Full-automatic bearing vibration survey instrument and method thereof

A measuring instrument, fully automatic technology, used in mechanical bearing testing, measuring devices, vibration testing and other directions, can solve the problems of increased labor intensity of testing personnel, uneconomical quality assurance, low management, etc., to avoid scratching the measuring surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings:

[0026] This embodiment provides a fully automatic bearing vibration measuring instrument.

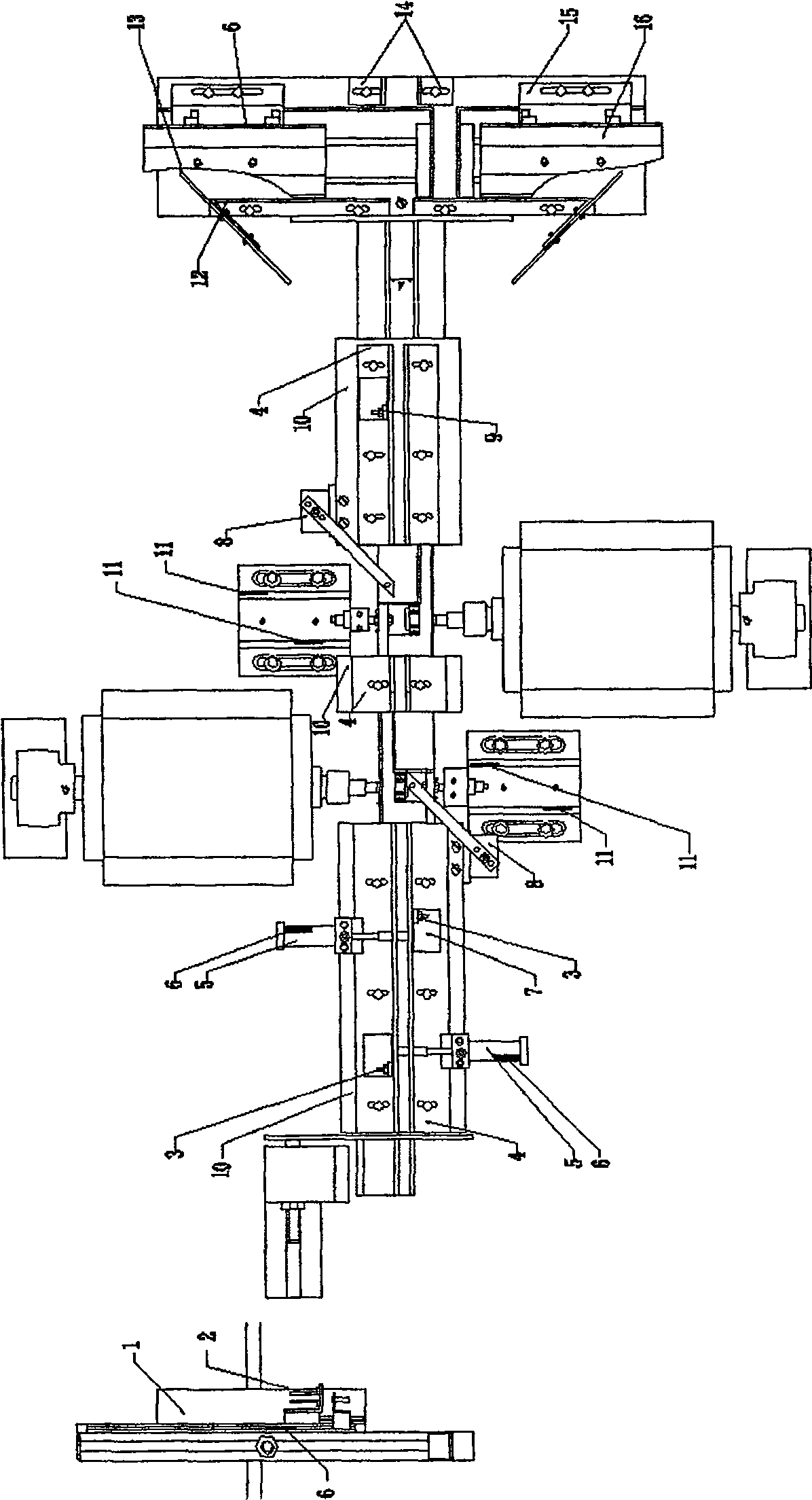

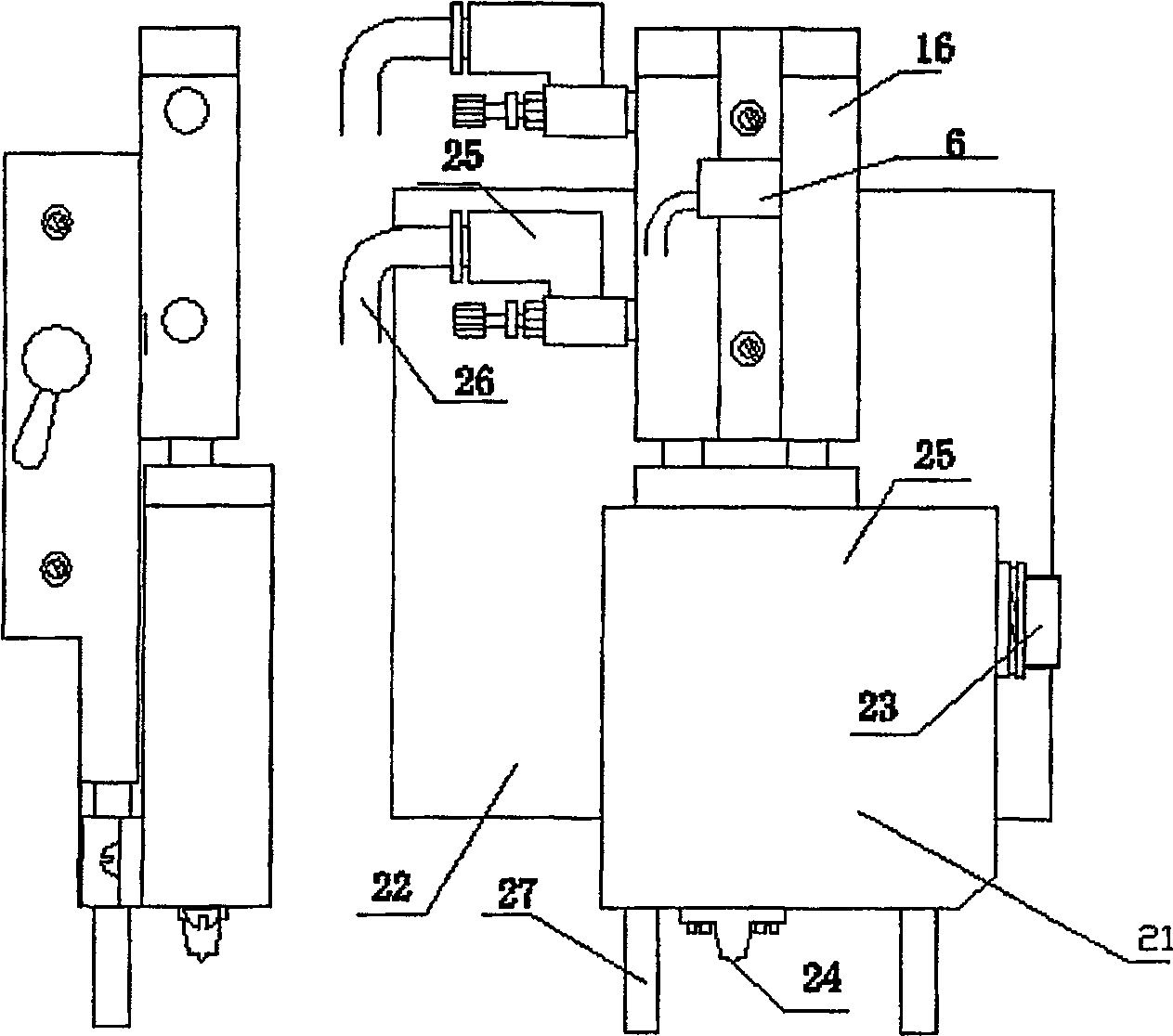

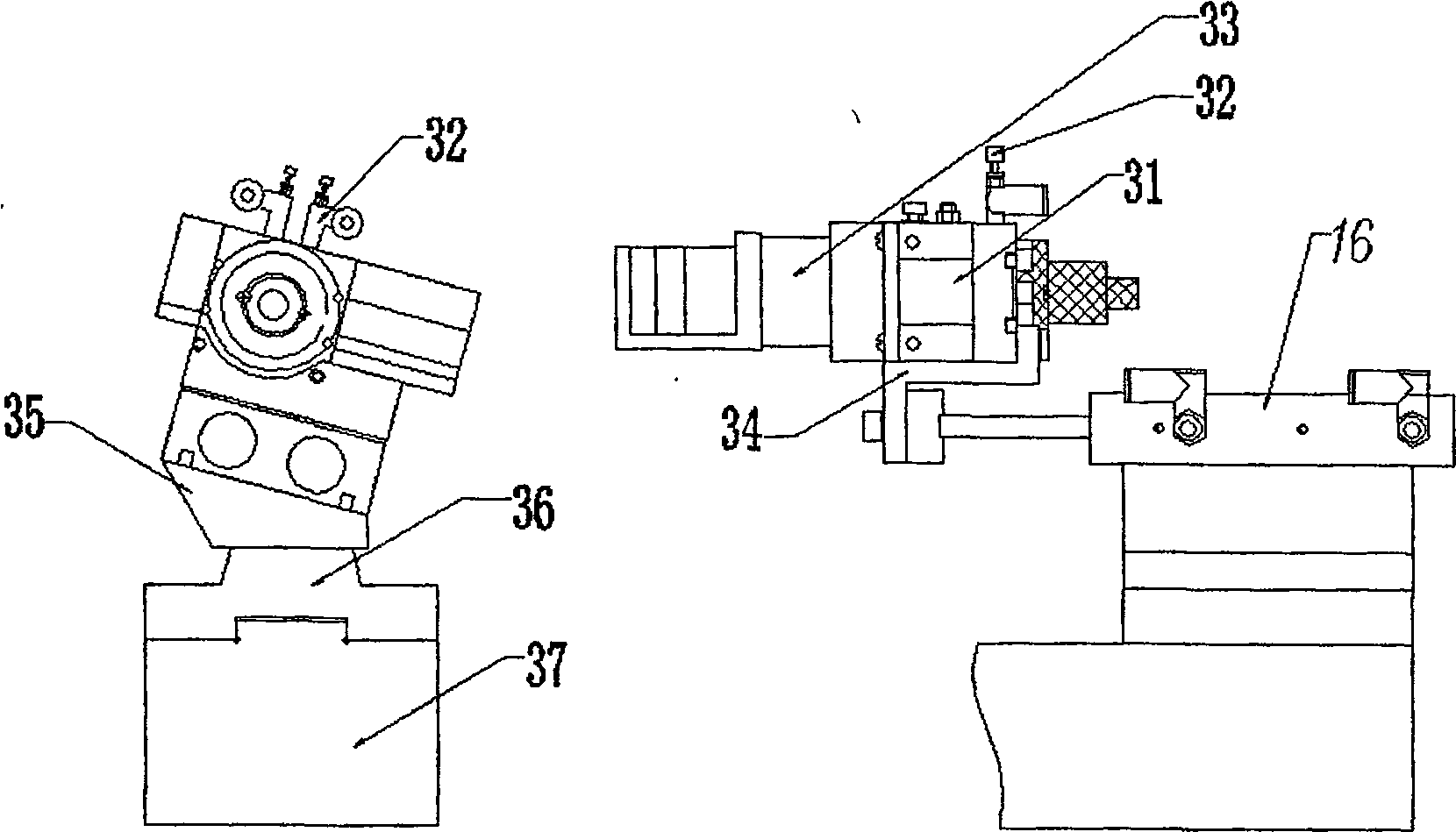

[0027] The fully automatic bearing vibration measuring instrument mainly includes: a probe lifting mechanism, a measuring mechanism, a protection mechanism and a material distribution mechanism. It is characterized in that the bearing to be tested is placed in a corresponding station through the lifting mechanism, and the The driving device transmits the bearing to be tested to the measuring mechanism, and then the bearing to be tested enters the material distribution mechanism according to the signal detected by the measuring mechanism.

[0028] Such as figure 1 As shown, it is the structure diagram of the material channel of the bearing vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com