Non-oriented silicon steel sheet having excellent core loss and production method thereof

A non-directional, electromagnetic steel plate technology, applied in the direction of manufacturing tools, inorganic material magnetism, furnace type, etc., can solve the problems that the growth of grains cannot be improved, the cost of steelmaking increases, and the reduction of iron loss is insufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below.

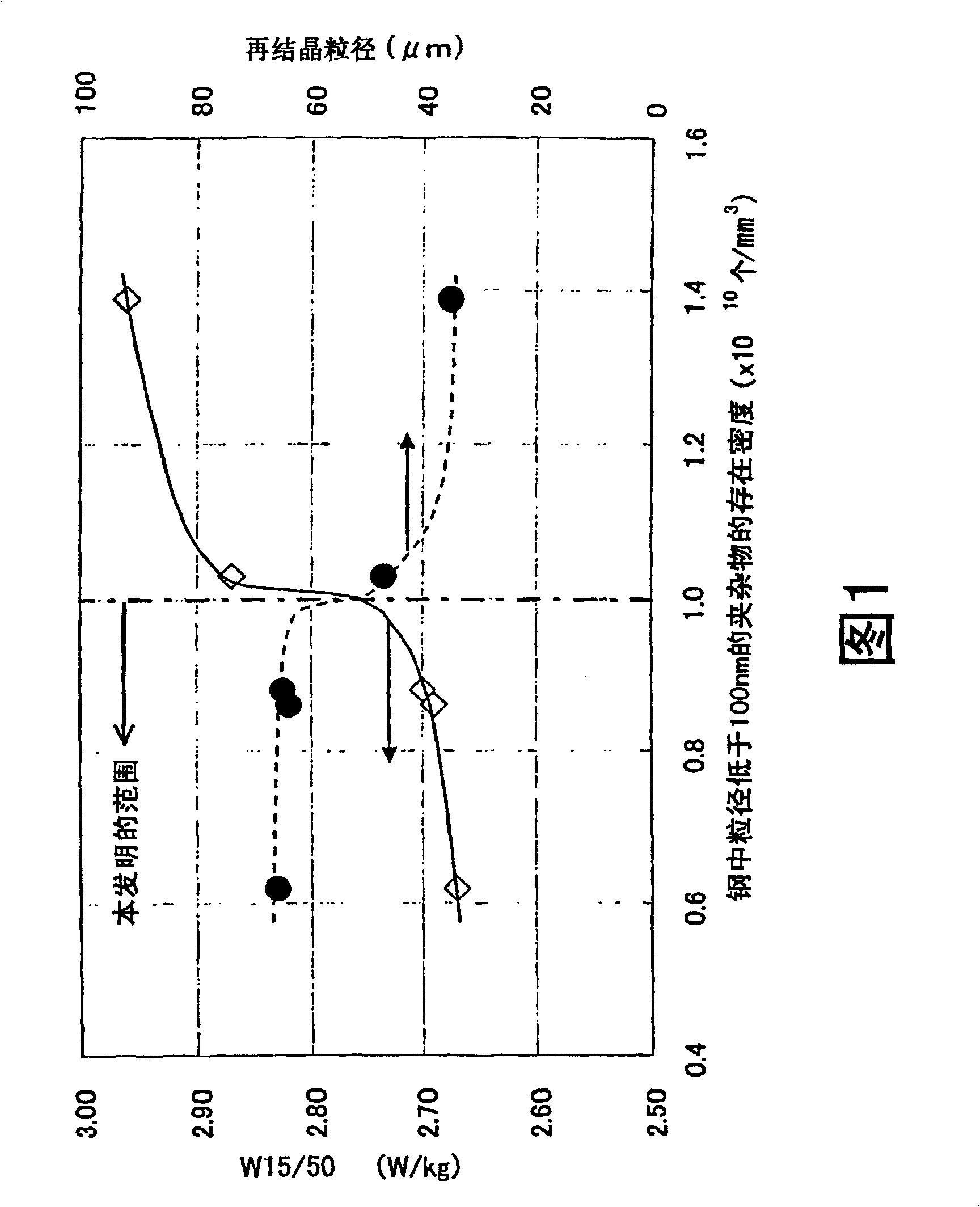

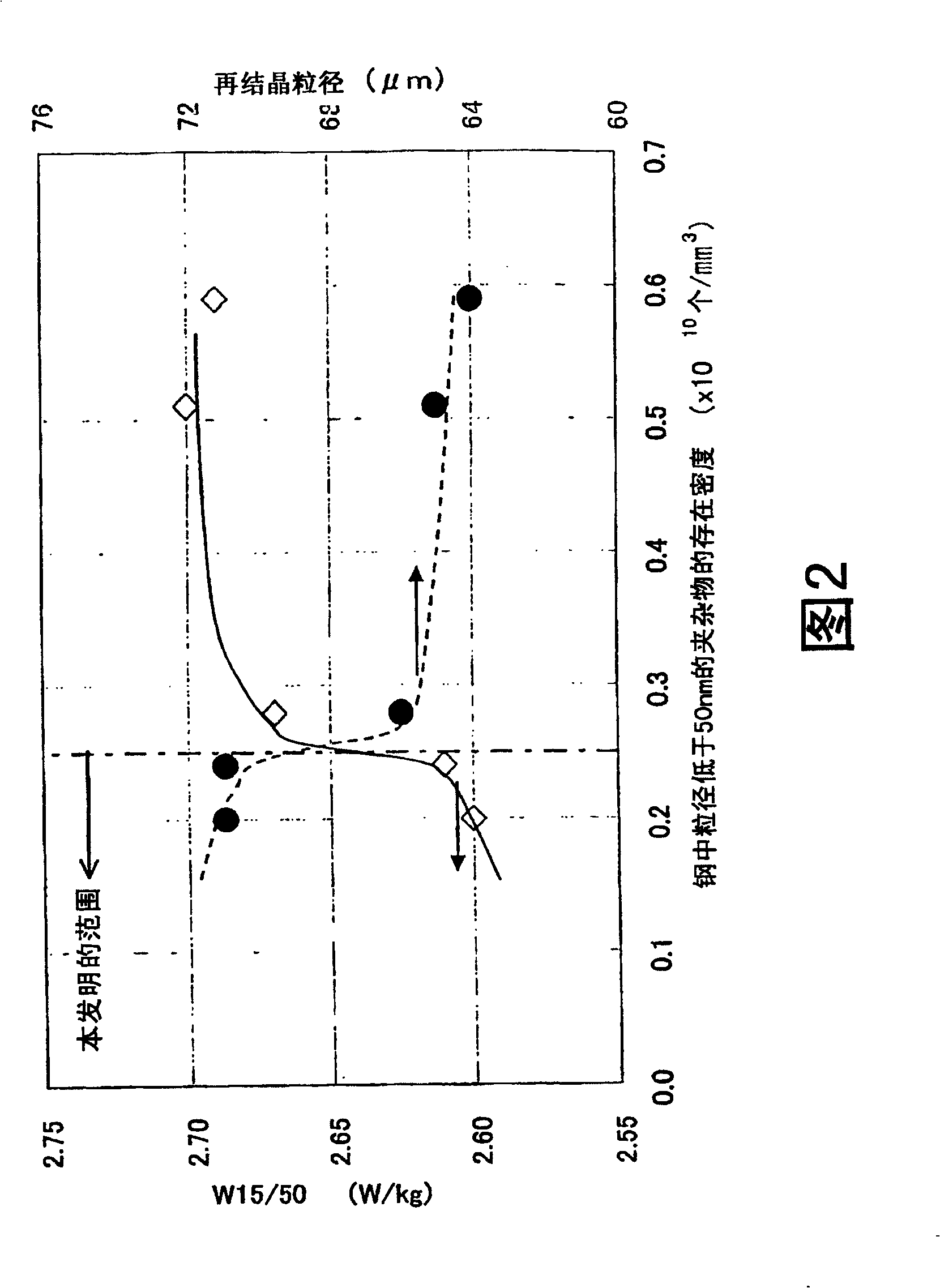

[0032] The inventors of the present invention focused on the influence of the fine inclusions contained in the steel sheet on the magnetic properties of the non-oriented electrical steel sheet, and recently discovered the optimum size and number density of the inclusions for exhibiting good magnetic properties and punching performance. scope.

[0033] The influence of the size and number density of inclusions on the magnetic properties will be described using the steels shown below. However, this steel is an example, and the present invention is not limited thereto.

[0034] The steel contains C, Si, Al, Mn, REM, Ti, S, and N, and the balance is Fe and unavoidable impurities. Steel with this composition is subjected to continuous casting, hot rolling, followed by hot-rolled sheet annealing, and cold-rolled to a thickness of 0.5mm, and then final annealing at 850°C for 30 seconds, and then coating insulation C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com