Driving mechanism

A driving device and a driven technology, applied in installation, TV, color TV, etc., can solve the problems of resonance frequency drop, narrow range, high device cost, etc., and achieve the effect of stable drive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Next, preferred embodiments of the driving device of the present invention will be described in detail with reference to the drawings. In addition, in description of drawings, the same code|symbol is attached|subjected to the same element, and repeated description is abbreviate|omitted.

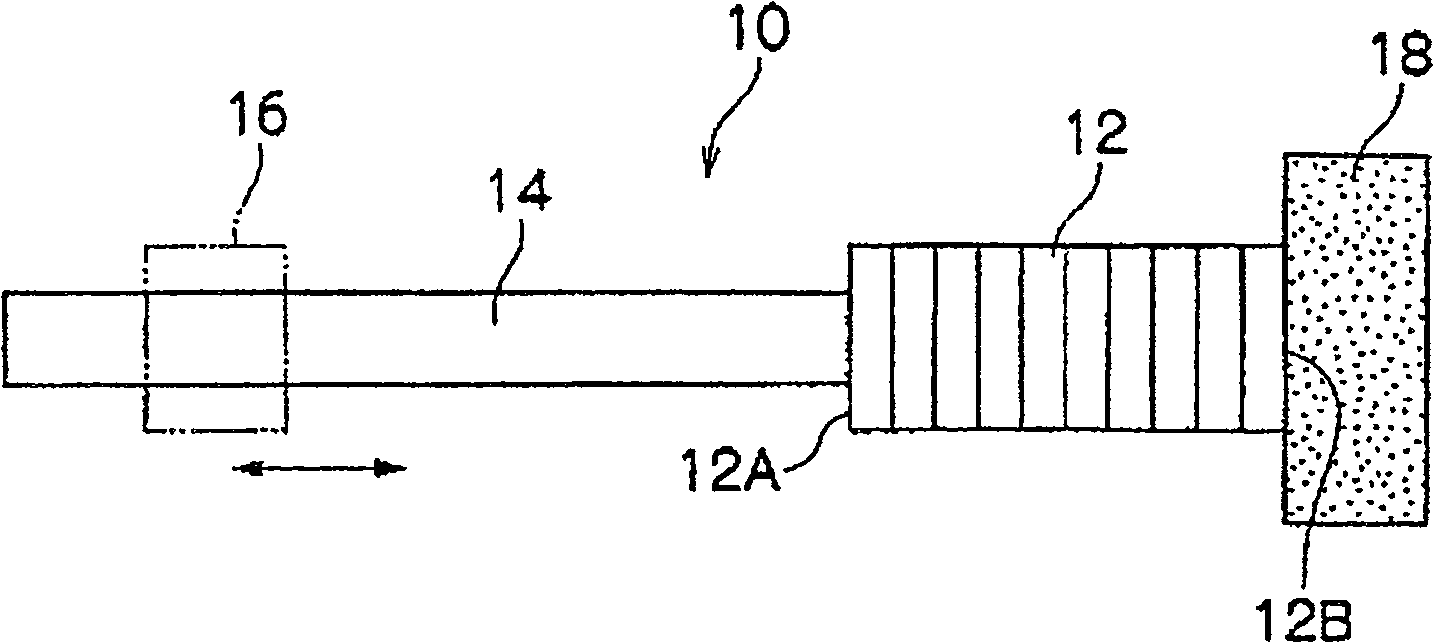

[0052] figure 1 It is a plan view showing the actuator 10 of the driving device 100 according to the first embodiment of the present invention. Such as figure 1 As shown, the actuator 10 is composed of a piezoelectric element (corresponding to an electromechanical conversion element) 12 , a drive member 14 , and a hammer member 18 . The piezoelectric elements 12 are stacked in the direction of the arrow, and deformed (expandable) in the stacking direction by application of a voltage. Accordingly, the end faces 12A and 12B in the longitudinal direction of the piezoelectric element 12 are displaced.

[0053] The proximal end of the driving member 14 is fixedly connected to one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com