Grain-oriented electrical steel sheet

An electromagnetic steel plate and directional technology, applied in the direction of circuits, magnetic objects, magnetic materials, etc., can solve the problems of increased cost, insufficient effect, and no synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

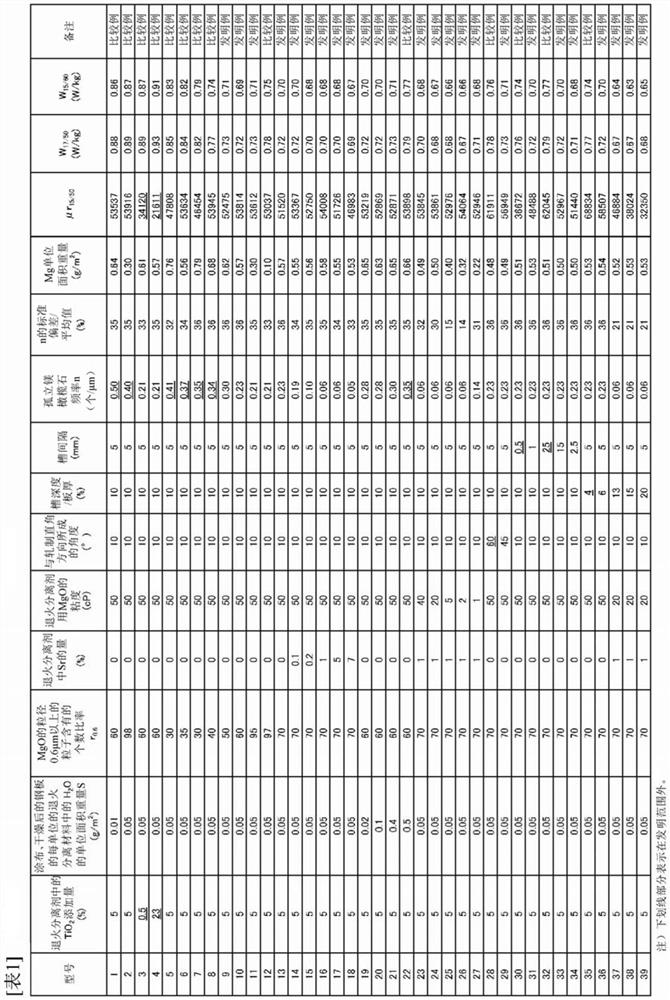

[0090] In terms of mass%, C: 0.06%, Si: 3.3%, Mn: 0.06%, P: 0.002%, S: 0.002%, Al: 0.025%, Se: 0.020%, Sb: 0.030%, Cu: 0.05% % and N: 0.0095% of the billet is loaded into a gas furnace, heated to 1230°C and held for 60 minutes, then heated at 1400°C for 30 minutes in an induction heating furnace, and hot-rolled to form a hot-rolled sheet with a thickness of 2.5mm. The hot-rolled sheet was annealed at 1000° C. for 1 minute, pickled, cold-rolled once to form a thickness of 1.7 mm, intermediate annealed at 1050° C. for 1 minute, pickled, and then used After secondary cold rolling to a final plate thickness of 0.23 mm, decarburization annealing was performed at 850° C. for 100 seconds in an oxidizing atmosphere mixed with hydrogen, nitrogen, and water vapor. Further adding TiO to MgO 2 An annealing separator and other reagents are mixed with water to form a slurry, which is coated on the surface of the steel sheet, dried, and then wound into a roll. At this time, use MgO with di...

Embodiment 2

[0098] A steel slab having the composition described in Table 2-1 and the remainder consisting of Fe and unavoidable impurities was produced by continuous casting, heated to a temperature of 1380°C, and then hot rolled to obtain a slab with a thickness of 2.0 mm. The hot-rolled sheet was annealed at 1030° C. for 10 seconds, then cold-rolled, and finished into a cold-rolled sheet with a final thickness of 0.20 mm. Thereafter, decarburization annealing is performed. Decarburization annealed at 50vol% H 2 -50vol%N 2 , Keep at 840°C for 100 seconds in a humid atmosphere with a dew point of 55°C. Next, the following three kinds of slurries (A), (B) and (C) were applied to each material, that is, (A) with the r of MgO 0.6 = 65%, MgO with a viscosity (after 30 minutes of stirring at 100 rpm) of 30 cP is the main component, and 10% of TiO is added 2 The annealed separator slurry, or (B) the r of MgO 0.6 = 65%, MgO with a viscosity of 50cP (after stirring with 100rpm impeller for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com