Wiring board wire connection structure and use method

A wire connection and terminal board technology, applied in conductive connection, connection, clamping/spring connection, etc., can solve the problems of large motor volume, waste of nut man-hours, hidden quality and safety hazards, etc., to achieve convenient and efficient connection, easy disassembly and assembly, Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

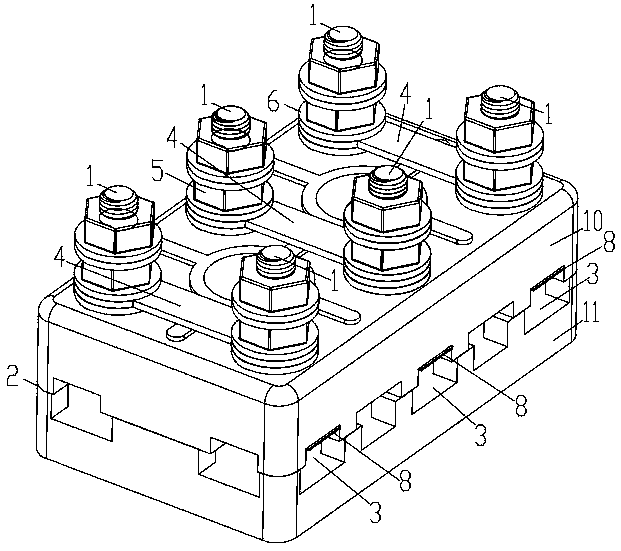

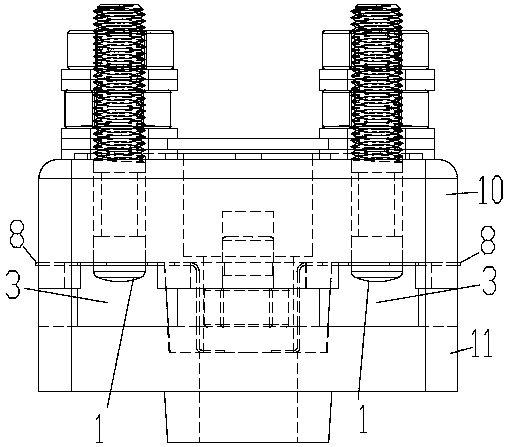

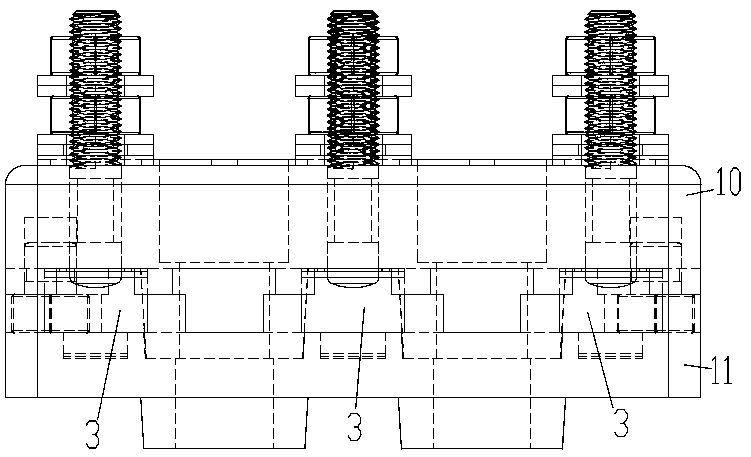

[0025] Such as Figure 1~8 As shown, a terminal block wire connection structure includes a terminal box 2 provided with a plurality of terminal posts 1, and the terminal box is provided with a reed at the end of each terminal post for pressing the terminal.

[0026] In the embodiment of the present invention, the junction box is provided with a plurality of wiring holes 3, and each wiring hole has an end of a terminal and a reed inside.

[0027] In the embodiment of the present invention, a plurality of wiring holes are distributed on the outer periphery of the junction box.

[0028] In the embodiment of the present invention, the terminal posts all extend vertically and the bottom ends extend into the inner top of the wiring hole. The nut 5 and the washer 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com