Method of testing multinomial performance of double mass flywheel torsion vibrating absorber and test stand

A dual-mass flywheel and torsional shock absorber technology, which is used in vehicle suspension/shock absorber testing and other directions, can solve the problems that there is no test standard test equipment, the maximum amplitude cannot meet the dual-mass flywheel and other problems, so as to avoid large moment of inertia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

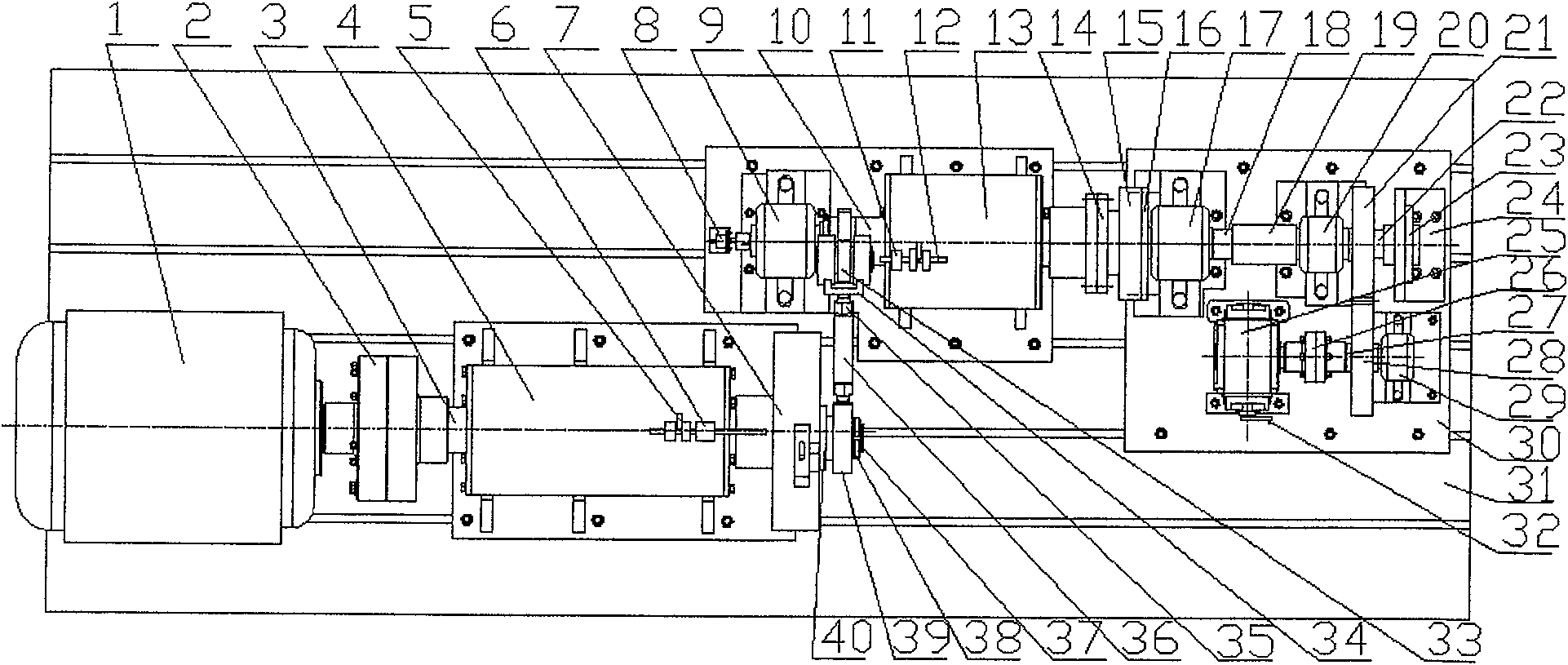

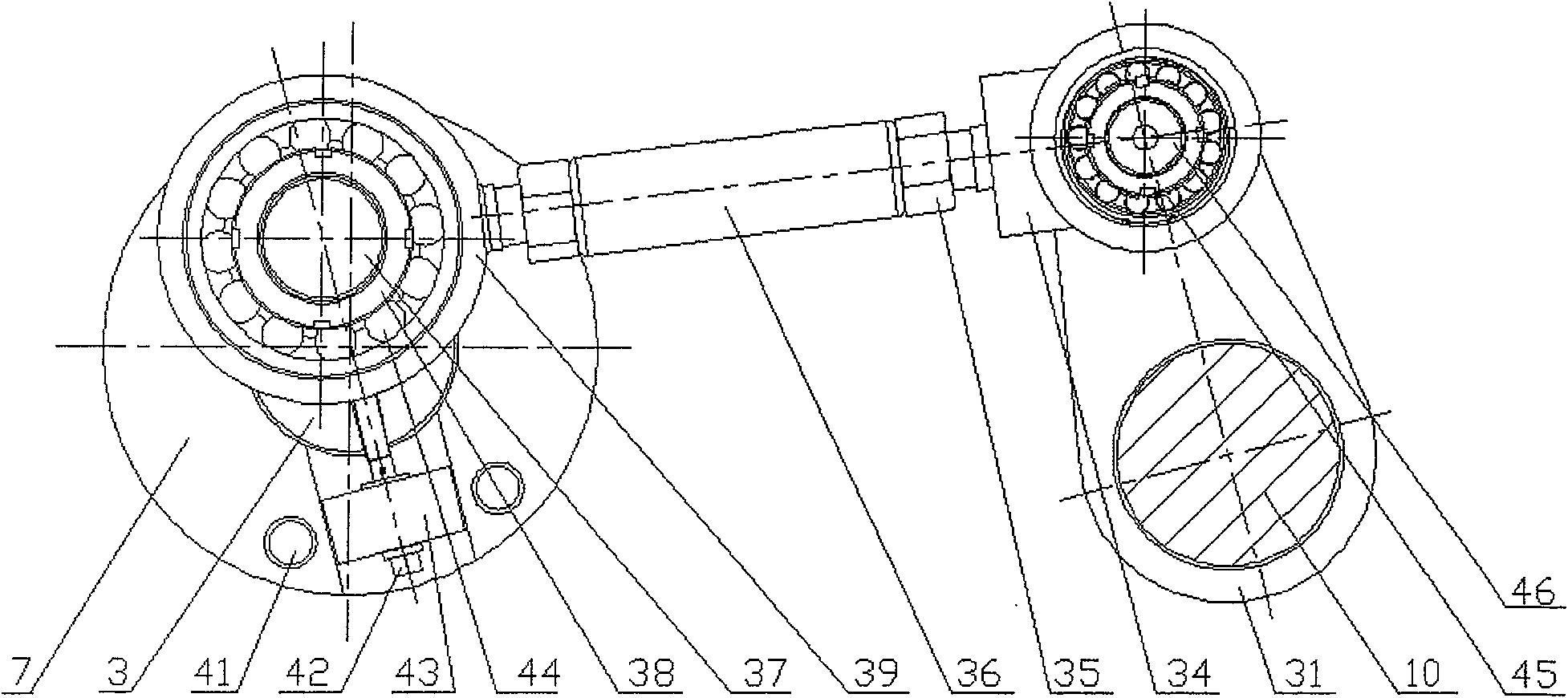

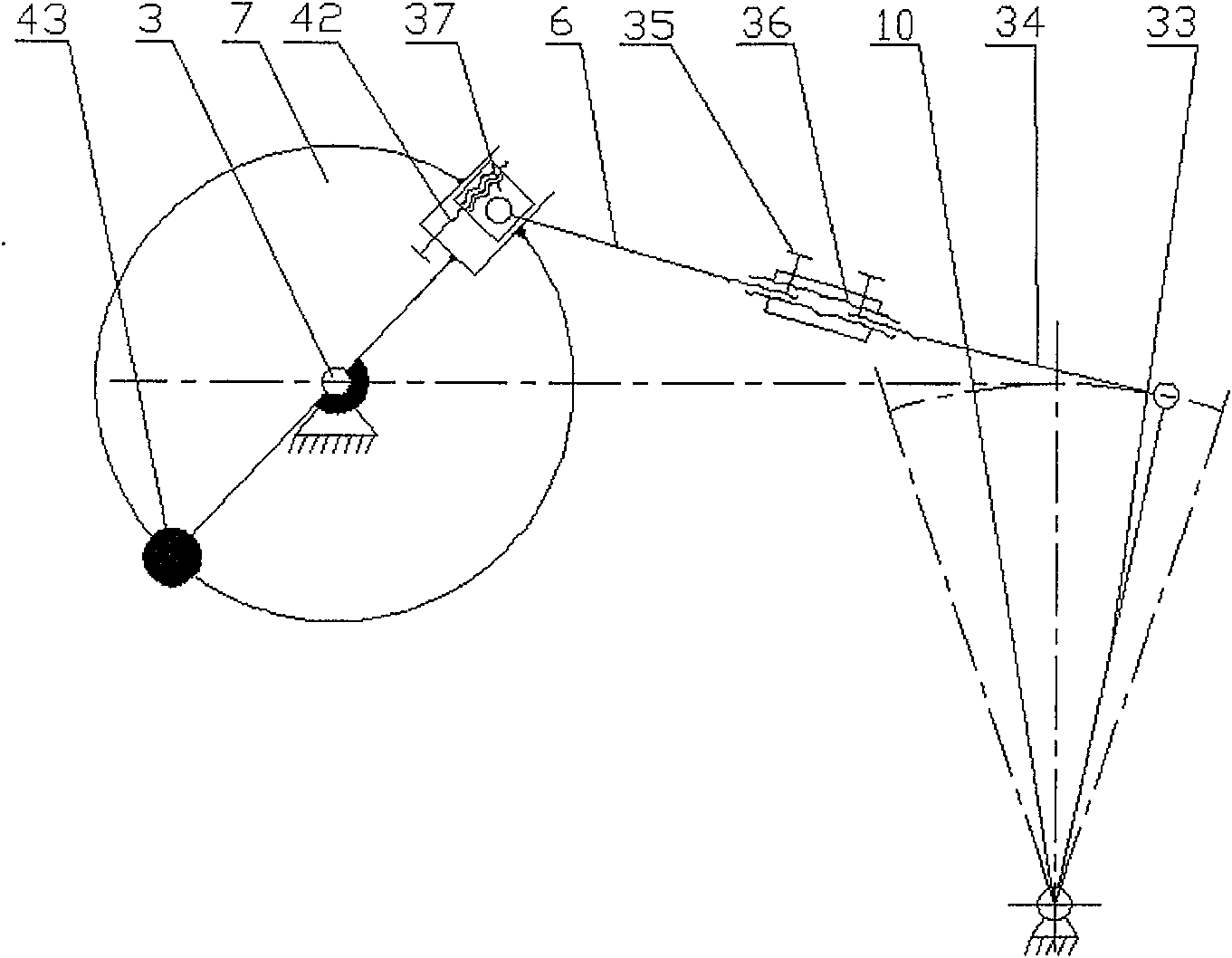

[0026] The test method for multiple performances of the dual-mass flywheel torsional damper provided by the present invention uses a torsional motion device to first convert the rotational motion of the variable-frequency motor into the torsional motion required for the dynamic test of the dual-mass flywheel torsional damper, and then through The frequency converter adjusts the rotation speed of the variable frequency motor to achieve the frequency required for the torsional motion, and then adjusts the eccentricity of the slider shaft installed on the crank wheel and the length of the adjustable connecting rod in the torsional motion device according to the swing angle to be realized in advance. Achieving the required swing amplitude for the dynamic test torsional pendulum. Specifically, a method comprising the following steps is adopted:

[0027] (1) Realization of basic symmetrical torsional pendulum motion:

[0028] A torsional motion device consisting of a pendulum conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com