Method for RTA constant temperature measurement and its used measurement and control wafer

A wafer and polysilicon layer technology, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as scrapping, inaccurate product temperature measurement and control, and achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

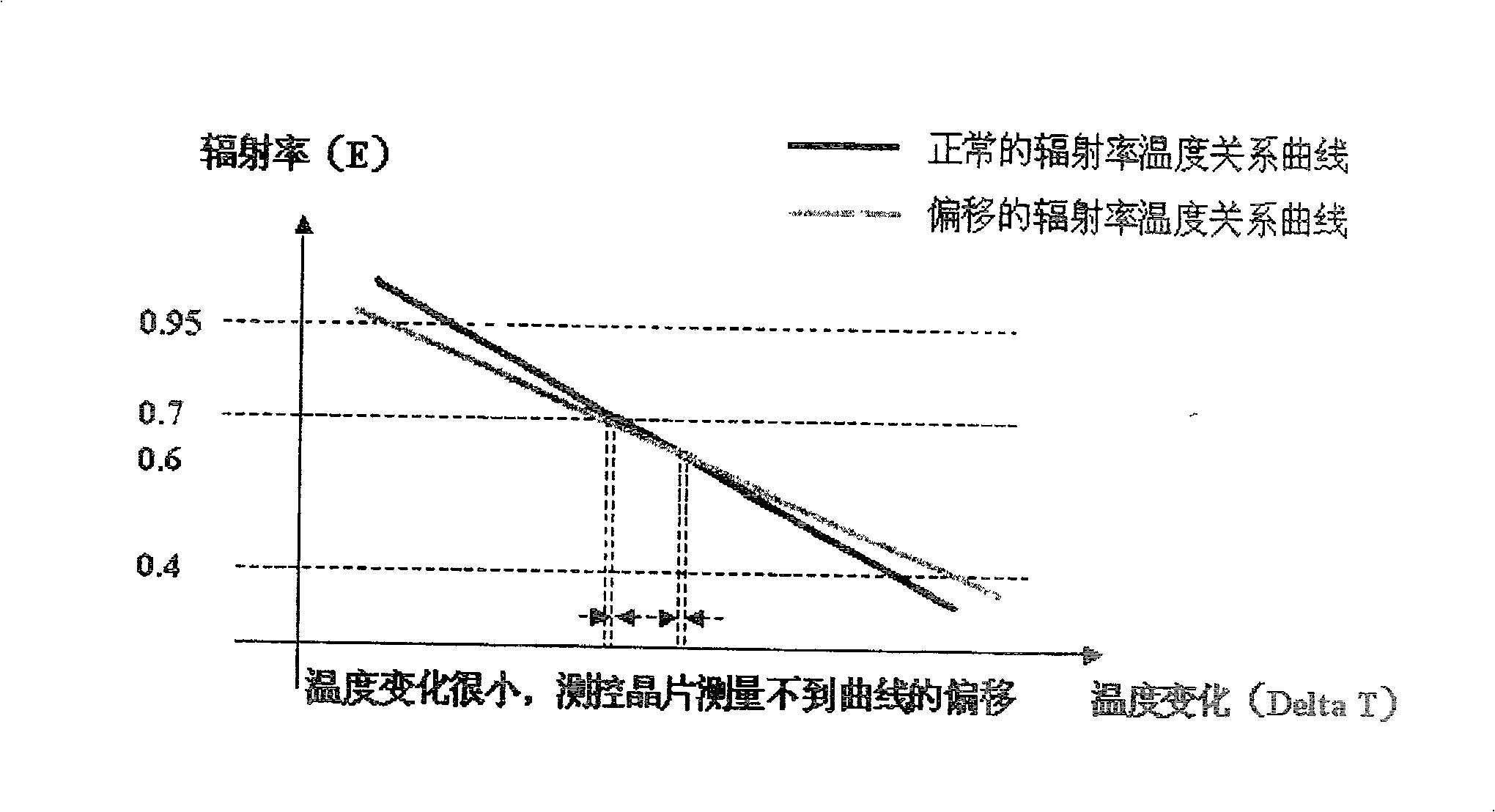

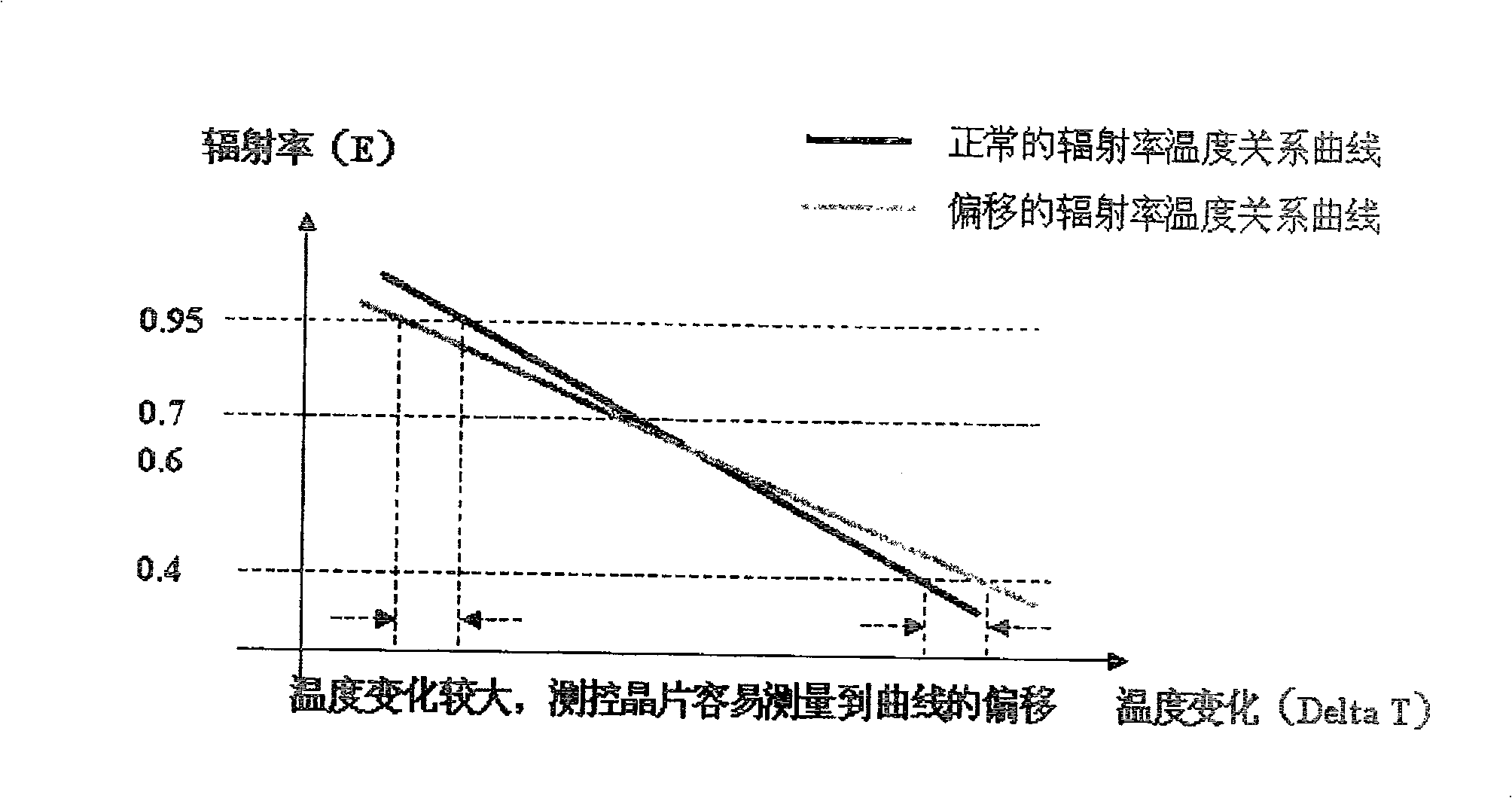

[0015] The method for carrying out RTA temperature control measurement of the present invention, at first develop two kinds of new measurement and control wafers with different crystal back emissivity, a kind of by adding Si Nitride (silicon nitride) layer on the wafer back, make its emissivity can be reduced to 0.35 , this kind of chip is a low emissivity measurement and control chip, and its preparation process is shown in Table 1 below; another kind of chip can increase its emissivity to 0.95 by adding a POLY layer on the back of the wafer, and this kind of chip is a high emissivity measurement and control chip , and its preparation process is shown in Table 2 below.

[0016] Table 1 Manufacturing process of low emissivity measurement and control chip

[0017] Preparation step number

[0018] Table 2 Preparation process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com