Motor

A technology for a motor and a driving coil, applied in the field of motors, can solve the problems of complex motor installation structure, inability to install the motor, and difficulty in obtaining rigidity, and achieve the effects of miniaturization, cost reduction, and plane rigidity improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiment of the invention

[0034] Embodiments to which the present invention is applied will be described below with respect to a spindle motor that can be used in various media drive rotary drive devices such as CD-ROMs.

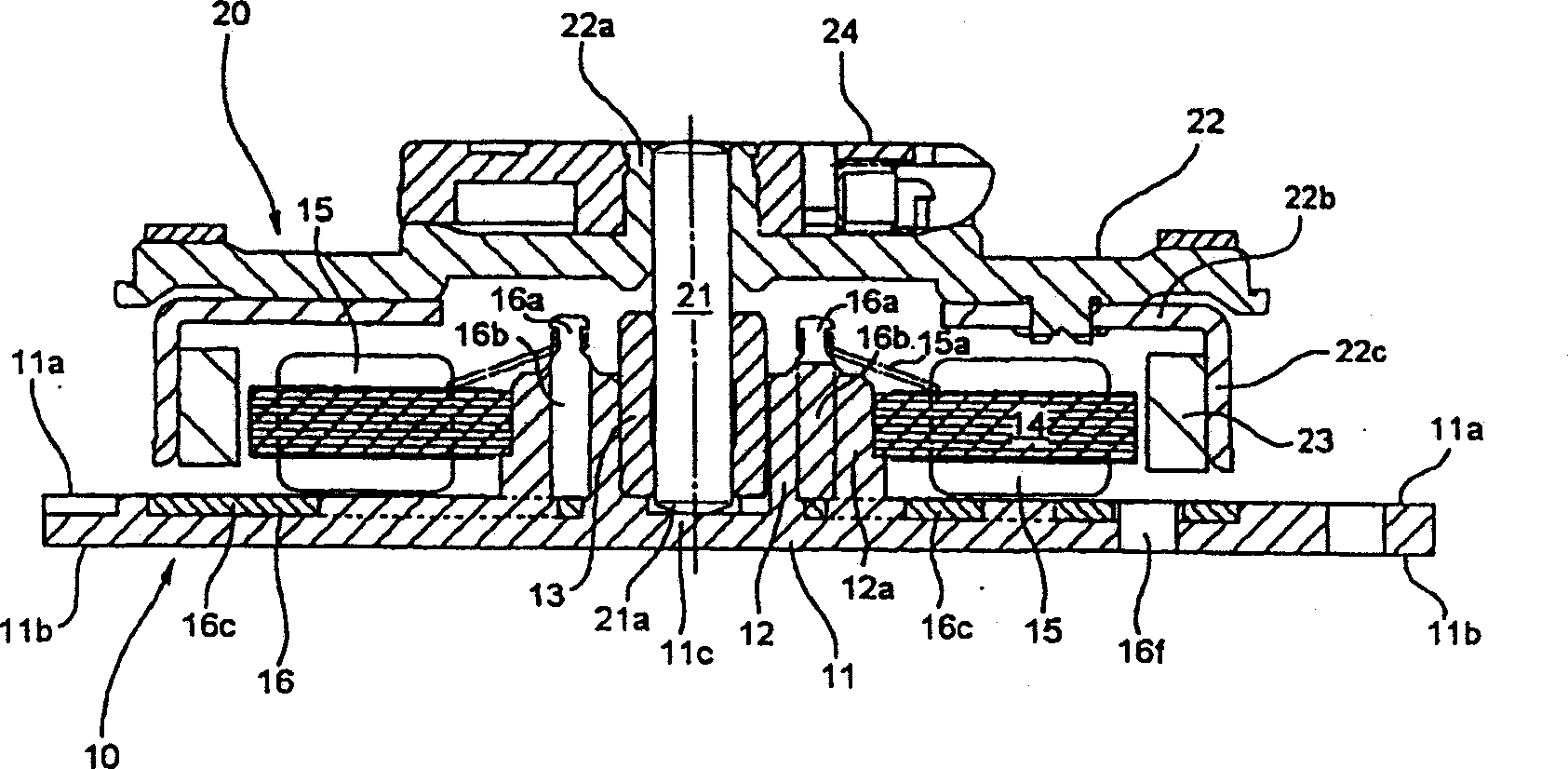

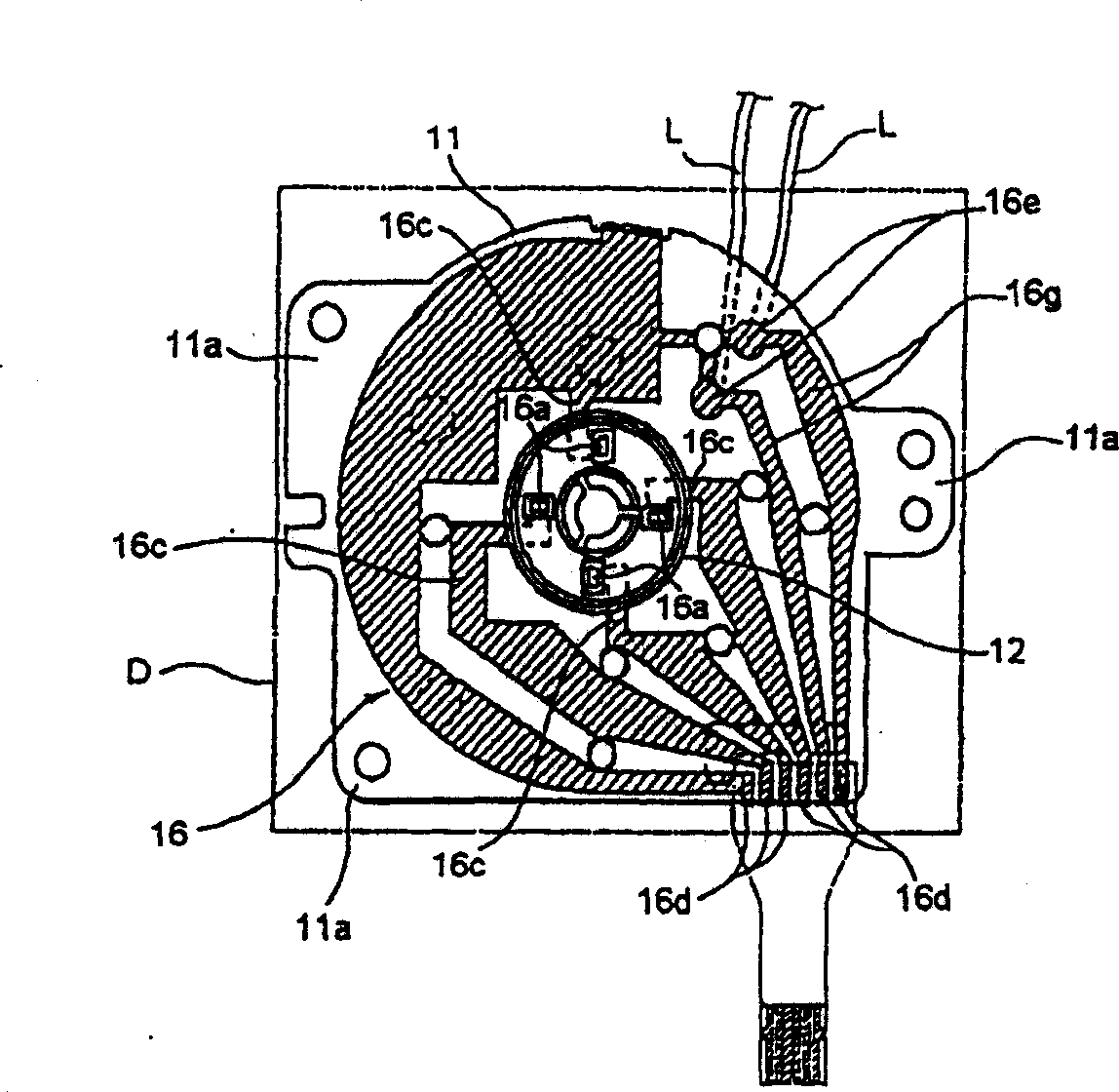

[0035] figure 1 and figure 2 The illustrated spindle motor for a shaft-rotating type media drive driving device is generally composed of a stator group 10 as a fixed member, and a rotor group 20 axially attached to the stator group 10 as a rotating member.

[0036] Among them, the stator group 10 is provided with a motor substrate 11 made of a synthetic resin plate-shaped member, and the reference surface 11b mounted on the motor mounting portion 11a of the motor substrate 11 is positioned by abutting against the main body device D side, and at the same time Secure the entire motor.

[0037] A substantially cylindrical bearing holder 12 is integrally provided at a substantially central portion of the motor substrate 11, and a metal bearing 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com