Resonance measuring chucking appliance of hard disk drive rack

A resonance measurement, hard disk drive technology, applied in measurement devices, ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of inaccurate measurement results, large differences in measurement results, and inability to more realistically reproduce the vibration characteristics of the drive frame. , to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

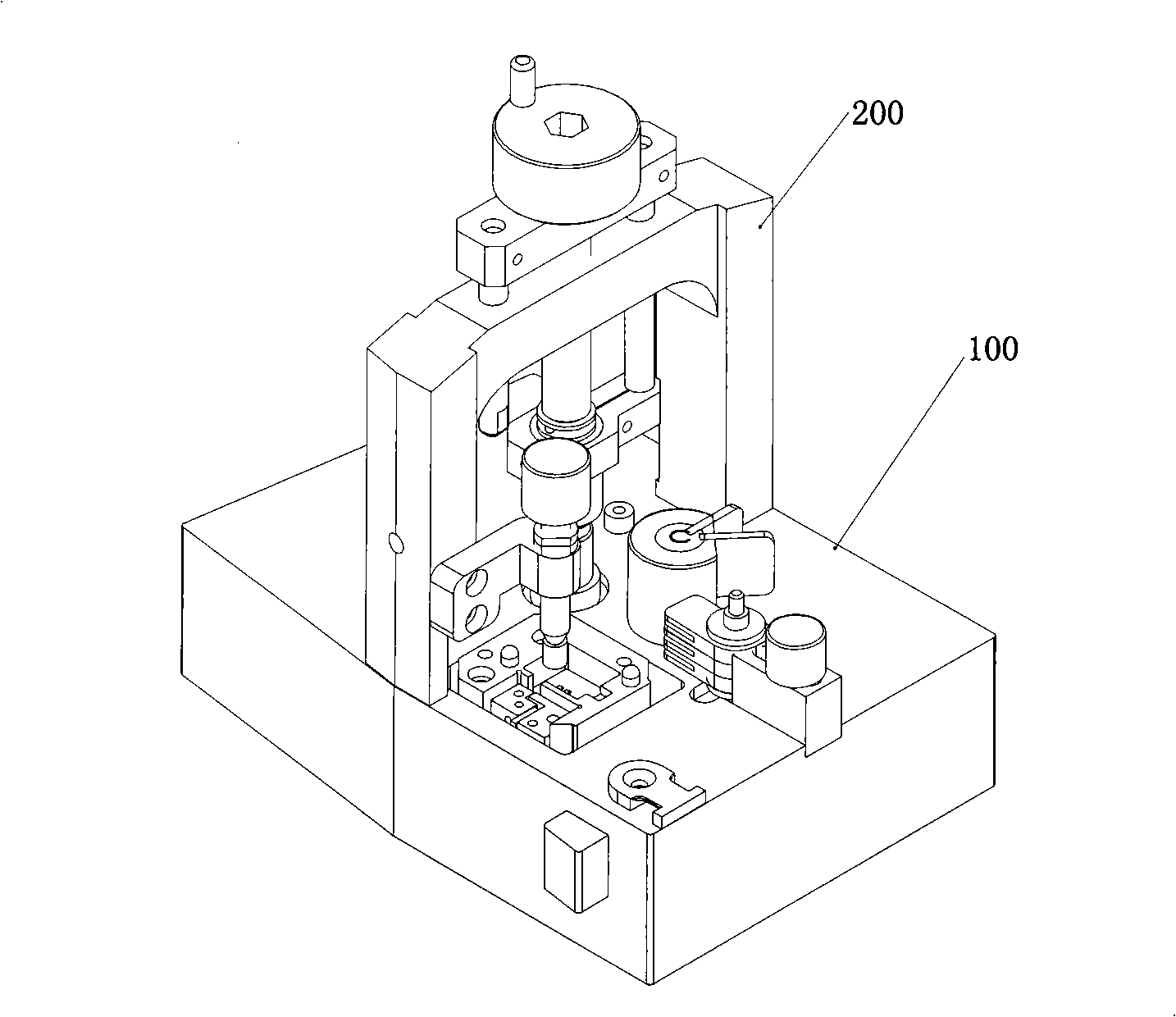

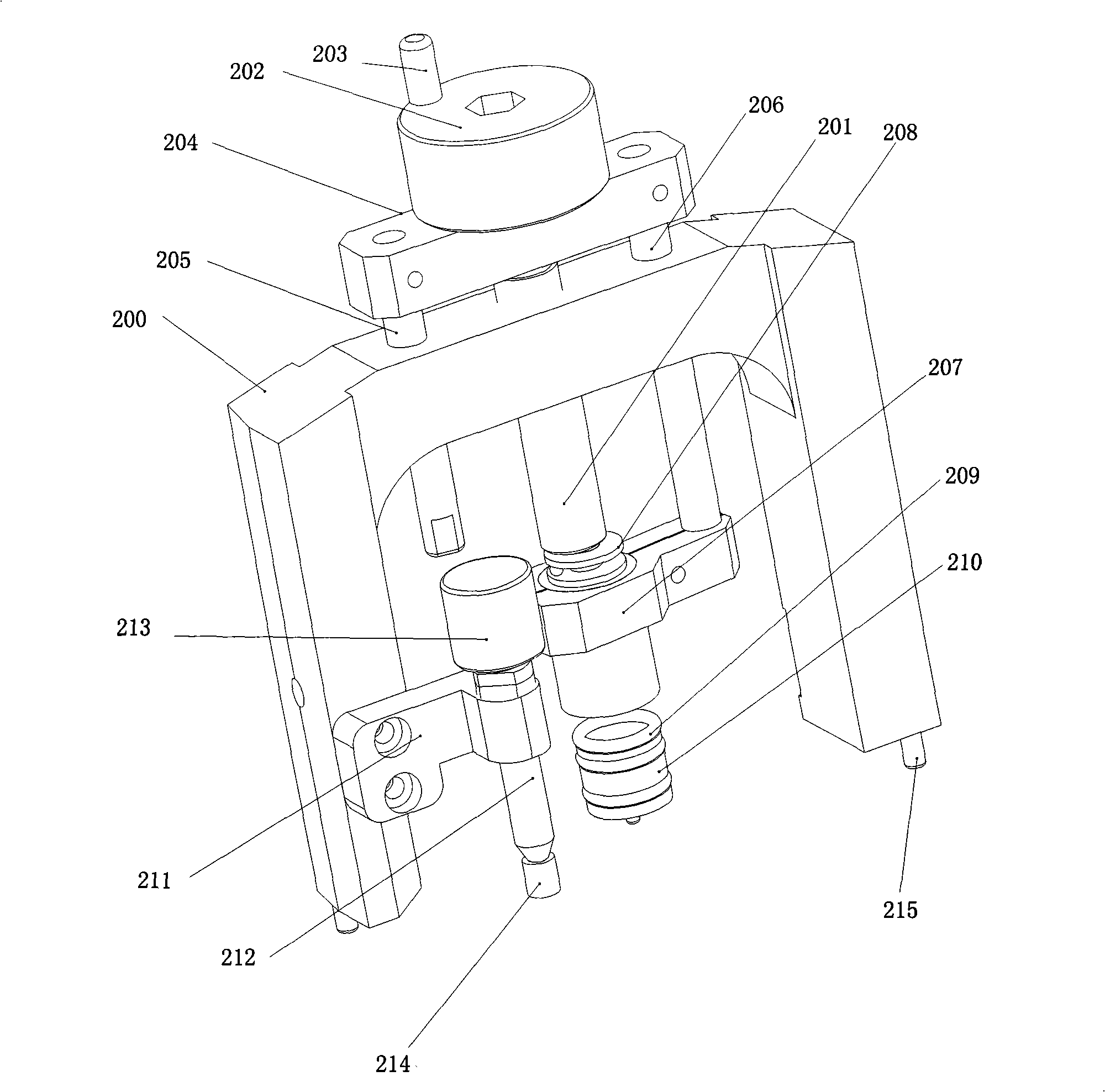

Embodiment 1

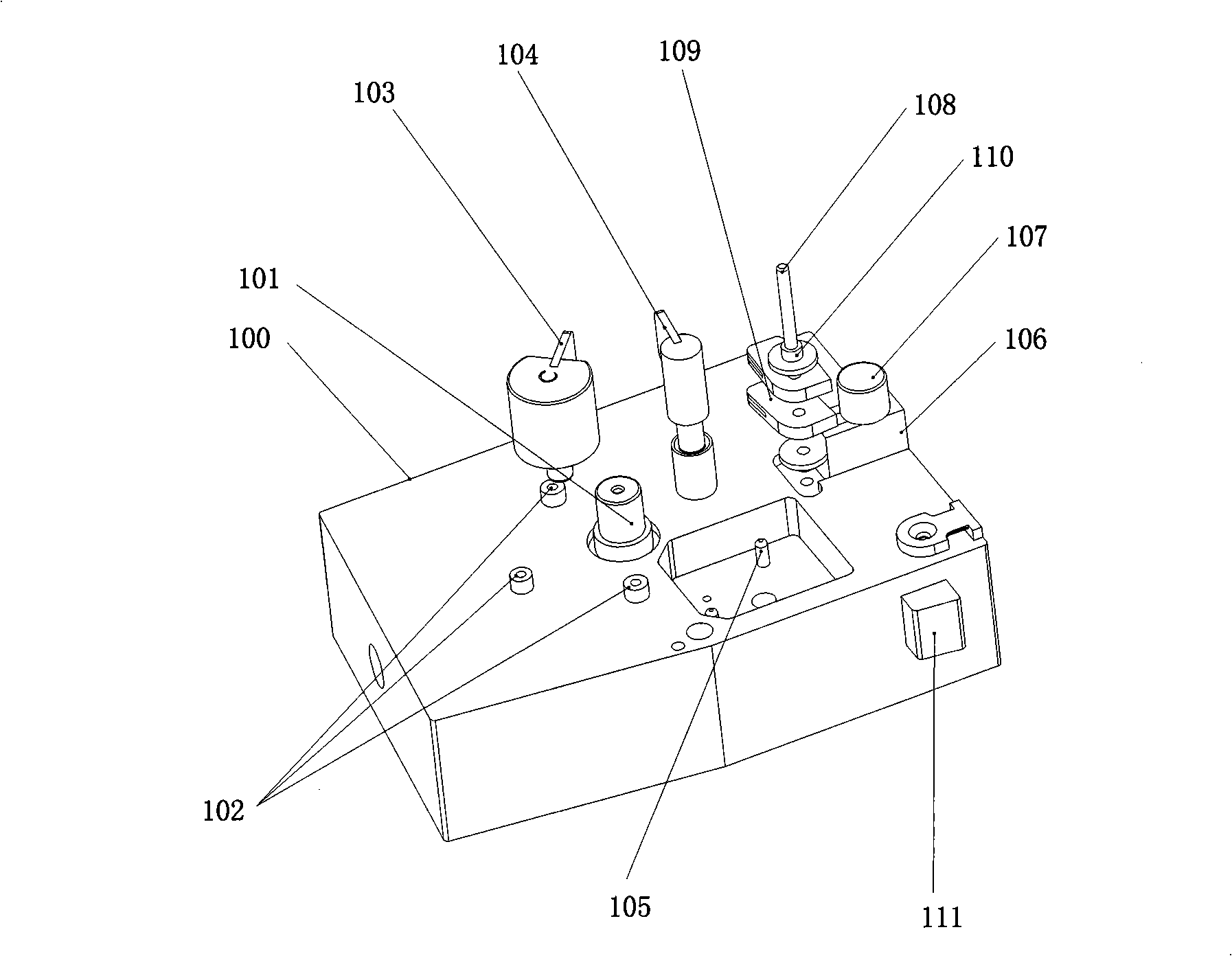

[0026] One surface of the base 100 is provided with a drive frame support column 101 for placing the drive frame. The drive frame support column 101 is generally located in the center of the plane, and can also be located near the center of the plane, or in other positions on the plane.

[0027] A magnet support column 102 is provided around the driving frame support column 101. Generally, about three magnet support columns 102 can be provided to better support the magnet. The drive frame support column 101 is higher than the magnet support column 102 by a set value. The set value is set according to different products, so that the magnet placed on the two has a certain height difference with the drive frame. To ensure that the height difference between the magnet and the excitation coil of the drive frame is 0.5 to 1.0 mm. This height dimension is the height dimension used by the analog drive frame during the actual use of the hard disk. This height dimension will vary according ...

Embodiment 2

[0033] This embodiment is based on the first embodiment. In this embodiment, drive frame positioning posts 103 and 104 are also provided around the drive frame support column 101. The drive frame positioning posts 103 and 104 are used to locate the position of the drive frame to ensure different In different measurement processes, the position of the drive frame is consistent, which improves the accuracy of the measurement results and the repeatability of the measurement process.

Embodiment 3

[0035] This embodiment is based on the first and second embodiments. In the present invention, in some cases, the drive frame is additionally connected with a cable piece and / or a magnetic head. When the drive frame is also connected with a cable piece or a magnetic head, corresponding positioning components need to be provided on the base 100.

[0036] When the drive frame is further connected with a cable sheet, in this embodiment, a groove is also provided around the drive frame support column 101, and a cable sheet positioning post 105 is provided in the groove to position the cable sheet.

[0037] When the drive frame is also connected to the sub-head, in this embodiment, a sub-head positioning assembly is also provided around the drive frame support column 101, and the sub-head positioning assembly includes a slider 106 that can move in the chute. A slider nut 107 that can lock the slider 106 above the slider 106, a post 108 on one side of the slider 106, a sub-head position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com