Pulsation type heat pipe

A heat pipe and pulse tube technology, applied in the field of heat transfer elements, can solve the problems of low heat transfer, difficulty in starting, poor ability to overcome gravity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

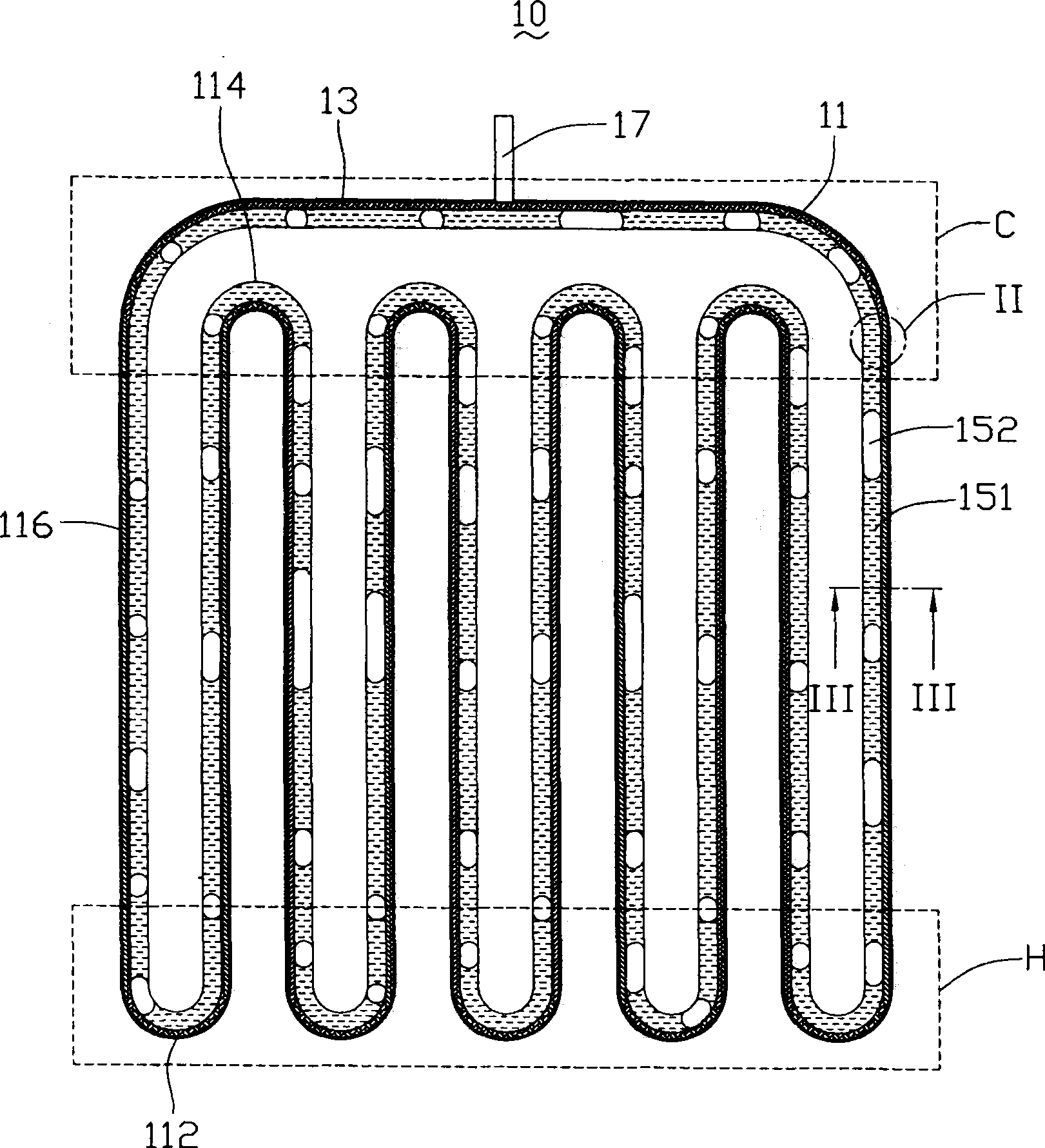

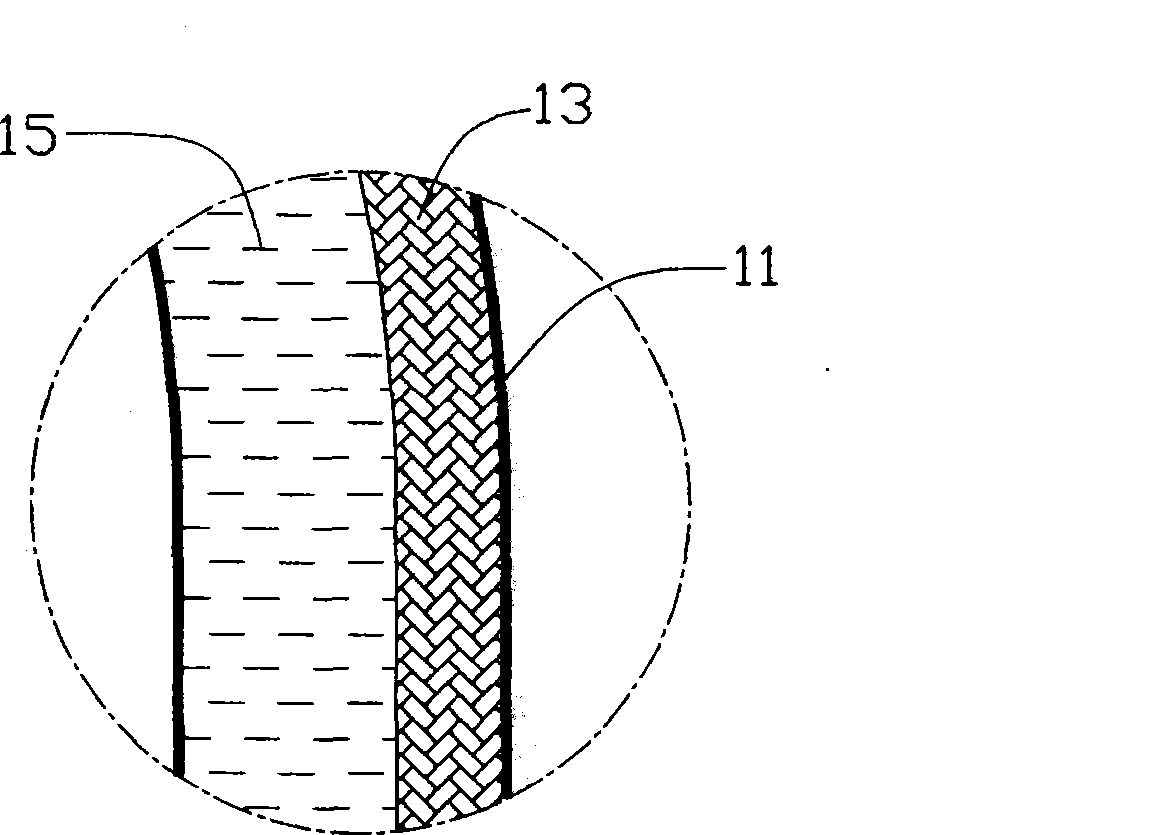

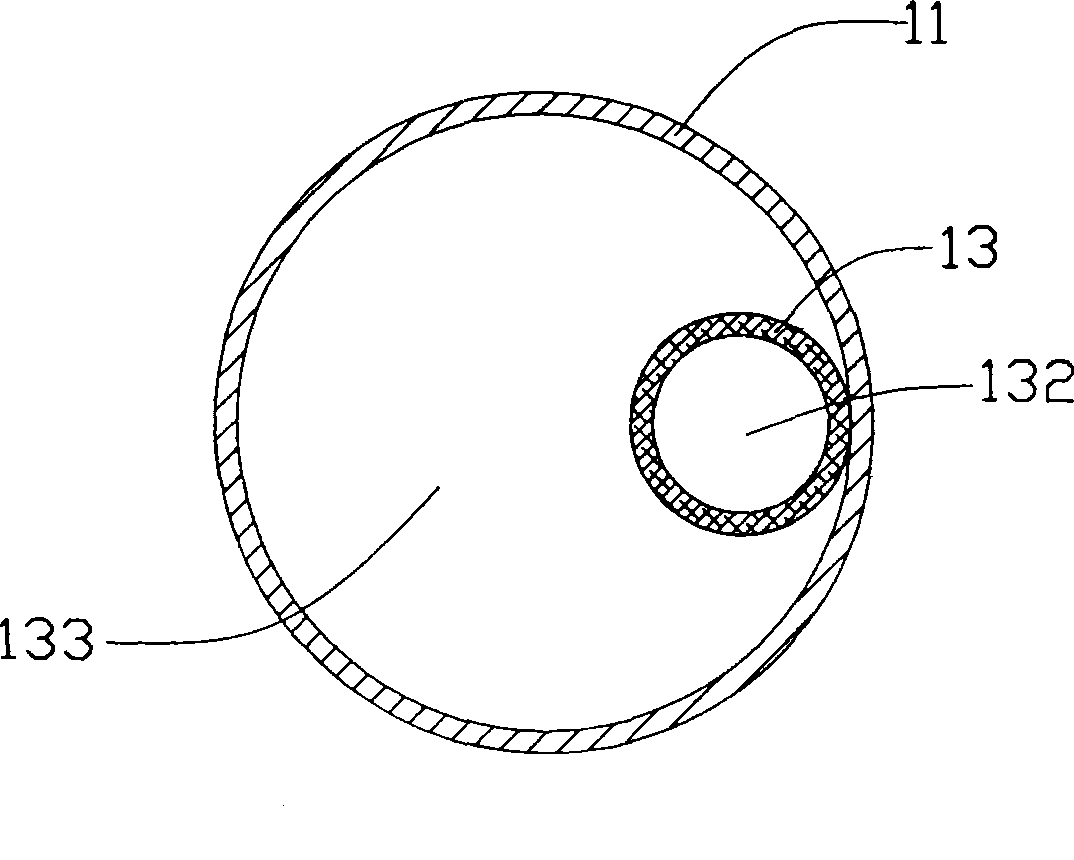

[0016] figure 1 Shown is a preferred embodiment of the pulsating heat pipe 10 of the present invention, the pulsating heat pipe 10 includes a continuously bent elongated capillary 11, a flexible braided vessel 13 and an appropriate amount of condensable working fluid 15 (such as figure 2 As shown), the vessel 13 is placed in the capillary 11, and the working fluid 15 is filled in the capillary 11 and the vessel 13. The capillary 11 is formed into a combination of multiple U-shaped tube bodies by continuous bending.

[0017] The capillary 11 is made of metal material, such as copper or aluminum. In this embodiment, the capillary 11 forms a closed loop (close loop) and its outline is generally palm-shaped, which has several U-shaped heat-absorbing sections 112, several U-shaped heat-dissipating sections 114, and The heat insulating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com