Gas detection method and device

A gas detection and gas technology, applied in the field of low-cost infrared gas detection, can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]In the following, the signal processing is described in detail as long as it differs from the prior art mentioned in WO 2005 / 026705 A1. The content of this document is incorporated by reference as far as signal processing is concerned, which signal processing may not be described in this specification.

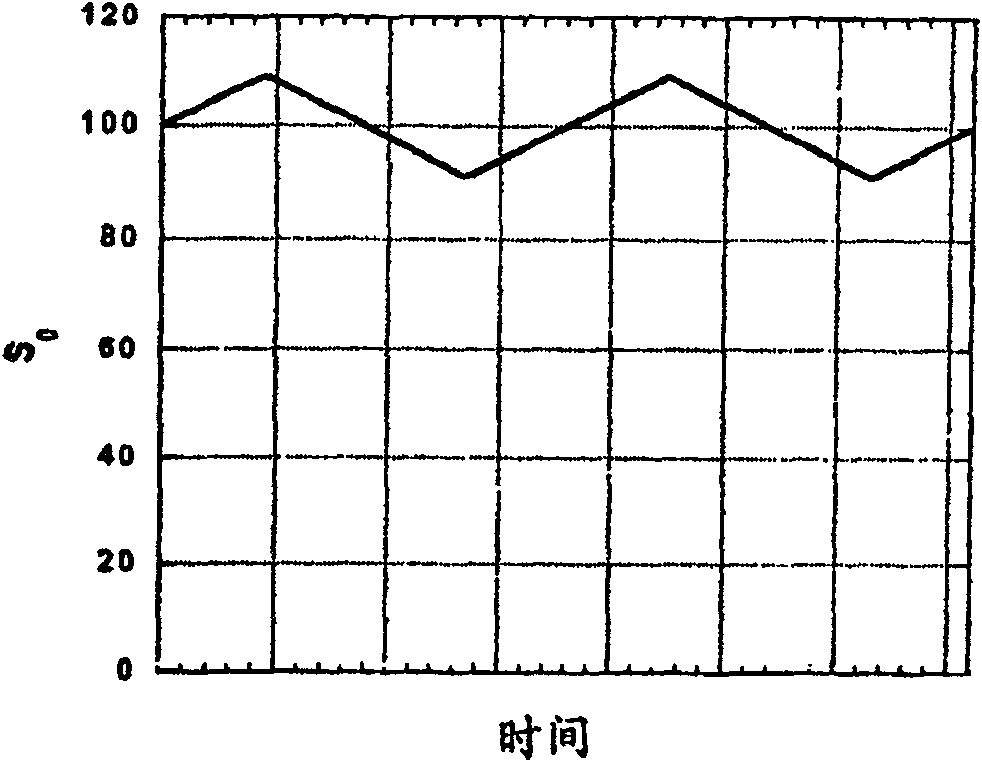

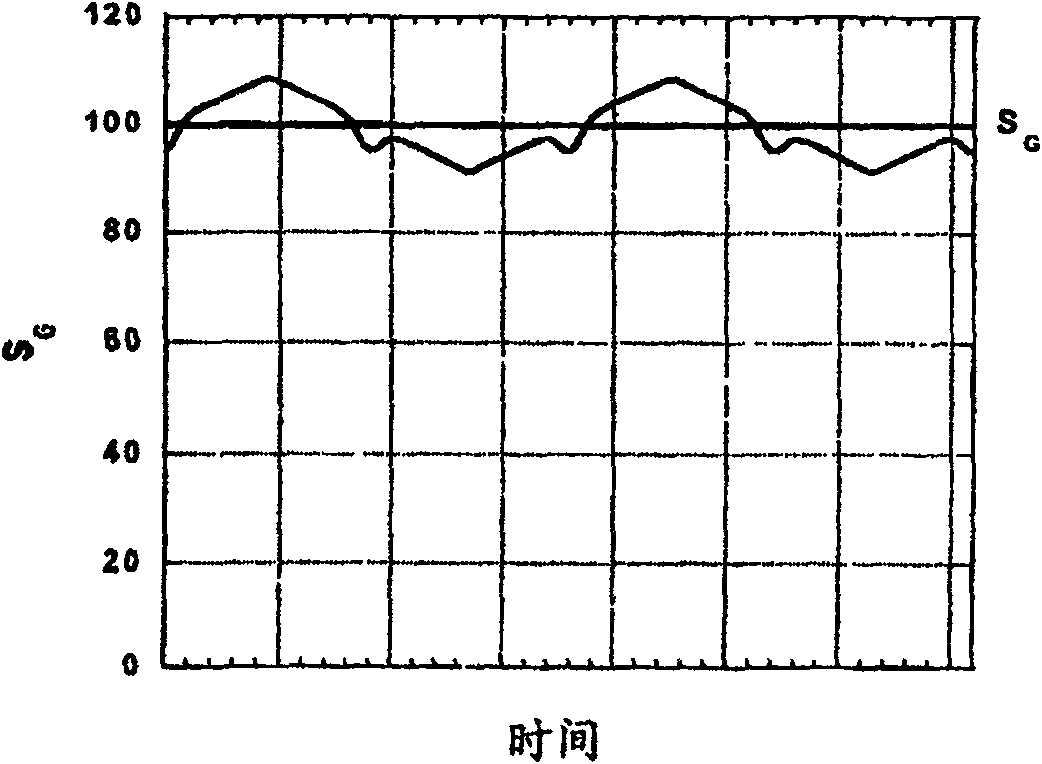

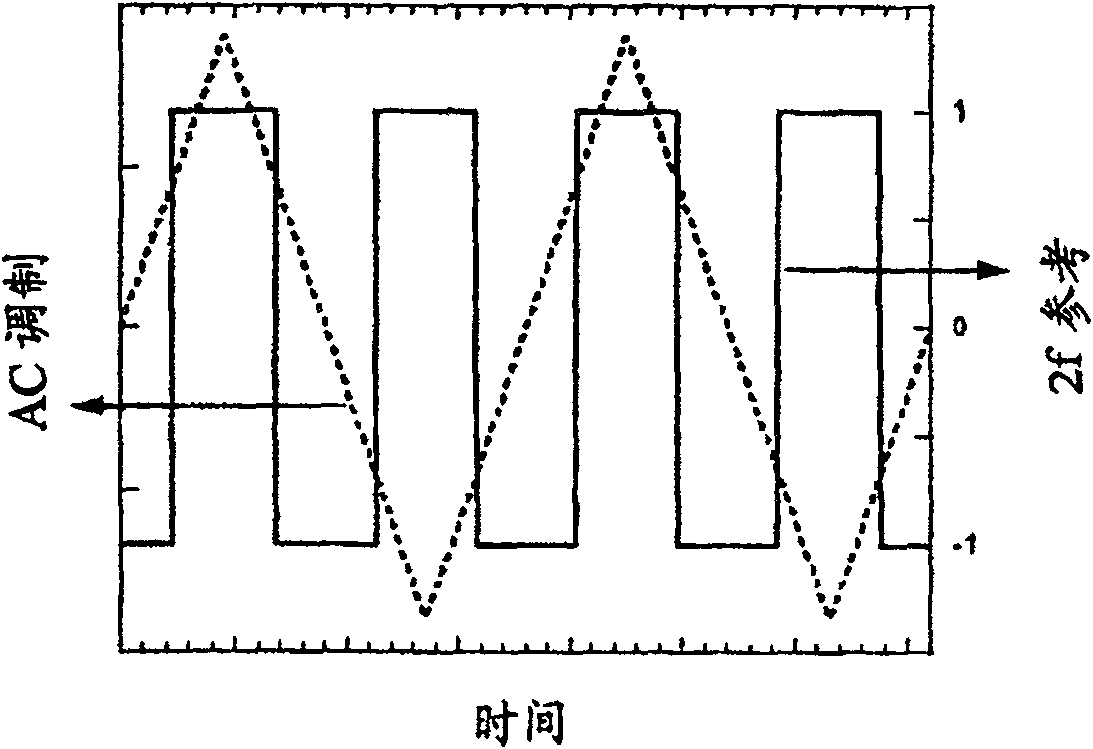

[0026] As already described and already mentioned in WO 2005 / 026705 A1, the laser source is operated with a DC current such that its wavelength corresponds exactly to the center of the gas absorption line. This current is constantly modulated with frequency f and amplitude such that the wavelength of the laser light completely scans the gas absorption line during each cycle by the corresponding AC modulation signal. figure 1 Shows as a function of time, reflected in the initial optical signal S 0 The laser output in which the detection region having the gas to be determined receives the laser output, and figure 2 shows the light intensity as a function of time, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com