Heat-generating body holding-board and mfg method thereof and smoke curing filling container

A heating element and holding plate technology, which can be applied to fumigators, devices for catching or killing insects, metal processing equipment, etc., can solve the problems of the heating element 105 for ignition falling off, the insertion strength being increased, and the material cost being reduced. The effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiment examples of the present invention will be described below, but the present invention is not limited to these examples.

[0044] First, use figure 1 and figure 2 The heating element holding plate of the present invention will be described.

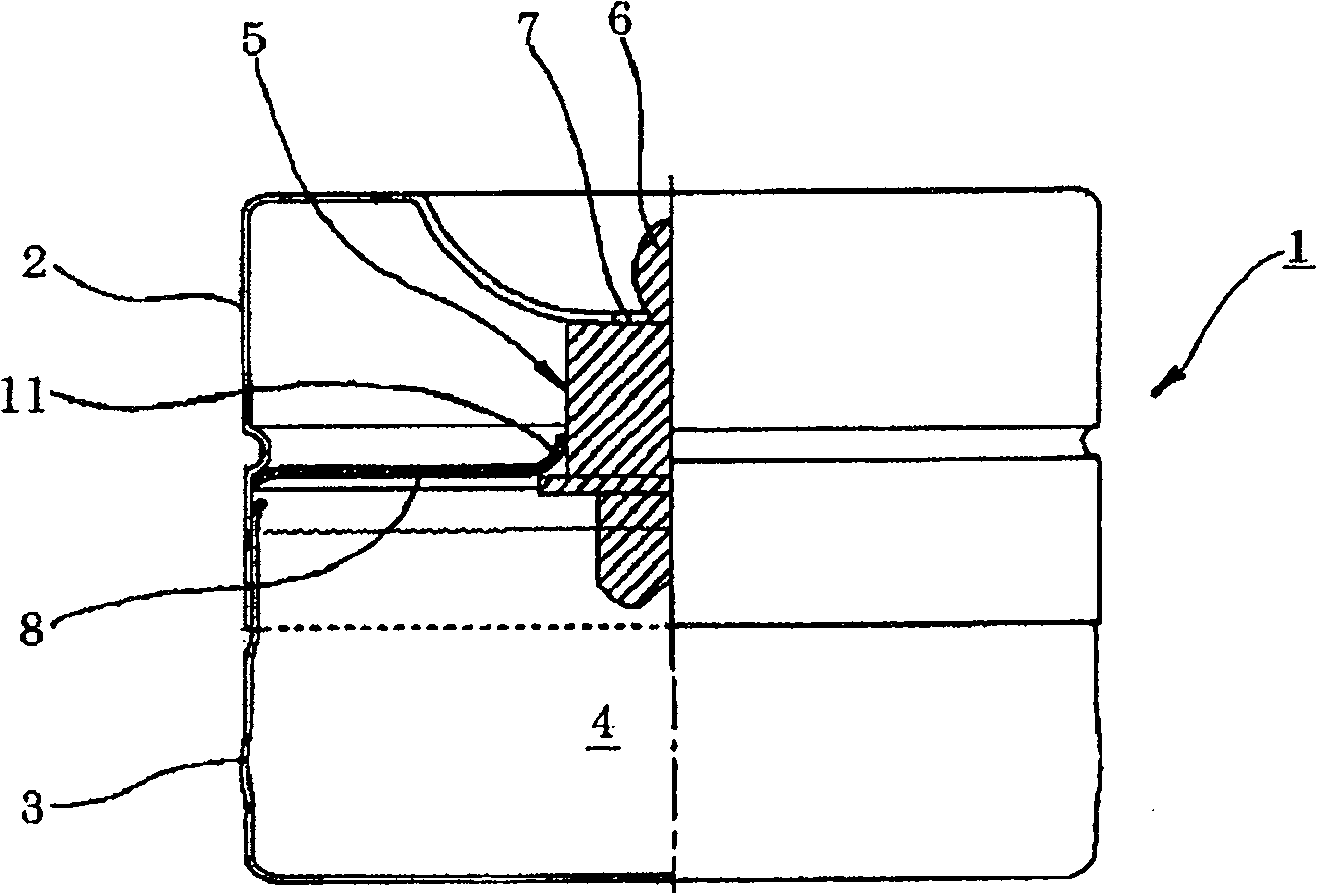

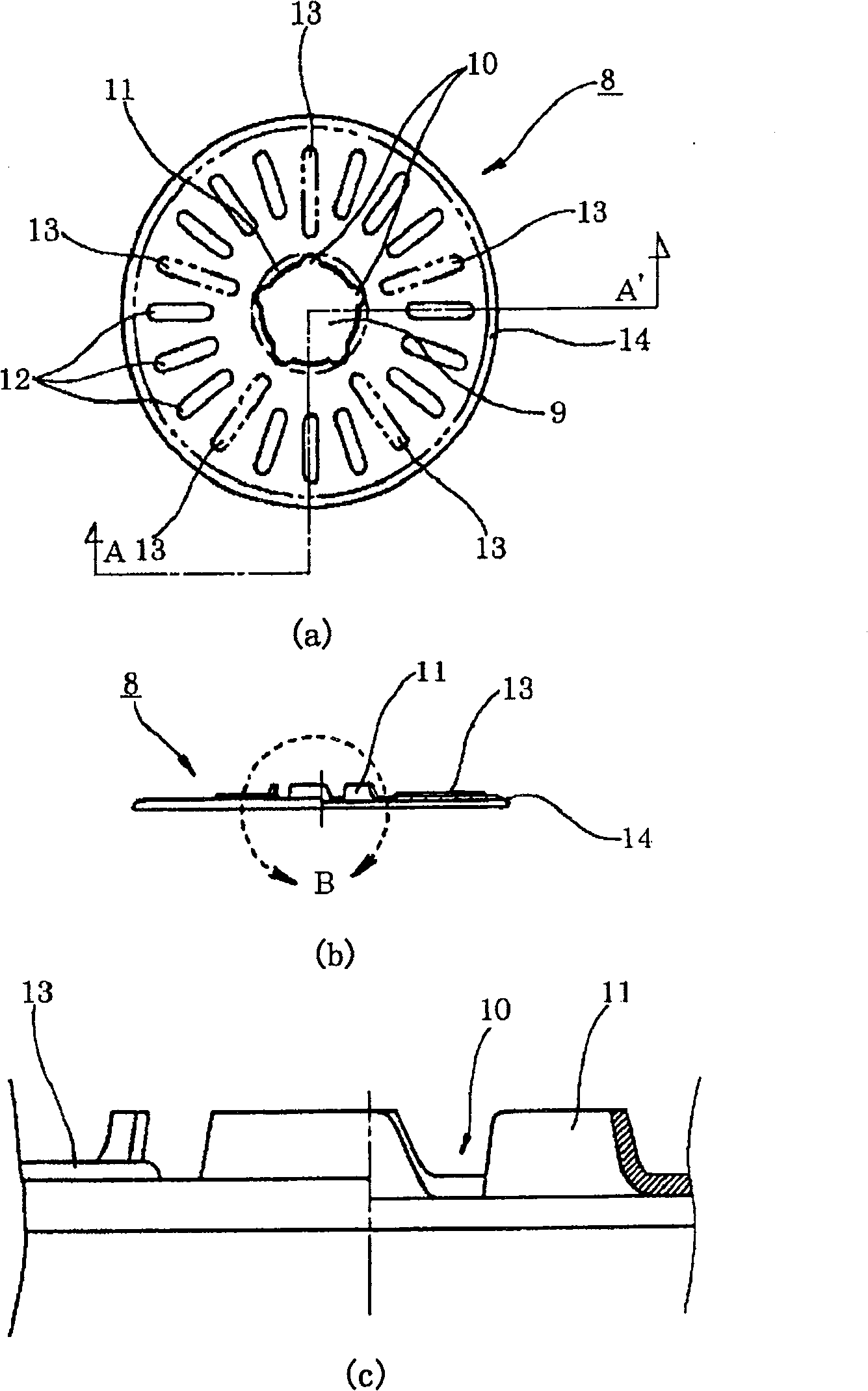

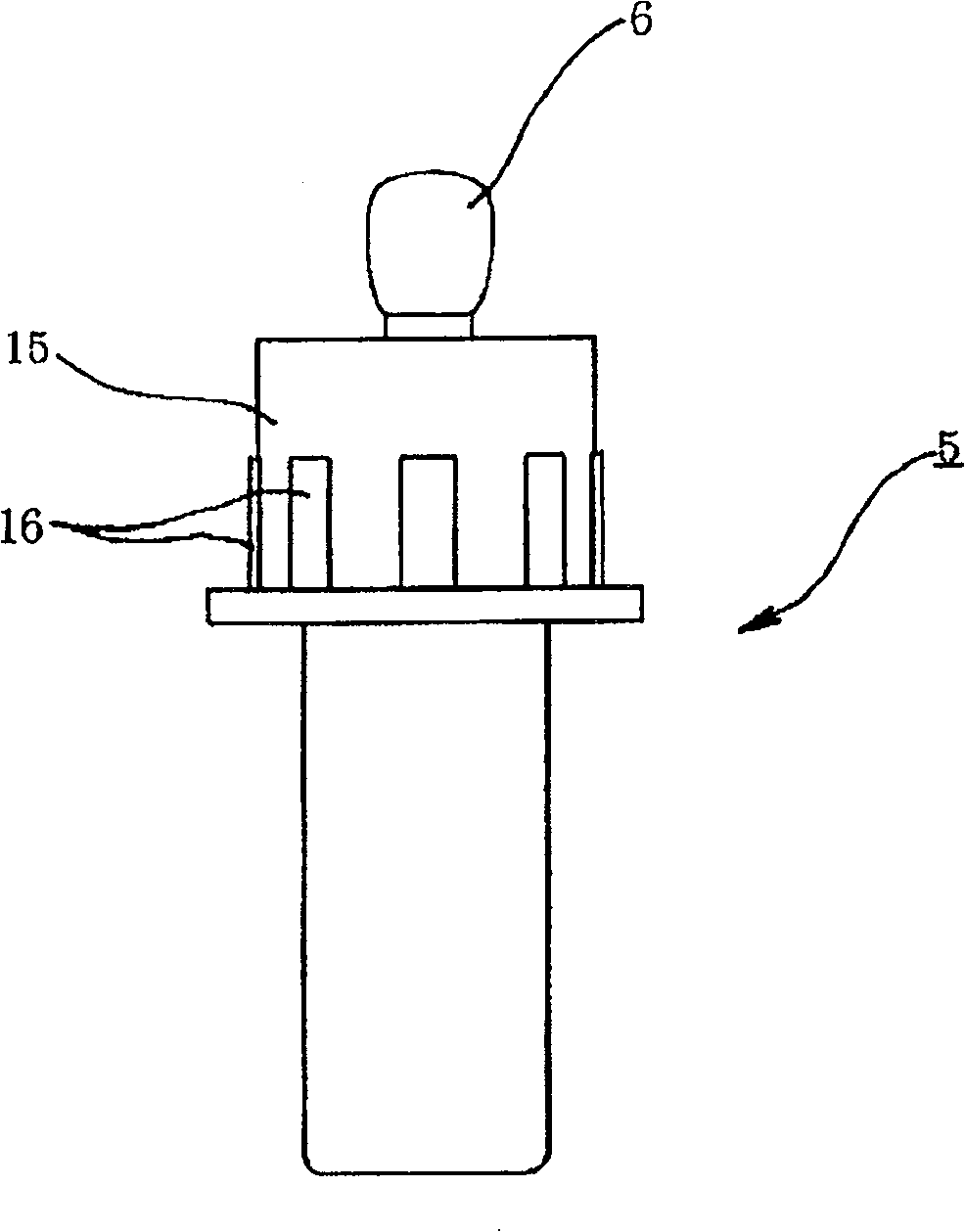

[0045] figure 1 It is a partially cutaway sectional view showing an example of a fumigant filled container equipped with the heating element holding plate of the present invention. figure 2 It is a schematic diagram of the heating element holding plate, (a) is a top view; (b) is a partial cross-sectional view of A-A' in (a); (c) is a partial enlarged view of B in (b).

[0046] Such as figure 1 and figure 2 As shown, the fumigant filling container 1 of this embodiment is mainly composed of a metal container composed of a housing portion 3 for accommodating fumigant 4 and an upper cover 2 .

[0047] On the top of loam cake 2, be provided with and expose the central hole 7 of the ignition head 6 of igniting heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com