Automatic sphericity falling device and automatic seeding system for plant growth grooved tray

A ball-shaped, automatic technology, applied to planter parts, sowing planters, single-grain planters, etc., can solve problems such as time-consuming, cost-increasing, and difficult-to-sow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

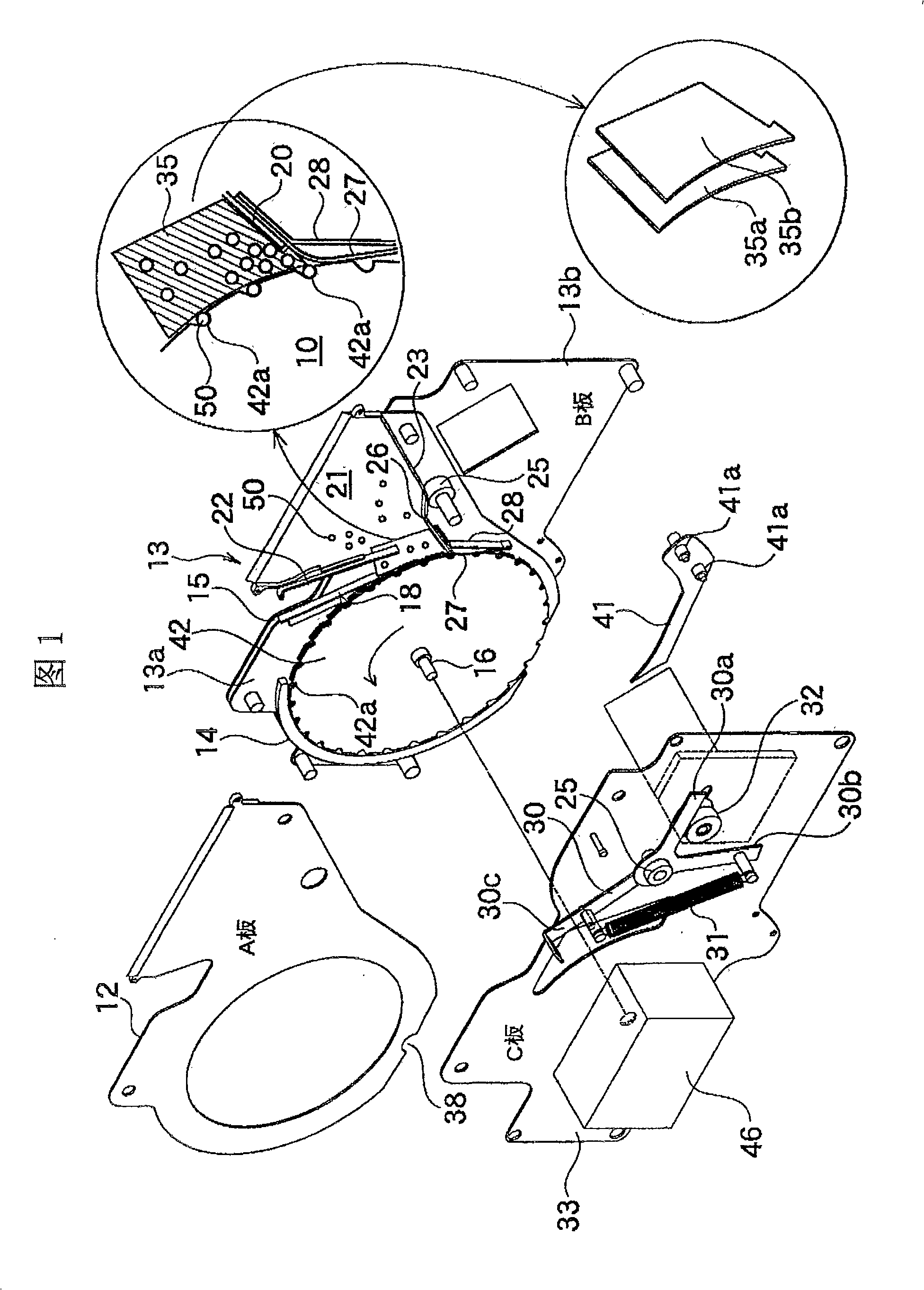

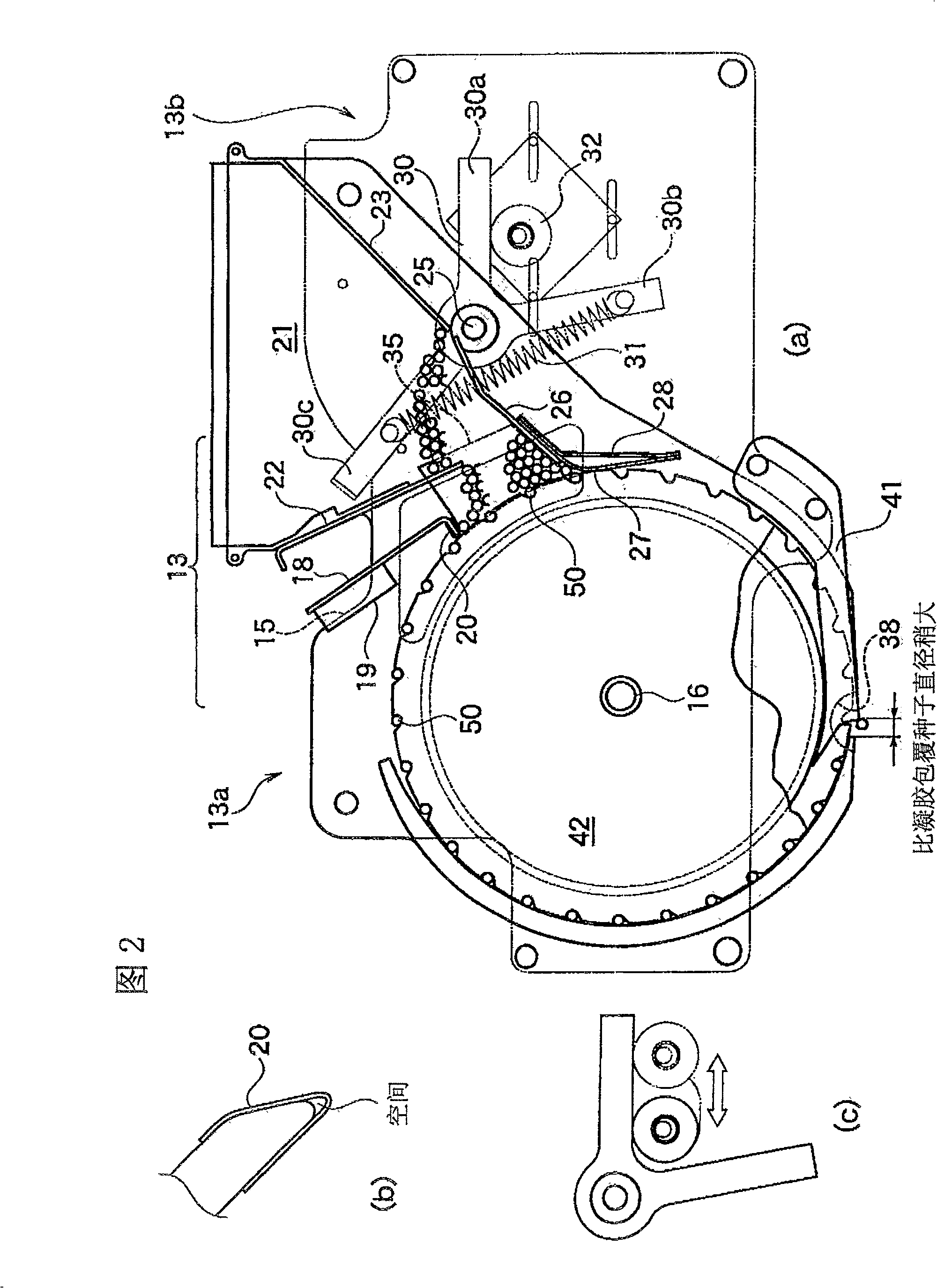

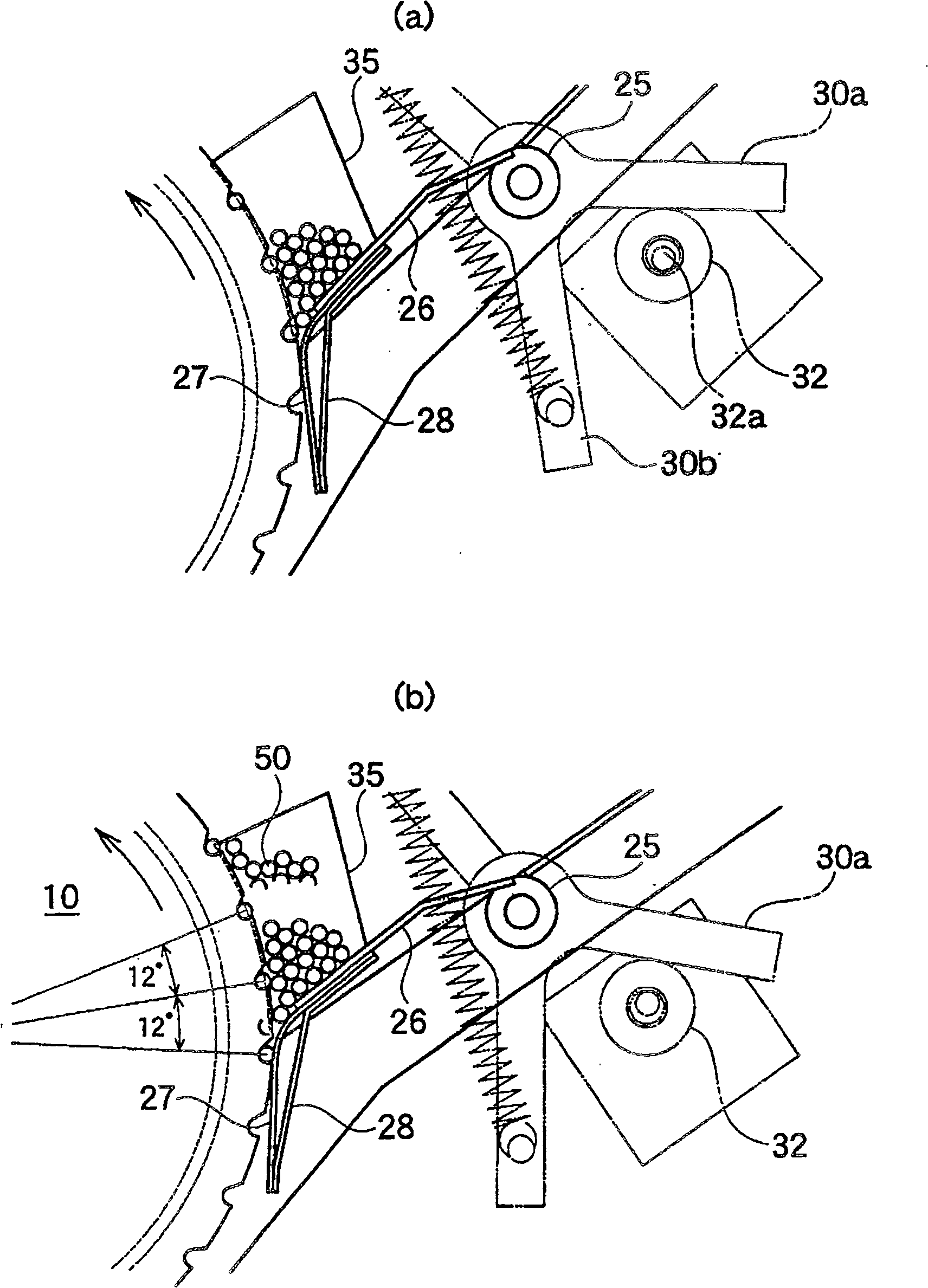

[0052] The first embodiment is suitable for use as an automatic drop device for gel-coated seeds using the ball drop device. This device has a friction rubber 27 provided to face the outer peripheral surface of the conveying roller 42 , and a swing mechanism portion that oscillates the friction rubber 27 while maintaining contact with the outer periphery of the conveying roller 42 .

[0053] Fig. 1 is a schematic perspective view of a device for automatically dropping gel-coated seeds. FIG. 2 is a side view of the series of gel-coated seed automatic dropping devices of FIG. 1 . As shown in FIGS. 1 and 2 , the disk-shaped conveyance roller 42 is pinched between the A plate 12 and the B plate 13 . The thickness of the conveying roller 42 has a diameter dimension (6mm or 10mm) of the gel-coated seeds 50, and recesses 42a for accommodating the gel-coated seeds are provided at regular intervals on the outer periphery thereof. The intervals between the recesses 42 a are, for examp...

Embodiment 2

[0102] In the first embodiment, the ball dropping device suitable for the automatic dropping device of gel-coated seeds is to keep the distance from the outer peripheral surface of the roller 42 at a distance not to overflow, and make the swinging plate and the The outer peripheral surfaces of the transport rollers 42 are oppositely arranged.

[0103] Fig. 7 is a schematic perspective view of the spherical object automatic dropping device (gel-coated seed spherical object automatic dropping device) of the second embodiment. Fig. 8 is a side view of the ball automatic dropping device in Fig. 7 . Here, gel-coated seeds are suitable as pellets.

[0104] As shown in Fig. 7 and Fig. 8, the spherical object automatic dropping device is by holding the disc-shaped conveying roller 42 and rotatable conveying roller unit 70 with A plate 67a and B plate 67b, and is installed on the side surface of conveying roller unit 70 , is equipped with a C plate 67c such as a driving device for dr...

Embodiment 3

[0141] The third embodiment is the situation that the multi-column connected gel-coated seed automatic dropping device of the first embodiment is used in the automatic seeding system for the seedling raising tank.

[0142] Fig. 12 shows an overall configuration diagram of this embodiment.

[0143] The automatic seeding system for the seedling-raising trough of the present invention is to rotate the seedling-raising trough 9 filled with soil in each groove and send it to the punching part 2 on the conveyor belt 6 and after making pits in the soil of each groove, It is transferred to the seeding section 3 to sow gel-coated seeds in the pits of each groove. This system consists of the conveying part 1 that is transported to the next process, the punching part 2 that makes the pits in the soil of each groove of the seedling raising groove tray 9 filled with soil, and the punching part 2 in each groove of the seedling raising groove tray 9 that has been filled with soil. The sowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com