mullions 2 and 3; a lifting mechanism 10 for lifting the slats 9; and a tilting mechanism 11 for tilting the respective respective slats by subjecting the connecting mechanisms 4 and 5 to relevant changes in their vertical positions when the lifting mechanism 10 raises or lowers the slats. slats9.

[0043]The hollow mullion 2 has a guide groove 15 extending vertically, and the hollow mullion 3 also has a guide groove 16 extending vertically. The connecting mechanisms 4 and 5 and the tilting me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com